2

OPERATION - PRIMING THE PUMP

WARNING: DO NOT RUN THE PUMP BEFORE PRIMING IT, SINCE THE SEAL AND IMPELLER COULD BE

PERMANENTLYDAMAGED.

MAINTENANCE

a) PRIMING: Never operate the pump dry as this may

damage the seal. To prime, remove the priming plug and

fill the pump casing with water. Replace the priming plug

and start the unit. If an exceptionally long suction line is

used, the water in the pump casing may become

overheated or vapor locked. Should this occur, replace

the water in the pump casing with cold water and

continue priming.

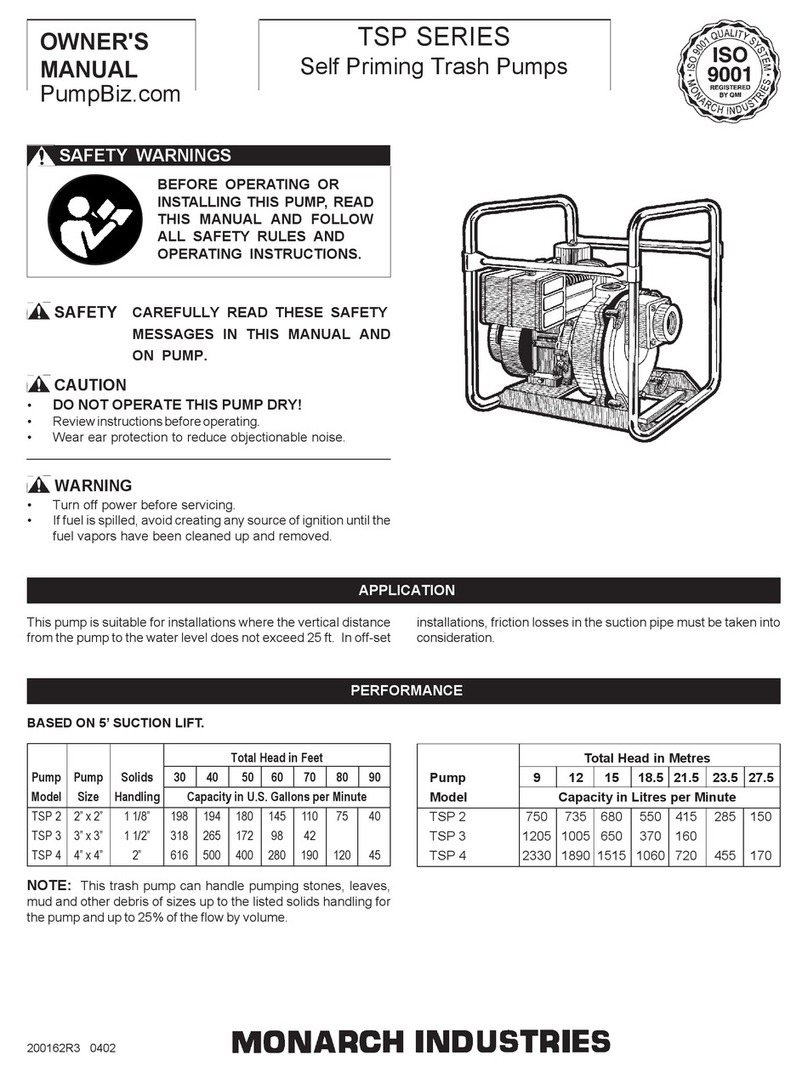

b) PRIMING UNDER PRESSURE: Should it be necessary

to prime under pressure, place a check valve on the

discharge of the pump and a pet cock ball type ‘air

bleeder' in place of the priming plug, or an air bleed line

with a gate valve connected to the discharge line (see

Fig. 1). It will then be possible for the liquid to remain in

the discharge pipe and allow the pump to draw the air

bleeder thereby priming itself. In cases where the pump

has to be reprimed often and it is not necessary that a

lot of water is delivered, e.g. draining seepage from

behind a cofferdam, then it is advisable to use a 90° or

45° elbow on the suction line. This enables the pump to

prime quickly and prevents kinking or breaks in the hose.

In cases where a maximum volume of water is required

over a prolonged period of time, the suction line should

be led horizontally to the pump.

c) DRAINING: During freezing temperatures, the pump

should be drained each time it is stopped for any

appreciable length of time. To drain, remove the drain

plug at the bottom of the pump casing and make sure

that the drain hole is not plugged. After all the water has

been drained from the pump casing, the unit should be

operated for a few seconds so that all of the water will be

removed from the impeller.

NOTE: The pump should also be drained after corrosive

liquids have been pumped.

A clogged impeller results in excessive vibration. Should this

occur, the impeller must be cleaned out immediately to avoid

serious damage to the unit.

The MIT20M, MIT20H and MIT40 feature an inspection plug

in the front of the casing for visual inspection at the impeller

eye.

LUBRICATION: Lubricate the bearings with a proper ball

bearing through the grease nipples provided. Do not over

lubricate. Ball bearings require a surprisingly small amount

of grease. Over lubrication causes the bearing to break down

because the grease then tends to churn and produce heat.

If this temperature goes above 200°F, it will break down

causing the bearing to fail.

Gate Valve (min. 3/4")

Check Valve Gate Valve

Discharge

Pump

Air Bleed Line

Suction Pipe

Strainer

FIG. 1