2

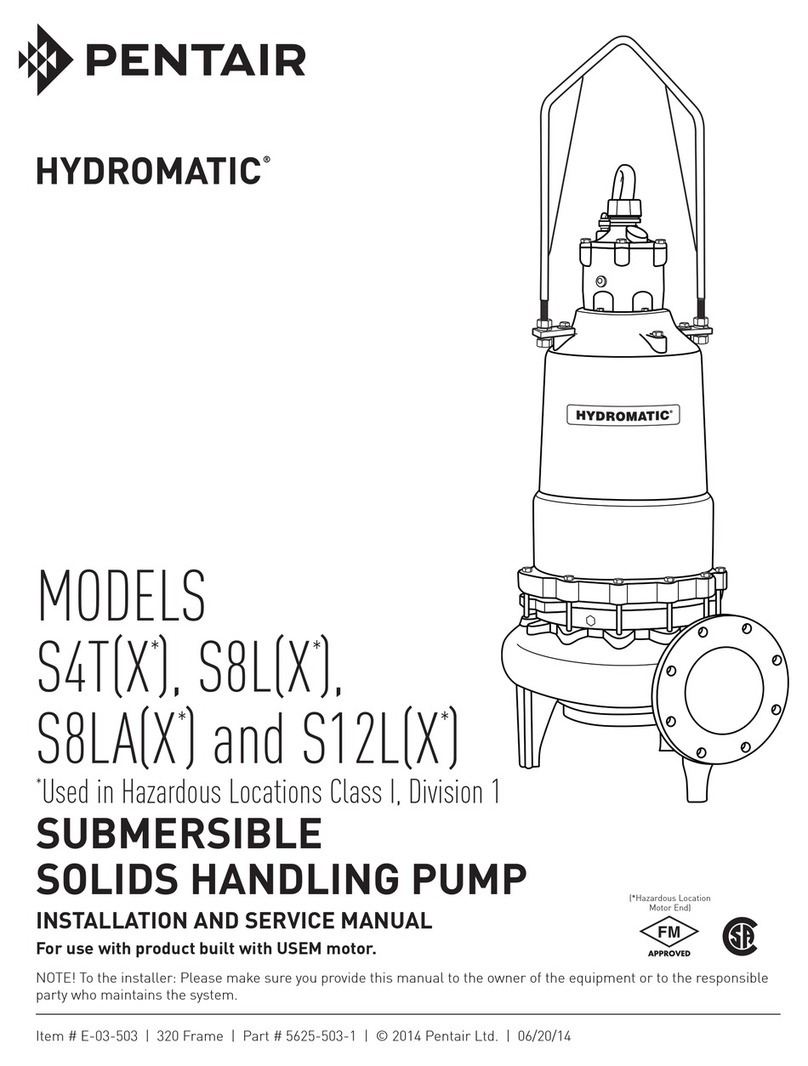

Thank you for purchasing your

Hydromatic®pump. To help

ensure years of trouble-free

operation, please read the

following manual carefully.

Pump

The explosion-proof submersible

pump family was designed in

accordance with requirements for

hazardous locations. These

pumps, connected properly, will

provide years of trouble-free

service. If servicing is required,

the repair should be done by a

Hydromatic approved service

center.

Application

These pumps are designed for on-

site residential sewage discharge

applications with a pH ranging

from 6 to 9, specific gravities from

0.9 to 1.1 viscosities ranging from

28 to 35 S.S.U., and temperatures

up to 140º F.

Receiving Pump

Pump should be checked on arrival

for possible concealed shipping

damage. Any damage should be

reported immediately to delivery

carrier. Claims for damage must

originate at the receiving end.

Claims for shipping damage

cannot be processed at the factory.

Codes

All local wiring codes must be

observed. Consult the local

inspector before installation to

avoid costly delays that can occur

due to rejection after job is

finished.

Pumps Not Operating or

in Storage

Pumps with carbon ceramic seals

must have impellers manually

rotated (6 revolutions) after

setting non-operational for 3

months or longer and prior to

electrical start-up.

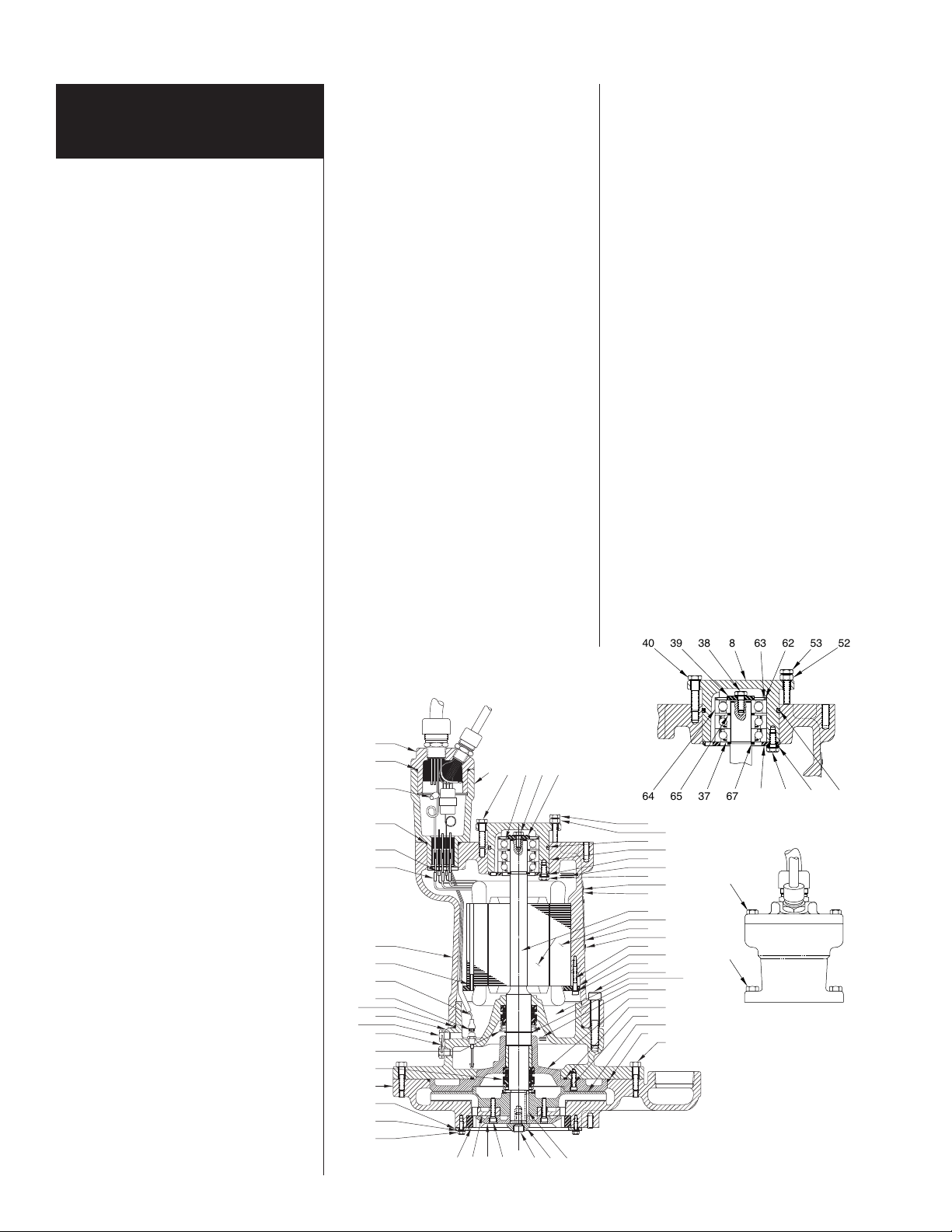

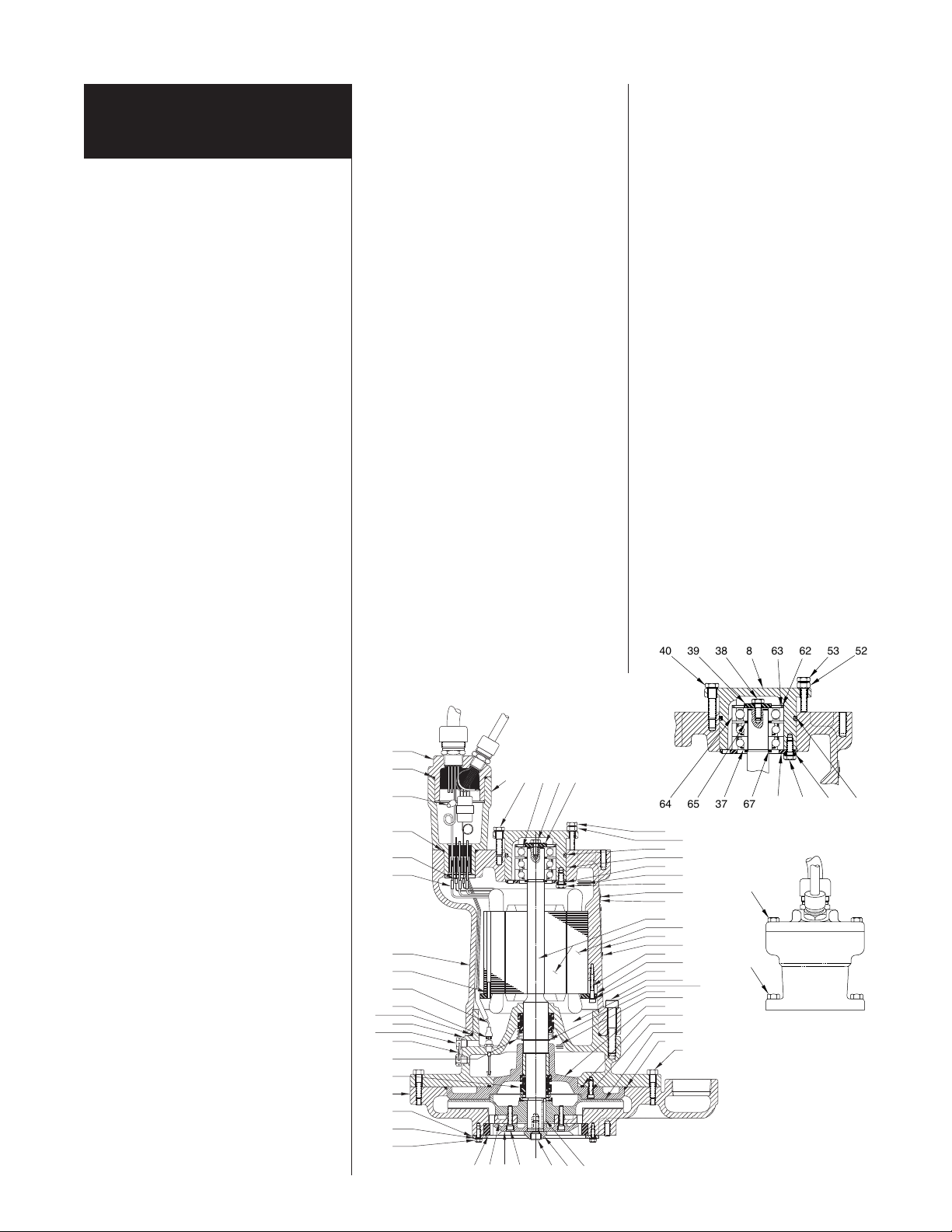

Seal Failure Probes

All explosion-proof submersible

pumps have two factory-installed

moisture detectors (seal failure

probes). They are in a normally

open series circuit, in the seal

chamber.

Under normal operating

conditions, the circuit remains

open. If the lower seal leaks and

moisture enters this chamber, the

moisture would settle to the

bottom of the chamber and will

complete the circuit between the

moisture detectors.

This circuit must be connected to

a sensing unit and signaling

device. This is supplied in a

Hydromatic control panel.

NOTE: Failure to install such a

device negates all warranties by

Hydromatic pumps.

Heat Sensors

All motors in this family have

heat sensors on or embedded in

the motor winding to detect

excessive heat. This prevents

damage to the motor. If the sensor

trips due to excessive winding

temperature, the starter in the

panel breaks power to the pump.

Once the sensor resets, the starter

is to be reset (automatic for F.M.)

for continued operation of the

pump. This circuitry is supplied in

a Hydromatic control panel. The

sensors are set to trip at 120º C.

NOTE: Failure to install such

circuitry would negate F.M.

approval and all warranties by

Hydromatic pumps.

General

Information

Power Cords

The power cord and heat sensor

seal failure cord are potted into

the connection box cap. The

cords must not be spliced.

NOTE: Each cable has a green

lead. This is the ground wire

and must be grounded properly

per N.E.C., and/or local codes.

During normal maintenance

procedures power cords should

be inspected for abnormal wear

and replaced accordingly.

Overload Heaters

If the Hydromatic electrical panel

is not used, starters with 3-leg

overload relay must be supplied

on 3-phase pumps. Each leg is to

have an identical heater sized in

accordance with the nameplate

amps on the motor housing. The

amp draw on these submersible

motors is slightly higher than

a corresponding horsepower

surface motor, so heaters must be

sized by the nameplate rating.

Single-phase pumps with

capacitor start have a run and a

start winding, each drawing a

different current. To adequately

protect these windings with the

appropriate heaters, consult the

factory.

NOTE: Red lead is always start

winding of pump using single

phase.

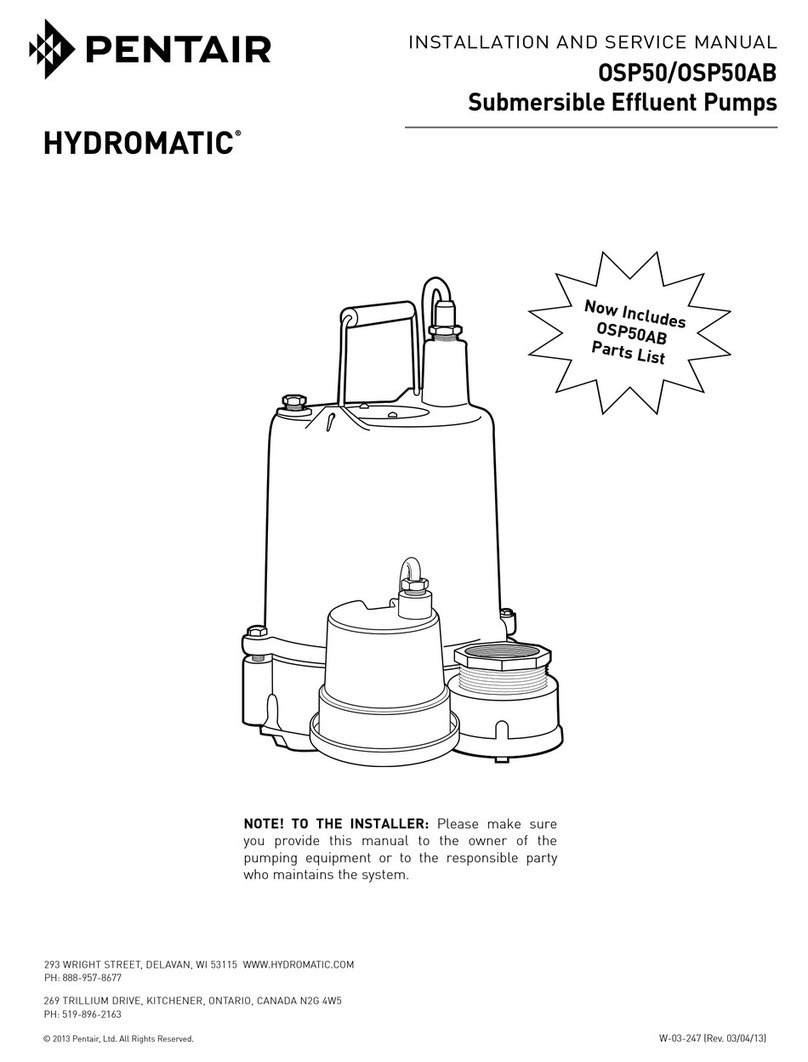

If pumps are installed in an

existing basin or concrete sump,

the piping can either be connected

permanently or rails and brackets

can be furnished for mounting to

walls of basin. In either case, be

sure the Hydromatic non-clog

ball check valve is used and that

the pumps are submerged in a

vertical position. The complete

factory built packaged system is

recommended for the most

satisfactory installation and