415

Once the freezer is running, the inside temperature will start to cool down within a couple of minutes.

Ensure that the freezer has reached the desired temperature (this will take between 2 to 3 hours) by

checking the electronic control display readout before loading product. It is strongly recommended to

run the freezer empty for 24 hours before loading any products.

NOTE:

If the freezer is running and the power supply is interrupted, the freezer will not restart

Immediately. There is a 6 minute delay for compressor protection.

OPERATING INSTRUCTIONS

WARNING

Check with your power company if you are not certain of your power supply.

Before connecting to power supply the freezer should be upright and idle for at least 1 hour.

Once the unit has been installed and the power supply has been connected, press

the power switch to the “ON” position using a pen or pencil.

The compressor will start to run after 6 minutes. This can be confirmed by

listening for a slight humming or a slight vibration.

for online reference go to minusforty.com

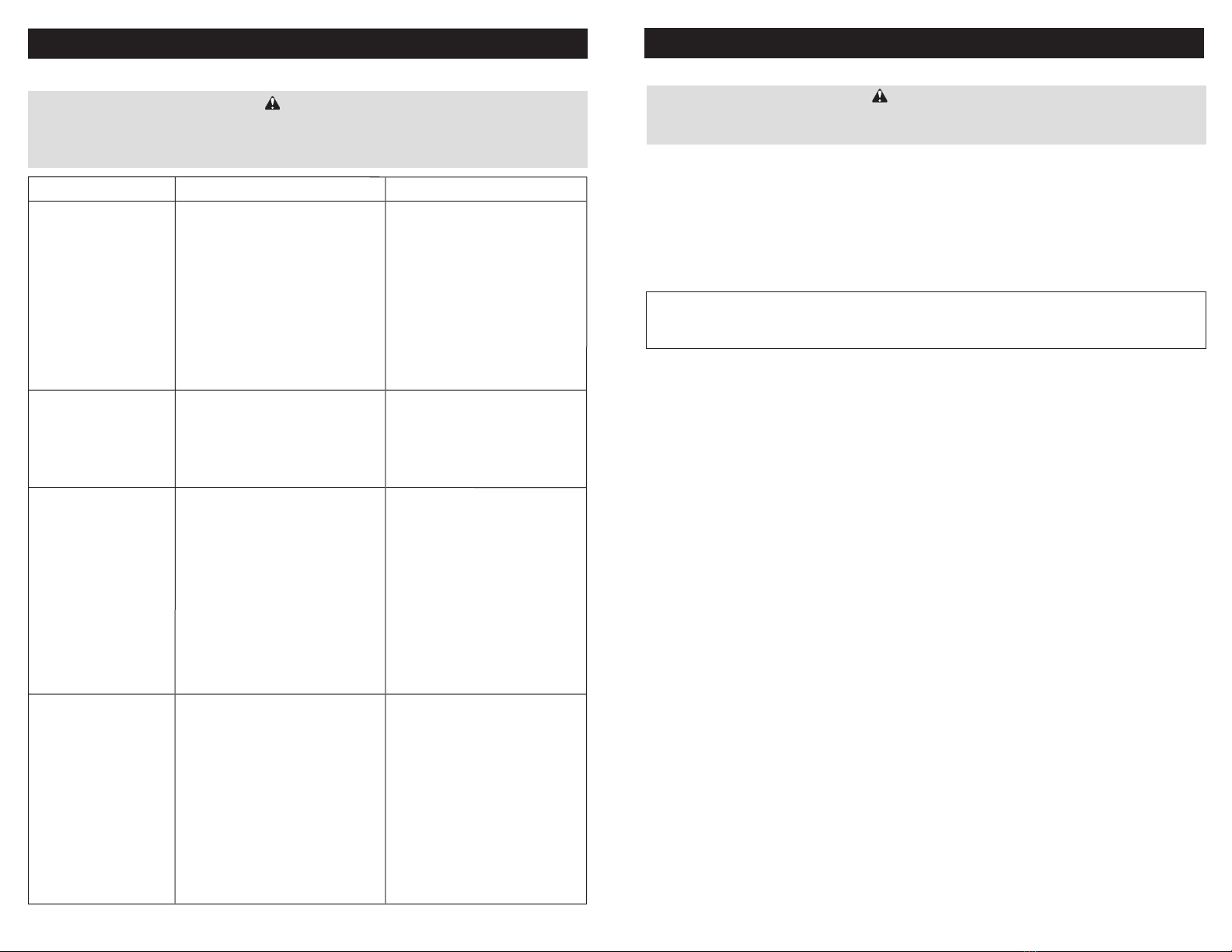

TROUBLESHOOTING GUIDE

Problem Possible Cause Action

Freezer not operating. • Freezer switch located on the front grill

turned off.

• Fuse blown / circuit breaker tripped.

• Power cord unplugged.

• Receptacle not working.

• Improper voltage supplied to

cabinet / over load circuit.

• Turn power switch on.

• Replace fuse/reset circuit breaker.

• Plug in power cord.

• Check receptacle.

• Remove extension cords or other

equipment on the same circuit.

Freezer not getting cold but

compressor is operating.

• Freezer located in direct sunlight or

ambient (room) temperature is too hot.

• Condenser clogged with dust.

• Move freezer away from direct

sunlight.

• Room temperature is recommended

not to exceed 86ºF (30ºC), 55% RH.

• See page 9 (Cleaning)

Condensing unit operating

for a prolonged period or

continuously.

• Freezer loaded with excessive amount

of warm product.

• Prolonged door opening or door ajar.

• Door not closing properly.

• Clogged condenser.

• Evaporator coil blocked with ice or

frost.

• Allow enough time for product

to cool down.

• Close door when not in use.

Avoid prolonged door openings.

• Level the unit (See page 2).

Check gasket condition.

Check the door spring.

• Clean the condenser (See page 9).

• Defrost manually if required

(See page 8).

Freezer cabinet temperature

too high.

• Electronic control set too high.

• Poor air circulation in cabinet.

• Insufficient clearance around cabinet or

ambient temperature too high.

• Clogged condenser

• Adjust control setting (See page 6).

• Follow instructions for product

loading (See page 5)

• Keep at least 6”(15.24cm) free space

around all sides of the freezer. Room

temperature is recommended not to

exceed 86ºF (30ºC), 55% RH.

Make sure the air flow to the

compressor is not obstructed.

• Clean the condenser (See page 9)

WARNING

Make sure the freezer is disconnected from the power supply before any service. Press the

freezer switch to the “Off” position then unplug the power cord from electrical receptacle.

All service work must be conducted by a certified technician only.