ù'

f, ..--'--

F!t

l, !

i;i

Tracking

force . 2.0gr.

v î

I

CASSETTE

DECK

SECTION

Type . ...4-track,2+hannelstereo i

æssette

deck i

Tape

speed ïii",^ttn (1-718

iPs) I

,l

Head

material ..

i..:r

{-{ I

REC/PB Hard

PermalloV i

i

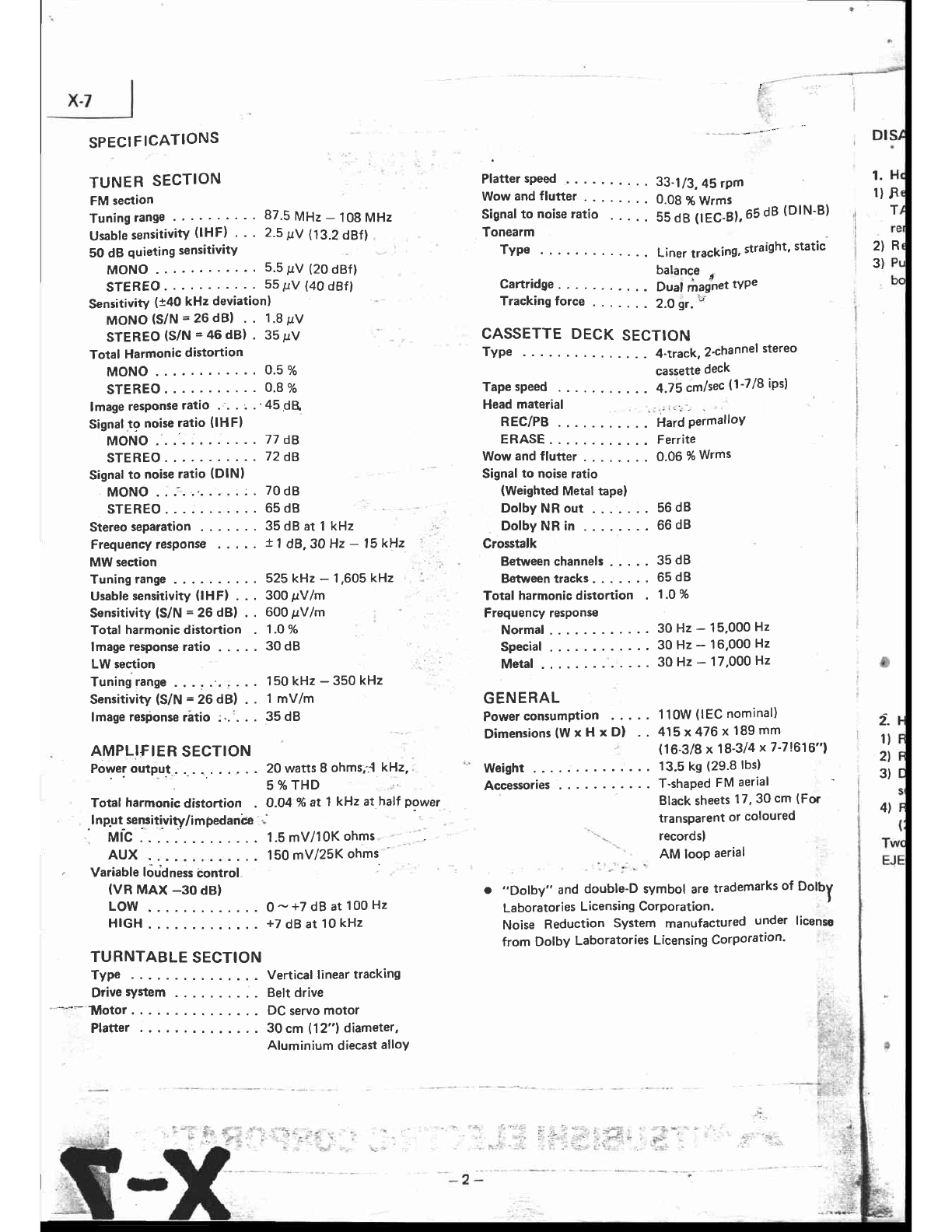

MONO . . 77dB ERASE . Ferrite

STEBEO . 72dB Wow

andflutter . . 0.06

%

Wrms

Signal

to noise

ratio (DlNl Signal

to noiseratio

MONO

.:.''..'....::. 70dB (WeightedMetaltapel

STEREO...:. .65d8 DolbyNRout.......56dB

Stereoseparation ..3sdBatlkHz ''" DolbyNRin...."" 66dB

Frequency

responss t 1dB,30 Hz- 15kHz ' Crosstalk

MWsection i Between

channell " " ' 35 d8

Tuningrange. ....525kH2-l,605kHz I Batrreentracks "65dB

Usable

sensitivity

(lHFl . . . 300pVlm Totalharmonic

distortion . 1.0

%

sensitivity ls/N = 26 dBl . . 600pVlm Frequency

resPonso

Totalharmonic

distortion 1.0

%

lmageresponseratio.....3OdB Special .30H2-16,000H2

LWsestion ' ' Metal ' 30 Hz - 17'000 Hz

Tuninglange. ;... 150kHz-350kHz

Sensitivity

(S/N

= 26dB) . . 1mV/m GENERAL

tmaç resionse

râtio :..'. . . 35dB Power

consumption 110W

(lEC

nominal) 2-

Dimensions(WxHxD)

.- 415

x476xt8ntT-.^.^,,.' l)

AMPLIF|

ER

sEcrloN 116'g/8x18-314x7-71616"1

::

,^^ ô ll-l Zt

Poweroutpùt 2owattsSohmsJ

kHz,, -' Weight

..... .... 13.5kS(29'8lbs) , 1l

- - -, ; - -L --^i Ert ^^vial rt

Totalharmonic

distortion . O.O4

%

at 1kHzathalfpower Black

sheets

17'30cm (For

.lnp.ut-sensitivity/impedanb - transparent

or coloured

. rvri'c

..... .... 1.5mV/10Kohms

' '..- records)

AUX . . . 150

mV/25K

ohms " AM loop

aerial

, Variablelôudness

êontrol : 'r : ' '

(VR MAX -30 dB) o ,,Dolby" anddoubte-D

rymbol are

trademarks

of Dolbl

LOW . . . O

-+7 dB at 100

Hz Laboratories

Licensing

Corporation. '

HIGH . . . +7 d}at l0 kHz Noise Reduction System manufactured

under licensc

from Dolby Laboratories

Licensing

Corporation'

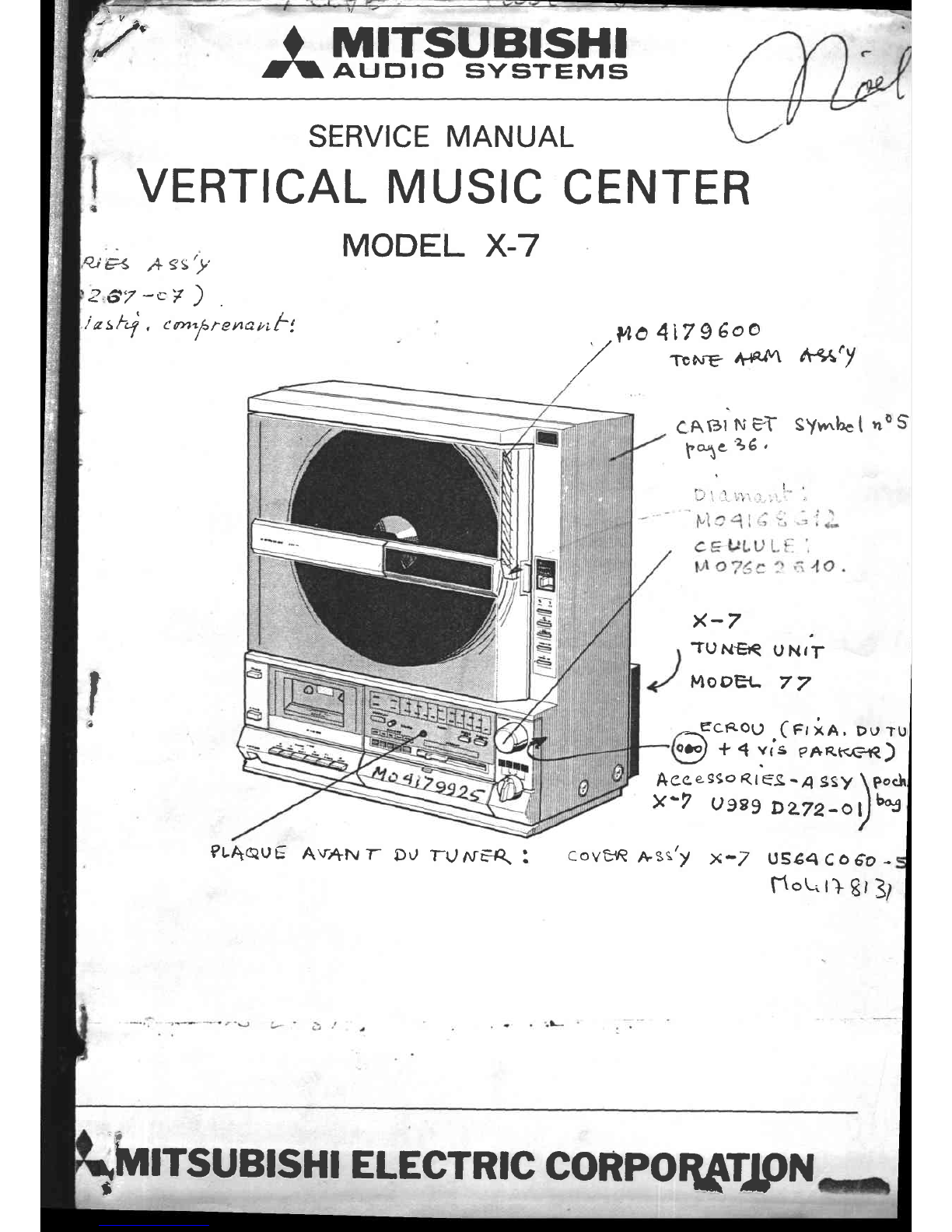

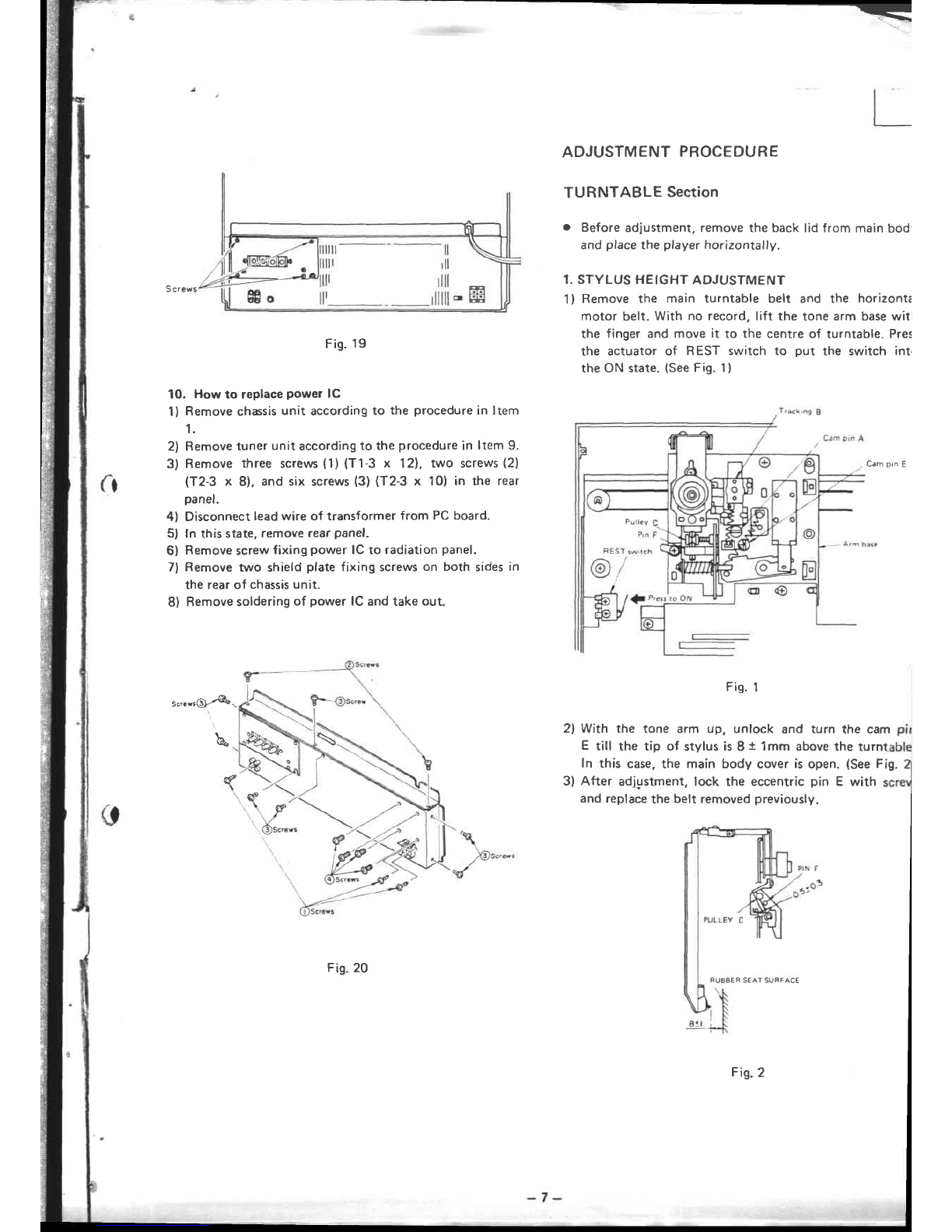

TURNTABLESECTION

Type . .... Vertical

lineartracking

Drivesystem

' -*-.- Îùlotor DCservo

motor i. ,r

,.,.

Platter . . . . 30 cm 112"1

diameter, ài '. 1'

Aluminium diecast

alloY li,;..;:i

, .'-':,i