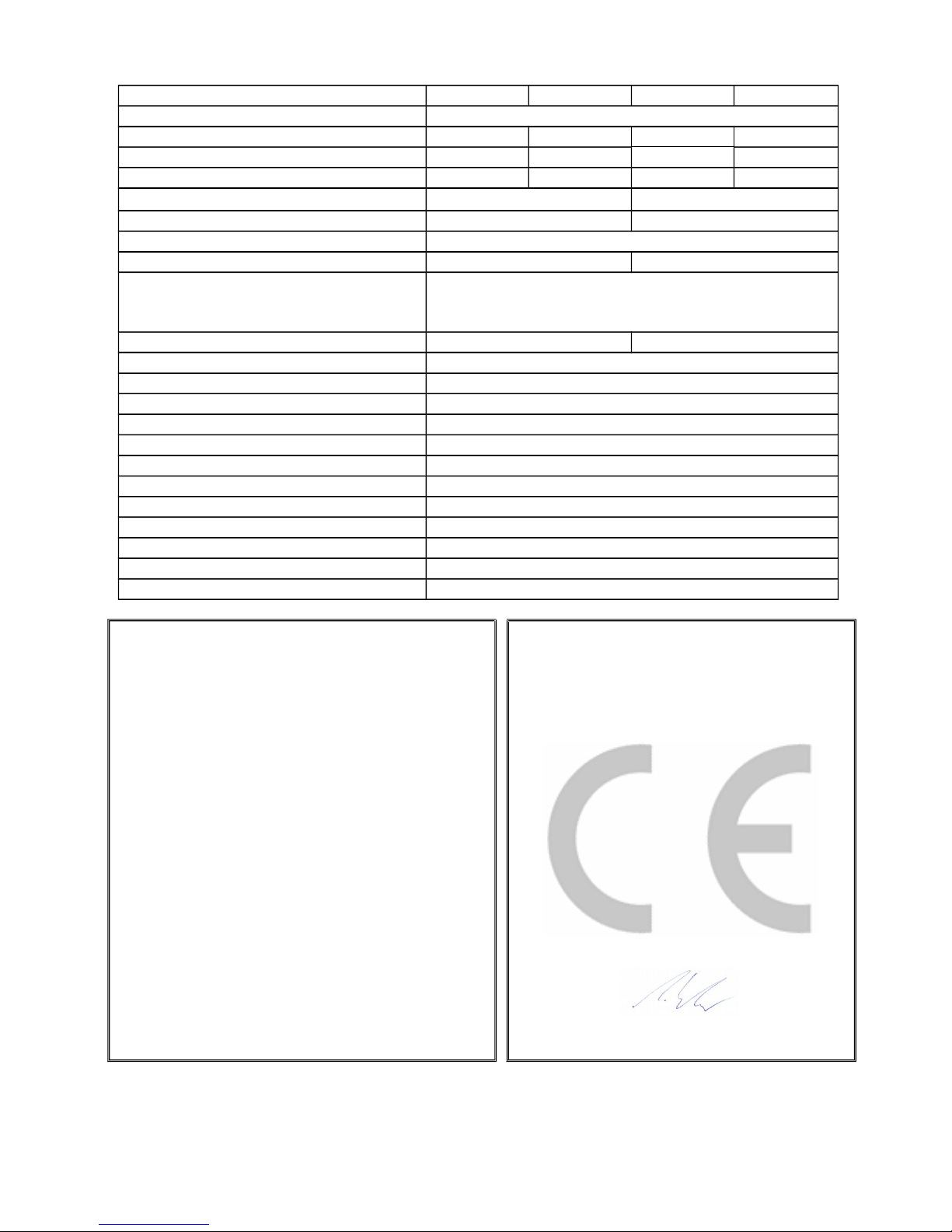

6.Technical Data

KSI 80VC-20 KSI 80VC-40 KSI 82VB-20 KSI 82VB-40

Output: RMS of vibration velocity, 4-20 mA

Measuring range (vMIN .. vMAX): 0.2 .. 25 mm/s 0.4 .. 50 mm/s 0.2 .. 25 mm/s 0.4 .. 50 mm/s

Nominal value at 20 mA: 20 mm/s 40 mm/s 20 mm/s 40 mm/s

Sensitivity: 0,8 mA/mms-1 0,4 mA/mms-1 0,8 mA/mms-1 0,4 mA/mms-1

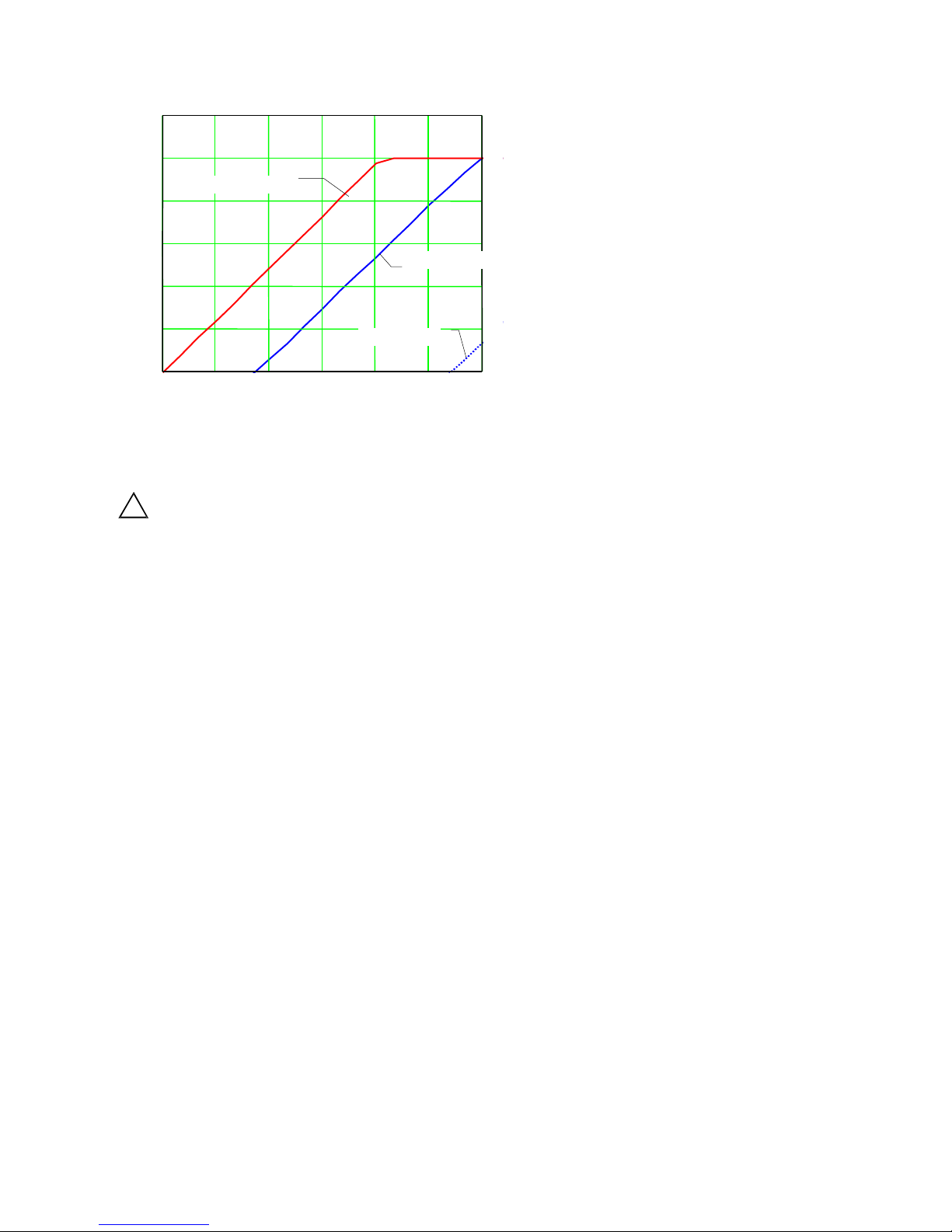

Frequency range (-3 dB): 1.5 .. 1000 Hz 10 .. 1000 Hz

Frequency range (-10 %): 3 .. 650 Hz 20 .. 650 Hz

Non-linearity (vMIN .. vMAX, 25 °C): ± 3 %

Residual noise: ± 0.01 mm/s ± 0.005 mm/s

Output ripple: f > 5 Hz

f = 3 Hz

f = 1,5 Hz

< 1 %

2 %

6 %

Settling time to 1 % tolerance: 10 s 2 s

Destruction shock limit: ± 4000 g

Transverse sensitivity: < 5 %

Loop supply voltage: 12 .. 30 V

Maximum linear output current: 25 mA

Maximum output current at overload: < 35 mA

Operating temperature range: - 40 .. 85 °C

Temperature coefficient of sensitivity: ± 0.05 %/K

Temperature drift of zero point: + 0.9 µms-1/K

Protection grade: IP67

Case material: Stainless steel

Weight ithout cable: 66 g

Mounting: M8 tapped hole in base

Warranty

Metra arrants for a period of

24 months

That its products ill free from defects in material and

orkmanship and shall conform to the specifications

current at the time of shipment. The arranty period

starts ith the date of invoice.

The invoice must be presented as proof of purchase.

The arranty period ends after 24 months.

Repairs do not extend the arranty period.

The limited arranty only covers defects hich arise

as a result of normal use according to the instruction

manual.

Metra's obligations under this arranty do not apply in

cases of improper or inadequate maintenance or

modification and operation outside the product's

specifications

Shipment to Metra ill be paid by the customer.

The repaired or replaced product ill be sent back to

the customer at Metra's expense.

Declaration of Conformity

According to EMC Directive 2014/30/EC

Product: Vibration Velocity Transmitters

Type: KSI80VC / KSI82VB

It is hereby certified that the above mentioned

product complies ith the demands pursuant to

the follo ing standards:

DIN EN 61326-1: 2013

DIN EN 61010-1: 2011

DIN 45669-1: 2010

The producer is responsible for this declaration

Metra Mess- und Frequenztechnik

in Radebeul e.K.

Meißner Str. 58, D-01445 Radebeul

declared by

Michael Weber

Radebeul, 3rd March 2016

May/16