Modine Manufacturing Company

1500 DeKoven Avenue

Racine, WI 53403

Phone: 1.877.679.4436 (4GEO)

www.modinehvac.com

© Modine Manufacturing Company 2016

As Modine Manufacturing Company has a continuous product improvement program, it reserves the right to change design and specifications without notice.

COMMERCIAL WARRANTY (For Residential Warranty, see GEO16-510)

Seller warrants its products to be free from defects in material and

workmanship, EXCLUSIVE, HOWEVER, of failures attributable to the use

of materials substituted under emergency conditions for materials normally

employed. This warranty covers replacement of any parts furnished from the

factory of Seller, but does not cover labor of any kind and materials not

furnished by Seller, or any charges for any such labor or materials, whether

such labor, materials or charges thereon are due to replacement of parts,

adjustments, repairs, or any other work done. This warranty does not apply to

any equipment which shall have been repaired or altered outside the factory of

Seller in any way so as, in the judgment of Seller, to affect its stability, nor

which has been subjected to misuse, negligence, or operating conditions in

excess of those for which such equipment was designed. This warranty does

not cover the effects of physical or chemical properties of water or steam or

other liquids or gases used in the equipment.

BUYER AGREES THAT SELLER’S WARRANTY OF ITS PRODUCTS TO BE

FREE FROM DEFECT IN MATERIAL AND WORKMANSHIP, AS LIMITED

HEREIN, SHALL BE IN LIEU OF AND EXCLUSIVE OF ALL OTHER

WARRANTIES, EITHER EXPRESS OR IMPLIED, WHETHER ARISING

FROM LAW, COURSE OF DEALING, USAGE OF TRADE, OR OTHERWISE,

THERE ARE NO OTHER WARRANTIES, INCLUDING WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PURPOSE, WHICH EXTEND

BEYOND THE PRODUCT DESCRIPTION CONFIRMED BY BUYER AND

SELLER AS OF THE DATE OF FINAL AGREEMENT.

This warranty is void if the input to the product exceeds the rated input as

indicated on the product serial plate by more than 5% on gas-fired and oil-fired

units, or if the product in the judgment of SELLER has been installed in a

corrosive atmosphere, or subjected to corrosive fluids or gases, been subjected

to misuse, negligence, accident, excessive thermal shock, excessive humidity,

physical damage, impact, abrasion, unauthorized alterations, or operation

contrary to SELLER’S printed instructions, or if the serial number has been

altered, defaced or removed.

BUYER AGREES THAT IN NO EVENT WILL SELLER BE LIABLE FOR

COSTS OF PROCESSING, LOST PROFITS, INJURY TO GOODWILL, OR

ANY OTHER CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND

RESULTING FROM THE ORDER OR USE OF ITS PRODUCT, WHETHER

ARISING FROM BREACH OF WARRANTY, NONCONFORMITY TO

ORDERED SPECIFICATIONS, DELAY IN DELIVERY, OR ANY LOSS

SUSTAINED BY THE BUYER.

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY COMPONENT WHICH

SHALL, WITHIN THE APPLICABLE WARRANTY PERIOD DEFINED HEREIN

AND UPON PRIOR WRITTEN APPROVAL, BE RETURNED TO SELLER

WITH TRANSPORTATION CHARGES PREPAID AND WHICH THE

EXAMINATION OF SELLER SHALL DISCLOSE TO HAVE BEEN DEFECTIVE;

EXCEPT THAT WHEN THE PRODUCT IS TO BE USED BY BUYER AS A

COMPONENT PART OF EQUIPMENT MANUFACTURED BY BUYER,

BUYER’S REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL BE

LIMITED TO ONE YEAR FROM DATE OF SHIPMENT FROM SELLER. FOR

GAS-FIRED PRODUCTS INSTALLED IN HIGH HUMIDITY APPLICATIONS

AND UTILIZING STAINLESS STEEL HEAT EXCHANGERS, BUYER’S

REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL BE LIMITED TO

TEN YEARS FROM DATE OF SHIPMENT FROM SELLER.

These warranties are issued only to the original owner-user and cannot be

transferred or assigned. No provision is made in these warranties for any

labor allowance or field labor participation. Seller will not honor any expenses

incurred in its behalf with regard to repairs to any of Seller’s products. No

credit shall be issued for any defective part returned without proper written

authorization (including, but not limited to, model number, serial number,

date of failure, etc.) and freight prepaid.

OPTIONAL SUPPLEMENTAL WARRANTY

Provided a supplemental warranty has been purchased, Seller extends the

warranty herein for an additional four (4) years on certain compressors.

Provided a supplemental warranty has been purchased, Seller extends the

warranty herein for an additional four (4) years or nine (9) years on certain

heat exchangers.

EXCLUSION OF CONSUMABLES & CONDITIONS BEYOND SELLER’S

CONTROL

This warranty shall not be applicable to any of the following items: refrigerant

gas, belts, filters, fuses and other items consumed or worn out by normal wear

and tear or conditions beyond Seller’s control, including (without limitation as

to generality) polluted or contaminated or foreign matter contained in the air or

water utilized for heat exchanger (condenser) cooling or if the failure of the part

is caused by improper air or water supply, or improper or incorrect sizing of

power supply.

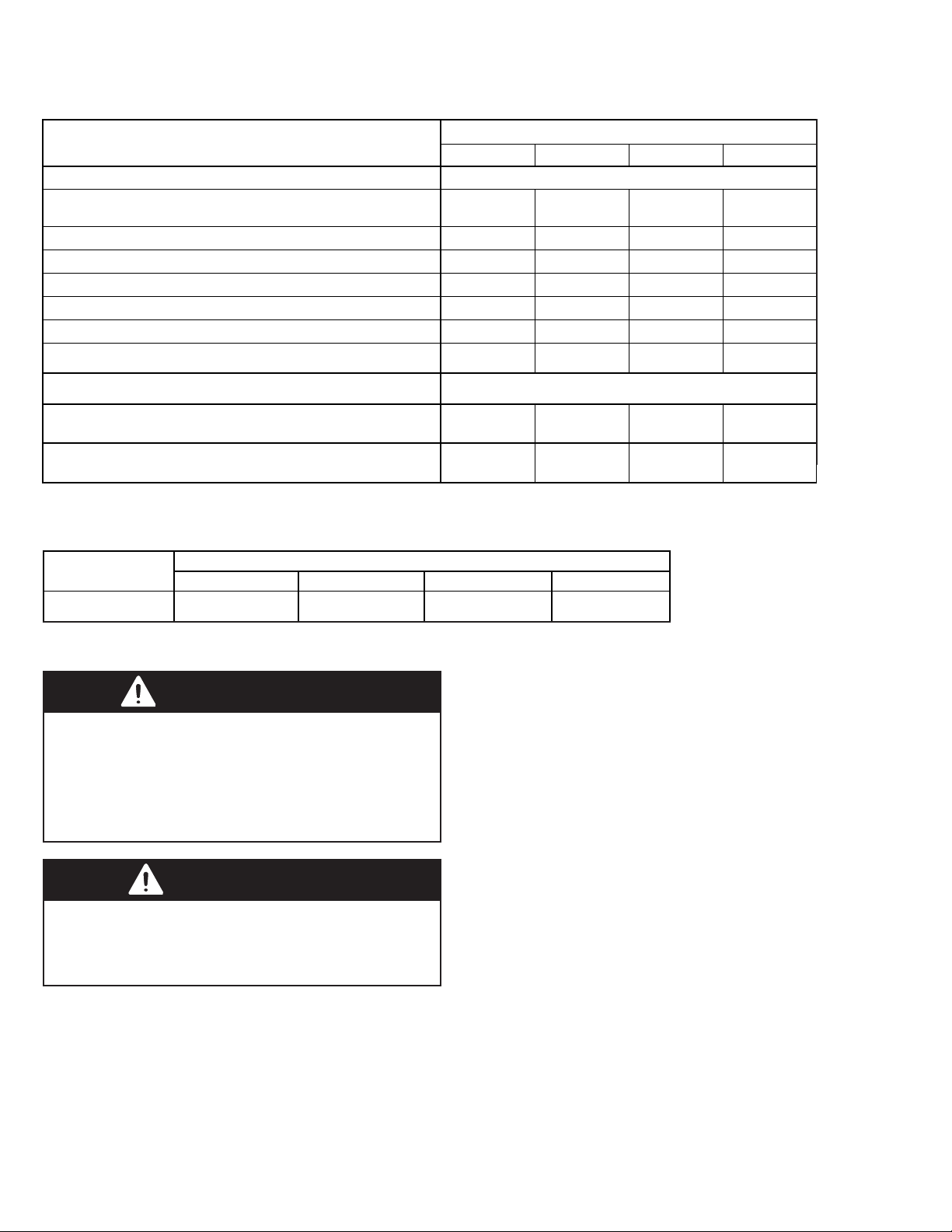

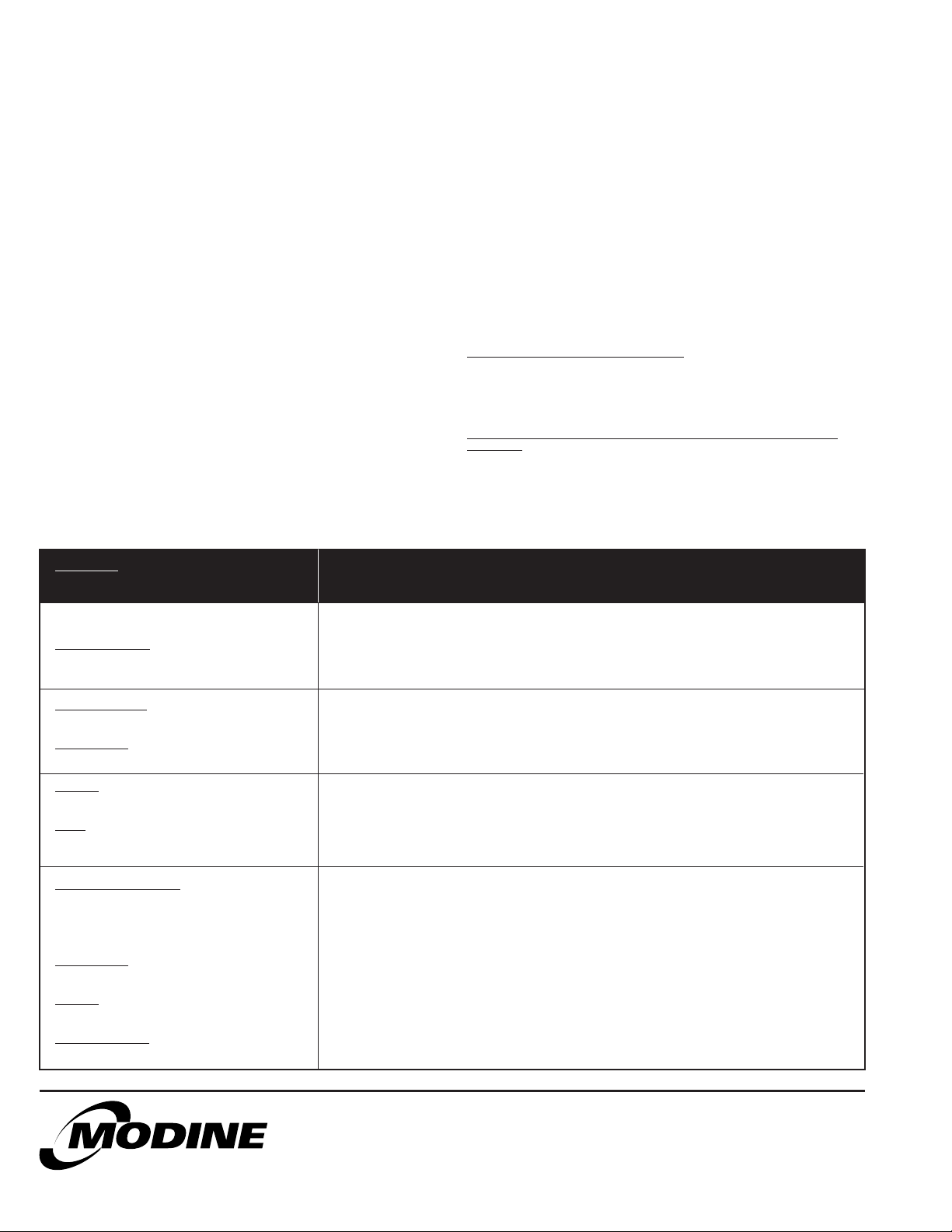

Component

Applicable Models “APPLICABLE WARRANTY PERIOD”

Heat Exchangers

Gas-Fired Units

Heat Exchangers

Low Intensity Infrared Units

Compressors

Condensing Units for Cassettes

Burners

Low Intensity Infrared Units

Other

Components excluding Heat Exchangers,

Coils, Condensers, Burners, Sheet Metal

Heat Exchangers/Coils

Indoor and Outdoor Duct Furnaces and

System Units, Steam/Hot Water Units,

Oil-Fired Units, Electric Units, Cassettes,

Vertical Unit Ventilators, Geothermal Units

Compressors

Vertical Unit Ventilators, Geothermal Units

Burners

High Intensity Infrared Units

Sheet Metal Parts

All Products

TEN YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

TEN YEARS FROM DATE OF RESALE BY BUYER OR ANY OTHER USER, WITHIN TEN YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN ONE

HUNDRED TWENTY-SIX MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER

OCCURS FIRST

FIVE YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

FIVE YEARS FROM DATE OF RESALE BY BUYER OR ANY OTHER USER, WITHIN FIVE YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN SIXTY-SIX

MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

TWO YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

TWO YEARS FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

THIRTY MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

ONE YEAR FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

ONE YEAR FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

EIGHTEEN MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST