1

Dear customer,

we would like to thank you for your trust in Mitek electric outboard motors.

Each motor has been designed and manufactured for maximum comfort, ease of use and safety, and has

been extensively tested before delivery.

We strive to improve our products on a daily basis. If you have any comments on the design and use of our

products, we would be pleased to hear from you. Our customer service is always available to answer any

questions you may have. Contact details can be found at the back of this manual.

Please read this manual carefully so that you can get the most out of your Mitek outboard motor and enjoy

it for a long time.

Enjoy the sea,

Team Mitek, 100% electric motors

Table of contents

1. Use and safety ..........................................................................................................................................................3

1.1. Important information for safe motor operation.................................................................................................3

1.2. General Warnings .................................................................................................................................................3

1.3. Technical data.......................................................................................................................................................4

1.4. Equipment and controls........................................................................................................................................4

1.4.1. The package comes with...................................................................................................................................4

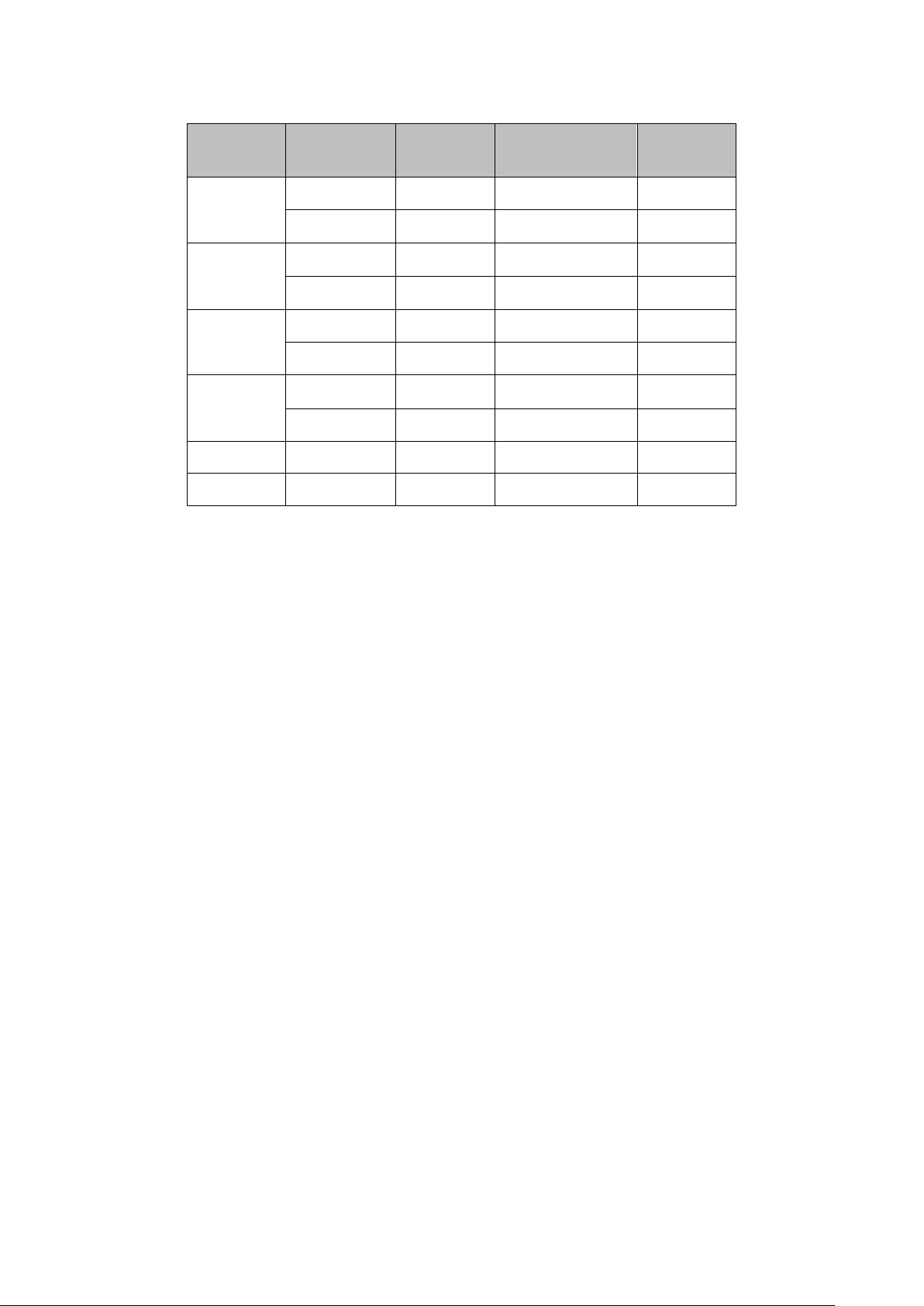

1.4.2. Main components.............................................................................................................................................5

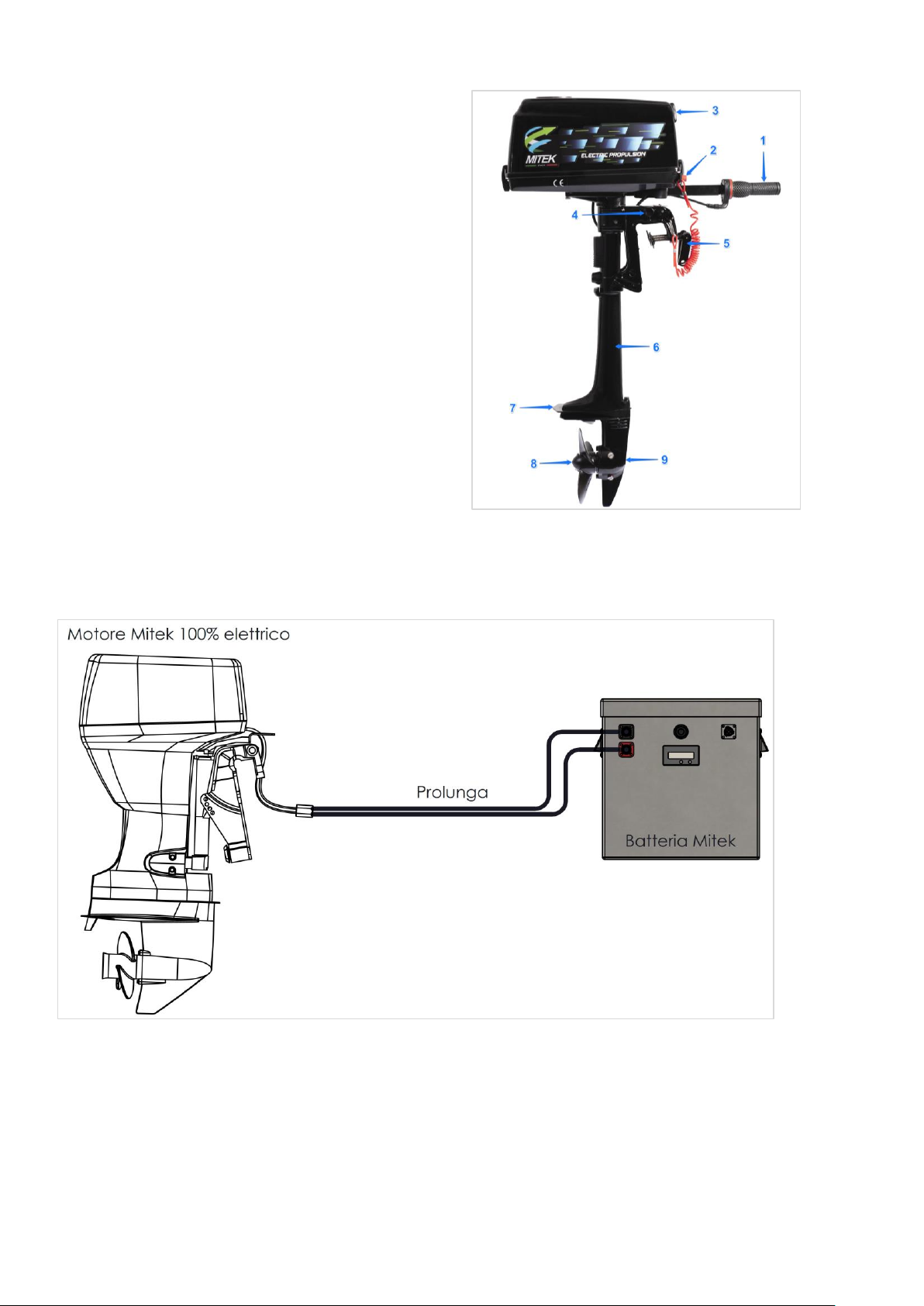

1.5. Electrical connections ...........................................................................................................................................5

2. Operating manual.....................................................................................................................................................6

2.1. Outboard Installation............................................................................................................................................6

2.2. Batteries................................................................................................................................................................6

2.3. Emergency situations............................................................................................................................................7

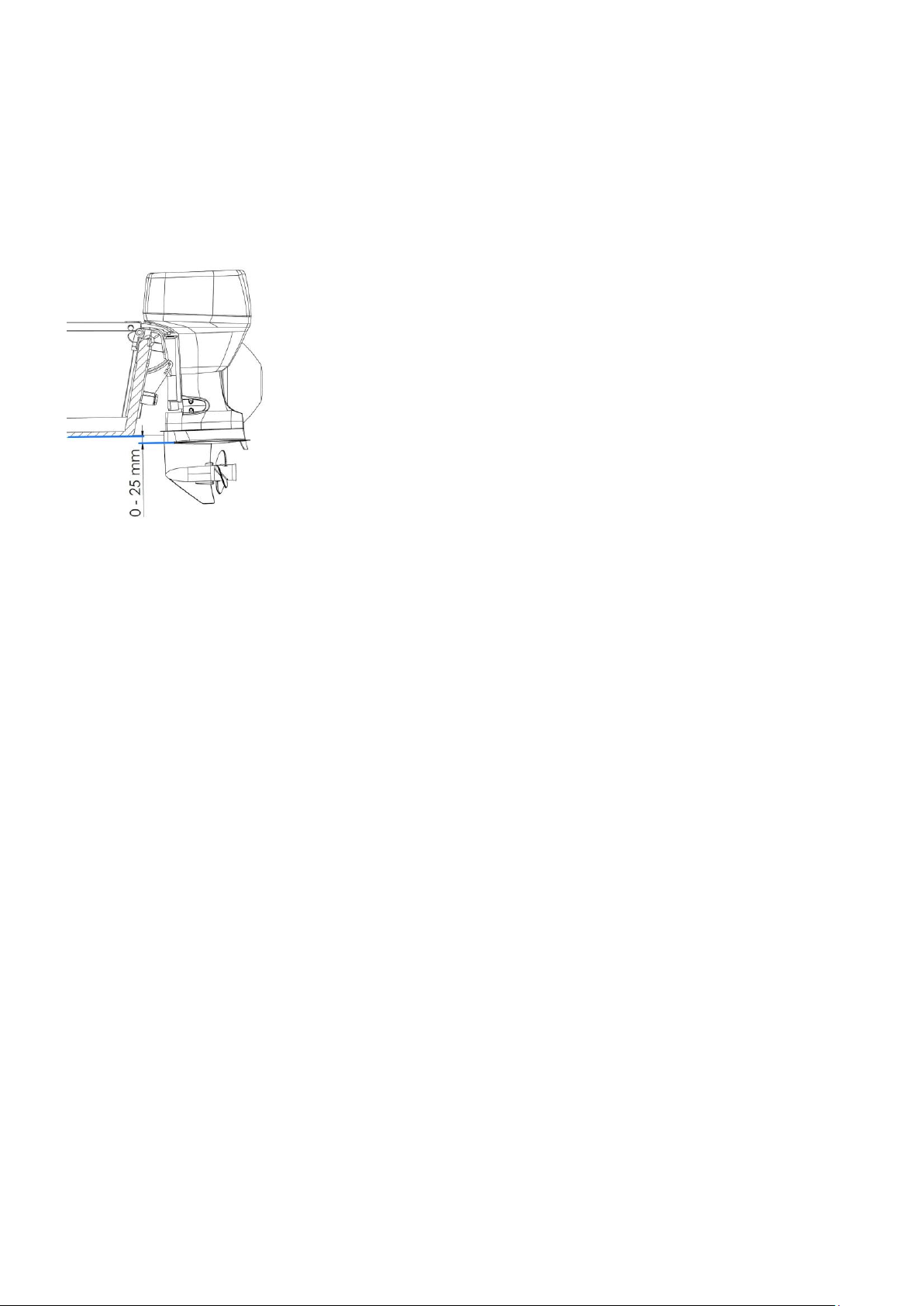

2.4. Setting outboard motor mounting height ............................................................................................................7

2.5. Pre-operation checks ............................................................................................................................................7

2.6. Starting the motor.................................................................................................................................................8

2.7. Tiller handle ..........................................................................................................................................................8

2.8. Adjusting the speed ..............................................................................................................................................9

2.9. Stopping the motor...............................................................................................................................................9

2.10. Gear shift lever..................................................................................................................................................9

2.11. Trimming the motor........................................................................................................................................10

2.12. Locking the tiller..............................................................................................................................................11

2.13. Tilting up and down ........................................................................................................................................12

2.14. Operating in shallow water.............................................................................................................................14