2

WARNING

Burns due to an increased heat of the head of the instrument

Burns in the oral area may occur due to an increased heat of the head of the instrument.

CAUTION

Accelerated deterioration and dysfunctions due to long term non-usage

→ Before storage, clean, maintain and dry the instrument according to the norm. Store in the original packing, dry and dustproof.

We recommend an annual check-up and maintenance of the enre spindle system by MK-dent or by personnel authorized by MK-dent.

3 Product descripon

This manual can be used for the following MK-dent products:

Turbines of the Prime Line series

Standard head Small head

HP21KL, HP21WL, HP21SL, HP21NL HP22KL, HP22WL, HP22SL, HP22NL

Turbines of the Classic Line series

Standard head Small head

HC20K/KL, HC21K/KL, HC21W/WL, HC21S/SL, HC21N/NL HC22K/KL, HC22W/WL, HC22S/SL, HC22N/NL

3.1 Intended purpose

This medical product may only be used in a dental surgery, especially for the following purposes:

Removal of decayed material, preparaons of cavies and crowns, removal of llings.

3.2 Use according to regulaons

This product may only be used for the intended purposes, executed by professionally trained personnel.

The indicaons and warnings in this manual must be considered. This also includes the observing of the processing (see chapter 5 Processing

according to ISO 17664 ) and the valid naonal health and safety regulaons. Any other use may result in an endangering of the paent, the

operator or others and is strictly prohibited. Before each applicaon, the funconality of the instrument must be tested.

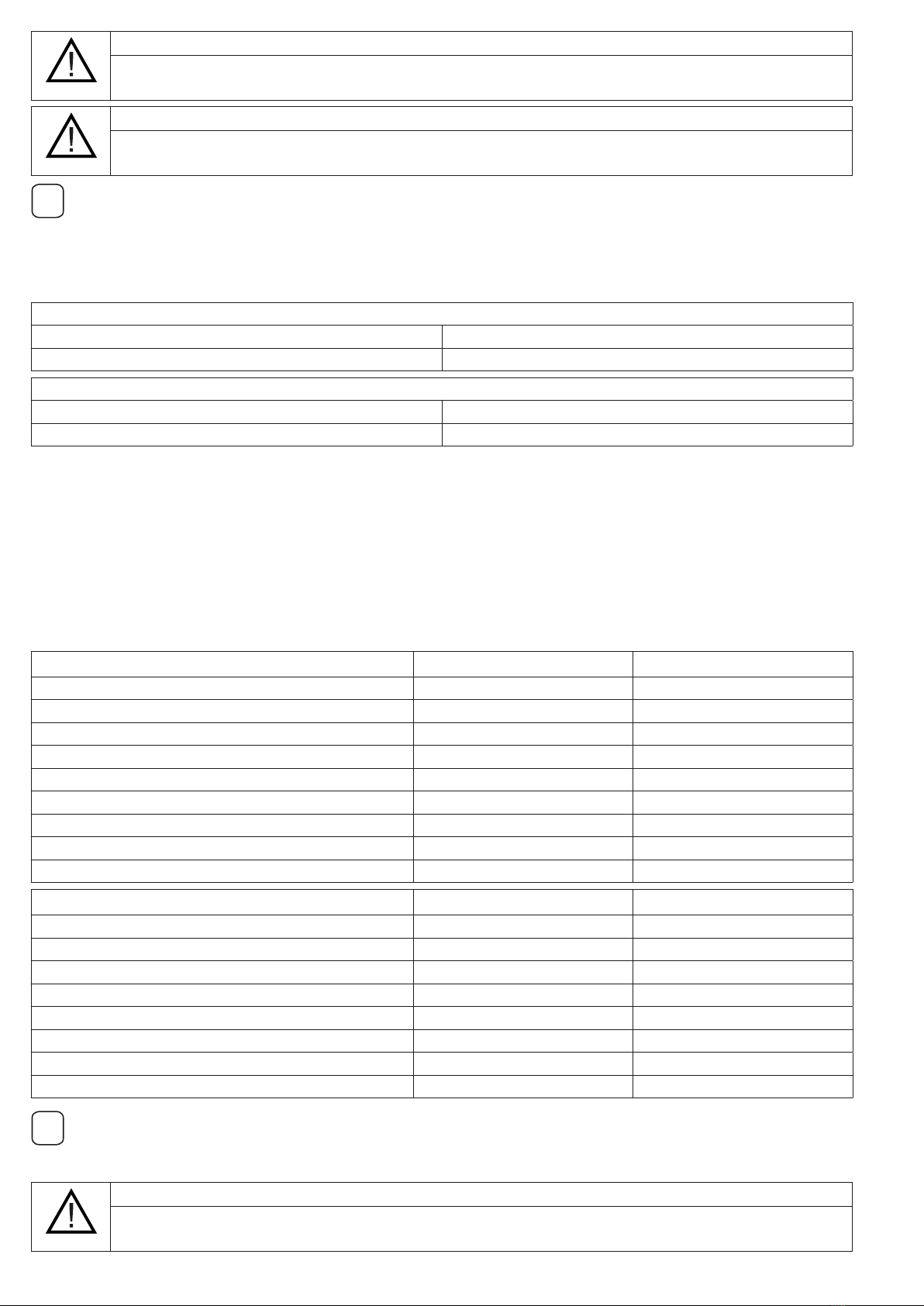

3.3 Technical specicaons

KaVo®-connecon W&H®-connecon

Driving pressure (bar) 2.8 3.0 - 3.3

Pressure of spray water (bar) 0.8 - 2.5 0.8 - 2.5

Pressure of spray air (bar) 1.0 - 4.0 1.0 - 4.0

Air consumpon (Nl/min) 40 40

RPM Standard head HC20... 360 000 - 375 000 -

RPM Standard head/Small head HC21.../HC22... 330 000 - 350 000/380 000 - 420 000 330 000 - 350 000/380 000 - 420 000

Recommended press-on force (N) 2 - 3 2 - 3

Spray water consumpon (ml/min) according to EN ISO 14457 > 50 > 50

Operang noise dB(A) Standard head/Small head 55/60 55/60

Sirona®-connecon NSK®-connecon

Driving pressure (bar) 2.7 2.8

Pressure of spray water (bar) 0.8 - 2.5 0.8 - 2.5

Pressure of spray air (bar) 1.0 - 4.0 1.0 - 4.0

Air consumpon (Nl/min) 40 40

RPM Standard head/Small head 330 000 - 350 000/380 000 - 420 000 330 000 - 350 000/380 000 - 420 000

Recommended press-on force (N) 2 - 3 2 - 3

Spray water consumpon (ml/min) lt. EN ISO 14457 > 50 > 50

Operang noise dB(A) Standard head/Small head 55/60 55/60

KaVo®, W&H®, Sirona® and NSK® are registered trademarks. MK-dent does not have any economical connecon to the companies

menoned above.

3.4 Transport and storage requirements

CAUTION

Dysfunction of the instrument while operating after an overcooled storage

→ Heavily cooled instruments must be warmed to room temperature prior to operang.