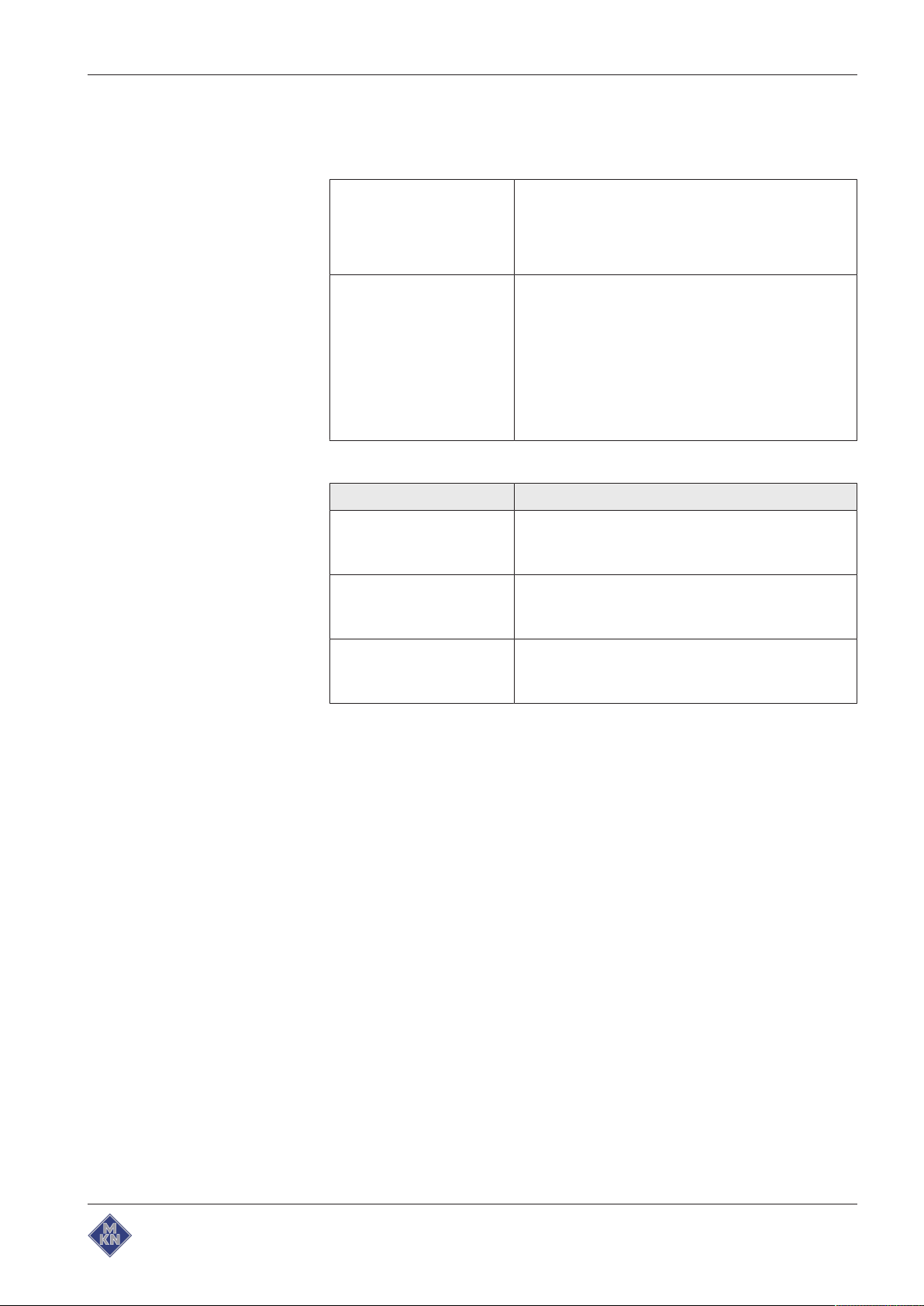

Directory of contents

3Installation instructions

1Introduction......................................................................... 5

1.1About this manual ............................................................................ 5

1.1.1Explanation of signs .................................................................................. 6

1.2Personnel qualifications.................................................................. 7

1.3Use of the unit................................................................................... 7

1.4Warranty............................................................................................ 7

2Safety information.............................................................. 8

3Description of the unit ..................................................... 11

3.1Overview of the unit ....................................................................... 11

3.2Equipment identification via order code...................................... 12

3.3Equipment and connection data................................................... 12

3.3.1Basic control setting ................................................................................ 15

4Transporting the unit ....................................................... 16

4.1Transporting the unit to the installation site ............................... 16

4.2Removing the transport protection .............................................. 17

4.3Unpacking the unit ......................................................................... 17

5Setting up the unit............................................................ 18

5.1Minimum clearances ...................................................................... 19

5.2Opening and closing the housing................................................. 20

5.2.1Removing and attaching the front panel of the control arm..................... 21

5.2.2Removing and attaching the cover of the control arm............................. 22

5.2.3Removing and attaching the front panel of the side arm......................... 23

5.2.4Removing and attaching the side arm cover ........................................... 24

5.2.5Opening and closing the lid ..................................................................... 25

5.3Placing the unit on the equipment legs........................................ 27

5.4Setting up the unit on the base..................................................... 28

5.5Removing the transport securing device..................................... 29

5.6Aligning the unit ............................................................................. 29

5.6.1Aligning the unit on the base ................................................................... 30

5.6.2Aligning the unit with equipment legs ...................................................... 31

5.6.3Checking alignment................................................................................. 32

5.7Attaching the cover plate .............................................................. 32

5.8Setting up FlexiChef Team ............................................................ 33

5.8.1Aligning single units with each other ....................................................... 33

5.8.2Connecting single units to each other ..................................................... 34

5.8.3Installing the control unit in the cover ...................................................... 35

5.8.4Connecting the control unit...................................................................... 36

5.8.5Installing the control unit front panel........................................................ 37

5.9Connecting the unit........................................................................ 38

5.10Fastening the unit to the floor..................................................... 39

10000008311AINBEB