STEP BY STEP ASSEMBLY

Please refer to the respective drawings for each section. We recommend browsing over the instructions and

looking at all drawings once before actually beginning to assemble the kit.

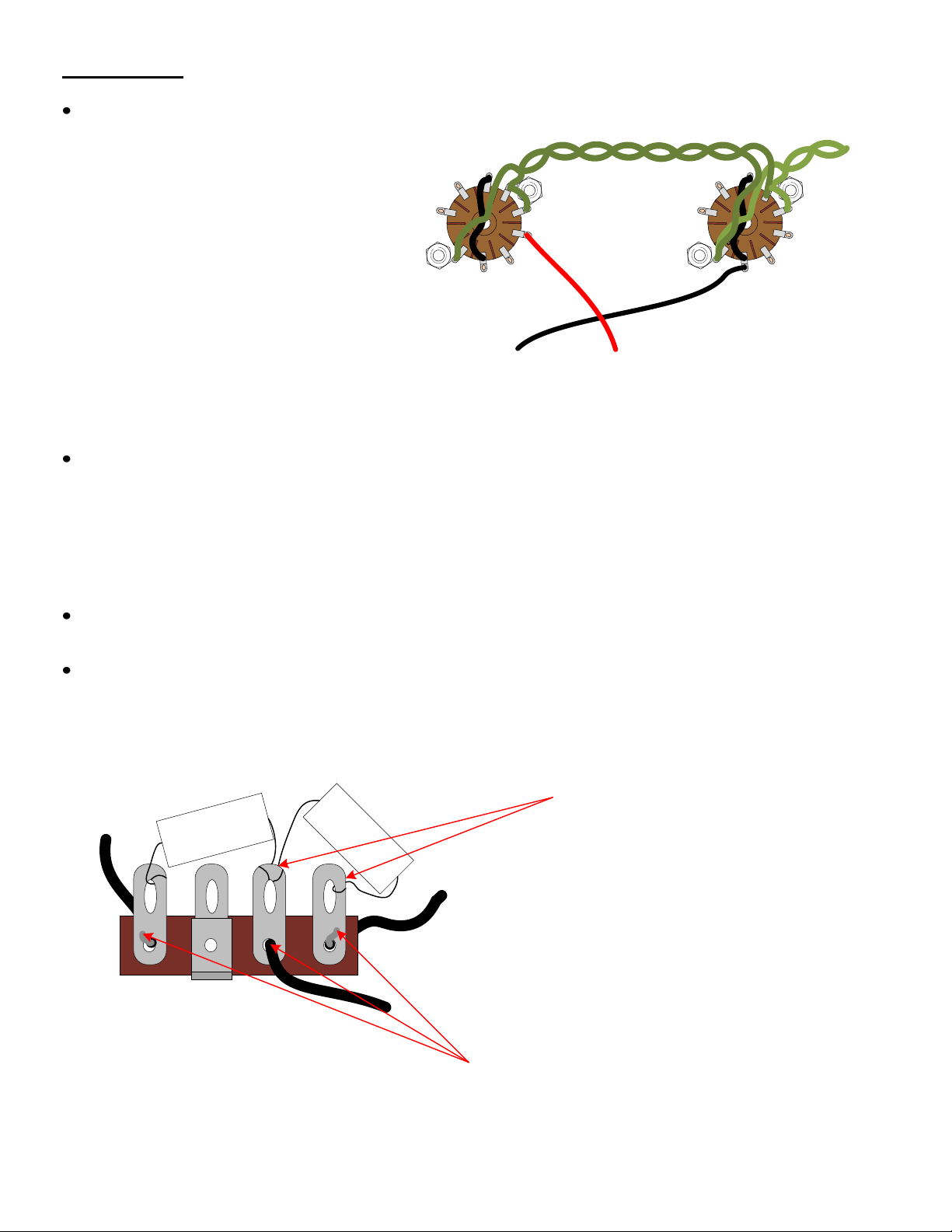

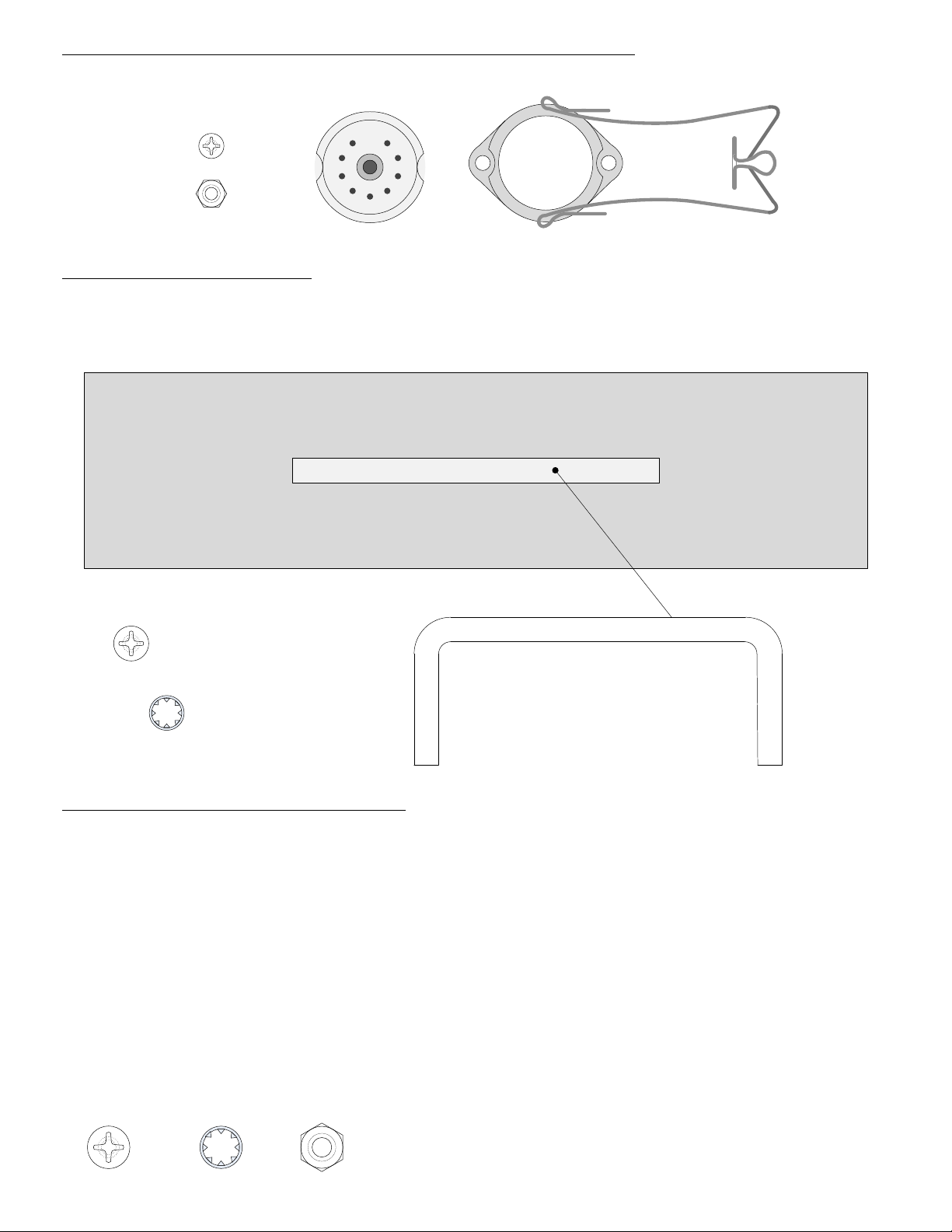

HARDWARE FASTENING TIP

When fastening components with mounting hardware (screws, lock washers, and hex nuts), the lock washer and

hex nuts should be fastened on the other side of the chassis from the head of the screw in the order pictured

below.

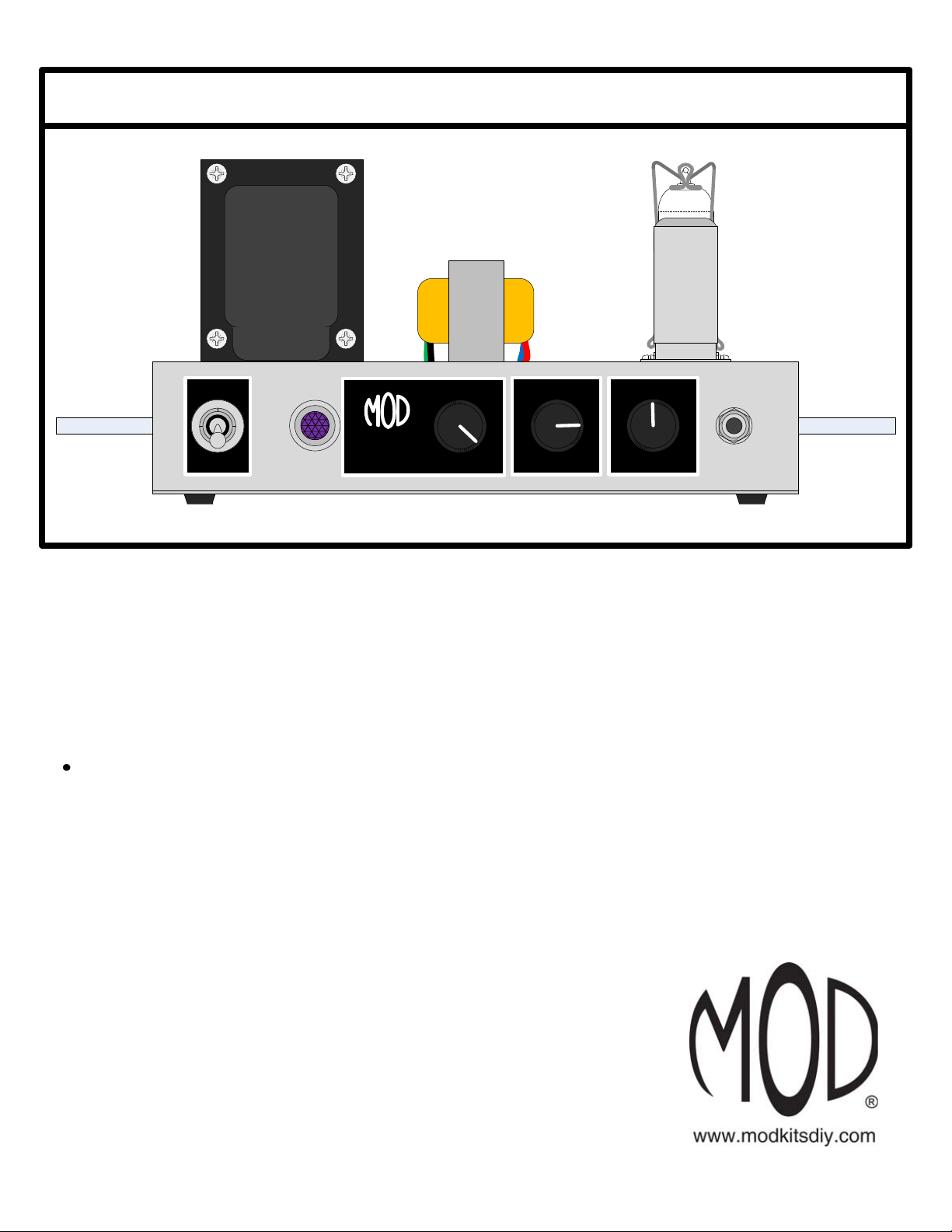

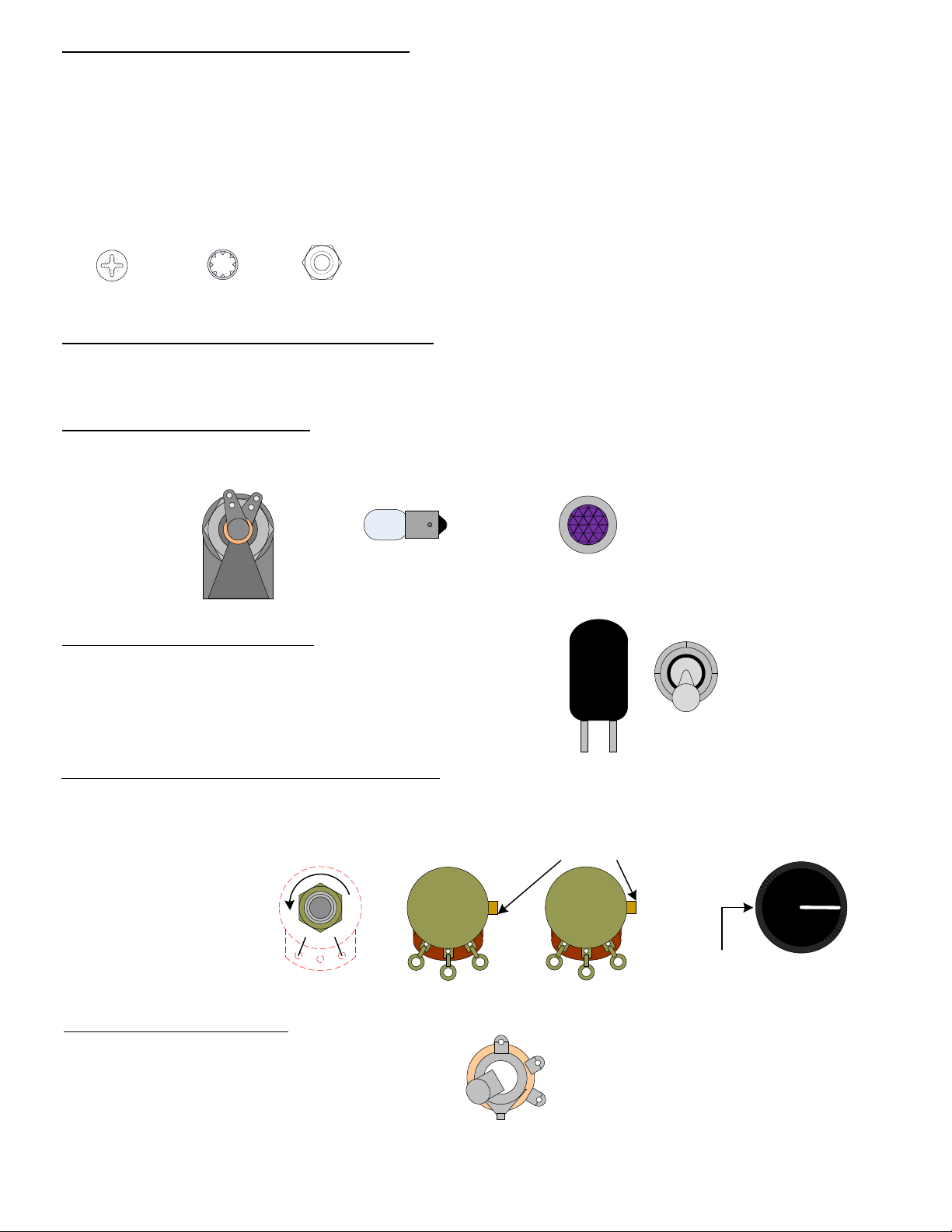

SECTION 1 – Mounting of Top Components

Please refer to Drawings 1 – 3. Find your chassis box. Drawing 1 identifies the names of

components that you will be mounting to the top of the chassis box.

Step 2 – Mount the rubber grommets with the 3/8" centers

Drawing 2 shows where to mount these four rubber grommets. Squeeze the grommet into

the hole and push it into place with your fingers.

8

Chassis

Screw Head

Lock Washer Hex Nut

Component Mounting

Bracket

(4)

Step 3 – Mount the 9 pin miniature tube socket for the 12AX7 with its tube shield

Drawing 2 shows where to mount the 9 pin miniature socket “V1”. Make sure that pins 1 & 9 face the front

of the chassis. Use #4 hardware and the tube shield to mount this socket.

(2)

(2)

1 9

Tip: Because the tube shield mounting holes are very close to the

socket edge, it may be easiest to fasten the first screw loosely and then

the second screw by holding the hex nut (flat side to socket edge)

against the chassis holes and then inserting the screw from the top of

the chassis. Finish up by fastening both screws tightly.

Top of Chassis

Before you begin!

Use a fine cut miniature round file to carefully file away the paint

coating only from the inside edge of each chassis hole.

(The chassis provides the ground connection for many components so it is

important that the inner edge of these holes are not insulated by the paint coating).

Step 1 – Mount the Labels

Follow the label mounting instructions on page 17 and attach each

label over its corresponding chassis hole.