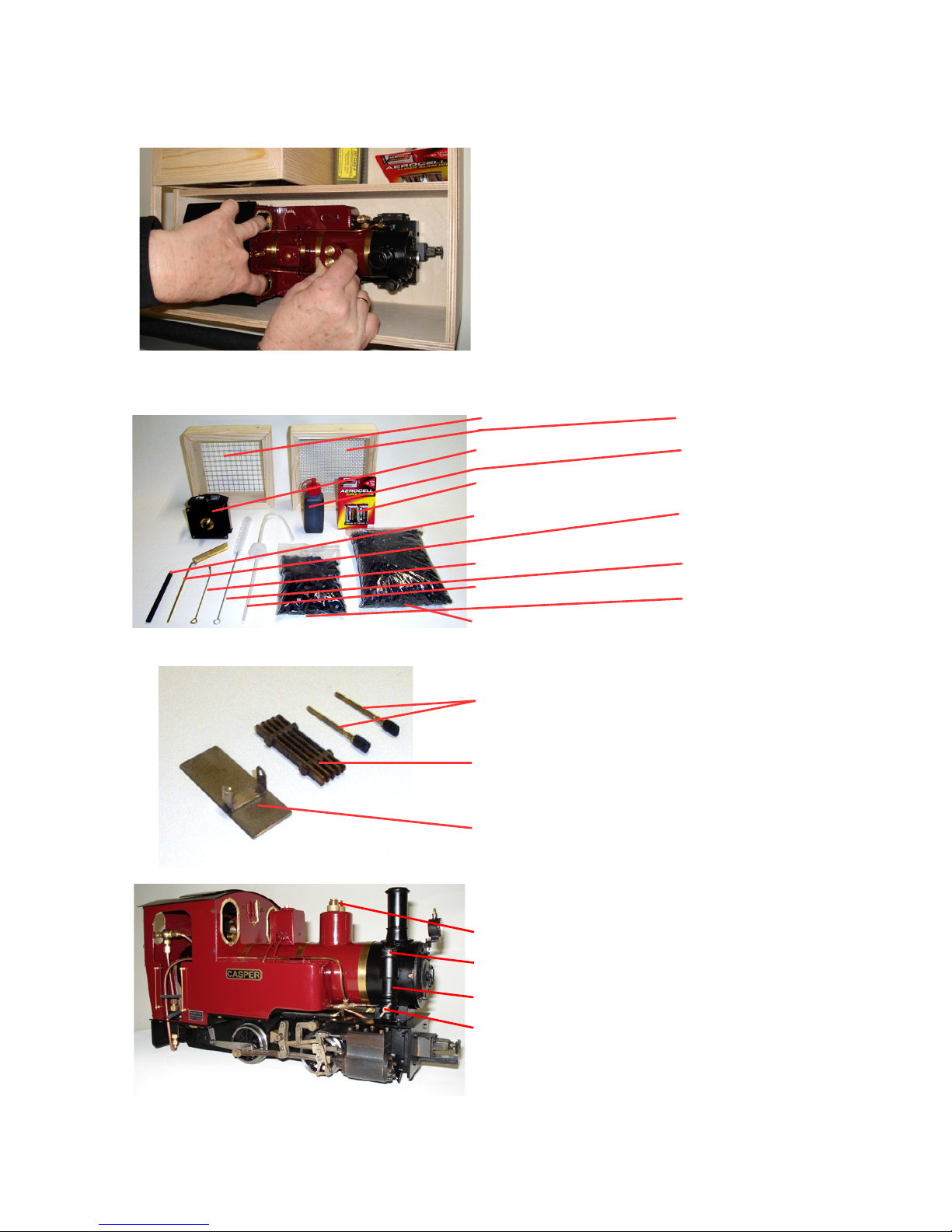

3. Put the electrical fan, after placing the batteries (included), in the chimney and switch ON.

4. Take a small scoop of lamp oil soaked charcoal, light it with an appropriate lighter and place the burning

charcoal in the fire box. Immediately close the fire door.

You may hear the fire in the fire box and smoke will come out of the fan through the chimney.

5. When the pressure gauge reaches pressure of 1,5 – 2 Bar, the blower valve can be opened and when it

operates cleanly, the electrical fan can be taken away and the blower takes over the task of the electrical fan

and causes fire draft.

6. When the charcoal fire glows white, you can start rebuilding the charcoal to a coal fire. Start with one

scoop of anthracite in the front and one scoop in the back of the firebox. Keep the fire door open as short as

possible in order to prevent the fire to go out, due to false air.

7. When the first layer of anthracite starts to glow, you can refill with anthracite, and so on until the charcoal

fire is replaced by an anthracite fire.

8. In the mean time the pressure gauge will indicate approx. 4 Bar and the safety valves will start to blow off.

9. Check if there is sufficient water in the boiler (approx. half way the gauge glass).

Open the blow down valve of the watergauge regularly in order to realise a true reading.

When neccessairy, with the bypass valve closed (turn clockwise), refill the boiler with the handpump.

Check and refill the watertanks.

Put the reverser handle in the direction you want to drive.

12. The regulator can be opened about 45 degrees (counter clockwise). Blower and bypass valves are

closed. After removing the water out of the cylinders through the chimney, the locomotive will start running

and can be coupled to the train.

13. In order to help with decondensation of the cilinders when they are cold, the cylinder cocks can be

opened bij pushing the handle downwards. After decondensation the handle can be pushed upwards in order

to close the cilinder cocks.

URING RUNNING

Just like a scale 1:1 locomotive it is crucial to keep steam production of the boiler in balance with the steam

requirements of the engine. At the same time sufficient draw on the fire should be maintained to prevent

dying of the fire.

This is a matter of experience and you will learn it during the driving the locomotive.

With a heavy load, the exhaust steam will take care for sufficient draw on the fire.

With a light load or low outside temperatures it can be neccessairy to open the blower valve slightly during

running in order to maintain sufficient draw on the fire.

Every 5 to 10 minutes, dependable of the load of the locomotive, a refill of anthracite is neccessairy in order

to prevent dying of the fire.

uring running, pressure gauge, water gauge and water tanks should be observed permanently as follows:

–waterlevel in water gauge to high: bypass valve more open (turn counterclockwise)*

–waterlevel in water gauge to low: close bypass valve (turn clockwise)

–pressure gauge to high (= > ca. 3,5 Bar) close blower valve (turn clockwise)

–pressure gauge to low (= < ca. 1,5 Bar) open blower valve (turn counter clockwise)

–waterlevel in tanks to low: refill

*Surplus water will be pumpe , through the return line, in the left water tank. This gives you also the

opportunity to a visual check of the function of the mechanical pump uring running.

HINT:

Un er certain con itions (i.e. quality of anthracite, higher outsi e temperatures) the boiler is able to pro uce

more steam than neccessairy . Safety valves are constantly blowing off which results in a high water

consumption. This effect can be avoi e by leaving open the fire oor by a small amount in or er to re uce

the raft on the fire.

Always take care of sufficient draft on the fire. If the locomotive is at a standstill always open the blower valve.

LUBRICATION URING A RUNNING SESSION:

When the locomotive is in steam for more than 15 minutes the lubricator should have a refill as follows:

Keep, while the locomotive is still in steam, the regulator closed and open the blower valve. Close the valve

(turn clockwise) at the bottom of the lubricator and remove the Nylon filler cap ( careful! hot, use gloves) refill

the lubricator with steam oil. (When you are not familiar with the amount of oil consumption check the oil level

every time you refill with water and/or coal).

Replace the filler cap and fix it fingertight. and open the lubricator valve at the bottom with 1/8 turn or less.

The locomotive is now ready to run again.

Page 4 of 9