9

Note: The relay can drive a load up to 10 amps at 120 VAC

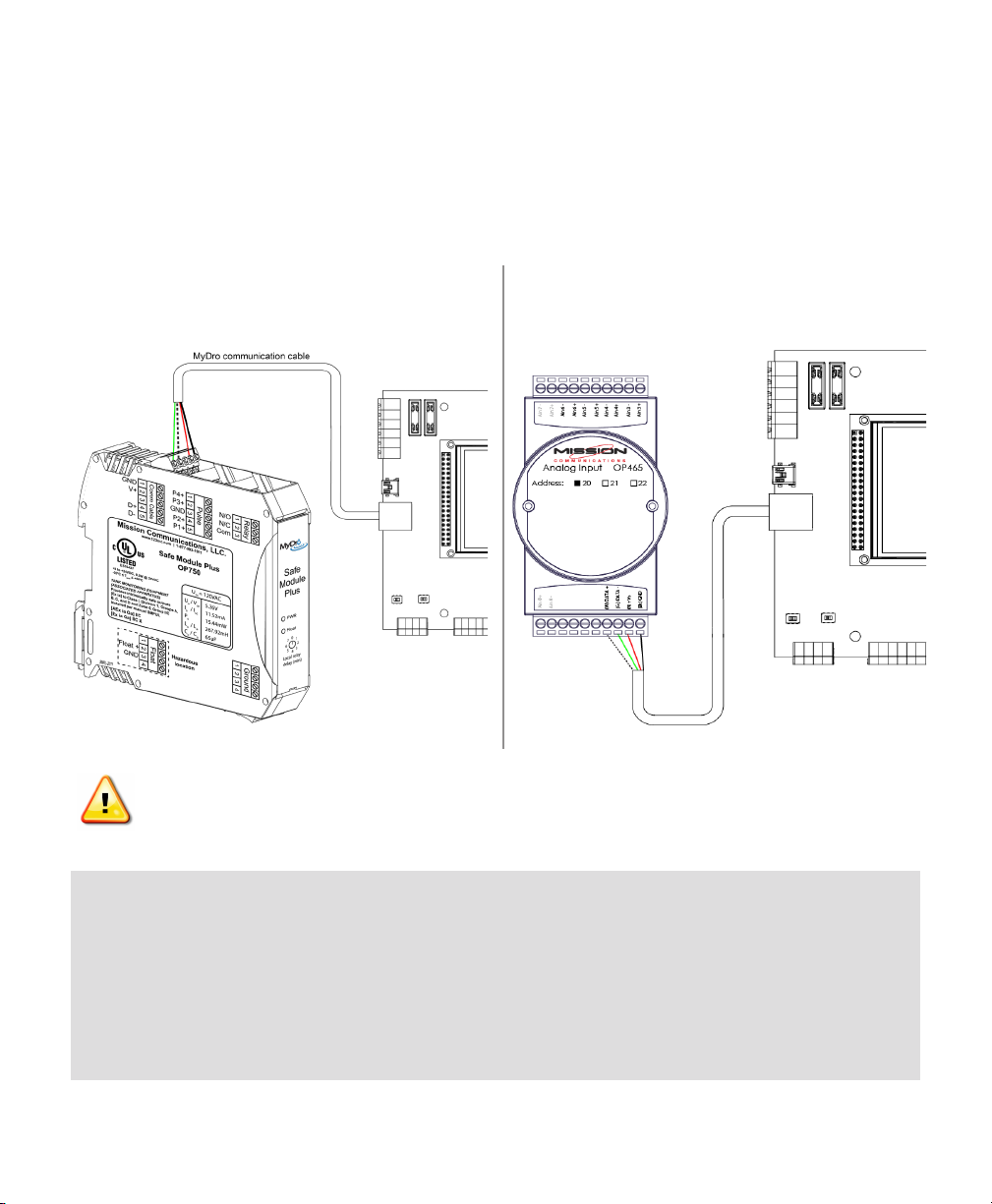

Safe Module Plus Overview

The Safe Module Plus (SMP) is an exclusive device

that speeds and simplies the installation of a Mission

MyDro 150 or 850 RTU. It supports four pulse counting

channels that can be used with rain tipping buckets

or pulse-based ow meters. It provides an intrinsically

safe circuit to a oat so that the state of the oat can be

transmitted by the MyDro RTU for alarm notications

as well as to energize a built-in-relay that is typically

associated with a local buzzer or light for sewer lift

station applications, or service-pump lock-out for clear

well applications.

Note: For legacy (M110, M800) RTU upgrades

that utilize the Wet Well Module, see Appendix A.

NEC Rule 22-704

National Electric Code (NEC)

Rule 22-704 offers comprehensive

criteria for classication of

hazardous locations. Sewer lift

stations are generally considered

Class I, Division I environments

and require corresponding

intrinsically safe apparatus.

Methane (explosive) and

hydrogen sulde (corrosive) are

common vapors present in these

environments.

The oat circuit associated with

the SMP is certied as intrinsically

safe: Class I, Div I, II, III, Groups

D–G.

Chapter 6: Safe Module Plus (PN OP750)

See the specication sheet for

overview and application data

and the UL Control Document

for intrinsically safe application

and installation information.

UL Control Document for

OP-750 Safe Module Plus

SAFETY DESCRIPTION:

The Safety Module Plus apparatus is to be installed in an

Unclassied Location while providing intrinsically safe output for

Class I, Division 1, Groups A, B, C and D Hazardous Locations in

the US and Canada. Additionally for [AEx ia Ga] X in the US and

[Ex ia Ga] IIC X in Canada. The apparatus is intended for use in

ambient temperature range of -20C to 60C.

WARNINGS

OP-750 series must be installed, operated and maintained only

by qualied personnel, in accordance to the relevant national/

international installation standards (e.g. ANSI/ISA RP12.06.01

Installation of Intrinsically Safe System for Hazardous (Classied)

Locations, National Electrical Code NEC ANSI/NFPA 70 Section

504 and 505, Canadian Electrical Code CEC) following the

established installation rules, particular care shall be given to

segregation and clear identication of I.S. conductors from non

I.S. ones.

De-energize power source (turn off power supply voltage) before

plugging or unplugging the terminal block (J4) when oat is

installed in Hazardous Locations or unless area is known to be

nonhazardous.

Warning: Explosion Hazard: to prevent

ignition of ammable or combustible

atmospheres, disconnect power before

servicing or unless area is known to be

nonhazardous.

Danger d’Explosion: pour prévenir une

inammation de l’atmosphère inammable

ou combustible, couper l’alimentation

avant de réparer à moins de savoir que

l’emplacement n’est pas dangereux.

Units must be protected against dirt, dust, extreme mechanical

(e.g. vibration, impact and shock) and thermal stress, and casual

contacts.

If enclosure needs to be cleaned use only a cloth lightly

moistened by a mixture of detergent in water.

Electrostatic Hazard: to avoid electrostatic

hazard, the enclosure must be cleaned only

with a damp or antistatic cloth.

Danger électrostatique: pour éviter le

danger électrostatique, l’enveloppe doit être

nettoyée au moyen d’un chiffon humide ou

antistatique. Any penetration of cleaning

liquid must be avoided to prevent damage

to the unit.

Failure to properly install or use the equipment may risk damage

to the unit or severe personal injury. The unit cannot be repaired

by the end user and must be returned to the manufacturer or his

authorized representative. Any unauthorized modication must be

avoided.

Warning: substitution of components may

impair Intrinsic Safety.

Avertissement: le remplacement des

composants peut dégrader la Sécurité

Intrinsèque.

It is tested for a maximum for AC power supply (Um) of 120 VAC.

Control equipment must not use or generate more than 120 V rms

or dc with respect to earth.

Selected intrinsically safe equipment must be third party listed

as intrinsically safe for the application, and have intrinsically safe

entity parameters conforming with Table 1 (see next page).

SPECIAL CONDITIONS FOR SAFE USE

The device does not meet the 500V rms dielectric requirement

between the IS circuit and earth.

ASSOCIATEDAPPARATUS

In sewer lift station applications, the high level oat (located in the

sump) including the cable is in a hazardous location. This simple

apparatus as dened and installed in accordance with Article

504.2 and with Article 504.10(D) of the National Electrical Code

(ANSI/NFPA 70), or other local codes, must comply with the entity

parameters described in Table 1 (see next page).

Capacitance and inductance of the eld wiring from the

associated apparatus to the Safe Module Plus shall be calculated

and must be included in the system calculations as shown

in Table 1. Cable capacitance, Ccable, plus intrinsically safe

equipment (oat switch) capacitance, Ci must be less than the

marked capacitance. Likewise, cable inductance plus intrinsically

safe equipment (oat switch) inductance (Li) must be less than the

marked inductance.

Where the cable capacitance and inductance per foot are not

known, the following values shall be used: Ccable = 60 pF/ft. (200

pF/m), Lcable = 0.2 μH/ft (1.0 μH/m.) These calculated maximum

lengths do not allow for any switch capacitance or inductance.

(The cable length must be less than 800 feet not including

allowances for the switch.)

For installations in which both the Ci and Li of the intrinsically

safe apparatus exceeds 1% of the Ca (or Co) and La (or Lo)

parameters of the associated apparatus (excluding the cable),

then 50% of Ca (or Co) and La (or Lo) parameters are applicable

and shall not be exceeded. The reduced capacitance shall not be

greater than 1 μF for Groups C and/or D (IIB and/or IIA), and 600

nF for Groups A and B (IIC).

The values of Ca (or Co) and La (or Lo) determined by this

method shall not be exceeded by the sum of all of Ci plus cable

capacitances and the sum of all of the Li plus cable inductances in

the circuit respectively.

This associated apparatus has not been evaluated for use in

combination with another associated apparatus.

Where multiple circuits extend from the same piece of associated

MyDro Expansion

Safe Module Plus

Intrinsically safe circuit to oat, speeds

installation, and supports pulse inputs

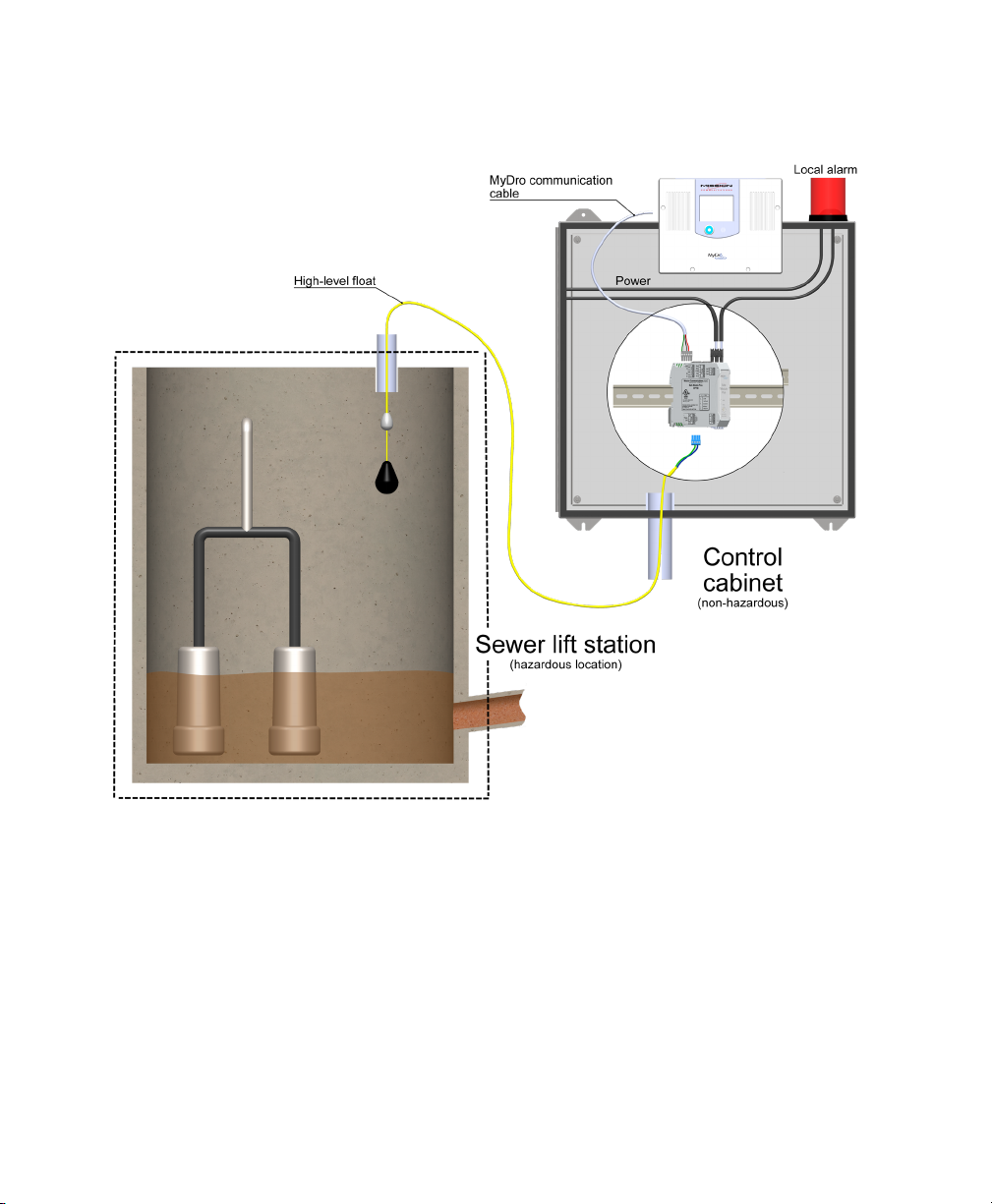

For Hazardous Environments

Most sewer lift stations are considered hazardous locations per the

National Electric Code (NEC Rule 22-704). The MyDro Safe Module

Plus allows the state of a high-level oat (located in the hazardous

location) to be shared with both the local control panel and the Mission

remote terminal unit (RTU) while complying with NEC requirements for

hazardous environments. The oat-sensing circuit is certied for Class I,

Division I (methane) environments typical of sewer lift stations.

Speeds Installation

The optional module connects to the MyDro 150 or 850 RTU with a

quick-connect communications cable. The cable powers the module and

includes the RS485 communications link between the two components.

The RS485 standard is capable of reliable communications up to 4,000

feet, allowing the module to be located closer to the sensed elements.

The enclosure is compatible with standard DIN rail. Terminals are front-

facing.

High Wet WellAlarms Even When AC Has Failed

High wet well events are reported even when there is no AC power to the

station because of the backup battery associated with MyDro unit.

Relay—Local Alarm

A built-in relay can drive a local alarm light and buzzer based on oat.

Relay—Lock-Out Functions

The relay can be used in specialty applications where safety lock-out

functions are desired. Aselectable debounce (time delay) can be set

for the included relay to avoid short cycling of equipment because of a

bouncing oat. For example, in clean water applications the relay can be

included in the control circuit of a service pump and used to lock-out the

pump before the supply runs dry, as indicated by a normally open (N/O)

low-level oat. The Mission notication system can be set to dispatch a

notication, such as “service pump lock-out activated because low supply

level.”

Four Pulse Channels

The module supports four pulse channels. They are typically used with

rain tipping buckets and pulse-based ow meters. The inputs support

dry, open collector, and wetted circuits. Non-volatile memory maintains

the pulse count for extended power outages or if communication cable is

disconnected. Pulse counts accumulate even if the MyDro RTU is ofine

as long as it has power.

Supervision

The MyDro will report RS485 communication failure as well as

intrinsically safe circuit failure if those conditions occur.

• Reduceinstallation time and complexity

• Float circuit designed for hazardous locations

typical of a sewer lift station

• Dispatcheshigh wet well alarms even if AC

power fails

• Spawn oat signal for multiple purposes

• Supports4 pulse channels