Interklima PCE 03 User manual

CASSETTE FAN COIL

COOLING/HEATING

TERMINAL UNIT

COOLING CAPACITY: 2,5 kW - 10,5 kW

HEATING CAPACITY: 5,7 kW - 17,2 KW

Features

Stylish.

Compact and lightweight.

Ideal for standardized false ceilings.

Low noise.

Variable air flow distribution patterns.

Infrared remote control. (standard) or wired controller availability.

aster-Slave control capability.

RS-485 Port, for B S communication.

Built-in condensate pump.

Easy access to all the components for maintenance

Standard filter for clean air.

Fresh air and branch ducting capability.

Self diagnosis.

Interklima Hydronic Cassette Fan Coils are the

ideal solution for cooling/heating applications.

They are available in eight models with

nominal capacities ranging from 2 5kW to

10 5 kW in cooling and 5 7kW up to 17 2kW

in heating.

This series is ideal in combination with

Interklima air cooled water chillers or heat

pumps for air conditioning offices shops or

any other commercial application where floor

and wall space is needed for fittings and

furniture by being installed flush into every

ceilling with various air flow pattern flexibility

according to the room shape and layout.

PCE 03-04-06-08-09-10-12-16

NO ENCLATURE

1 Interklima Hydronic cassette

2 Model numbers

03=2kW

04=3kW

06=4kW

08=6kW

09=6,5kW

10=7,5kW

12=9kW

16=10,5kW

3 Type

V- 2 pipe P- 4 pipe

4 Electrical Characteristic

S- 230V 1ph / 50Hz

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 3

1. Technical Specifications

2. Capacity Tables

- Cooling

- Heating

3. Outlook Drawings

4. Wiring Diagrams

5. Installation

6. Controller

Instruction and Specifications

7. Service

Contents

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

4

Technical specifications1.

PCE -03

Single

7.5

6.6

5.6

2.5

2.25

2.1

2.03

1.79

1.67

5.7

5.15

4.8

3

2.71

2.52

30/35/38

33.5

0.149

0.34

480

7.0

1.3

570

570

250

31

Model

Numbers of fan blowers

Nomimal airflow

Nominal cooling capacity*

Nominal sensible

cooling capacity*

Nominal eating capacity**

Nominal sensible

eating capacity**

Noise level@1M (L/M/H)

Power supply (V/P /Hz)

Fan motor power

Fan motor running current

Fan motor starting current

Operation control & t ermostat

Water flow rate

Water pressure drop

Water content

Cond. drain connection I.D.

Casing dimentions

Panel dimentions

Cross weig t

Connection met od

Water Connection

PCE -04

Single

8.5

7

5.8

3

2.6

2.21

2.17

1.92

1.67

6

5.45

4.7

3.3

2.84

2.5

30/36/39

36.7

0.168

0.438

587

10.2

1.3

570

570

250

31

PCE -06

Single

10.4

9.4

7.8

4

3.4

2.9

2.84

2.51

2.19

6.9

6

5.2

4.2

3.65

3.17

35/41/43

54.2

0.241

0.759

765

9.6

1.79

570

570

290

33

PCE -08

Single

12.8

10.4

8.6

5

4.2

3.52

3.17

2.84

2.47

9

7.6

6.52

5.2

4.4

3.8

37/43/46

70.7

0.32

0.886

940

13.9

1.79

570

570

290

33

PCE -09

Twin

17

14

11.5

6.5

5.67

4.8

4.7

4.04

3.48

11.5

10

8.6

7.2

6.22

5.36

34/39/40

33.5x2

0.149x2

0.876

1.265

22.5

1.47

1.100

570

290

57

PCE -10

Twin

19.3

16

13

7.5

6.48

5.34

5.2

4.48

3.9

13

11.3

9.7

8.3

7.18

6.17

36/40/43

54.2x2

0.241x2

1.518

1.450

24.9

2.84

1.100

570

290

57

PCE -12

Twin

21.4

18.5

15.5

9

7.6

6.4

5.38

4.73

4.2

14.6

12.5

11.1

9.9

8.5

7.6

38/45/49

60.2x2

0.315x2

1.518

1.500

12.3

2.84

1.100

570

290

57

PCE -16

Twin

25

21

17.5

10.5

9

7.5

6.3

5.6

4.92

17.2

15.04

13.2

11

9.76

8.6

40/47/50

70.7x2

0.32x2

1.77

1.770

15.4

2.84

1.100

570

290

57

H

M

L

H

M

L

H

M

L

H

M

L

H

M

L

L

W

D

In

Out

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

dB(A)

Watt

Amp

Amp

L/h

KPa

L

mm(in)

mm

mm

mm

mm

kgs

mm(in)

mm(in)

230/1/50

Remote control handset & wired wall pad

19.05(3/4)

Socket (threaded female)

19.05 (3/4)

19.05 (3/4)

PCE-VS

NOTES

All capacities are based on: cooling: indoor 27oC DB 19.5oC WB outdoor: 35oC DB 24oC WB

heating: indoor 20oC DB outdoor: 7oC DB 6oC WB

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 5

Capacity Tables2.

Qw 1/h

502

593

670

387

425

476

306

353

400

240

264

302

189

208

236

Pf kW

2.33

2.75

3.10

1.63

1.88

2.12

1.31

1.51

1.71

1.00

1.11

1.19

0.75

0.81

0.86

Pfs kW

1.70

2.00

2.21

1.43

1.67

1.90

1.28

1.47

1.67

0.98

1.09

1.17

0.74

0.79

0.84

Tad

9.9

10.3

10.9

12.7

12.8

12.9

13.8

14.1

14.3

16.4

16.4

17.4

18.5

19.1

19.6

Taw

9.9

10.1

10.3

12.7

12.8

12.9

13.7

13.8

13.9

14.7

14.9

15.1

15.5

15.7

15.9

Pf kW

2.53

3.01

3.41

1.82

2.12

2.39

1.53

1.76

1.99

1.20

1.34

1.47

0.92

1.00

1.11

Pfs kW

1.82

2.16

2.38

1.53

1.82

2.07

1.45

1.68

1.9

1.18

1.31

1.44

0.90

0.97

1.09

Tad

10.7

11.1

11.7

13.2

13.5

13.6

14.4

14.5

14.8

16.6

17.2

17.7

19.1

19.7

19.9

Taw

10.7

10.9

11.0

13.2

13.5

13.6

14.4

14.5

14.6

15.4

15.6

15.8

16.3

16.5

16.6

Pf kW

2.66

3.14

3.55

2.05

2.25

2.52

1.62

1.87

2.12

1.27

1.40

1.60

1.00

1.10

1.25

Pfs kW

1.80

2.09

2.30

1.58

1.79

2.03

1.41

1.64

1.79

1.24

1.34

1.53

0.97

1.07

1.23

Tad

10.9

11.5

12.2

13.4

13.8

13.9

14.7

14.8

15.5

16.2

16.9

17.2

18.4

19.0

19.2

Taw

10.9

11.1

11.3

13.4

13.8

13.9

14.7

14.8

14.9

15.8

16.0

16.1

16.6

16.8

16.9

Pf kW

3.05

3.61

4.11

2.43

2.74

3.06

2.04

2.32

2.61

1.60

1.81

2.01

1.26

1.40

1.56

Pfs kW

1.95

2.30

2.51

1.74

1.98

2.16

1.54

1.75

1.93

1.33

1.40

1.68

1.22

1.35

1.52

Tad

11.6

12.0

12.8

14.1

14.3

15.0

15.5

15.9

16.6

17.2

17.8

18.1

18.2

18.8

19.3

Taw

11.6

11.8

11.9

14.1

14.3

14.5

15.2

15.4

15.6

16.5

16.7

16.9

17.5

17.7

17.9

Dpw kPa

7.69

10.4

12.9

4.81

5.70

6.97

3.15

4.08

5.11

2.03

2.42

3.08

1.32

1.57

1.97

Qa[m3/h]

323

391

452

340

398

453

336

396

458

338

393

462

337

397

469

PCE-03

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

Cooling

PCE-03

Qw1/h

540

644

755

417

491

587

323

378

446

253

287

327

208

232

259

Pf kW

2.48

2.94

3.48

1.95

2.29

2.71

1.45

1.70

2.00

1.05

1.19

1.38

0.87

0.95

1.05

Pfs kW

1.82

2.11

2.35

1.60

1.83

2.09

1.40

1.61

1.83

1.03

1.17

1.34

0.85

0.93

1.02

Tad

10.1

10.6

11.6

11.9

12.4

13.0

13.5

13.9

14.5

16.4

16.9

17.2

18.0

18.5

19.1

Taw

10.1

10.2

10.3

11.9

12.0

12.1

13.5

13.6

13.7

14.7

14.9

15.0

15.3

15.5

15.7

Pf kW

2.75

3.29

3.89

2.17

2.56

3.06

1.67

1.96

2.32

1.27

1.45

1.69

1.07

1.20

1.34

Pfs kW

1.98

2.31

2.60

1.74

2.00

2.29

1.54

1.79

2.05

1.24

1.41

1.64

1.04

1.17

1.31

Tad

10.7

11.3

12.2

12.6

13.1

13.9

14.2

14.6

15.2

16.6

17.2

17.5

18.3

18.8

19.4

Taw

10.7

10.8

10.9

12.6

12.7

12.8

14.2

14.3

14.4

15.4

15.6

15.7

16.0

16.2

16.4

Pf kW

2.86

3.41

4.00

2.21

2.60

3.11

1.71

2.00

2.36

1.34

1.52

1.73

1.10

1.23

1.37

Pfs kW

1.94

2.19

2.50

1.67

1.92

2.17

1.48

1.73

1.96

1.30

1.48

1.68

1.07

1.19

1.34

Tad

11.0

12.0

12.7

13.1

13.6

14.5

14.7

15.0

15.7

16.2

16.7

17.3

18.1

18.7

19.2

Taw

11.0

11.1

11.3

13.1

13.2

13.3

14.7

14.8

14.9

15.8

16.0

16.2

16.5

16.7

16.9

Pf kW

3.26

3.91

4.59

2.62

3.10

3.68

2.00

2.37

2.80

1.59

1.82

2.08

1.30

1.47

1.65

Pfs kW

2.09

2.41

2.71

1.84

2.10

2.38

1.60

1.87

2.11

1.45

1.63

1.86

1.24

1.40

1.57

Tad

11.7

12.5

13.5

13.8

14.5

15.3

15.6

16.0

16.8

16.9

17.6

18.2

18.6

19.2

19.8

Taw

11.7

11.8

12.0

13.8

13.9

14.0

15.6

15.7

15.8

16.8

17.0

17.2

17.6

17.8

18.0

DpwkPa

8.76

12.0

16.0

5.51

7.38

10.2

3.47

4.60

6.20

2.24

2.81

3.54

1.57

1.92

2.33

Qa[m3/h]

352

425

510

351

420

510

354

423

510

356

427

514

358

429

514

PCE-04

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

PCE-04

NOTES

TAI: Air in temperature Pf: Total cooling capacity

TWI: Fluid in temperature Pfs: Sensible cooling capacity

Qw: Fluid flow rate in heat exchanger tad: Discharge air dry bulb temperature

Dpw: Pressure drop standard coil Taw: Discharge air wet bulb temperature

Qa: Air flow

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

6

Qw1/h

816

974

1146

665

793

940

506

591

695

329

385

449

251

291

336

Pf kW

3.80

4.51

5.30

3.01

3.59

4.25

2.20

2.61

3.07

1.44

1.69

1.96

1.10

1.27

1.46

Pfs kW

2.62

2.97

3.36

2.3

2.64

2.98

2.03

2.3

2.61

1.41

1.65

1.9

1.07

1.23

1.43

Tad

10.4

11.2

12.0

12.0

12.7

13.4

13.5

14.2

14.8

16.9

17.2

17.5

18.8

19.1

19.3

Taw

9.7

9.8

10.0

11.5

11.6

11.7

13.3

13.4

13.5

14.9

15.0

15.1

15.6

15.7

15.8

Pf kW

4.20

5.02

5.96

3.41

4.06

4.83

2.59

3.06

3.55

1.70

2.00

2.33

1.25

1.45

1.67

Pfs kW

2.85

3.25

3.66

2.55

2.90

3.26

2.24

2.55

2.88

1.68

1.96

2.30

1.23

1.42

1.63

Tad

11.0

11.9

12.8

12.6

13.4

14.3

14.3

15.0

15.7

17.4

17.7

17.9

19.9

20.2

20.5

Taw

10.3

10.4

10.5

12.1

12.2

12.3

13.9

14.0

14.2

15.7

15.8

15.9

16.6

16.7

16.8

Pf kW

4.32

5.16

6.07

3.52

4.20

4.98

2.68

3.13

3.68

1.74

2.04

2.38

1.33

1.54

1.78

Pfs kW

2.78

3.15

3.58

2.47

2.84

3.17

2.16

2.46

2.77

1.69

2.00

2.33

1.30

1.50

1.73

Tad

11.4

12.3

13.1

13.0

13.7

14.6

14.7

15.4

16.1

17.3

17.5

17.8

19.5

19.8

20.1

Taw

10.7

10.8

11.0

12.5

12.6

12.7

14.3

14.5

14.6

16.2

16.3

16.4

17.0

17.1

17.2

Pf kW

5.00

5.93

7.05

4.10

4.88

5.80

3.18

3.72

4.40

2.15

2.54

2.98

1.73

2.02

2.35

Pfs kW

3.02

3.42

3.82

2.68

3.06

3.42

2.35

2.68

3.02

2.03

2.33

2.62

1.68

1.90

2.13

Tad

12.0

13.0

14.1

13.8

14.6

15.6

15.6

16.3

17.1

17.3

17.9

18.6

19.3

19.9

20.5

Taw

11.2

11.4

11.5

13.2

13.3

13.4

15.1

15.3

15.4

17.1

17.2

17.3

17.9

18.0

18.1

DpwkPa

10.79

14.83

19.88

7.46

10.25

13.92

4.56

6.04

8.08

2.10

2.79

3.68

1.29

1.69

2.18

Qa[m3/h]

516

624

750

516

624

750

516

626

751

517

625

752

518

624

752

PCE-08

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

PCE-08

Qw1/h

1100

1300

1550

906

1070

1265

695

827

972

493

585

672

429

506

576

Pf kW

5.13

6.16

7.41

4.12

4.92

5.80

3.02

3.68

4.37

2.07

2.45

2.86

1.75

2.05

2.38

Pfs kW

3.69

4.37

4.95

3.26

3.83

4.39

2.80

3.32

3.85

2.02

2.38

2.76

1.71

2.00

2.31

Tad

9.6

10.0

11.0

11.4

11.8

12.5

13.2

13.5

14.0

16.4

16.7

17.0

17.7

18.0

18.3

Taw

9.6

9.7

9.8

11.4

11.5

11.7

13.2

13.2

13.3

14.7

14.8

14.9

15.2

15.3

15.4

Pf kW

5.71

6.85

8.15

4.65

5.56

6.60

3.53

4.21

5.03

2.56

3.04

3.56

2.16

2.55

2.98

Pfs kW

4.03

4.77

5.47

3.58

4.15

4.81

3.12

3.73

4.26

2.52

2.98

3.48

2.11

2.54

2.92

Tad

10.2

10.6

11.5

12.0

12.6

13.3

13.8

14.0

14.8

16.3

16.6

16.9

18.0

18.1

18.5

Taw

10.2

10.3

10.5

12.0

12.1

12.3

13.8

13.9

14.0

15.3

15.4

15.5

15.9

16.0

16.1

Pf kW

5.80

6.90

8.20

4.80

5.67

6.70

3.68

4.38

5.15

2.61

3.10

3.56

2.27

2.68

3.05

Pfs kW

3.90

4.58

5.27

3.48

4.04

4.70

3.04

3.59

4.10

2.54

3.03

3.57

2.22

2.53

2.97

Tad

10.7

11.2

12.0

12.4

13.0

13.6

14.2

14.5

15.3

16.2

16.4

16.7

17.5

18.1

18.4

Taw

10.7

10.9

11.1

12.4

12.6

12.8

14.2

14.3

14.5

15.8

15.9

16.1

16.3

16.4

16.6

Pf kW

6.85

8.16

9.71

5.63

6.70

8.00

4.40

5.28

6.30

3.10

3.78

4.37

2.47

2.90

3.42

Pfs kW

4.31

5.01

5.68

3.80

4.47

5.05

3.32

3.96

4.51

2.85

3.45

3.89

2.38

2.82

3.30

Tad

11.0

11.7

12.8

13.0

13.5

14.5

14.9

15.2

16.0

16.8

16.9

17.7

18.8

19.0

19.4

Taw

11.0

11.2

11.4

13.0

13.2

13.3

14.9

15.0

15.1

16.8

16.8

17.0

17.7

17.8

17.9

DpwkPa

17.3

23.7

32.3

12.3

16.6

22.5

7.64

10.5

14.0

4.1

5.6

7.2

3.2

4.3

5.45

Qa[m3/h]

691

840

1022

694

841

1022

695

843

1029

694

846

1028

695

846

1027

PCE-09

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

PCE-09

NOTES

TAI: Air in temperature Pf: Total cooling capacity

TWI: Fluid in temperature Pfs: Sensible cooling capacity

Qw: Fluid flow rate in heat exchanger tad: Discharge air dry bulb temperature

Dpw: Pressure drop standard coil Taw: Discharge air wet bulb temperature

Qa: Air flow

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 7

Qw1/h

1227

1472

1755

1010

1223

1450

793

961

1148

527

631

746

425

504

569

Pf kW

5.80

6.97

8.28

4.64

5.61

6.74

3.48

4.20

5.01

2.19

2.60

3.06

1.52

1.78

2.06

Pfs kW

4.19

4.76

5.45

3.64

4.19

4.83

3.19

3.69

4.29

2.15

2.53

2.97

1.49

1.74

2.00

Tad

9.7

10.7

11.5

11.5

12.3

13.0

13.1

13.8

14.3

16.9

17.2

17.5

19.3

19.6

19.9

Taw

9.7

9.8

10.0

11.4

11.5

11.6

13.1

13.2

13.3

14.9

15.0

15.1

15.8

15.9

16.0

Pf kW

6.42

7.73

9.21

5.24

6.35

7.54

4.06

4.90

5.86

2.73

3.27

3.87

2.15

2.57

2.96

Pfs kW

4.54

5.20

5.96

4.03

4.64

5.34

3.55

4.13

4.70

2.67

3.18

3.80

2.10

2.45

2.91

Tad

10.2

11.3

12.2

12.0

12.9

13.7

13.7

14.4

15.2

16.9

17.2

17.4

19.1

19.4

19.6

Taw

10.2

10.4

10.6

12.0

12.1

12.3

13.7

13.8

13.9

15.5

15.6

15.7

16.3

16.4

16.5

Pf kW

6.50

7.80

9.30

5.35

6.48

7.68

4.20

5.09

6.08

2.79

3.34

3.95

2.25

2.67

3.01

Pfs kW

4.38

5.13

5.84

3.90

4.48

5.20

3.43

4.00

4.58

2.72

3.25

3.84

2.18

2.59

2.94

Tad

10.8

11.5

12.5

12.5

13.4

14.0

14.1

14.8

15.5

16.7

17.0

17.3

18.7

19.0

19.5

Taw

10.8

11.0

11.2

12.5

12.6

12.8

14.1

14.2

14.3

16.0

16.1

16.2

16.7

16.8

17.0

Pf kW

7.65

9.21

11.03

6.37

7.63

9.18

4.99

6.03

7.20

3.43

4.12

4.90

2.78

3.32

3.8

Pfs kW

4.74

5.44

6.18

4.26

4.86

5.59

3.76

4.35

4.95

3.20

3.73

4.30

2.73

3.16

3.57

Tad

11.4

12.5

13.6

13.3

14.2

15.0

14.9

15.7

16.5

16.9

17.5

18.1

18.6

19.2

19.9

Taw

11.1

11.3

11.5

13.1

13.2

13.3

14.9

15.0

15.1

16.9

17.0

17.1

17.7

17.8

18.0

DpwkPa

21.3

29.5

40.5

15.0

21.2

24.9

9.7

13.7

18.9

4.64

6.4

8.7

3.2

4.3

5.3

Qa[m3/h]

783

961

1172

783

963

1172

781

963

1173

783

964

1174

784

964

1173

PCE-10

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

PCE-10

Qw1/h

1365

1610

1912

1089

1280

1510

814

952

1108

593

685

784

487

561

631

Pf kW

6.29

7.41

8.90

4.96

5.82

6.84

3.56

4.15

4.91

2.52

2.90

3.27

1.90

2.16

2.38

Pfs kW

4.47

5.05

5.72

3.93

4.42

5.04

3.47

3.91

4.41

2.46

2.81

3.19

1.84

2.16

2.32

Tad

11.1

11.8

12.7

12.7

13.4

14.1

14.1

14.7

15.4

17.2

17.5

18.0

19.1

19.3

19.9

Taw

10.4

10.5

10.6

12.1

12.2

12.4

13.8

13.9

14.0

15.0

15.1

15.3

15.7

15.8

16.0

Pf kW

7.03

8.30

9.95

5.60

6.55

7.73

4.15

4.83

5.62

3.08

3.56

4.08

2.53

2.91

3.27

Pfs kW

4.84

5.51

6.25

4.31

4.93

5.52

3.87

4.33

4.9

3.02

3.48

3.92

2.47

2.83

3.21

Tad

11.9

12.6

13.5

13.5

14.0

15.0

14.8

15.5

16.3

17.4

17.7

18.4

19.1

19.4

19.9

Taw

11.0

11.1

11.2

12.8

12.9

13.1

14.5

14.6

14.8

15.7

15.8

16.0

16.3

16.4

16.6

Pf kW

7.23

8.53

10.13

5.77

6.78

8.00

4.31

5.04

5.87

3.14

3.63

4.15

2.58

2.97

3.34

Pfs kW

4.70

5.33

6.05

4.20

4.73

5.38

3.70

4.19

4.76

3.05

3.56

4.05

2.50

2.91

3.26

Tad

12.3

13.0

13.9

13.8

14.5

15.3

15.3

15.9

16.6

17.3

17.5

18.1

19.0

19.2

19.8

Taw

11.4

11.5

11.7

13.2

13.3

13.5

14.9

15.0

15.2

16.2

16.3

16.5

16.8

16.9

17.1

Pf kW

8.30

9.78

11.65

6.70

7.90

9.45

5.11

5.98

7.00

3.70

4.30

4.95

3.12

3.60

4.10

Pfs kW

5.04

5.77

6.54

4.53

5.14

5.86

4.01

4.51

5.15

3.51

3.96

4.54

2.90

3.23

3.70

Tad

13.2

13.8

14.8

14.7

15.4

16.2

16.3

17.0

17.7

17.8

18.4

19.0

19.7

20.3

20.8

Taw

12.1

12.2

12.4

14.0

14.1

14.2

15.8

15.9

16.1

17.3

17.4

17.6

17.9

18.0

18.2

DpwkPa

10.30

13.90

18.90

6.90

9.20

12.40

4.10

5.40

7.10

2.30

2.99

3.80

1.60

2.10

2.60

Qa[m3/h]

930

1111

1352

931

1111

1353

932

1112

1354

933

1112

1354

932

1113

1354

PCE-12

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

PCE-12

NOTES

TAI: Air in temperature Pf: Total cooling capacity

TWI: Fluid in temperature Pfs: Sensible cooling capacity

Qw: Fluid flow rate in heat exchanger tad: Discharge air dry bulb temperature

Dpw: Pressure drop standard coil Taw: Discharge air wet bulb temperature

Qa: Air flow

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

8

Qw1/h

1544

1831

2128

1231

1456

1707

900

1057

1231

633

733

818

553

638

702

Pf kW

7.10

8.40

9.76

5.61

6.61

7.73

4.02

4.70

5.46

2.45

2.82

3.22

2.05

2.34

2.64

Pfs kW

5.19

5.90

6.67

4.63

5.24

5.91

3.92

4.60

5.17

2.37

2.76

3.14

2.01

2.29

2.57

Tad

10.7

11.4

12.1

12.2

12.9

13.5

14.1

14.3

14.9

18.3

18.5

18.8

19.3

19.6

19.9

Taw

10.4

10.5

10.7

12.1

12.2

12.3

13.8

13.9

14.0

15.4

15.5

15.6

15.8

15.9

16.0

Pf kW

7.94

9.41

10.93

6.31

7.40

8.75

4.58

5.38

6.25

3.17

3.68

4.23

2.76

3.19

3.65

Pfs kW

5.72

6.46

7.21

5.04

5.78

6.47

4.44

5.07

5.70

3.08

3.61

4.14

2.69

3.09

3.58

Tad

11.2

12.1

13.0

13.0

13.5

14.4

14.6

15.2

15.8

18.3

18.5

18.8

19.4

19.7

19.9

Taw

11.0

11.1

11.3

12.8

12.9

13.0

14.6

14.7

14.8

16.0

16.1

16.2

16.4

16.5

16.6

Pf kW

8.18

9.70

11.27

6.52

7.71

9.04

4.77

5.60

6.52

3.35

3.88

4.33

2.93

3.38

3.72

Pfs kW

5.57

6.28

7.05

4.92

5.60

6.30

4.29

4.93

5.50

3.27

3.78

4.20

2.84

3.31

3.63

Tad

11.6

12.5

13.3

13.3

14.0

14.7

15.0

15.5

16.2

17.8

18.1

18.7

19.0

19.2

19.8

Taw

11.4

11.5

11.7

13.2

13.3

13.4

15.0

15.1

15.2

16.4

16.5

16.7

16.8

16.9

17.1

Pf kW

9.35

11.09

12.93

7.55

8.94

10.5

5.65

6.65

7.78

3.86

4.50

5.20

3.30

3.82

4.23

Pfs kW

5.61

6.32

7.00

4.93

5.60

6.31

4.37

4.89

5.57

3.83

4.40

4.90

3.20

3.71

4.10

Tad

13.4

14.3

15.3

15.2

15.9

16.6

16.7

17.5

18.0

18.2

18.7

19.3

19.9

20.2

20.8

Taw

12.1

12.2

12.4

14.0

14.1

14.2

15.9

16.0

16.1

17.6

17.7

17.8

18.1

18.2

18.4

DpwkPa

12.9

17.5

23.0

8.6

11.6

15.4

4.9

6.5

8.6

2.6

3.37

4.1

2.03

2.63

3.1

Qa[m3/h]

1050

1262

1502

1051

1262

1504

1052

1262

1503

1058

1265

1510

1059

1267

1508

PCE-16

Twi

5

7

9

11

13

TAI DB25-WB17.8 TAI DB27-WB19 TAI DB27-WB19.5 TAI DB29-WB21.1

PCE-16

NOTES

TAI: Air in temperature Pf: Total cooling capacity

TWI: Fluid in temperature Pfs: Sensible cooling capacity

Qw: Fluid flow rate in heat exchanger tad: Discharge air dry bulb temperature

Dpw: Pressure drop standard coil Taw: Discharge air wet bulb temperature

Qa: Air flow

Design and specification are subject to change without prior notice for product improvement

Qw 1/h

105

122

133

183

211

236

267

314

346

351

413

449

Pf kW

1.46

1.72

1.87

2.51

2.96

3.26

3.58

4.24

4.66

4.65

5.51

6.00

Tad

32.0

31.4

30.6

42.0

41.0

40.0

52.1

51.0

49.5

62.3

61.0

58.5

Pf kW

1.35

1.56

1.71

2.35

2.71

3.03

3.42

4.03

4.44

4.50

5.31

5.76

Tad

32.9

32.2

31.5

42.5

41.2

40.4

52.6

51.5

50.0

62.7

61.6

58.8

Pf kW

1.20

1.40

1.53

2.23

2.58

2.85

3.28

3.81

4.26

4.31

5.10

5.59

Tad

33.5

33.0

32.3

43.3

42.2

41.2

53.4

51.7

50.8

63.4

61.5

59.7

Pf kW

1.06

1.24

1.37

2.07

2.40

2.67

3.11

3.64

4.05

4.15

4.88

5.35

Tad

34.2

33.7

33.2

43.8

42.7

42.0

53.9

52.3

51.3

63.9

62.0

60.2

DpwkPa

0.410

0.530

0.627

1.110

1.440

1.760

2.180

2.930

3.500

3.580

4.800

5.580

Qa[m3/h]

323

395

459

323

395

459

324

395

458

326

394

458

PCE-03

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

Heating

PCE-03

NOTES

TAI: Air in temperature Pf: Total cooling capacity

TWI: Fluid in temperature tad: Discharge air dry bulb temperature

Qw: Fluid flow rate in heat exchanger

Dpw: Pressure drop standard coil

Qa: Air flow

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 9

Qw 1/h

109.0

128.0

145.0

195.0

221.3

256.5

286.0

328.0

376.0

366.0

425.0

482.0

Pf kW

1.55

1.78

2.03

2.69

3.07

3.50

3.85

4.41

5.06

4.91

5.71

6.54

Tad

31.5

30.9

30.3

41.4

40.3

39.1

51.6

50.0

48.5

60.9

59.5

57.5

Pf kW

1.40

1.64

1.86

2.50

2.84

3.29

3.67

4.20

4.82

4.70

5.45

6.18

Tad

32.2

31.9

31.2

41.8

40.7

39.8

52.0

50.5

49.0

61.0

59.7

57.2

Pf kW

1.28

1.46

1.64

2.36

2.68

3.03

3.50

3.98

4.53

4.54

5.29

5.93

Tad

33.1

32.6

31.9

42.4

41.5

40.3

52.4

50.9

49.3

61.6

60.3

57.8

Pf kW

1.14

1.31

1.46

2.20

2.52

2.84

3.32

3.80

4.31

4.42

5.11

5.75

Tad

34.0

33.5

32.8

43.2

42.3

41.1

53.1

51.6

50.1

62.4

61.1

58.6

DpwkPa

0.44

0.58

0.73

1.24

1.56

2.04

2.50

3.16

4.05

3.97

5.05

6.34

Qa[m3/h]

355.0

425.0

513.0

354.0

424.0

513.5

354.0

425.0

513.6

354.0

424.0

513.4

PCE-04

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-04

Qw 1/h

140

161

184

252

291

334

366

425

486

483

556

640

Pf kW

1.97

2.27

2.60

3.46

3.98

4.57

4.94

5.71

6.54

6.43

7.40

8.54

Tad

31.2

30.5

29.7

41.0

39.9

38.7

50.9

49.2

47.6

60.7

58.6

56.4

Pf kW

1.79

2.06

2.36

3.24

3.73

4.29

4.70

5.45

6.24

6.20

7.13

8.21

Tad

31.9

31.3

30.7

41.6

40.5

39.4

51.4

49.6

48.2

61.0

59.0

57.0

Pf kW

1.620

1.855

2.126

3.020

3.490

3.970

4.460

5.155

5.930

5.930

6.840

7.900

Tad

32.7

32.2

31.6

42.2

41.1

40.4

51.8

50.3

48.8

61.5

59.6

57.5

Pf kW

1.435

1.650

1.890

2.810

3.230

3.680

4.230

4.890

5.630

5.680

6.570

7.560

Tad

33.6

33.1

32.5

42.7

41.8

41.1

52.2

50.8

49.3

61.9

59.9

58.1

DpwkPa

0.386

0.497

0.634

1.120

1.450

1.860

2.190

2.860

3.650

3.610

4.600

6.000

Qa[m3/h]

465

563

682

464

562

683

463

568

684

467

565

686

PCE-06

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-06

Qw 1/h

159

183

216

288

331

391

417

481

570

546

635

753

Pf kW

2.24

2.58

3.05

3.93

4.54

5.37

5.62

6.49

7.70

7.31

8.45

10.05

Tad

31.6

30.9

30.5

41.8

40.5

40.1

52.0

50.3

49.6

62.1

60.1

59.1

Pf kW

2.04

2.35

2.77

3.69

4.25

5.02

5.35

6.18

7.32

7.01

8.15

9.66

Tad

32.3

31.7

31.4

42.3

41.1

40.6

52.2

50.7

50.0

62.3

60.3

59.5

Pf kW

1.84

2.11

2.49

3.44

3.97

4.70

5.09

5.88

6.97

6.75

7.81

9.28

Tad

33.1

32.5

32.3

42.8

41.8

41.3

52.7

51.2

50.6

62.8

60.9

60.1

Pf kW

1.63

1.88

2.22

3.19

3.69

4.36

4.82

5.57

6.6

6.47

7.48

8.89

Tad

33.9

33.4

33.1

43.3

42.3

41.9

53.1

51.7

51.1

63.1

61.3

60.5

DpwkPa

0.488

0.630

0.847

1.420

1.830

2.470

2.770

3.590

4.870

4.510

5.910

8.020

Qa[m3/h]

513

621

751

511

622

753

513

622

754

512

625

756

PCE-08

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-08

NOTES

TAI: Air in temperature Qw: Fluid flow rate in heat exchanger Qa: Air flow Pf: Total cooling capacity

TWI: Fluid in temperature Dpw: Pressure drop standard coil tad: Discharge air dry bulb temperature

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

10

Qw 1/h

232

270

312

409

475

549

591

686

790

768

895

1028

Pf kW

3.29

3.82

4.39

5.60

6.52

7.53

7.95

9.20

10.62

10.30

11.95

13.79

Tad

32.7

32.0

31.3

43.0

41.9

40.8

53.4

51.8

50.1

63.9

61.9

59.7

Pf kW

2.98

3.46

4.00

5.25

6.10

7.05

7.59

8.80

10.14

9.85

11.48

13.20

Tad

33.3

32.7

32.1

43.5

42.4

41.3

53.9

52.3

50.6

64.0

62.0

59.9

Pf kW

2.69

3.11

3.57

4.92

5.71

6.59

7.21

8.35

9.59

9.51

11.03

12.73

Tad

34.0

33.4

32.8

44.0

43.0

41.9

54.2

52.7

51.0

64.5

62.5

60.5

Pf kW

2.39

2.77

3.17

4.57

5.30

6.12

6.82

7.92

9.12

9.10

10.57

12.20

Tad

34.7

34.2

33.6

44.4

43.5

42.5

54.5

53.1

51.5

64.7

62.8

60.9

DpwkPa

0.914

1.200

1.550

2.530

3.320

4.310

4.920

6.420

8.300

7.870

10.400

13.300

Qa[m3/h]

692

842

1022

690

841

1023

692

842

1024

692

845

1022

PCE-09

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-09

Qw 1/h

256

298

343

452

526

608

650

757

875

848

988

1142

Pf kW

3.62

4.21

4.84

6.19

7.21

8.32

8.75

10.21

11.78

11.32

13.18

15.26

Tad

32.3

31.5

30.78

42.4

41.2

39.9

52.6

50.8

49.1

62.7

60.4

58.2

Pf kW

3.29

3.83

44.00

5.80

6.75

7.80

8.34

9.72

11.23

10.98

12.68

14.66

Tad

33.0

32.3

31.6

42.9

41.7

40.6

53.0

51.2

49.6

63.0

60.8

58.7

Pf kW

2.96

3.45

3.97

5.41

6.31

7.28

7.92

9.23

10.67

10.44

12.18

14.07

Tad

33.7

33.1

32.5

43.4

42.3

41.2

53.3

51.7

50.1

63.3

61.2

59.1

Pf kW

2.63

3.06

3.53

5.03

5.87

6.76

7.50

8.74

10.10

10.00

11.67

13.47

Tad

34.4

33.8

33.3

43.9

42.7

41.8

53.7

52.1

50.6

63.6

61.5

59.6

DpwkPa

1.09

1.44

1.84

3.03

3.98

5.17

5.83

7.68

9.96

9.41

12.30

16.10

Qa[m3/h]

782

962

1172

783

962

1170

781

963

1172

782

960

1171

PCE-10

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-10

NOTES

TAI: Air in temperature Qw: Fluid flow rate in heat exchanger Qa: Air flow Pf: Total cooling capacity

TWI: Fluid in temperature Dpw: Pressure drop standard coil tad: Discharge air dry bulb temperature

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 11

Qw 1/h

275

310

358

496

562

648

717

815

943

943

1064

1239

Pf kW

3.87

4.39

5.04

6.77

7.70

8.86

9.68

10.96

12.70

12.60

14.28

16.50

Tad

30.8

30.3

29.5

40.4

39.5

38.2

50.0

48.7

47.0

59.7

57.9

55.7

Pf kW

3.53

3.98

4.59

6.37

7.21

8.32

9.20

10.46

12.10

12.10

13.65

15.90

Tad

31.7

31.1

30.5

41.1

40.2

39.0

50.5

49.3

47.6

60.0

58.2

56.3

Pf kW

3.18

3.57

4.12

5.94

6.72

7.76

8.75

9.92

11.48

11.63

13.10

15.25

Tad

32.5

32.0

31.4

41.6

40.8

39.7

51.0

49.8

48.2

60.5

58.7

56.8

Pf kW

2.81

3.18

3.67

5.52

6.25

7.19

8.32

9.42

10.88

11.15

12.60

14.62

Tad

33.3

32.9

32.4

42.3

41.5

40.4

51.5

50.4

48.8

61.0

59.3

57.4

DpwkPa

0.497

0.620

0.800

1.440

1.800

2.330

2.790

3.510

4.570

4.570

5.670

7.450

Qa[m3/h]

932

1108

1351

933

1103

1353

932

1103

1354

935

1104

1354

PCE-12

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-12

Qw 1/h

300

341

383

542

616

694

786

898

1013

1029

1172

1332

Pf kW

4.23

4.82

5.40

7.42

8.41

9.53

10.59

12.06

13.61

13.74

15.70

17.70

Tad

30.4

29.8

29.1

39.8

38.6

37.6

49.1

47.5

46.0

58.3

56.4

54.4

Pf kW

3.85

4.38

4.91

6.95

7.90

8.90

10.08

11.52

13.00

13.2

15.04

17.10

Tad

31.3

30.7

30.1

40.4

39.3

38.3

49.6

48.2

46.7

58.8

56.8

55.1

Pf kW

3.47

3.92

4.43

6.48

7.35

8.32

9.57

10.94

12.35

12.72

14.48

16.40

Tad

32.2

31.6

31.1

41.0

40.0

39.1

50.1

48.8

47.4

59.4

57.4

55.7

Pf kW

3.07

3.51

3.94

6.03

6.85

7.73

9.08

10.36

11.71

12.18

13.90

15.70

Tad

33.0

32.6

32.1

41.7

40.8

39.9

50.6

49.4

48.1

59.8

58.0

56.3

DpwkPa

0.58

0.73

0.90

1.68

2.12

2.63

3.29

4.18

5.19

5.34

6.75

8.51

Qa[m3/h]

1053

1265

1502

1053

1265

1503

1052

1262

1505

1051

1263

1505

PCE-16

Twi

40

50

60

70

TAI 18 TAI 20 TAI 22 TAI 24

PCE-16

NOTES

TAI: Air in temperature Qw: Fluid flow rate in heat exchanger Qa: Air flow Pf: Total cooling capacity

TWI: Fluid in temperature Dpw: Pressure drop standard coil tad: Discharge air dry bulb temperature

Design and specification are subject to change without prior notice for product improvement

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

12

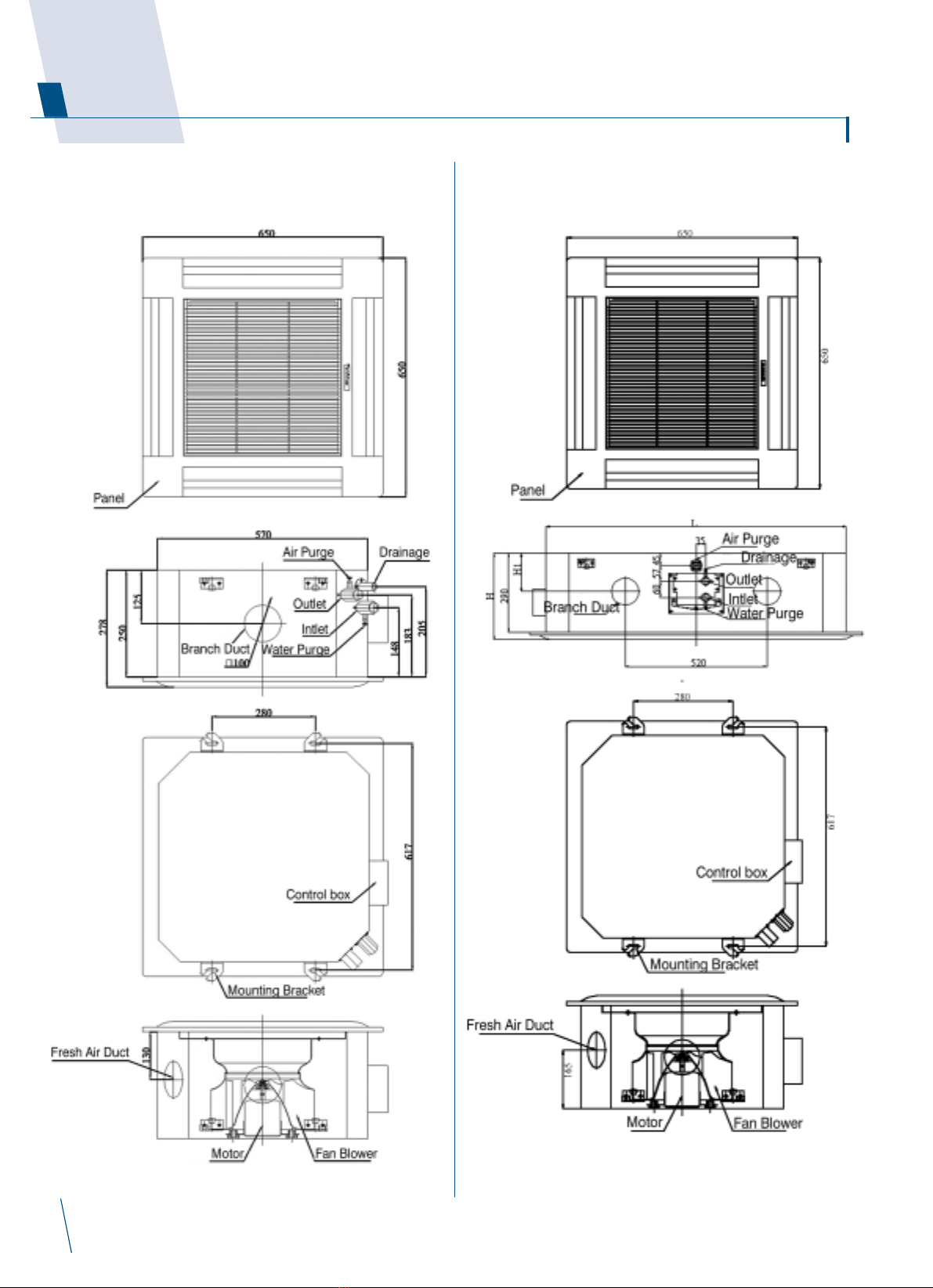

Outlook drawings3.

PCE-03/04-VS PCE-06/08-VS

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 13

PCE-09/10/12/16-VS

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

14

Wiring Diagrams4.

Control and power supply wiring diagram PCE-03/04/06/08

NOTES

Wirring diagrams on unit take precidents.

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 15

Control and power supply wiring diagram PCE-09/10/12/16

NOTES

Wirring diagrams on unit take precidents.

aster - Slave control wiring diagram

Factory supplied accessories

Check to ensure all factory supplied accessories are supplied with

the unit.

The appliance should be installed in accordance with

national wiring regulation.

Safety considerations

ñ When working on air conditioning equipment observe

precautions in this manual and on plates and tables attached

to the unit. Follow all safety codes and other safety

precautions that may apply.

ñ Installing and servicing air conditioning equipment should be

done by trained and qualified service personnel only.

Untrained personnel can perform only basic maintenance

functions such as cleaning coils filters and replacing filters.

ñ Ensure that the electrical supply and frequency are adequate

for the operating current required for this specific installation.

Warning

Before any service or maintenance operations turn off the main

power switch.

ñ The manufacturer denies any responsibility and warranty shall

be void if these installation instructions are not observed.

ñ Never switch off the power main supply when unit is operating

in the cooling cycle.

To switch off the fan coil unit use only the ON-OFF button.

ñ This avoids over-flow in the drain pan by allowing the pump

to drain any condensate water due to regulating valve losses

when chiller is working.

Operation limits

ñ Power supply

ñ Water circuit

- Minimum entering water temperature: +2ÆC

- Maximum entering water temperature: +80ÆC

- Water side maximum pressure: 1400 kPa (142 m.w.c)

Before installation

The installation site must be established by the system designer

or other qualified professional taking account of the technical

requisites and current standards and legislation.

PCE fan coils must be installed by an authorized company only.

PCE fan coils are designed for installation in a false ceiling for

intake of fresh air from outside and for deviation of a small part of

the treated air for discharge in a neighboring room.

They must be installed in such a way as to enable treated air to

circulate throughout the room and in respect of the minimum

distances required for technical maintenance operations.

ñ It is advisable to place the unit close to the installation site

without removing it from the packaging.

Do not put heavy tools or weights on the packaging.

ñ Upon receipt the unit and the packaging must be checked for

damage sustained in transit and if necessary a damage claim

must be filed with the shipping company.

ñ Check immediately for installation accessories inside the

packaging.

ñ Do not lift unit by the condensate drain discharge pipe or by

the water connections; lift it by the four corners.(Fig.1)

ñ Check and note the unit serial number.

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

16

Installation5.

FACTORY SUPPLIED ACCESSORIES AMOUNT

LCD Remote control 1

Mounting Bracket (Already on the unit) 1

Installation manual 1

Batteries 2

External drain pan 1

Volt P ase Hz

230 1 50

fig.1

fig.2

Cover A

Selection location

ñ Do not install the unit in rooms where flammable gas or

alkaline acid substances are present.

Aluminum/copper coils and/or internal plastic components

can be damaged irreparably.

ñ Do not install in workshops or kitchens; oil vapors drawn in by

treated air might deposit on the coils and alter their

performance or damage the internal plastic parts of the unit.

ñ Installation of the unit will be facilitated by using a stacker and

inserting a plywood sheet between the unit and the elevated

stacker.(Fig.2)

ñ It is recommended to position the unit as centrally as possible

in the room to ensure optimum air distribution. (Fig.3)

Generally the best louver position is the one which allows air

diffusion along the ceiling.

Alternatively intermediate positions can be selected.

ñ Check that it is possible to remove panels from ceiling in the

selected position to allow enough clearance for maintenance

and servicing operations.

Installation location

Install the unit in a position:

ñ Having sufficient strength to carry the weight of the unit.

ñ Where the inlet and outlet grilles are not obstructed and the

conditioned air is able to blow all over the room.

ñ From where condensate can be easily run to drain.

ñ Check the distance between the upper slab and false ceiling to

ensure the unit will suit the distance. See Fig.4

ñ Ensure there is sufficient space around the unit to service it.

See Fig.5

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 17

Model A (mm.) B (mm.)

PCE-03/04 250 10 or more

PCE-06/08/09/10/12/16 290 10 or more

fig.3

fig.5

Fig.4

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

18

Installation met od

Cassette Unit

ñ Using the installation template open ceiling panels and install

the suspension bolts as in Fig.6 below

590 x 590: Dimensions for opening

616 x 280: Suspension Bolts

MODELS PCE-03/04/06/08

590 x 1120: Dimensions for opening

517.5 x 1047.5: Suspension Bolts

MODELS PCE-09/10/12/16

Opening Dimensions and Positions for Suspension Bolts

ñ Mark position of suspension rods water lines and

condensate drain pipe power supply cables and remote

control cable.

Supporting rods can be fixed depending on the type of

ceiling as shown in Fig. 7 and Fig.8.

ñ Fit suspension brackets supplied with the unit to the threaded

rods (Fig.9).

Do not tighten nuts and counter nuts; this operation has to

be done only after final leveling of the unit when all the

connections have been completed.

Fig. 6

Fig. 7

Fig.9

Fig. 8

ñ Ensure the ceiling is horizontally level otherwise condensate

water cannot drain.

ñ The casing is fixed to the slab with 4 drop rods. The rods

should have two nuts and washers to lock the unit in position.

The Cassette brackets will then hook over the washers.

ñ When lifting the Cassette into position care should be taken

not to lift the unit by the drip tray which could be damaged.

ñ Lift unit (without the air panel) with care by its four corners

only. Do not lift unit by the condensate drain discharge pipe

or by the piping connections.

ñ Incline unit (Fig.10 Fig.11 Fig.13 Fig.14) and insert it into

the false ceiling. Insert the rods into the bracket slot.

With minimum height (see table) false ceilings it might be

necessary to remove some T brackets of the false ceiling

temporarily.

ñ Using a level guide line up the unit with a spirit level and

keep dimension between the body and the lower part of the

false ceiling (Fig.12 Fig.15).

ñ Line up the unit to the supporting bars of the false ceiling

tightening the nuts and counter nuts of the threaded rods.

ñ After connection of the condensate drain piping and piping

connections check again that the unit is level.

Interklima Terminal nits

PCE -VS ñ Hydronic cassette 19

Fig. 10

Fig.12

Fig. 11

Fig. 13

Fig.15

Fig. 14

MODEL PCE/03/04/06/08

A (mm.) 3

MODEL PCE/09/10/12/16

A (mm.) 3

Interklima Terminal nits

PCE -VS ñ Hydronic cassette

20

ñ The spaces between the unit and ceiling can now be adjusted.

Use the drop rods to make the adjustment.

ñ Check to ensure the unit is level. The drain will then

automatically be lower than the rest of the drip tray.

ñ Tighten the nuts on the suspended rods.

Drain pipe work

Indoor Unit

ñ The unit is fitted with a condensate pump with a 500 mm. lift.

ñ The unit is provided with 22 mm. bore flexible hose 300 mm.

long.

ñ The flexible hose should be fitted into a 22 mm O/S º.

polyvinyl tube and sealed. The drain must be installed with a

downward slope.

ñ On completion the drain line should be insulated

Water connections

ñ Water connections are fixed to the unit body to avoid breaks

when pipes are connected to valve assemblies; it is advisable

to tighten the connection with a spanner.

ñ The upper coil connection is supplied with air purge screw the

lower connection with water purge screw suitable for 8mm.

wrench or screw-driver.

ñ Coil is partially drainable; it is advisable to blow air into the coil

for complete drainage.

Pipe connection kit (Option)

Pipe connection dimensional drawings

PCE-03/04-VS

PCE-06/08-VS

PCE-09/10/12/16-VS

Fig.16

This manual suits for next models

15

Table of contents

Popular Heat Pump manuals by other brands

ACD

ACD CHD09KCH19S owner's manual

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions

Daikin

Daikin SkyAir RZQ200 250C7Y1B Service manual

Airwell

Airwell CW-AR Installation and maintenance manual

Toshiba

Toshiba ESTIA HWS-802XWHM3-E engineering data

Daikin

Daikin Altherma EBLQ05CAV3 User reference guide

Thermocold

Thermocold MEX VS 15 RH Technical bulletin

Fujitsu

Fujitsu AOYA18LALL Installation and operating manual

Fujitsu

Fujitsu WATERSTAGE WS A050DD6 Series Maintenance Document

Geostar

Geostar Aston Compact Series installation manual

Viessmann

Viessmann VITOCAL 200-G Installation and service instructions for contractors

AXEN

AXEN AXSPS-90 Operation and installation manual