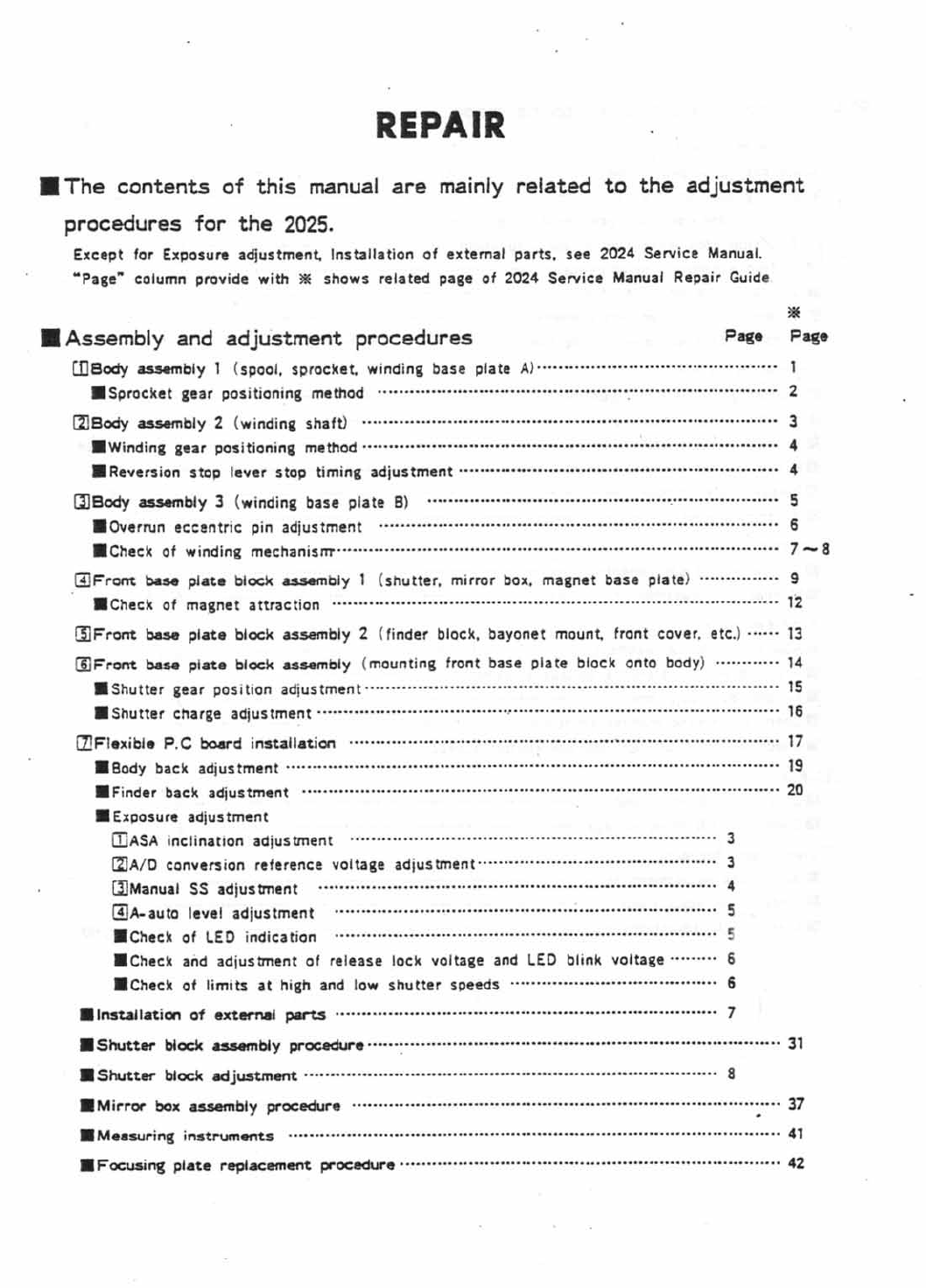

REPAIR

Mi

The

contents

of

this

manual

are

mainly

related

to

the

adjustment

procedures

for

the

2025.

Except

for

Exposure

adjustment,

Installation

of

external

parts,

see

2024

Service Manual.

“Page” column

provide

with

*

shows

related

page

of

2024

Service

Manual

Repair

Guide

M

Assembly

and

adjustment

procedures

Page

Page

(DBody

assembly

1

(spool,

sprocket,

winding

base

plate

A)crrssssrrsrerrstssstetesenseeeeereeseresneeees

1

WSprocket

gear

positioning

methad

-+----+--++-++sesseseeeeeeeenseeseenseceesnnererserscareresencessacsaessees

2

Body

assembly

2

(winding

GMalt)

vcereeeceseeseeeeeeeeeeeeeeeneeeessareenteemenseeeeneceeecssesaseseraesnanes

3

Winding

gear

positioning

MOthOd

‘ocrtrscseee

erect

ese

cceeeecessscsnenceencasnsnaceennassnasssensasaseenensces

4

HiReversion

stop

lever

stop

timing

adjustment

ss:sercttsetssssetsseessenesseesessenecseceenesccescescess

4

GBedy

assembly

3

(winding

base

plate

B)

vcrrrrrereesrsreserreeeeernessesensesessenerasssssenteseresenanens

5

W

Overrun

eccentric

pin

adjustment

PTTeTiTTiTr

Tt

ttt

ee

et

ee

ree

6

Wcheck

of

WINING

Mechanismnss*srs+essrsseennccnsesenseessswecssescessesstsenssesenssasessteesencenessensston

7~8

GFront

base

plate

biock

assembly

|

(shutter,

mirror

box,

magnet

base

plate)

sss+++++++-++

9

W

Check

of

magnet

attraction

Prrrre

rrr

Titre

12

()Front

base

plate block

assembly

2

(finder

block,

bayonet

mount,

front

cover.

etc.)

-----

13

(S)Front

base

piate

block

assembly

(mounting

front

base

plate

black

onto

body)

----+-+-----

14

M

Shutter:

gear:

position:

-adjus

tmeritissccs-eessetetsesee

nsevess

erstsesnnsnnostecsansersereereesererssreersvese

es

15

W

Shutter

charge

adjustment

wevenden

socepsenecnecentencseseetsas,

TeeTririre

TrTrririliTririitie

et

iT

ee

16

(IF

lexible

P.C

board

imstallation

-scrtsrecestststeeenretsesseceeeceeeeeesneseeeeenenereneseecseereatecseereeeens

7

Wi

Body

back

adjustment

Sereerrerrrrrrr

errr

errr

eee

rr

19

WFinder

back

AGIUSTME|NT

<s1--trerr

ess

eereoenseeenesseecnensnsnssnoracesensasoscsssaccrconcernsoserencencorsceseass

20

MExposure

adjustment

(UASA

INclination

adjustment

“ssrresssresesseetesereeeseeeeteeeeeteaneesecsnnesenccnetessncanenens

3

(GJA/D

conversion

reference

voltage

adjustment

--------ssrseseeserseetseeeeeneeeeeeneee

3

(3]Manual

SS

adjustment

-ssrererersveverseesensenesseennercesenassssansarssnsenanacssasncenscsonecs

4

(@A-

BUtO

level

adjustment

--*sr~rresserereesenesecescesetecersesnenessesssercsssuceastcssnssrseses

ia

Wi

Check

Of

LED

indication

vstrestsrssssresseecsesseceereteeesencneeesersnreasseaseeesesaenaaaanes

6

MiCheck

and

adjustment

of

release

lock

voltage

and

LED

blink

voltage

«~~

&

MiCheck

of

limits

at

high

and

low

shutter

speeds

~srrr+rrsretsssserrereereerereeeserees

6

Binstallation

of

external

POPES

*oseecencsseseccssevoeesesasacressasssscnesnasseqeasnseccoccoasonsencsss

7

@

Shutter

block

assembly

procedure

eeececsnenceeeceteeeens

oo

see

ceeeneeeeneaereenee

31

W

Shutter

block

adjustment

+--+--++s1ssseersereeeeceenersenseneesenessnesssesesaceaseeeasacsanecsscessees

8

ME

Mirror

box

assembly

procedure

ss-++sssssssseerrerrersersesseessesencessareancrsssscesassncncesausaseesecesceses

37

Bi

Measuring

PSTPUMENtS

«cer

seer

eet

e

ee

eeeeee

eee

eeeeeee

en

eren

eee

eeeenenecseeeeeerneeeeneeneseesaeeneneneeeaeeeneenee

41

Bi

Focusing

plate

replacement

procedure

Perrerrrre

rrr

eter

rr

rrr)

42