USA Ed. 0215

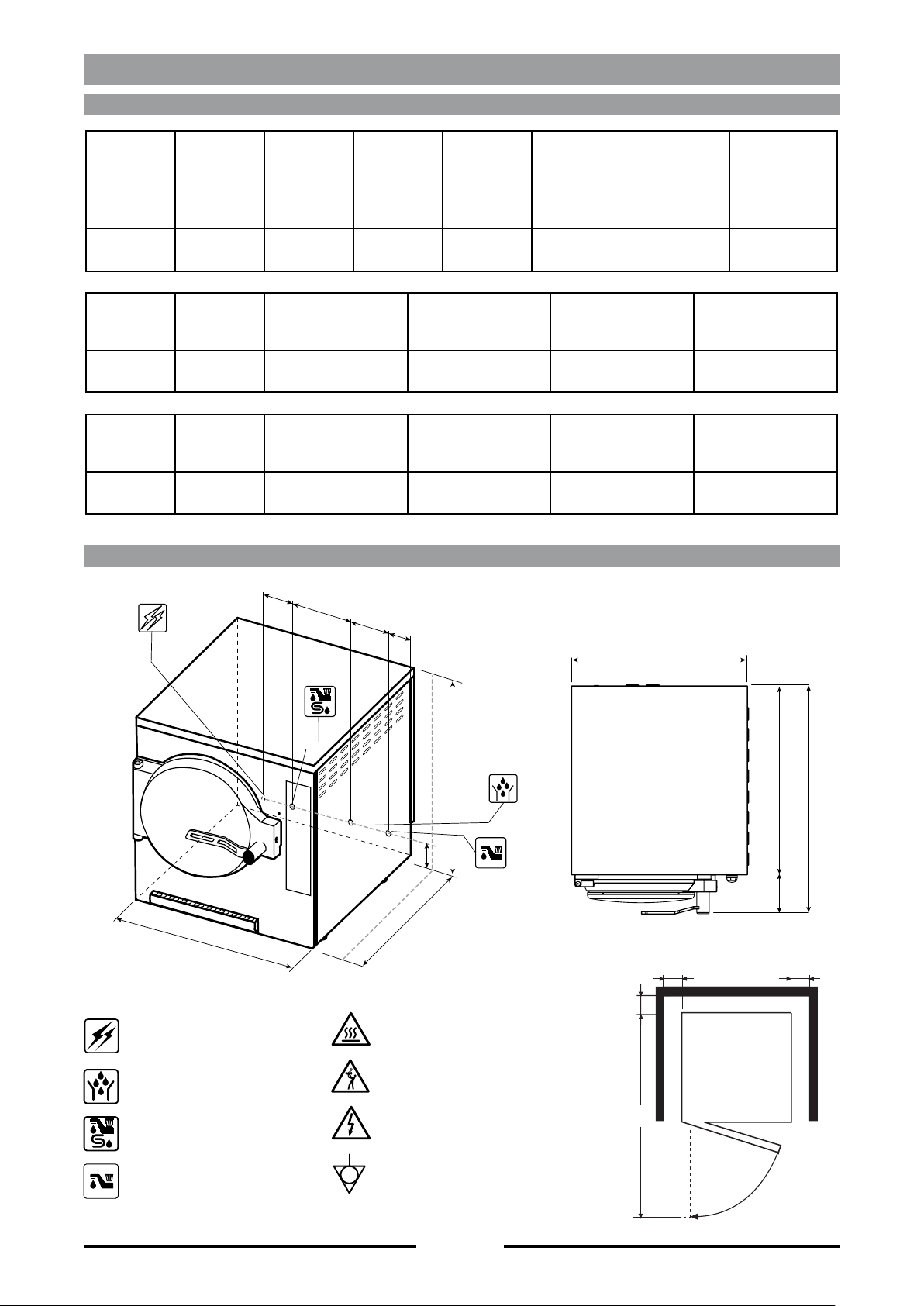

2 • INSTALLATION INSTRUCTIONS INSTALLATION

Water connection

At the back of the machine, there are 2 inputs for hydraulic connection with ¾ male thread. They are indi-

connection pipes that have already been used.

Softened water input

WATER HARDNESS PARAMETER CONVERSION TABLE

1 °fH (°tH) °dH °eH (Clark°) ppm (mg/lt) gr/gal (US)

1 °fH (°tH) 10,56 0,7 10 0,6

1 °dH 1,79 11,25 17,9 1,07

1 °eH (Clark°) 1,43 0,8 114,28 0,86

1 ppm (mg/lt) 0,1 0,06 0,07 10,06

1 gr/gal (US) 1,71 0,96 1,2 17,15 1

Mains water input

Used for the cooling of the oven discharge.

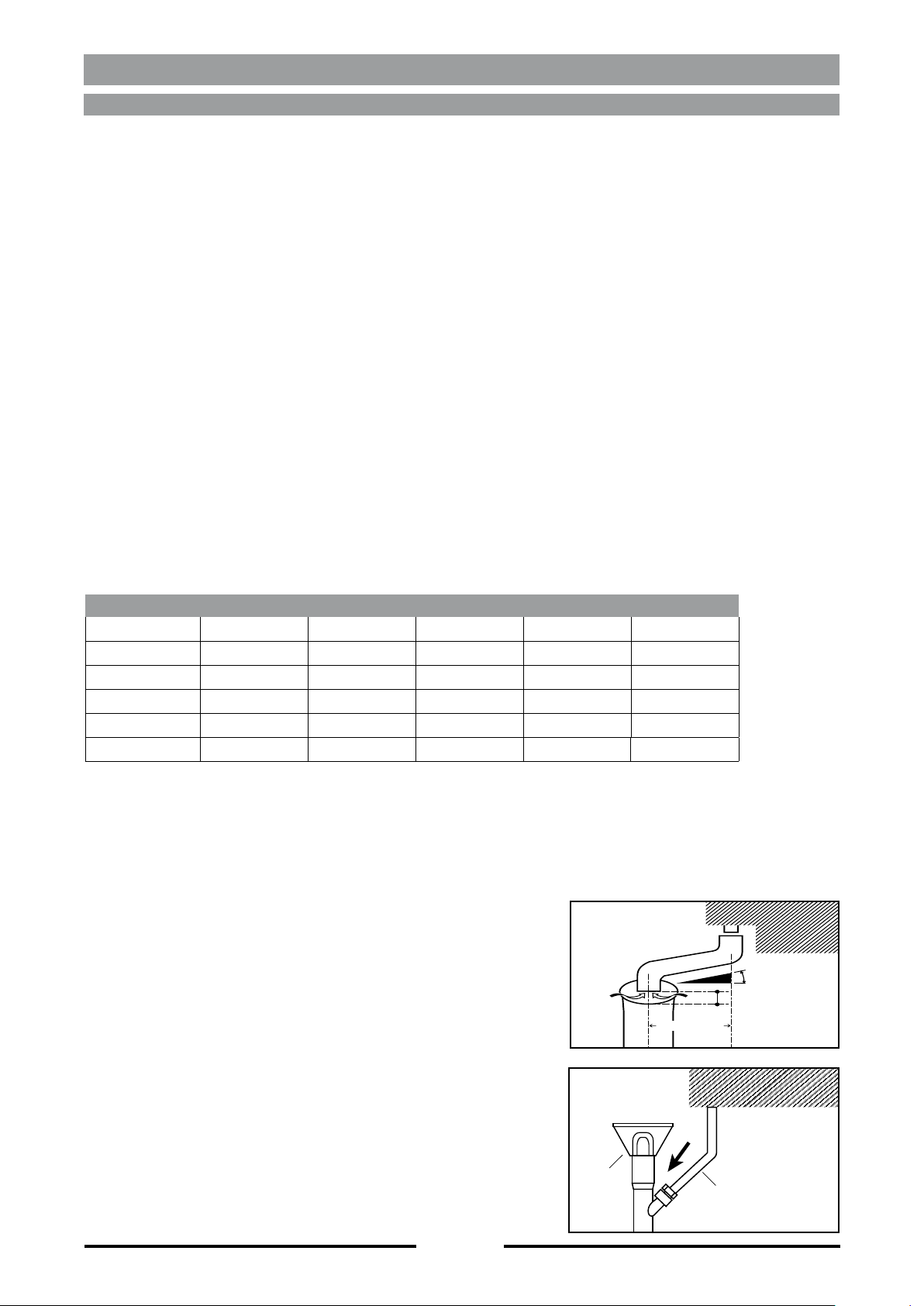

Discharge

channelled into a continuous system, while a gap of at least 25mm

WARNING! – The drain line, as shown in the drawing,

2.4 - INSTRUCTIONS FOR WATER CONNECTION (IF AVAILABLE)

Hose

Vent

opening