MITSUBISHI ELECTRIC ENGINEERING FA1-TE40PA User manual

Spring Clamp Terminal Block Conversion Adapter

MODEL

User’s Manual

(Detailed Edition)

Time and Wire Saving Devices

FA1-TE40PA

2

SAFETY PRECAUTIONS

(Read these precautions before using the products.)

Before using the products, please read this manual and the relevant manuals carefully, and pay full

attention to safety to handle the products correctly.

The precautions given in this manual are concerned with time and wire saving devices only.

For the safety precautions of the programmable controller system, refer to the user's manual for the

programmable controller used.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by

the equipment may be impaired.

In this manual, the safety precautions are classified into two levels: " WARNING" and

"CAUTION".

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead

to serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

[Design Precautions]

WARNING

●Configure safety circuits externally to ensure that the entire system operates safely even when a fault occurs in the

external power supply, the programmable controller, or the products. Failure to do so may result in an accident

due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting operations (such as

forward/reverse rotations or upper/lower limit positioning) must be configured externally.

(2) Outputs may remain on or off due to a failure of a component such as a relay, transistor, and triac used for

digital signal converter outputs. Configure an external circuit for monitoring output signals that could cause a

serious accident.

●In an output circuit for digital signal converter outputs, when a load current exceeding the rated current or an

overcurrent caused by a load short-circuit flows for a long time, it may cause smoke and fire. To prevent this,

configure an external safety circuit, such as a fuse.

●Configure a circuit so that the programmable controller is turned on first and then the external power supply. If

the external power supply is turned on first, an accident may occur due to an incorrect output or malfunction.

3

[Design Precautions]

CAUTION

●Do not install the control lines or communication cables together with the main circuit lines or power cables. Keep

a distance of 100mm (3.94 inches) or more between them. Failure to do so may result in malfunction or failure

due to noise.

●When using a terminal block conversion module for a high-speed counter module, do not install the control lines

or communication cables together with the main circuit lines or power cables. Keep a distance of 150mm (5.91

inches) or more between them. Failure to do so may result in malfunction or failure due to noise.

●Keep a distance of 100mm (3.94 inches) or more between a thermocouple or RTD (Resistance Temperature

Detector) and the main circuit line or AC control lines. Also, keep the thermocouple or RTD away from a circuit that

includes harmonics, such as a high-voltage circuit and a load circuit of an inverter. If not, the thermocouple or RTD

is more likely to be affected by noise, surges, and induction.

●At power-on or power-off, a voltage may occur or a current may flow between output terminals for a moment. To

use an analog signal converter or analog terminal block conversion module, start the control after analog outputs

become stable.

●Do not place an analog signal converter or analog terminal block conversion module near a device that generates

magnetic noise.

●When a device such as a lamp, heater, or solenoid valve is controlled using a module for digital signal converter

outputs, a large current (approximately 10 times greater than normal) may flow when the output is turned from

off to on. Therefore, select a module for digital signal converter outputs that has a sufficient current rating.

[Installation Precautions]

WARNING

●Shut off the external power supply (all phases) used in the system before installation. Failure to do so may result

in electric shock or damage to the products.

[Installation Precautions]

CAUTION

●Use products in an environment that meets the general specifications in this manual. Failure to do so may result in

electric shock, fire, malfunction, or damage to or deterioration of the products.

●Securely fix the products with a DIN rail or screws. Incorrect installation may cause malfunction, failure, or drop of

the module. When using the products in an environment of frequent vibrations, fix the products with screws.

●Tighten the screws within the specified torque range. Undertightening can cause drop of the screw, short circuit,

or malfunction. Overtightening can damage the screw and/or products, resulting in drop,

short circuit, or

malfunction.

●Attach DIN rail stoppers on the right and left sides of the spring clamp conversion module to fix the module securely.

●Shut off the external power supply (all phases) used in the system before mounting or removing the products.

Failure to do so may result in damage to, malfunction of, or failure of the products.

●Do not directly touch any conductive parts and electronic components of the products. Failure to do so may cause

malfunction or failure of the products.

●Install the products in the correct orientation if it is specified. Failure to do so may result in damage to or

deterioration of the products.

●When drilling screw holes, be careful not to drop chips into the inside of the products or conductive parts. Such

foreign matter can cause a fire, failure, or malfunction.

●When using modules for replacing digital signal converters or signal conversion modules, use them in the correct

combination. Incorrect combination may cause failure.

●Shut off the power supply before installing/removing a module for replacing digital signal converters. Failure to do

so may cause failure or malfunction.

●Securely mount a module for replacing digital signal converters and signal conversion module on a digital signal

converter and installation base. Failure to do so may cause damage to or drop of the products, or malfunction due

to poor contact. Follow the correct procedure to install/remove them. Failure to do so may cause damage to or

drop of the products, or malfunction due to poor contact.

●When a module for digital signal converters or signal conversion module is mounted on a digital signal converter

or installation base, hold the digital signal converter or installation base to transport them or install them to a panel.

Holding the module for digital signal converters or signal conversion module may cause drop or failure of the digital

signal converter or installation base.

4

[Wiring Precautions]

WARNING

●Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may result in

electric shock or damage to the products.

●After wiring, attach the included terminal cover to the products before turning them on for operation. Failure to do

so may result in electric shock.

[Wiring Precautions]

CAUTION

●Use applicable solderless terminals and tighten them within the specified torque range. Failure to do so may cause

failure, damage, or malfunction.

●Check the rated voltage and terminal layout before wiring to the products, and connect the cables correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or failure.

●Do not install the control lines or communication cables together with the main circuit lines or power cables. Keep

a distance of 100mm or more between them. Failure to do so may result in malfunction due to noise.

●When using a terminal block conversion module for a high-speed counter module, do not install the control lines or

communication cables together with the main circuit lines or power cables. Keep a distance of 150mm (5.91 inches)

or more between them. Failure to do so may result in malfunction or failure due to noise.

●Keep a distance of 100mm (3.94 inches) or more between a thermocouple or RTD (Resistance Temperature

Detector) and the main circuit line or AC control lines. Also, keep the thermocouple or RTD away from a circuit that

includes harmonics, such as a high-voltage circuit and a load circuit of an inverter. If not, the thermocouple or RTD

is more likely to be affected by noise, surges, and induction.

●Do not place an analog signal converter or analog terminal block conversion module near a device that generates

magnetic noise.

●Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled, resulting in

damage to the products or cables or malfunction due to poor contact.

●Tighten the terminal screws within the specified torque range. Undertightening can cause short circuit, fire, or

malfunction. Overtightening can damage the screw and/or products, resulting in drop, short circuit, or malfunction.

●Tighten the connector screws within the specified torque range. Undertightening can cause short circuit, fire, or

malfunction. Overtightening can damage the screw and/or products, resulting in drop, short circuit, fire, or

malfunction.

●Securely connect connectors to the products. Failure to do so may cause malfunction.

●When disconnecting a cable from the products, do not pull the cable by the cable part. For the cable with connector,

hold the connector part of the cable. For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the products may result in malfunction or damage to the products or cable.

●Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an incorrect

interface) may cause failure of the products and external device.

●Prevent foreign matter such as dust or wire chips from entering the products. Such foreign matter can cause a fire,

failure, or malfunction.

●The products must be installed in control panels. Connect the main power supply to the products in the control

panel through a relay terminal block. Wiring and replacement of the products must be performed by qualified

maintenance personnel with knowledge of protection against electric shock.

●When connecting the products with a programmable controller, check that the product configuration is correct. An

incorrect configuration may cause failure or malfunction.

●Use the products with no force applied to their connectors. Applied force may cause failure or disconnection.

●Attach protective covers or signal conversion modules to unused connectors or empty slots of the products. Failure

to do so may cause a fire, failure, or malfunction due to foreign matter.

●When using modules for replacing digital signal converters or signal conversion modules, use them in the correct

combination. Incorrect combination may cause failure of a programmable controller, digital signal converter,

installation base, or external device.

●Securely mount modules for replacing digital signal converters and signal conversion modules on a digital signal

converter and installation base. Failure to do so may cause damage to or drop of the products, or malfunction due

to poor contact. Follow the correct procedure to install/remove them. Failure to do so may cause damage to or

drop of the products, or malfunction due to poor contact.

●Individually ground the FG terminal of the products with a ground resistance of 100 ohms or less. Failure to do so

may result in electric shock or malfunction.

5

[Startup and Maintenance Precautions]

WARNING

●Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

●Shut off the external power supply (all phases) used in the system before cleaning the products or retightening the

terminal screws, connector screws, or products fixing screws. Failure to do so may result in electric shock or cause

failure or malfunction of the products. Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or products, resulting in drop, short circuit, or malfunction.

[Startup and Maintenance Precautions]

CAUTION

●Do not disassemble or modify the products. Doing so may cause failure, malfunction, injury, or a fire.

●Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone System) more than

25cm away in all directions from the programmable controller and products. Failure to do so may cause malfunction.

●Shut off the external power supply (all phases) used in the system before mounting or removing the products.

Failure to do so may cause failure or malfunction of or damage to the products.

●After the first use of the products, do not connect/remove the products and cables more than 50 times. Exceeding

the limit may cause malfunction.

●Startup and maintenance of a control panel must be performed by qualified maintenance personnel with knowledge

of protection against electric shock. Lock the control panel so that only qualified maintenance personnel can operate

it.

●The ESD susceptibility symbol shown below is placed on the products. This symbol products is susceptible static

electricity passed. Before handling the connector, touch a conducting object such as a grounded metal to release

the static electricity from your body. Failure to do so may cause the products to fail or malfunction. Do not touch

the connector when the products is powered. Doing so may result in injury or cause the products to malfunction

due to the static electricity in your body.

[Disposal Precautions]

CAUTION

●When disposing of the products, treat them as industrial waste.

[Transportation Precautions]

CAUTION

●Do not apply shock that exceeds the shock resistance described in the general specifications during transportation

since the products are precision devices. Doing so may cause failure of the module.

●The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant used for

disinfection and pest control of wood packaging materials, may cause failure of the products. Prevent the entry of

fumigant residues into the product or consider other methods (such as heat treatment) instead of fumigation. The

disinfection and pest control measures must be applied to unprocessed raw wood.

EMC and Low Voltage Directives

Compliance with the EMC Directive, which is one of the EU directives, has been mandatory for products sold within EU

member states since 1996 as well as compliance with the Low Voltage Directive since 1997.

For products compliant to the EMC and Low Voltage Directives, their manufacturers are required to declare compliance

and affix the CE marking.

(1) Sales representative in EU member states

The sales representative in EU member states is:

Company: MITSUBISHI ELECTRIC EUROPE B.V.

Address: Mitsubishi-Electric-Platz 1, 40882 Ratingen, Germany

(2) Method of ensuring compliance*1

To ensure that products maintain EMC and Low Voltage Directives when incorporated into other machinery or

equipment, certain measures may be necessary. Please refer to "EMC and Low Voltage Directives Compliant Manual"

(50D-FA9010-108).

*1: The FA1-TE40PA are excluded.

6

REVISIONS

*The manual number is given on the bottom left of the last page.

Print Date

*Manual Number

Revision

August, 2020

50D-FG0474

First edition

September, 2020 50D-FG0474-AAdded parts

Connectable modules addition︓RD77MS2,QD77MS2

5-2. Wiring to a spring clamp terminal block,

8.CONNECTABLE MODULES

September, 2023 50D-FG0474-B Added parts

Connectable modules addition:Q172DLX,Q172LX

Q173DPX,Q173PX,Q173PX-S1

5-2. Wiring to a spring clamp terminal block

8. CONNECTABLE MODULES

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Engineering cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2020(2023) MITSUBISHI ELECTRIC ENGINEERING COMPANY LIMITED

7

CONTENTS

SAFETY PRECAUTIONS ···································································································2

EMC and Low Voltage Directives······················································································· 5

REVISIONS ···················································································································6

CONTENTS····················································································································7

1. INTRODUCTION ·········································································································8

2. GENERAL SPECIFICATIONS ·························································································8

3. PERFORMANCE SPECIFICATIONS ·················································································9

4. PART NAMES ··········································································································· 10

5. CONNECTING METHOD ····························································································· 11

5-1. Connection to a programmable controller···························································· 11

5-2. Wiring to a spring clamp terminal block ······························································ 12

6. INTERNAL WIRING DIAGRAM ···················································································· 15

7. APPLICABLE SOLDERLESS TERMINALS(Ferrule)···························································· 16

8.CONNECTABLE MODULES························································································· 17

9.EXTERNAL DIMENSIONS ·························································································· 18

9-1. Spring Clamp Terminal Block Conversion Adapter (FA1-TE40PA) ···························· 18

9-2. Depth and height···························································································· 19

10. PRECAUTIONS ······································································································· 20

11. GRATIS WARRANTY TERMS AND GRATIS WARRANTY RANGE······································· 20

12. EXCLUSION FROM LIABILITY FOR OPPORTUNITY LOSS AND SECONDARY LOSS ············· 20

13. TRADEMARKS ········································································································ 20

8

1. INTRODUCTION

This manual describes the specifications and handling of the spring clamp terminal block conversion adapter used in

combination with Mitsubishi Electric Corporation programmable controller I/O modules, high-speed counter modules, or

Positioning modules.

2. GENERAL SPECIFICATIONS

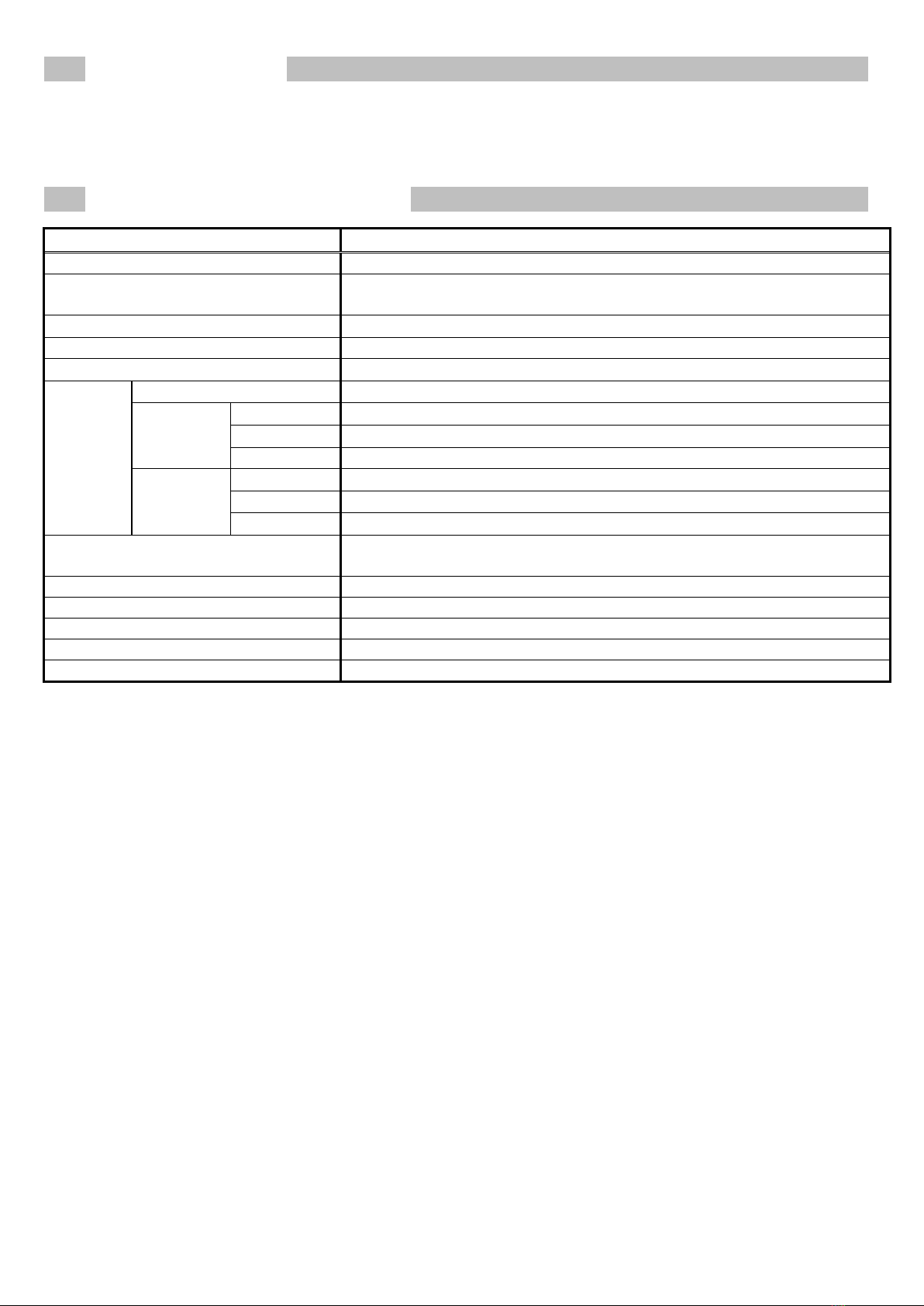

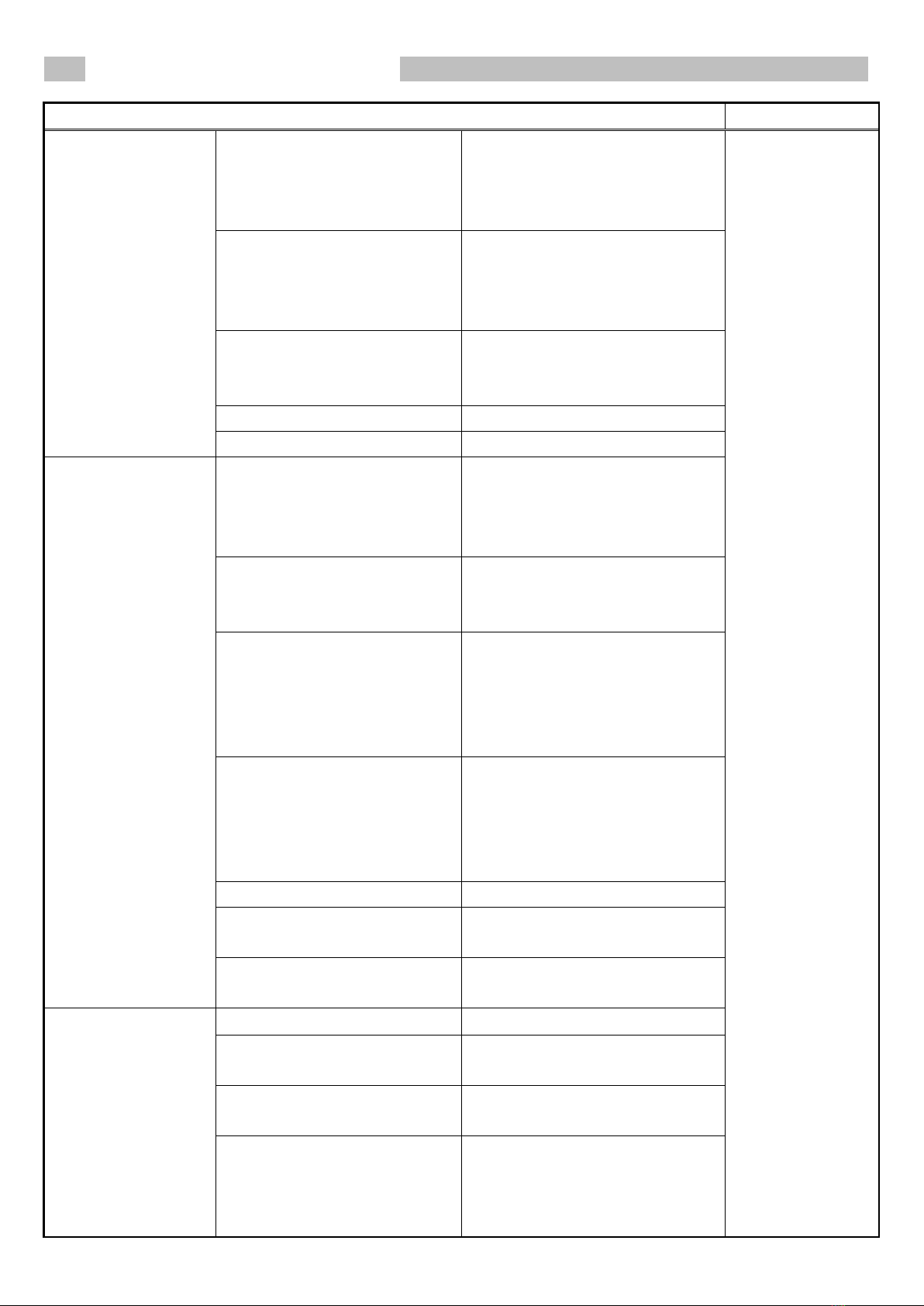

Item

Specifications

Model

FA1-TE40PA

Operating ambient temperature 0 to 55°C(When an extended temperature range base unit is not used)

0 to 60

°

C (When an extended temperature range base unit is used)

Storage ambient temperature

-25 to 75

°

C

Operating ambient humidity

5 to 95%RH, non-condensing

Storage ambient humidity

5 to 95%RH, non-condensing

Vibration

resistance

Compliance with standards

JIS B 3502, IEC 61131-2

Under

intermittent

vibration

5 to 8.4Hz

Half amplitude: 3.5mm

8.4 to 150Hz

Constant acceleration: 9.8m/s2(1G)

Sweep count

10 times each in X, Y, and Z directions

Under

continuous

vibration

5 to 8.4Hz

Half amplitude: 1.75mm

8.4 to 150Hz

Constant acceleration: 4.9m/s

2

(0.5G)

Sweep count

-

Shock resistance Compliant with JIS B 3502 and IEC 61131-2

(147m/s

2

(15G), 3 times each in X, Y, and Z bidirections)

Operating atmosphere

No corrosive gases

Operating altitude*1

2000m or lower

Installation location

Inside a control panel*4, Indoor use

Overvoltage category*2

II or less

Pollution degree*3

2 or less

*1: Do not use or store the products under pressure higher than the atmospheric pressure of altitude 0m. Doing so

may cause malfunction.

*2: This category indicates the section of the power supply to which the equipment is assumed to be connected between

the public electrical power distribution network and the machinery within premises.

*3: This index indicates the degree to which conductive material is generated in terms of the environment in which the

equipment is used.

*4: The enclosure is suitably designed for those specific environmental conditions, as applicable, and enclosure rate

meets IP20 and minimum type 1 of UL 50.

9

3. PERFORMANCE SPECIFICATIONS

Model

Item

FA1-TE40PA

Number of points

40 points

Rated voltage

24VDC(Class2 or SELV+LIM)*3

Maximum operating voltage

30VDC(Class2 or SELV+LIM)*3

Maximum operating current

0.5A/pt,2A/pt(1A,2A,1B,2B)

Terminal

block

Number of terminals

40 terminals

Applicable

wire*1*2

When a ferrule is not used

(stranded wire or solid wire)

0.2 to 1.5mm

2

(24 to 16 AWG),

Copper wire with a temperature rating of 75°C or more

When a ferrule is used

(stranded wire)

0.08 to 0.75mm

2

(28 to 18 AWG),

Copper wire with a temperature rating of 75°C or more

Wire strip length

8mm

Applicable tightening

torque

Mounting bracket fixing screw

(M2.6×4)

0.20 to 0.29N・m

C

onversion adapter anchor

base installation screw

(M3×20)

0.43 to 0.57N・m

Withstand voltage

500VAC for 1 minute

Insulation resistance (initial) 10MΩ or more

(measured with 500VDC insulation resistance tester)

Weight About 100g

(including the mounting bracket and screws)

*1: Select wires depending on the current value used.

*2: For UL certification, suitable for field wiring when a ferrule is not used.

*3: The power supply must use CLASS 2 power supply or a power supply conforming to the SELV

(Safety Extra-Low Voltage) and LIM(Limited Energy Circuit) circuit.

10

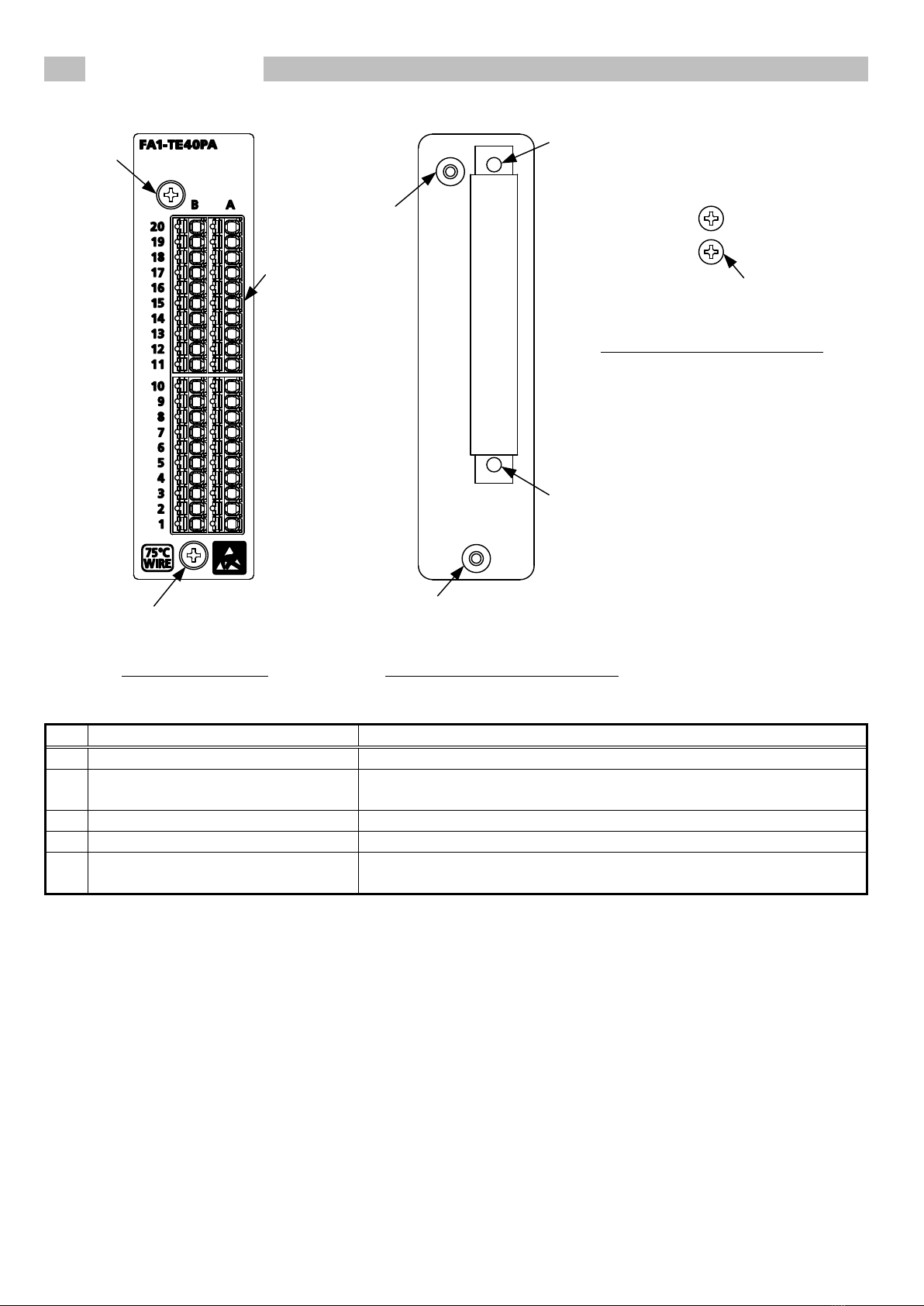

4. PART NAMES

(1)

(4)

(2)

(5)

(2)

(3)

(4)

(3)

Conversion adapter Mounti ng bracket(included item)

Mounti ng bracket fixing screw

(M2.6×4)(included item)

No.

name

Description

(1)

Spring clamp terminal block

This is a terminal block to connect external signals.

(2) Conversion adapter installation screw

(M3×20)

This is a screw to install the conversion adapter on the mounting

bracket.

(3)

Mounting bracket fixing hole

This is a hole to fix the mounting bracket to a programmable controller.

(4)

Conversion adapter mounting hole

This is a hole to fix the conversion adapter to the mounting bracket.

(5) Mounting bracket fixing screw

(M2.6×4)(included item)

This is a screw to fix the mounting bracket to a programmable controller.

11

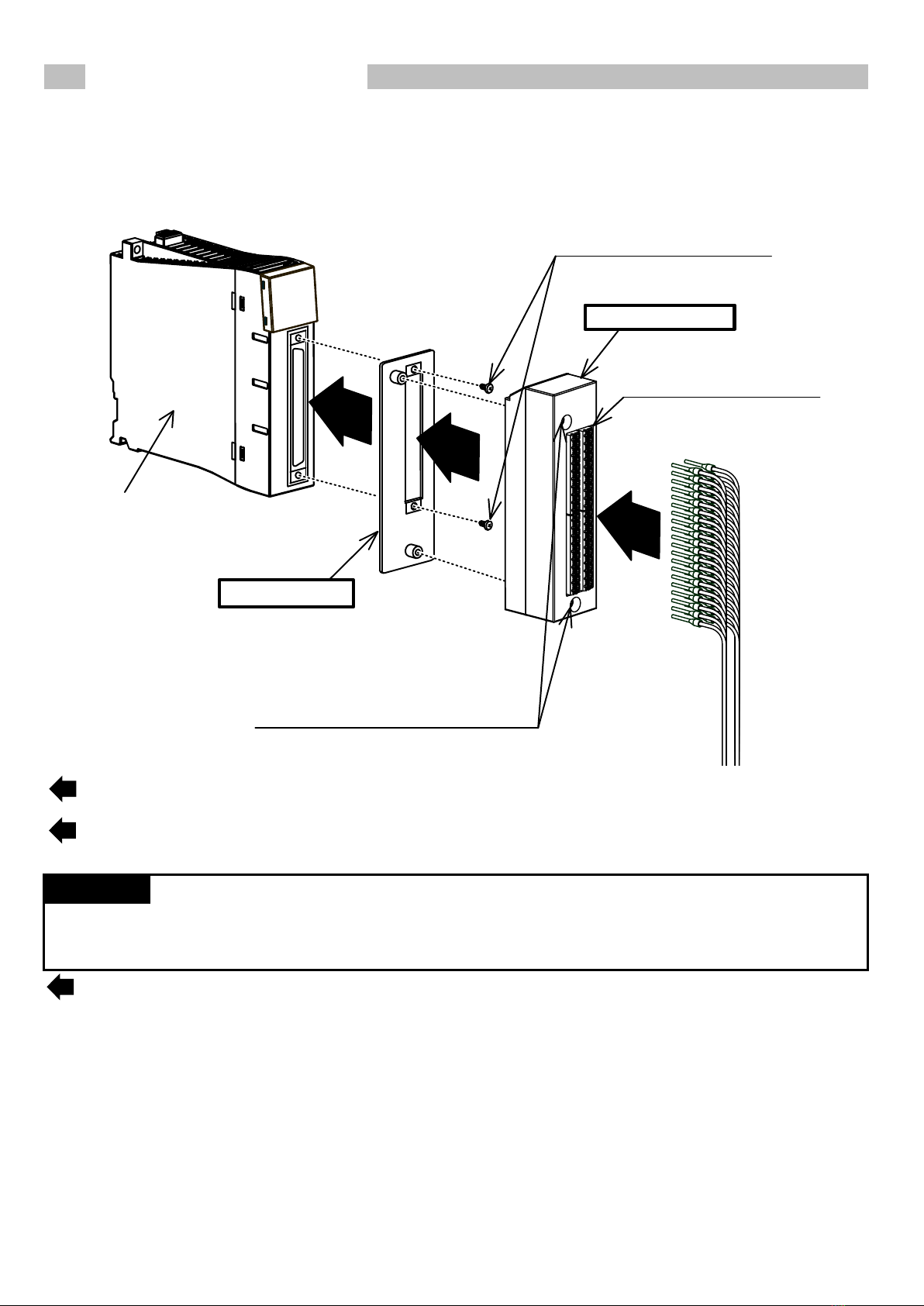

5. CONNECTING METHOD

5-1. Connection to a programmable controller

Spring clamp terminal block

②

Conversion Adapter

Conversion adapter installation screw

M3×20

Mounting bracket

Programmable

controller

①

③

Mounting bracket fixing screw

M2.6×4

①Secure the mounting bracket to the Programmable Controller Module using the

Mounting bracket fixing screws(M2.6×4;2 upper/lower locations)

②Mount the Conversion Adapter onto the Mounting Bracket, and secure the Conversion Adapter

Using the Conversion Adapter installation screws (M3×20;2 locations)

Precaution

Before tightening the installation screws, check that the Conversion Adapter has been se

curely installed on the

Programmable controller.Tightening the screws in floating-off state or tilting state will damage the Conversion Adapter

installation screws and the Mounting Bracket.

③Install wires to the spring clamp terminal block.

12

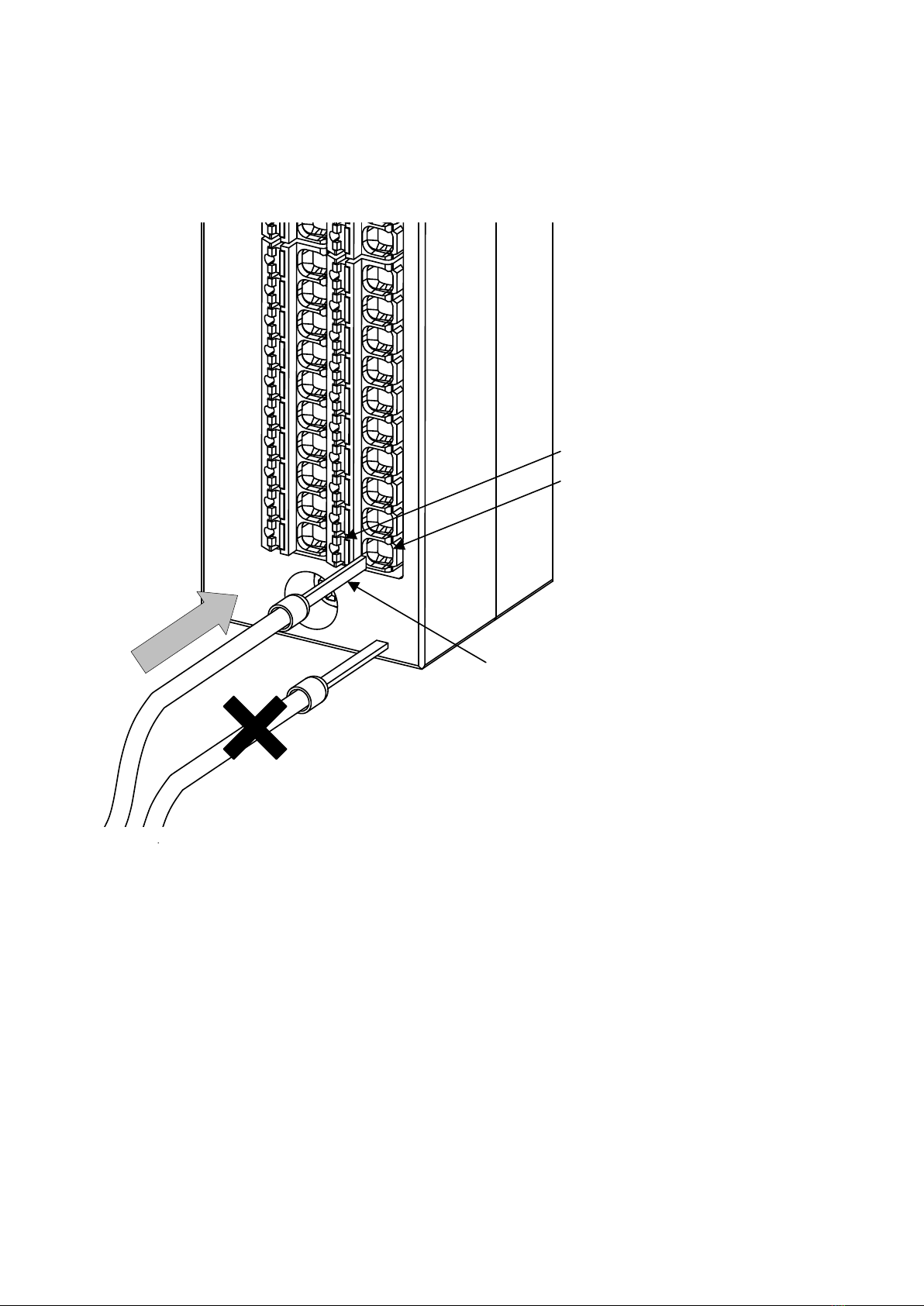

5-2. Wiring to a spring clamp terminal block

(1) Wires routing

(a) Fabrication on cable insulator

Strip the wire as follows. If the length of the sheath peeled is too long, a short circuit may occur with

neighboring

wires. If the length is too short, wires might come off. Wire the stripped cable after twisting it to prevent it from

becoming loose. In addition, do not solder it.

(b) Using a ferrule terminal

Insert wires to a ferrule terminal and crimp it. Make sure that core wire slightly comes out of the ferrule.

Check the condition of the ferrule terminal after crimping. Do not use a ferrule terminal of which the crimping is

inappropriate, or the face is damaged.

Refer to chapter 9 for the applicable ferrule terminal.

* Ferrule terminals crimped onto one wire are applicable to the terminal block of this product.

If multiple wires need to be installed (such as for the power supply), provide an external common terminal.

(For example, ABCOM of a high-speed counter module or COM of a simple motion module)

8mm

13

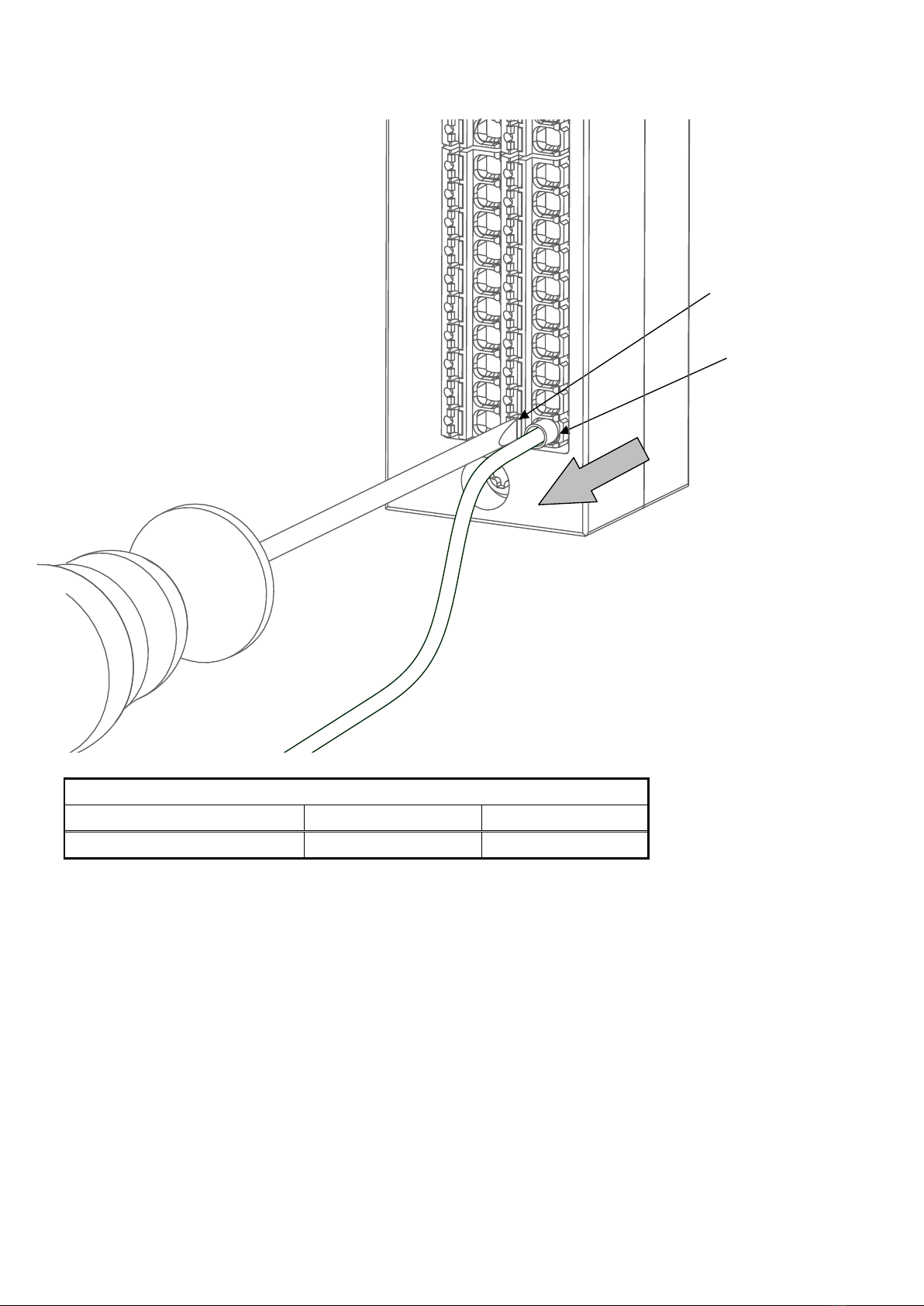

(c) Inserting wires

The wire with ferrule or solid cable can be inserted into the wire insertion hole. After

inserting, pull the wire lightly to confirm that the wire is surely connected.

For the correct terminal insertion direction, refer to the figure below.

When binding twisted wires, press the push button using the screw driver, then insert the twisted wires

into the wire insertion hole.

* Make sure to insert the wire straight and vertically as far as it will go.

(Push button)

Cable insertion hole

Ferrule terminals

14

(2) Wires removal

Press the push button all the way using the screw driver, then pull out the wire.

(Push button)

Cable insertion hole

Use the screw driver shown in the table below.

Recommended tool (screw driver)

Manufacturer

Model

Blade edge size

PHOENIX CONTACT

SZS 0,4×2,5 VDE

2.5x0.4mm

15

6. INTERNAL WIRING DIAGRAM

Conversion Adapter

B20 A20

B19 A19

B18 A18

B17 A17

B16 A16

B15 A15

B14 A14

B13 A13

B12 A12

B11 A11

B10 A10

B9 A9

B8A8

B7A7

B6 A6

B5A5

B4 A4

B3 A3

B2 A2

B1 A1

A19

A20

A17

A18

A15

A16

A13

A14

A11

A12

A9

A10

A7

A8

A5

A6

A4

A2

A3

A1

B19

B20

B17

B18

B15

B16

B13

B14

B11

B12

B9

B10

B7

B8

B5

B6

B4

B2

B3

B1

40-pin connector

Spring clamp

terminal block

Pin No.

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

Pin No.

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

Rated current value

︓2.0A

︓0.5A

16

7. APPLICABLE SOLDERLESS TERMINALS(Ferrule)

Type

Applicable ferrule Crimp tool

Manufacturer

Applicable wire size

PHOENIX CONTACT

0.25/24

AI 0.25-8 YE

CRIMPFOX 6

0.3,0.34/22

AI 0.34-8 TQ

0.5/20

AI 0.5-8 WH

0.75/18

AI 0.75-8 GY

WAGO

0.08 to 0.34 mm

2

/AWG28 to 22

216-302

206-220

0.34 mm

2

/AWG24 and 22

216-302

206-1204,

206-204

0.5 mm

2

/AWG22 and 20

216-201

0.75 mm

2

/AWG20 and 18

216-202

17

8. CONNECTABLE MODULES

Module model for a programmable controller

Module model

MELSEC iQ-Rseries

Connector type

Input modules

RX41C4

RX41C6HS

RX71C4

RX61C6HS

FA1-TE40PA

Output modules

RY41NT2P

RY41PT1P

RY41NT2H

RY41PT2H

High-Speed Counter Module

RD62P2

RD62P2E

RD62D2

Positioning Module

RD75P2

Simple Motion Module

RD77MS2

MELSEC-Q series

Connector type

Input modules

QX41

QX41-S1

QX41-S2

QX71

Output modules

QY41P

QY41H

QY71

High-Speed Counter Module

QD62

QD62E

QD62D

QD63P6

QD64D2

Positioning Module

QD75P1/QD75P1N

QD75D1/QD75D1N

QD75P2/QD75P2N

QD75D2/QD75D2N

QD70P4

Simple Motion Module

QD77MS2

Servo external signals

interface module

Q172DLX/Q172LX

Manual pulse generator

interface module

Q173DPX/Q173PX/Q173PX-S1

MELSEC-L series

Connector type

Input modules

LX41C4

Output modules LY41NT1P

LY41PT1P

High-Speed Counter Module LD62

LD62D

Positioning Module

LD75P1

LD75D1

LD75P2

LD75D2

18

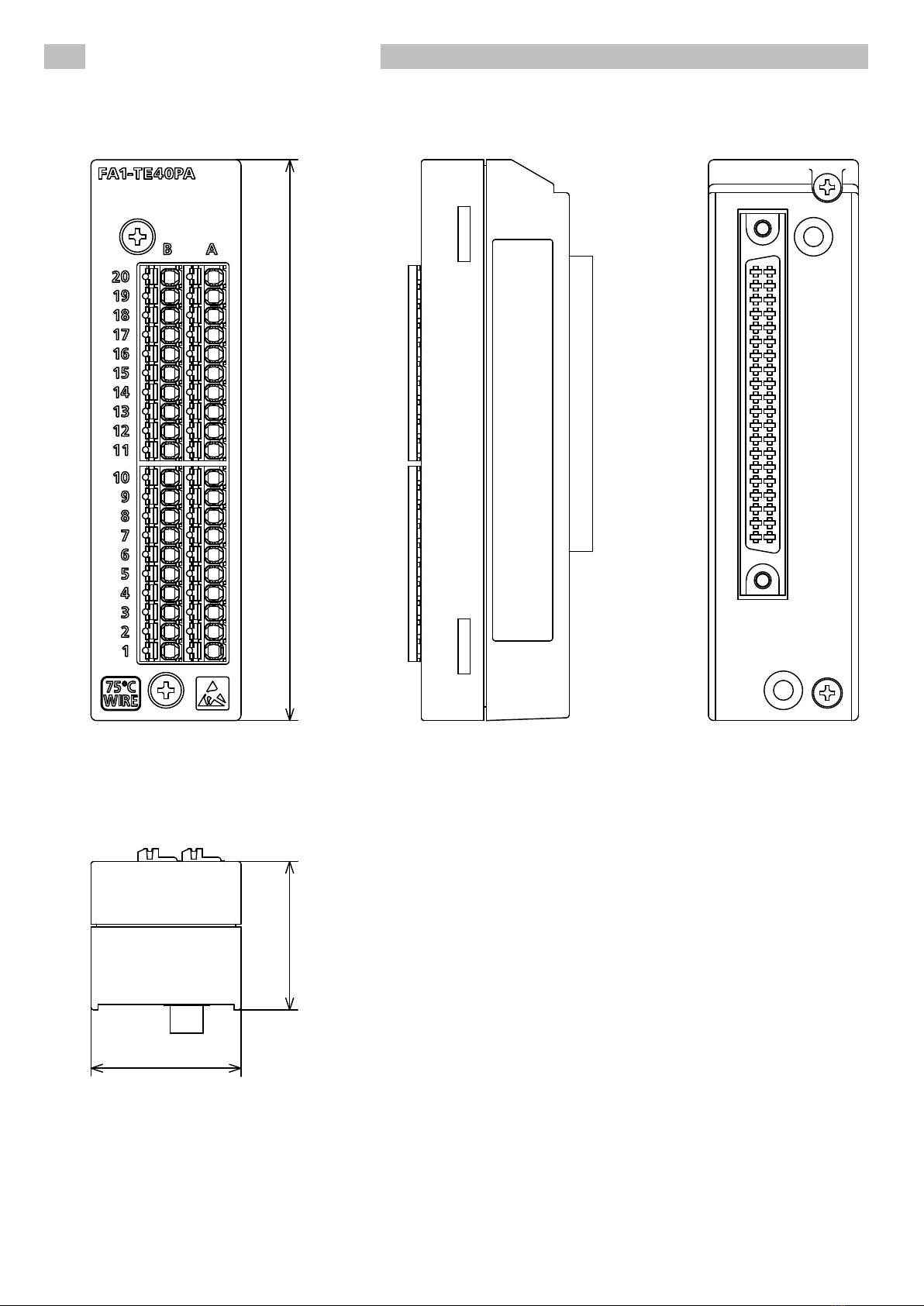

9. EXTERNAL DIMENSIONS

9-1. Spring Clamp Terminal Block Conversion Adapter (FA1-TE40PA)

[Unit︓mm]

27.4

27 102

19

9-2. Depth and height

[Unit︓mm]

MELSEC iQ-R ︓16.7

MELSEC-Q/L︓19.5

27

20

10. PRECAUTIONS

(1) For wiring to the terminal block, refer to the manual of the programmable controller module to be connected, published

by Mitsubishi Electric.

11. GRATIS WARRANTY TERMS AND GRATIS WARRANTY RANGE

If any fault or defect (hereinafter referred to as "Failure") attributable to Mitsubishi Electric Engineering should occur

within the gratis warranty period, Mitsubishi Electric Engineering shall replace the product free of charge via the

distributor from whom you made your purchase.

● Gratis warranty period

The gratis warranty period of this product shall be one (1) year from the date of purchase or delivery to the designated

place.

Note that after manufacture and shipment from MEE, the maximum distribution period shall be six (6) months, and

the gratis warranty period after manufacturing shall be limited to eighteen (18) months.

In addition, the gratis warranty period for repaired products shall not exceed the gratis warranty period established

prior to repair.

● Gratis warranty range

(1) The gratis warranty range shall be limited to normal use based on the usage conditions, methods and environment,

etc., defined by the terms and precautions, etc., given in the instruction manual, userʼs manual, and caution labels

on the product.

(2) In the following cases, a repair fee shall be applied even if within the gratis warranty period.

1) Failure resulting from inappropriate storage or handling, carelessness or negligence by the user, or Failure caused

by the user's hardware or software design.

2) Failure caused by unapproved modifications, etc., to the product by the user.

3) Failure that could have been avoided if, when the Mitsubishi Electric Engineering product was assembled into the

user's device, safeguards defined by legal regulations applicable to the user's device or functions or structures

considered standard by the industry had been provided.

4) Failure recognized as preventable if the consumed products specified in instruction manuals, etc., were normally

maintained or replaced.

5) Replacement of consumable parts (relays, etc.).

6) Failure caused by external factors beyond anyone's control such as fires or abnormal voltage, and Failure caused

by Force Majeure such as earthquakes, lightning, or wind and water damage.

7) Failure caused by reasons unpredictable by scientific technology standards at the time of shipment from Mitsubishi

Electric Engineering.

8) Any other failure not attributable to Mitsubishi Electric Engineering or found by the user to not be attributable to

Mitsubishi Electric Engineering.

12. EXCLUSION FROM LIABILITY FOR OPPORTUNITY LOSS AND SECONDARY LOSS

Regardless of the gratis warranty period, Mitsubishi Electric Engineering shall not be liable for compensation for damages

arising from causes not attributable to Mitsubishi Electric Engineering, opportunity losses or lost profits incurred by the

user due to Failures of Mitsubishi Electric Engineering products, damages or secondary damages arising from special

circumstances, whether foreseen or unforeseen by Mitsubishi Electric Engineering, compensation for accidents,

compensation for damages to products other than Mitsubishi Electric Engineering products, or compensation for

replacement work, readjustment of onsite machinery and equipment, startup test runs or other duties carried out by

the user.

13. TRADEMARKS

MELSEC, MELSEC iQ-R, CC-Link, CC-Link IE, and CC-Link/LT are trademarks or registered trademarks of Mitsubishi

Electric Corporation. Other company names and product names in the text are trademarks or registered trademarks of

each company.

In some cases, trademark symbols such as '™' or '®' are not specified in this manual.

Table of contents

Other MITSUBISHI ELECTRIC ENGINEERING Adapter manuals