INSTALLATION

This manual has been prepared for personnel

qualified to install gas equipment, who should

perform the initial field start-up and

adjustments of the equipment covered by this

manual.

Qualified installation personnel are individuals,

a firm, corporation, or company which either in

person or through a representative are

engaged in and are responsible for:

1. The installation or replacement of gas

piping or the connection, installation, repair

or servicing of equipment, who is

experienced in such work familiar with all

precautions required, and have complied

with all requirements of state or local

authorities having jurisdiction. reference:

National Fuel Gas Code, ANSI Z223.1,

section 1.4, latest addenda.

2. The installation of electrical wiring from the

electric meter, main control box or service

outlet to the electric appliance. Qualified

installation personnel must be experienced

in such work, be familiar with all

precautions required and have complied

with all requirements of state and local

authorities having jurisdiction. Reference:

National Electric Code, ANSI / NFPA No.

70, latest addenda.

READ CAREFULLY AND FOLLOW THESE

INSTRUCTIONS

The broiler(s) must be installed in accordance

with local codes, or in the absence of local

codes, with the national fuel gas code, ANSI

Z223.1 latest addenda, including:

1. The appliance and its individual shutoff

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psig (3.45 kpa).

2. The appliance must be isolated from the

gas supply piping system by closing its

individual manual shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psig (3.45 kpa).

Post in a prominent location the instructions to

be followed in the event the smell of gas is

detected. This information can be obtained

from the local gas supplier.

In the event of a power failure, do not attempt

to operate this device.

IMPORTANT

IN THE EVENT A GAS ODOR IS

DETECTED, SHUT DOWN UNITS AT MAIN

SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

CAUTION

PROVISIONS MUST BE MADE TO ASSURE

ADEQUATE AIR SUPPLY TO UNIT FOR

PROPER BURNER OPERATION.

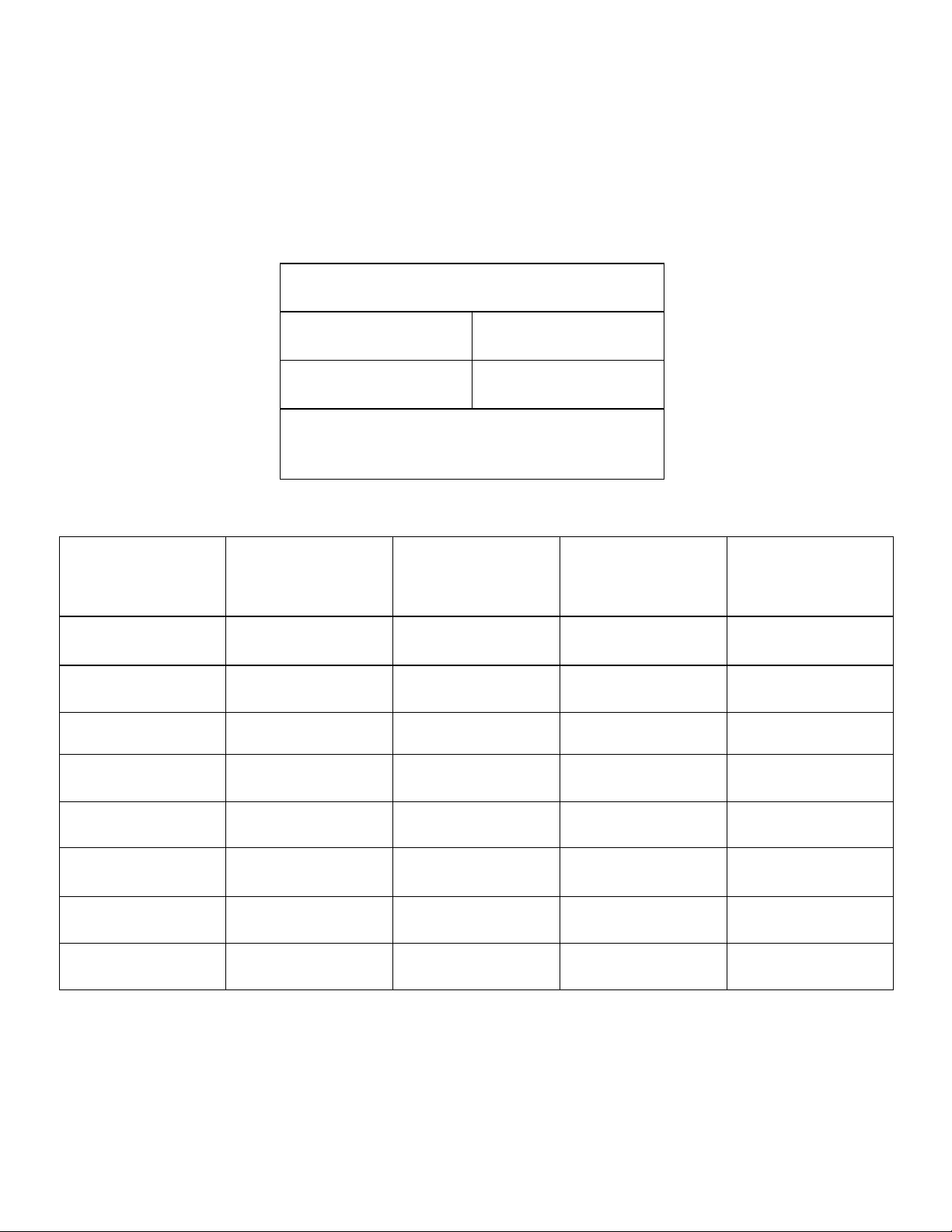

CLEARANCES

The following are minimum clearances from

combustible and noncombustible materials.

With 6” Legs: Suitable for installation on

combustible floors.

Without Legs: For use with special insulated

base on noncombustible floors only.

4

Location Combustible

Construction

Noncombustible

Construction

Back Wall 6” 0”

Left Side 6” 0”

Right Side 6” 0”