Moog Norlin 204D User manual

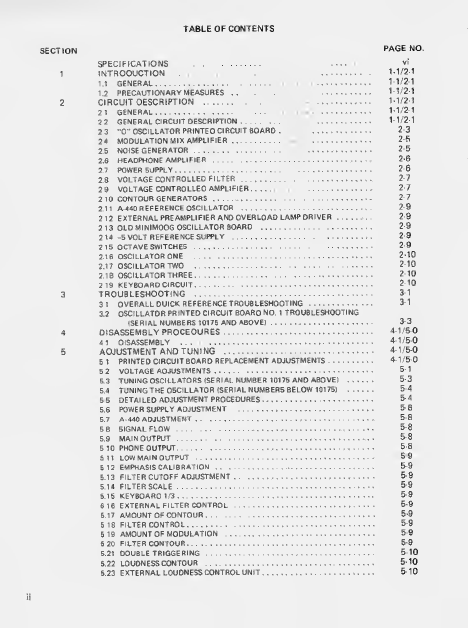

TABLE

OF

CONTENTS

SPECIFICATIONS

.

1

INTRODUCTION

.

1.1

GENERAL.

1.2

PRECAUTIONARY

MEASURES

.

2

CIRCUIT

DESCRIPTION

.

2.1

GENERAL.

2.2

GENERAL

CIRCUIT

DESCRIPTION.

2.3

"D"

OSCILLATOR

PRINTED

CIRCUIT

BOARD.

2.4

MODULATION

MIX

AMPLIFIER.

2.5

NOISE

GENERATOR.

2.6

HEADPHONE

AMPLIFIER

.

2.7

POWER

SUPPLY.

2.8

VOLTAGE

CONTROLLED

FILTER

.

2.9

VOLTAGE

CONTROLLED

AMPLIFIER.

2.10

CONTOUR

GENERATORS

.

2.11

A-440

REFERENCE

OSCILLATOR

.

2.12

EXTERNAL

PREAMPLIFIER

AND

OVERLOAD

LAMP

DRIVER.

2.13

OLD

MINIMOOG

OSCILLATOR

BOARD

.

2.14

-5

VOLT

REFERENCE

SUPPLY

.

2.15

OCTAVE

SWITCHES

.

2.16

OSCILLATOR

ONE

.

2.17

OSCILLATOR

TWO

.

2.18

OSCILLATOR

THREE.

2.19

KEYBOARD

CIRCUIT..

3

TROUBLESHOOTING

.

3

1

OVERALL

QUICK

REFERENCE

TROUBLESHOOTING

.

3.2

O

SCILLATOR

PRINTED

CIRCUIT

BOARD

NO.

1

TROUBLESHOOTING

(SERIAL

NUMBERS

10176

AND

ABOVE).

4

DISASSEMBLY

PROCEDURES.

41

DISASSEMBLY

.

5

ADJUSTMENT

AND

TUNING

.

5.1

PRINTED

CIRCUIT

BOARD

REPLACEMENT

ADJUSTMENTS.

5.2

VOLTAGE

ADJUSTMENTS.

5.3

TUNING

OSCILLATORS

(SERIAL

NUMBER

10175

AND

ABOVE)

.

.

5.4

TUNING

THE

OSCILLATOR

(SERIAL

NUMBERS

8ELOW

10175)

.

.

.

5.5

DETAILED

ADJUSTMENT

PROCEDURES.

5.6

POWER

SUPPLY

ADJUSTMENT

.

5.7

A-440

ADJUSTMENT.

5.8

SIGNAL

FLOW

.

5.9

MAIN

OUTPUT

.

5.10

PHONE

OUTPUT.

5.11

LOW

MAIN

OUTPUT

.

5.12

EMPHASIS

CALIBRATION.

5.13

FILTER

CUTOFF

ADJUSTMENT.

5.14

FILTER

SCALE.

5.15

KEYBOARD

1/3.

5.16

EXTERNAL

FILTER

CONTROL

.

5.17

AMOUNT

OF

CONTOUR

.

.

.

5.18

FILTER

CONTROL.

5

19

AMOUNT

OF

MODULATION

.

5.20

FILTER

CONTOUR.

5.21

DOUBLE

TRIGGERING

.

5.22

LOUDNESS

CONTOUR

.

5.23

EXTERNAL

LOUDNESS

CONTROL

UNIT.

PAGE

NO.

11

/

2-1

11/2-1

1

-1/2-1

11/2-1

11/2-1

11/2-1

2-3

2-5

2-5

2-6

2-6

2-7

2-7

2-7

2-9

2-9

2-9

2-9

2-

9

2-10

2-10

2

10

2-10

3-

1

3-1

3-3

4-1/5-0

4-1/5-0

4-1/5-0

4

1/5-0

5-1

5-3

5-4

5-4

5-8

5-8

5-8

5-8

5-8

5-9

5-9

5-9

5-9

5-9

5-9

5-9

5-9

5-9

5-9

5-10

5-10

5-10

TABLE

OF

CONTENTS

(Continued)

SECTION

PAGE

NO.

5.24

NOISE

.

5

10

5.25

CONTOUR

GENERATOR

BALANCE.

5-10

5.26

EXTERNAL

SIGNAL

INPUT

.

5-10

5.27

AUDIO

NOISE

GENERATOR

.

5-10

5.28

GLIDE

.

5-10

5.29

KEYBOARD

PITCH

CONTACTS

.

5-11

5.30

OSCILLATOR

ADJUSTMENTS

FOR

BOARD.

5-11

5.31

OSCILLATOR

RANGE

.

5-11

5.32

OSCILLATOR

1

TUNING.

5-11

5.33

OSCILLATOR

2

AND

3

TRACKING.

5-11

5

3

4

OCTAVE

ADJUST

.

5-11

5.35

RANGE

OF

TUNE.

PITCH

AND

FREQUENCY

ADJUST

CONTROLS.

5-11

5.36

OSCILLATOR

3

WIDE

RANGE.

5-12/6-0

5.37

MODULATION

OF

OSCILLATOR.

5-12/6-0

5.38

EXTERNAL

CONTROL

OF

OSCILLATOR.

5-1

2/6-0

6

KEYBOARD

MAINTENANCE

.

5-12/6-0

6.1

CLEANING

.

5-12/6-0

6.2

KEYBOARD

ADJUSTING

PROCEDURE

.

6-1

7

REPLACEMENT

PARTS

LIST

.

7-0

7.1

ORDERING

.

7-0

8

MODIFICATIONS

.

8-1

8.1

SERVICE

BULLETINS.

8

1

8.2

OSCILLATOR

BOARD

ASSEMBLY

.

8

1

8.3

CONTOUR

GENERATOR

ASSEMBLY

.

8-1

8.4

POWER

SUPPLY

ASSEMBLY

.

8-1

8.5

FILTER

ASSEM8LY

.

8-1

8.6

KEYBOARD

CIRCUIT

PRINTED

CIRCUIT BOARD

NO.

2

.

8

1

8.7

MINIMOOG

OSCILLATOR

TUNING.

8-2

8.8

OSCILLATOR

BOARD

NO

1.

POWER

SUPPLY

CONNECTION

AND

OCTAVE

BUFFER.

8-2

9

SCHEMATIC

DIAGRAMS

AND

PRINTED

CIRCUIT

BOARDS

.

8-8/9-0

LIST

OF

ILLUSTRATIONS

2-1

Simplified

Block

Diagram

.

2-11

2-2

Subassembly

Location

Diagram

.

2-12

2-3

Printed

Circuit

Board

Socket

Location.

2-12

2-4

Left

Hand

Controller

.

3-1

5-1

Power

Supply

Adjustment

Location

Diagram

.

5-2

5-2

Rear

Panel

Tuning

Control

Location

Diagram

(Serial

Numbers

10175

And

Above).

5-2

5-3

Filter

Adjustment

Location

Diagram

.-.

5-2

5-4

Front

Panel

Control

Settings

(Serial

Numbers

10175

And

Below)

.

5-2

5-

5

Front

And

Rear

Panel

Location

(Serial

Numbers

10175

And

Below)

....

5-2

6-

1

Use

Of

Keyboard

Adjusting

Tool.

6

1

7-

1

Front

Panel

Control

Diagram

.

7-1

8-

1

Printed

Circuit

Board

2

Modification

.

8-3

8-2

Rear

Panel

Modification

Diagram.

8-4

8-3

Front

Panel

Controls

Diagram.

8-5

8-4

Rear

Panel

Adjustment

Location

Diagram

.

8-5

8-5

Connector

Modification

Diagram.

8-7

8-6

Octave

Buffer

Schematic.

8-8/9-0

POLYPEDAL

MODEL

285A

Specifications

SOUND

SOURCES

NO.

OF

SOUND

SOURCES:

5

(3

Oscillators,

1

Noise

Source,

1

External

Input/Microphone

Pre-

OSCILLATOR

FREQUENCY:

0.1

to

20kHz

(cycles/second)

in

six

overlapping

ranges.

SHORT

TERM

OSCILLATOR

STABILITY:

Better

than

0.25%.

OSCILLATOR

WAVEFORM

OUTPUTS:

Tri¬

angular,

Sawtooth,

Triangular-Sawtooth

Mix

(Oscil¬

lators

1

and

2

only).

Reverse

Sawtooth

(Oscillator

2

only),

3

widths

of

Rectangular.

NOISE

SOURCE

OUTPUTS:

White

or

Pink

random

waveforms.

PREAMPLIFIER

INPUT:

10

millivolts

mini¬

mum:

2

volts

maximum.

PREAMP

INPUT

IMPEDANCE:

100K

ohms

or

greater.

FILTER

FILTER

CHARACTERISTIC:

Wide-range

low-

pass

filter

with

variable-height

resonant

peak

at

cut-off

frequency,

and

24dB/octave

cutoff

slope.

RANGE

OF

CUTOFF

FREQUENCY:

Con¬

tinuously

variable

from

40Hz

to

20kHz

(9

octaves).

VOLTAGE

CONTROLLED

AMPLIFIERS

NUMBER

OF

AMPLIFIERS:

2

(one

controUed

only

by

its

Contour

Generator;

the

other

con¬

trolled

by

optional

external

controller).

DYNAMIC

RANGE

OF

EACH

AMPLIFIER:

80dB.

CONTOUR

GENERATORS

NUMBER

OF

CONTOUR

GENERATORS:

2

(one

controlling

filter

through

an

attenuator;

the

other

controlling

the

first

voltage

Controlled

Amplifier).

RANGE

OF

ATTACK

TLME:

10

milliseconds

to

10

seconds.

RANGE

OF

DECAY

TIME:

10

milliseconds

to

10

seconds.

RANGE

OF

SUSTAIN

LEVEL:

0

to

100%

of

contour

peak.

WIDTH

OF

SWEEP

OF

FILTER

BY

ITS

CON¬

TOUR

GENERATOR:

Continuously

variable

from

0

to

4

octaves.

AUDIO

SIGNAL

OUTPUTS

HIGH

LEVEL

OUTPUT:

0.5

volts

typical,

with

3K

ohms

nominal

output

impedance.

LOW

LEVEL

OUTPUT:

15

millivolts

typical,

with

IK

ohm

output

impedance.

HEADPHONE

OUTPUT:

0.3

volts

maximum,

into

standard

8-ohm

stereo

headphones.

CONTROLLERS

KEYBOARD

FUNCTION:

Permanently

con¬

nected

to

(a)

control

Oscillators

1

and

2,

and

(b)

trigger

Contour

Generators.

Keyboard

may

be

switched

to

control

Oscillator

3

and

Filter.

DESCRIPTION

OF

KEYBOARD:

Standard

44

key

(3-1/2-octave)

organ

keyboard.

Only

lowest

key

depressed

has

effect

in

controlling

Oscillators

and

Filter.

Contour

Generators

are

activated

when¬

ever

a

single

key

is

depressed.

RATE

OF

KEYBOARD

GLIDE:

Continuously

variable

from

1

millisecond

to

1

second/octave.

PITCH

BENDING

RANGE:

5

semitones

mini-

MODULATION

INJECTION

RANGE:

0

to

1-1/4

octaves.

CONTROL

AND

POWER

CONNECTIONS

EXTERNAL

PITCH

CONTROL

INPUT

CHAR¬

ACTERISTIC:

1

volt

change

produces

1

octave

frequency

change,

+

2

percent.

EXTERNAL

FILTER

CONTROL

INPUT:

1

volt

change

produces

1

octave

change

in

cutoff

frequency,

+

5

percent.

EXTERNAL

AMPLIFIER

CONTROL

INPUT:

Linear

control

voltage/gain

relationship.

Gain

range

spanned

by

0-4

volts.

EXTERNAL

TRIGGER

INPUT:

Switch-closing

activates

both

Contour

Generators.

AUXILIARY

DC

POWER

SOCKET:

+10

volts

and

-10

volts

at

50

mill

am

peres.

DIMENSIONS

AND

WEIGHT

OVERALL

SIZE

(with

Front

Panel

down):

28-5/8

inches

(72cm)

wide,

17-1/8

inches

(41cm)

deep,

5-3/4

inches

(14cm)

high.

NET

WEIGHT:

28

pounds

(12.7kg).

SHIPPING

WEIGHT:

45

pounds

(20.5kg).

POWER

REQUIREMENTS

100-135

and

200-270

volte,

50-60Hz,

40

watts

maximum.

Specifications

subject

to

change.

major

differences

in

the

two

boards

is

that

common

summing

is

used

on

the

new

board

while

individual

summing

is

used

on

the

old

board.

All

three

oscillators

have

individual

octave

switching

signals

applied

to

three

adjustable

poten¬

tiometers

providing

precision

octave

switching

of

the

individual

oscillators.

2.2.2

MODULATION

MIX

AMPLIFIER

A

modulation

mix

amplifier

selects

the

output

of

oscillator

3

or

noise,

or

both,

sums

and

routes

them

to

the

amount

control

in

the

left

hand

con¬

troller.

2.2.3

NOISE

GENERATOR

The

Minimoog

contains

a

noise

generator

using

a

transistor

generating

white

noise

in

the

range

of

-60dB

which

is

amplified

to

produce

white,

pink

or

red

noise,

selected

by

the

noise

selector

switch.

White

or

pink

noise

is

used

for

audio

and

pink

or

red

for

modulation.

2.2.4

HEAD

PHONES

An

amplifier

is

provided

to

supply

sufficient

current

to

drive

standard

stereo

headphones.

2.2.5

POWER

SUPPLY

A

dual

output

power

supply

with

the

rectifier

on

Board

3,

the

filter

on

Board

5

and

the

transformer

on

the

chassis,

provides

+

10

volt

regulated

power.

The

input

is

either

115

or

230

volt

as

selected

through

a

switch

on

the

top

of

the

panel.

2.2.6

KEYBOARD

CIRCUIT

The

keyboard

circuit

consists

of

a

temperature

compensated

current

source,

the

actual

keyboard

and

a

track

and

hold

amplifier.

The

keyboard

voltage

is

routed

to

a

track

and

hold

amplifier

where,

with

no

keys

depressed,

the

circuit

is

in

a

hold

mode.

With

a

key

depressed,

the

pitch

voltage

occurs

before

the

trigger

and

the

trigger

goes

off

before

the

pitch

voltage

is

released.

2.2.7

A-440

REFERENCE

OSCILLATOR

The

A-440

reference

oscillator

is

based

on

a

standard

We

in

Bridge

oscillator

design.

The

bridge

has

a

phase

shift

of

zero

degrees

at

approximately

440Hz,

supplying

a

positive

feedback

and

causing

the

circuit

to

oscillate.

The

frequency

of

the

oscil¬

lation

is

set

by

a

resistor.

Three

capacitors

and

a

resistor

limit

the

signal

amplitude

to

a

transistor

collector

resulting

in

a

clean

sine

wave

output.

2.2.8

EXTERNAL

AMPLIFIER

The

external

preamplifier

is

fed

to

the

EX¬

TERNAL

INPUT

VOLUME

control

where

the

out¬

put

is

fed

through

a

200

gain

amplifier

and

in

turn

routed

to

the

EXTERNAL

INPUT

ON

OFF

switch.

This

switch

allows

an

external

source

to

be

summed

with

other

signal

sources.

2.2.9

OVERLOAD

LAMP

DRIVER

The

output

from

the

200

gain

amplifier

is

also

fed

to

the

overload

lamp

driver

circuit.

The

amplitude

envelope

of

the

signal

is

detected

and

fed

to

a

voltage

divider.

When

the

AC

input

voltage

reaches

ap¬

proximately

1.2

volts,

the

OVERLOAD

lamp

illumi¬

nates

and

is

held

for

a

suitable

period.

2.2.10

VOLTAGE

CONTROLLED

FILTER

“Audio”

signals

are

summed

and

a

differential

signal

current

is

generated

and

applied

to

a

filter

ladder.

Cutoff

frequency

of

the

filter

is

controlled

by

the

standing

current

through

the

ladder.

The

higher

the

standing

current,

the

higher

the

cutoff

frequency.

A

differential

signal

is

created

and

fed

to

a

gain

amplifier

which

converts

the

differential

input

to

a

single

ended

output

in

tum

fed

to

a

transistor

in

the

voltage

control

amplifier.

The

FILTER

EM¬

PHASIS

control

is

also

connected

to

the

gain

ampli¬

fier

providing

positive

feedback

at

the

cutoff

fre¬

quency.

As

the

amount

of

emphasis

is

increased,

the

Q

increases

and

the

filter

starts

a

sine

wave

oscillation

at

the

cutoff

frequency.

The

cutoff

frequency

control

current

originates

in

an

exponential

voltage

to

a

current

converter.

Control

voltages

from

the

external

input,

keyboard

2-2

switches,

modulation

and

the

contour

generator

are

summed

and

fed

to

the

exponential

convertor.

A

resistor

sets

the

keyboard

scale

at

one

volt

per

octave

and

in

turn

the

front

panel

filter

CUTOFF

FRE¬

QUENCY

control

is

calibrated

in

a

similar

manner.

Z.2.11

VOLTAGE

CONTROLLED

AMPLIFIER

The

input

signal

from

the

voltage

controlled

filter

is

AC

coupled

to

a

differential

transconductance

multiplier.

The

gain

of

the

transistor

is

current

controlled;

the

greater

the

current,

the

higher

the

gain.

2.2.12

CONTOUR

GENERATORS

Separate

contour

generators

are

provided

for

both

filter

and

loudness

contours.

Each

contour

generator

has

its

own

controls

consisting

of

ATTACK,

DECAY

and

SUSTAIN’.

Contour

generators

are

triggered

by

an

internal

voltage

trigger

from

the

keyboard

and/or

the

rear

panel

S-TRIG

jack.

The

amount

of

contour

control

adjusts

the

sweep

of

the

voltage

controlled

lowpass

filter.

2.3

"D"

OSCILLATOR

PRINTED

CIRCUIT

BOARD

(Refer

to

Figures

9-1

and

9-2)

The

new

“D”

oscillator

printed

circuit

board

is

a

plug-in

replacement

card

for

earlier

oscillator

boards.

This

board

contains

three

precision

voltage

controlled

oscillators

with

a

variety

of

control

inputs

and

a

number

of

waveform

outputs

for

each

of

the

three

oscillators.

The

schematic

diagram

shows

not

only

the

oscillator

board

itself,

but

several

of

the

associated

control

circuits

and

output

selection

circuits

for

circuit

clarity.

A

variety

of

input

control

signals

namely,

PITCH

WHEEL,

TUNE,

MOD

WHEEL

and

OSCILLATOR

(three

oscillators)

are

summed

via

the

"primary

oscillator

summer"

amplifier

IC1A.

This

common

summing

(as

opposed

to

individual

summing

sections

for

these

control

inputs

in

the

old

Minimoog

oscillator

printed

circuit

board)

guarantees

that

when

the

oscillators

track

the

keyboard

input,

they

also

track

these

other

common

drive

signals.

The

output

of

the

primary

oscillator

summer,

IC1A,

is

scaled

at

this

point

to

provide

1.00

volt

per

octave

by

adjusting

oscillator

scale

adjust

potentiometers

R16,

R55

and

R91

of

the

three

oscillator

sections.

These

three

scale

potentiometers

are

adjusted

so

that

the

three

oscil¬

lators

on

each

board

track

the

keyboard

drive

signal

exactly.

Final

adjustments

of

these

scale

potentio¬

meters

must

be

made

for

an

assembled

unit,

since

the

keyboard

scale

factor

for

different

frames

will

vary

slightly.

All

three

oscillators

have

individual

octave

switching

signals

applied

to

the

octave

adjust

po¬

tentiometers

R18.

R57

and

R92.

These

octave

adjust

inputs

provide

precision

octave

switching

of

the

individual

oscillators,

and

as

the

scale

adjusts,

must

be

adjusted

to

their

final

value

in

the

assembled

Oscillator

2

has

an

additional

input

labeled

OSCILLATOR-2

FREQUENCY

which

provides

for

tuning

+

a

musical

fifth.

Oscillator

3

has

two

addi¬

tional

inputs

which

are

both

driven

by

the

OSCIL¬

LATOR-3

FREQUENCY

CONTROL

providing

+

a

musical

fifth

control

when

the

OSCILLATOR-3

CONTROL

is

on

(namely,

when

the

keyboard

con¬

trol

voltage

is

applied

to

oscillator

3

by

the

switch¬

ing

FET

Q2)

or

providing

+

3

octaves

of

control

when

the

OSCILLATOR-3

CONTROL

is

off.

When

this

control

is

off,

both

feed

resistors

R96

and

R97

are

connected

to

the

OSCILLATOR-3

FREQUENCY

front

panel

potentiometer.

The

various

frequency

control

inputs

for

the

three

oscillators

are

summed

together

in

amplifiers

IC1B,

1C3A

and

IC3B.

Resistors

R22,

R62

and

R100

provide

for

bias

current

temperature

drift

compensa¬

tions.

It

should

be

noted

at

this

point

that

all

three

oscillators

are

identical

from

this

point

on,

except

for

the

addition

of

a

reverse

sawtooth

circuit

asso¬

ciated

with

Q20

in

oscillator

3.

For

this

reason

we

will

discuss

the

detailed

operation

of

only

oscillator

3.

The

composite

frequency

control

signal

appear¬

ing

at

the

output

of

IC3B

is

applied

to

the

precision

voltage

divider

comprised

of

R101

and

R102

which

divides

the

composite

frequency

control

signal

down

to

21.0mV.

octave.

This

divided

down

frequency

control

signal

is

applied

to

the

base

of

the

expo¬

nentiating

transistor

Q17

which

is

contained

along

with

its

companion

transistor

Q18

in

a

tempera¬

ture

stabilized

package.

IC15

(Fairchild

726).

This

2-3

integrated

circuit

is

maintained

at

a

constant

temper¬

ature

of

approximately

78.4°C

by

circuitry

internal

to

the

integrated

circuit.

The

actual

temperature

of

the

chip

is

set

by

the

resistor

R105.

Transistor

Q18

is

a

Vjj

C

compensation

transistor

whose

collector

current

is

maintained

constant

by

a

combination

of

R108,

R106

and

IC16.

The

plus

input

of

IC16

is

maintained

at

ground.

The

output

of

IC16

sinks

current

through

the

emitter

of

Q18

such

that

the

voltage

appearing

on

pin

2

of

IC16

is

also

ground.

If

we

assume

that

there

is

no

bias

current

flowing

into

the

negative

input

of

IC16

(valid

since

this

integrated

circuit

is

a

FET

input

operational

amplifier)

then

we

see

that

5.0

microamperes

of

current

is

flowing

into

the

collector

of

transistor

Q18.

regardless

of

the

current

drawn

through

the

emitter

of

transistor

Q17.

This

circuit

configuration

provides

a

precision

tempera¬

ture

compensated

base

emitter

reference

subtraction

voltage

for

the

exponentiating

transistor

Q17.

The

current

flowing

into

the

collector

of

Q17

is

expo¬

nentially

related

to

the

voltage

applied

to

the

base

on

pin

1.

This

current

is

applied

to

the

oscillator

inte¬

grating

capacitor

C29

via

the

“high

end

comp”

potentiometer

R109.

The

reference

side

of

the

inte¬

grating

capacitor

C29

is

tied

to

a

5.0VDC

reference

rail

derived

from

the

+10VDC

rail

via

the

resistor

divider

network

R103

and

R104,

and

the

voltage

follower

IC14A

whose

output

is

bypassed

to

ground

via

C28.

The

FET

Q14

shunts

the

integration

capaci¬

tor

C29

to

+5

whenever

the

voltage

appearing

at

the

input

of

the

comparator

amplifier

IC17

reaches

ground.

The

voltage

appearing

on

the

lower

side

of

the

integrating

capacitor

C29

is

a

ramp

headed

toward

0.0VDC.

The

voltage

appearing

on

the

inte¬

grating

capacitor

plus

the

voltage

drop

across

the

“high

end

comp”

potentiometer

R109

is

buffered

by

the

voltage

follower

comprised

of

IC17

and

emitter

follower

Q15,

R114.

R115

and

R116.

The

buffered

negative

ramp

appearing

on

the

emitter

of

Q15

is

applied

to

the

comparator

IC18B

which

switches

the

shunt

FET

Q14

on

when

the

ramp

voltage

reaches

zero

via

coupling

diode

CR5

and

capacitor

C31.

When

the

shunt

transistor

Q14

turns

on,

the

capacitor

voltage

is

returned

to

+5VDC

which

in

turn

causes

the

shunt

FET

Q14

to

turn

off

via

the

buffer

amplifier

IC17,

the

comparator

1C18B

and

pull

up

resistor

R110.

Then

the

negative

going

ramp

integration

begins

again.

As

the

integration

current

supplied

via

R109

is

increased,

a

residual

voltage

up

and

above

the

linear

ramp

signal

appearing

across

R109

shows

up

at

the

voltage

follower

IC17

and

thereby

at

the

voltage

comparator

IC18B.

This

residual

voltage

means

that

the

actual

ramp

value

appearing

on

the

capacitor

required

to

trigger

the

comparator

IC18B

is

reduced

at

higher

frequencies.

It

is

posable

to

set

R109

so

that

the

effect

of

non-

linearities

due

to

a

finite

reset

time

of

the

capacitor

C29

are

compensated

for

by

this

additional

residual

voltage.

Resistor

R112

and

capacitor

C34

provide

for

a

small

amount

of

positive

regeneration

(Schmitt

trigger

action)

to

insure

clean

switching

during

saw¬

tooth

reset.

The

sawtooth

voltage

appearing

at

the

emitter

of

Q15

is

applied

to

the

bias

network

com¬

prised

of

R114,

R115

and

R116.

The

values

of

this

network

are

chosen

so

that

the

voltage

appearing

on

the

sawtooth

output

(

pin

13B)

is

precisely

+1.75VDC

to

-1.75VDC.

Resistor

R137

is

a

selected

resistor

whose

value

is

chosen

to

achieve

accurate

symmetry

in

this

output

waveform.

This

symmetry

is

important

to

achieve

an

accurate

50

percent

duty

cycle

of

the

rectangular

waveform

appearing

on

pin

15B.

While

the

sawtooth

appearing

on

the

emitter

of

Q15

goes

precisely

from

+5VDC

to

0.0VDC,

a

voltage

equal

to

V^

e

above

this

is

available

at

the

base

of

Q15.

This

base

voltage

is

also

applied

to

the

triangular

wave

converter

transistor

Q16.

Triangular

conversion

circuit

comprised

of

Q16,

R118

and

R120

acts

as

a

precision

inverter

as

the

sawtooth

waveform

travels

between

OVDC

and

+2.5VDC.

From

2.5VDC

to

5.0VDC

transistor

Q16

is

in

saturation

with

essentially

zero

collector

to

emitter

voltage

drop.

In

this

condition

the

emitter

of

Q16

follows

very

closely

the

emitter

of

Q15

which,

of

course,

is

the

sawtooth

waveform.

Since

there

is

negligible

col-

lector-to-emitter

voltage

drop

in

this

saturated

condi¬

tion,

the

collector

of

Q16

then

follows

accurately

the

sawtooth

waveform

between

2.5VDC

and

5VDC.

Therefore,

during

half

of

the

cycle

the

triangular

conversion

circuit

acts

as

a

precision

inverter

and

during

the

second

half

of

the

cycle

it

acts

as

a

pre¬

cision

voltage

follower,

resulting

in

a

precision

triangular

waveform

output.

This

precision

triangular

waveform

appearing

at

the

collector

of

Q16

is

then

applied

to

the

buffer

with

gain

comprised

of

IC14B,

R121

and

R122

via

the

de-glitching

RC

network

comprised

of

R119

and

C35.

This

suppresses

the

fast

transient

which

occurs

in

the

triangular

wave

output

which

occurs

during

the

sawtooth

waveform

2-4

reset.

The

output

of

the

follower

IC14B

is

a

trian¬

gular

waveform

which

goes

from

+1.75VDC

to

-1.75VDC.

The

sawtooth

waveform

appearing

on

the

out¬

put

pin

13B

is

applied

to

the

rectangular

wave

shap¬

ing

circuit

comprised

of

1C18A,

R117,

R125

through

R127,

and

R131

and

R132.

A

control

voltage

which

ranges

between

OVDC

and

-2.5VDC

is

applied

to

the

negative

input

of

IC18A

via

the

biased

divider

net¬

work

R126

and

R127.

The

sawtooth

waveform

is

applied

to

the

positive

input

of

1C18A

via

R117.

Resistor

R125

provides

a

very

small

amount

of

positive

regenerative

feedback

to

give

clean

square

wave

switching.

When

the

control

voltage

on

pin

16B

is

O.OVDC,

a

square

wave

output

swinging

be¬

tween

the

negative

rail

and

ground

appears

on

the

output

of

IC18A.

This

voltage

is

divided

down

by

R131

and

R132

to

give

a

OVDC

to

-3.5VDC

trian¬

gular

wave

output.

When

the

voltage

applied

to

the

control

input

on

16B

is

taken

to

-2.5VDC,

a

15

per¬

cent

duty

cycle

should

appear

on

pin

1

of

IC18A.

All

of

this

paragraph

is

relevant

to

oscillators

1

and

2.

However,

oscillator

3

has

a

sawtooth

inverter

circuit

comprised

of

R123,

R124,

R128,

R129,

R130,

R133,

R134

and

Q20.

This

is

a

standard

common

emitter

transistor

inverter

with

a

biased

network

on

the

output

comprised

of

R133

and

R134

to

provide

a

reverse

sawtooth

signal

which

goes

from

+1.75VDC

to

-1.75VDC

(unloaded).

A

minus

5

volt

regulator

comprised

of

the

voltage

divider

R9,

RIO

and

emitter

follower

com¬

prised

of

IC2,

Rll,

R8

and

Q1

provides

a

precision

-5

volt

potential

for

the

octave

switching

network

shown

to

the

far

left

of

the

schematic.

This

circuit

has

remote

sense

via

pin

18A

to

eliminate

effects

of

edge

connector

voltage

offsets.

Combined

sawtooth

and

triangular

waveforms

are

achieved

by

the

mix

resistor

shown

to

the

right-

hand

side

of

the

schematic,

off

the

printed

circuit

board.

It

should

be

noted

that

the

voltage

applied

to

the

base

of

exponentiating

transistor

Q17

is

scaled

so

that

21.0mV

equals

one

octave.

This

means

that

a

17.5

microvolt

level

on

the

base

of

Q17

is

equiv¬

alent

to

1

percent.

If

an

accuracy

of

1

percent

is

required,

then

all

noise

contributions

appearing

at

the

base

of

Q17

must

be

kept

below

17.5

microvolts.

While

this

is

not

an

unusually

tight

specification

for

a

741

type

operational

amplifier,

occasional

problems

may

be

encountered.

Popcorn

noise

or

supply

de¬

coupling

in

the

integrated

circuit

or

supply

spiking

due

to

larger

board

trace

resistances

may

lead

to

occasional

instruments

which

exhibit

jitter.

2.4

MODULATION

MIX

AMPLIFIER

There

are

two

modulation

signals

available

in

the

Minimoog;

the

output

of

Oscillator

3

and

noise.

Oscillator

3

produces

periodic

modulation

utilizing

triangle,

sawtooth

and

pulse

waveforms.

Noise

pro¬

duces

random

modulation

utilizing

noise

voltages

in

the

pink

and

red

spectrum.

The

Modulation

Mix

amplifier

selects

either

or

both

modulation

signals,

sums

them

and

routes

them

to

the

Modulation

Amount

Control

in

the

Left-hand

controller.

The

output

of

OSCILLATOR-3's

WAVEFORM

SELEC¬

TOR

SWITCH,

SW8,

and

the

output

of

the

NOISE

SELECTOR

SWITCH.

SW14,

are

fed

thru

R23

and

R24

respectively

and

to

the

MODULATION

MIX

potentiometer

R3.

The

wiper

of

R23

is

connected

to

ground

and,

therefore,

when

the

MODULATION

MIX

potentiometer

is

rotated,

it

pans

between

the

two

modulation

signals.

The

two

ends

of

R3

feed

the

input

resistors

of

the

Modulation

Mix

amplifier

composed

of

Q7,

Q17

and

Q18.

The

Modulation

Mix

amplifier

is

an

invertor

with

a

gain

of

2.

The

output

of

the

modulation

mix

amplifier

is

fed

through

R57

to

the

AMOUNT

of

MODULATION

control

in

the

Left-Hand

Controller.

Resistor

R38

and

capacitor

C14

provide

phase

compensation

to

the

amplifier

to

suppress

oscillation.

2.5

NOISE

GENERATOR

The

noise

generator

of

the

Minimoog

uses

a

small

signal

transistor

operated

in

the

avalanche

mode.

The

base-to-emitter

junction

is

biased

in

reverse

breakdown

which

generates

white

noise

in

the

range

of

-60dB.

This

signal

is

amplified

to

pro¬

duce

white,

pink

and

red

noise.

The

noise

selector

switch

selects

white

or

pink

noise

for

audio

and

pink

or

red

noise

for

modulation.

Transistor

Q15

is

the

noise

generator

transistor

which

is

selected,

burned-

in

and

retested

for

uniform

noise

clear

of

pops

and

2-5

clicks.

Resistor

R47

and

capacitor

C25

form

a

noise-

free

bias

supply

for

this

transistor.

The

noise

on

Q15

is

fed

to

common

emitter

amplifier

Q12.

Resistor

R26

adjusts

the

gain

of

this

amplifier

until

the

white

noise

output

is

-5dB.

Q4

forms

an

emitter

follower

which

provides

a

low

impedance

output

drive

for

the

white

noise

circuit.

The

white

noise

output

is

filtered

by

R16,

C3,

R8,

C2

and

R13

to

provide

pink

noise.

Transistor

Q3

amplifies

the

pink

noise

and

provides

a

low

impedance

output.

The

pink

noise

output

is

then

filtered

by

R12

and

C7

and

amplified

by

Q6

to

provide

the

red

noise

output.

2.6

HEADPHONE

AMPLIFIER

The

headphone

amplifier

in

the

Minimoog

is

a

push-pull

current

amplifier

that

provides

sufficient

current

to

drive

standard

8

ohm

headphones.

The

signal

from

the

final

VCA

is

fed

to

the

headphone

volume

control

R21.

This

is

AC

coupled

through

C19

through

driver

transistor

Q16.

Diodes,

CR1

and

CR2

provide

the

1.2

voltage

drop

required

to

bias

Q10

and

Qll

into

class

AB

operation.

CR1

and

CR2

are

connected

to

Q10

and

Q11

for

temperature

compensation.

Audio

signals

are

AC

coupled

through

C21

into

the

headphone

output

jack.

2.7

POWER

SUPPLY

The

Minimoog

employs

a

±

10

volt

dual

regu¬

lated

supply.

The

regulators

are

located

on

the

left

hand

portion

of

Board

3,

the

rectifier

and

filter

capacitors

are

located

on

Board

5,

and

the

AC

line

circuitry

and

low

voltage

transformer

are

mounted

on

the

chassis.

The

regulated

supply

can

operate

on

either

115

volt

or

230

volt

AC

line

voltage

selected

by

a

rear

panel

line

voltage

switch.

The

supply

has

both

primary

AC

line

fuses

and

secondary

DC

line

Raw

AC

from

the

line

cord

passes

through

fuse

F3

and

to

POWER

switch

SW20.

VOLTAGE

SELEC¬

TOR

SW21

connects

the

primaries

of

T1

in

series

for

230

volt

operation

and

in

parallel

for

115

volt

opera¬

tion.

The

step-down

secondary

voltage

from

T1

is

applied

to

rectifier

Board

5.

The

low

voltage

AC

is

bridge

rectified

by

diodes

CR1

through

CR4

on

Board

5.

Capacitors

Cl

and

C2

filter

the

raw

DC

to

provide

unregulated

+15

volts.

This

raw

output

is

fed

through

secondary

fuses

FI

and

F2

to

Board

3.

Raw

+15

volts

is

also

fed

to

various

boards

in

the

system

to

provide

additional

The

power

supply

on

the

Minimoog

employs

two

series

pass

voltage

regulators.

The

+10

volts

is

regulated

first

and

the

-10

volts

tracks

the

+10

voltage.

The

+10

voltage

regulator

is

composed

of

Ql,

Q2,

Q5,

Q8,

Q9

and

referenced

diode

CR3.

Diode

CR3

is

the

master

voltage

reference

for

the

-10

volt

regulator

and,

therefore,

the

master

refer¬

ence

for

the

entire

system.

The

negative

voltage

regulator

is

composed

of

Q13,

Q14,

Q19

and

Q20.

The

+10

volt

regulator

operates

in

the

following

manner:

Resistor

R44

feeds

7.5milliamperes

through

zener

diode

CR3

giving

a

6.2

voltage

drop

across

CR3.

This

6.2

volts

is

virtually

insensitive

to

both

changes

in

temperature

and

current,

thereby

provid¬

ing

a

very

stable

voltage

reference.

Transistors

Q9

and

Q8

compare

the

voltage

drop

across

CR3

with

a

voltage

drop

at

the

wiper

of

R21.

To

provide

6.2

volts

at

the

wiper

of

R21,

10

volts

must

appear

across

the

total

resistor

string

comprised

of

R39

and

R21

and

R34.

Therefore,

the

voltage

across

CR3

sets

the

+10

volt

power

supply

voltage.

Transistors

Q8,

Q9.

Q5.

and

Ql

form

a

negative

feedback

regulator

to

maintain

the

voltage

at

exactly

+10

volts.

If

the

voltage

on

the

collector

of

Ql

rises

above

10

volts,

the

voltage

on

the

bases

of

Q8

ends

up

being

lower

than

the

voltage

on

Q9.

Transistor

Q9

cuts

off

the

drive

to

Q5,

which

reduces

the

drive

to

Ql.

This

brings

the

voltage

on

the

collector

of

Ql

back

to

+10

volts.

Variable

resistor

R21

sets

the

output

voltage

to

precisely

+10.000

volts.

Transistor

Q2

only

operates

during

the

initial

turn

on

of

the

instrument.

When

the

power

is

first

applied,

the

collector

of

Ql

has

no

voltage

on

it,

therefore

the

regulator

will

not

func¬

tion.

Transistor

Q2

has

no

drive

and

is,

therefore,

turned

off

allowing

raw

DC

to

be

fed

through

R5

and

R14

to

the

base

of

Q5,

turning

Q5

on.

Transistor

Q5

supplies

drive

to

Ql,

turning

Ql

on

causing

the

voltage

on

the

collector

of

Ql

to

rise

towards

+10

volts.

As

this

voltage

rises,

Q2

is

turned

on,

thereby

removing

the

raw

DC

feed

to

Q5

allowing

the

regula¬

tor

to

operate

normally.

Plus

10

volts

is

remote

sensed

at

the

oscillator

card

to

insure

a

stable

oscil¬

lator

voltage.

Resistor

R45

provides

+10

volt

sensing

in

case

the

internal

sense

lines

to

the

oscillator

open.

Without

R45,

the

regulated

voltage

would

jump

to

the

raw

supply

voltage

if

the

sense

line

opens.

Resis¬

tor

R45

protects

the

electronic

circuitry

from

dam¬

age.

The

various

capacitors

throughout

the

system

suppress

parasitic

oscillations.

The

-10

volt

supply

is

referenced

to

the

+10

voltage

and

the

operation

is

identical

to

the

+10

volt

supply.

Resistors

R65,

R58

and

R52

form

a

voltage

divider

across

the

+10

and

-10

volt

supply

rails.

Transistors

Q13

and

Q14

compare

the

voltage

on

the

wiper

of

R58

with

ground

potential.

Transistors

Q13

and

Q14

adjust

the

drive

to

Q20

to

maintain

ground

potential

on

the

wiper

of

R58

which

provides

-10

volts

on

the

rail.

Variable

resistor

R58

adjusts

the

-10

voltage

to

precisely

-10.000

volts.

Again,

remote

sensing

is

used

for

oscillator

stability

with

sense

resistor

R66

providing

sense

line

protection

and

various

capacitors

are

placed

throughout

the

regulator

to

insure

stable

operation.

Both

the

+10

volt

and

-10

volt

supply

voltages

are

applied

directly

to

the

oscillators

and

to

Board

5

for

distribution

to

the

rest

of

the

system.

2.8

V

OLTAGE

CONTROLLED

FILTER

Audio

signals

from

the

three

VCO's,

the

noise

generator,

and

the

external

audio

input

are

summed

and

applied

to

the

base

of

Q29.

Transistors

Q29

and

Q30

generate

a

differential

signal

current

and

apply

it

to

the

lowpass

filter

ladder.

The

four-pole

lowpass

filter

ladder

is

a

patented

design

consisting

of

the

base-emitter

junction

of

transistors

Q2,

Q3,

Q10,

Qll,

Q19,

Q20,

Q23,

Q24,

and

capacitors

C16,

Cll,

C7

and

C3.

Cutoff

frequency

of

the

filter

is

controlled

by

the

standing

current

through

the

lad¬

der.

The

higher

the

standing

current,

the

higher

the

cutoff

frequency.

The

filtered

signal

is

taken

dif¬

ferentially

across

C3

and

therefore

the

control

current

is

rejected.

This

differential

signal

is

fed

to

the

gain

recovery

amplifier

consisting

of

Q5,

Q6,

Q7,

and

Q8

which

converts

the

differential

input

to

a

single

ended

output.

This

is

then

fed

to

Q16

in

the

voltage

control

amplifier.

The

FILTER

EMPHASIS

control,

R14,

is

also

connected

to

the

gain

recovery

amplifier

to

provide

positive

feedback

at

the

cutoff

frequency.

As

the

amount

of

emphasis

is

increased,

the

Q

increases

until

the

filter

breaks

into

a

sine

wave

oscillation

at

the

cutoff

frequency.

The

FILTER

EMPHASIS

control

is

calibrated

by

resistor

R73.

The

cutoff

frequency

control

current

originates

in

an

linear

voltage

to

exponential

current

convertor

consisting

of

a

matched

NPN-PNP

pair

Q26

and

Q28.

Control

voltages

from

the

external

input,

the

key¬

board

switches,

modulation,

and

the

contour

genera¬

tor

are

summed

by

their

individual

control

resistors

and

fed

to

the

exponential

convertor.

Resistor

R49

sets

the

keyboard

scale

at

one

volt

per

octave

and

R39

calibrates

the

front

panel

filter

CUTOFF

FRE¬

QUENCY

control.

2.9

VOLTAGE

CONTROLLED

AMPLIFIER

The

input

signal

from

the

voltage-controlled

filter

is

AC

coupled

to

the

base

of

Q16.

Transistors

Q16

and

Q15

form

a

differential

input

transcon¬

ductance

multiplier.

The

gain

of

the

differential

amplifier

is

controlled

by

the

current

through

Q18;

the

greater

the

current,

the

higher

the

gain.

Tran¬

sistor

Q18

is

connected

to

the

loudness

contour

generator

which

gives

the

signal

from

the

VCF

its

overall

loudness

contour.

Resistor

R14

adjusts

the

common

mode

rejection

of

the

first

stage

to

mini¬

mize

pops

and

clicks

resulting

from

the

control

voltage.

The

output

of

Q16

and

Q15

is

fed

to

another

transconductance

multiplier

consisting

of

Q14

and

Q13.

The

control

voltage

for

this

multiplier

comes

from

the

EXTERNAL

LOUDNESS

control

input

jack,

J3.

This

shorting

jack

applies

a

positive

bias

which

keeps

the

VCA

stage

ON

when

external

con¬

trol

of

loudness

is

not

necessary.

When

an

1120

Foot

Pedal

controller

or

another

voltage

controller

is

plug¬

ged

into

J3,

this

internal

connection

is

broken

and

the

external

applied

control

voltage

controls

loudness.

Resistor

R12

balances

this

stage

to

minimize

pops

and

clicks.

Transistors

Q12

and

Q17

convert

the

differential

signal

to

a

signal-ended

output

voltage

which

is

routed

to

the

main

output

and

headphone

output

VOLUME

controls.

The

high

level

output

signal

appears

on

J4

while

a

resistor

divider

consist¬

ing

of

R57

and

R58

provide

the

low

level

output.

2.10

CONTOUR

GENERATORS

The

Minimoog

has

separate

contour

generators

for

both

filter

and

loudness

contours.

Each

contour

generator

has

its

own

separate

ATTACK,

DECAY,

and

SUSTAIN

controls.

The

final

decay

rate

is

equal

to

the

initial

decay

rate

and

is

selected

by

means

of

a

switch

on

the

left

hand

controller.

The

contour

generators

are

triggered

by

an

internal

voltage

trigger

from

the

keyboard

and/or

the

rear

panel

S-trigger

jack.

The

filter

contour

generator

consists

of

the

following

parts:

•

R-S

Flip-Flop

—

Q1

and

Q4

•

Attack

Time

Electronic

Switch

—

Q5

•

Decay

Time

Electronic

Switch

—

Q7

•

Sustain

Driver

—

Q8

•

Voltage

Follower

—

Q22

and

Q21

•

Trigger

Driver

—

Q20

•

Voltage

Trigger

Driver

—

Q12

•

ATTACK

TIME

Control

-

R12

•

DECAY

TIME

Control

-

R15

•

SUSTAIN

LEVEL

Control

-

R18

•

Amount

of

FILTER

EMPHASIS

Control

-

R17

When

there

is

no

external

S-trigger

applied

or

there

are

no

keys

depressed,

the

contour

generator

is

in

the

off

mode.

In

this

mode,

transistor

Q20

is

turned

off

and

therefore,

Q12

is

turned

on.

Current

is

fed

through

R37,

R35,

and

CR1

to

the

base

of

Q4,

holding

the

flip-flop

in

the

reset

mode.

Q12

shorts

CR2

and

CR7

to

ground

eliminating

the

sustain

voltage

and

discharging

C5

to

ground.

Therefore,

the

output

from

pin

11

of

the

contour

generator

is

ground.

When

any

key

on

the

keyboard

is

depressed,

the

following

events

occur.

The

keyboard

trigger

on

pin

20

of

the

contour

board

turns

Q20

on.

This

removes

the

reset

voltage

from

the

flip-flop

and

turns

Q12

off

removing

the

short

on

CR2

and

CR7.

The

voltage

rise

on

the

collector

of

Q12

is

AC

coupled

to

the

base

of

Q1

turning

the

flip-flop

on.

This

turns

Q5

on

putting

+9.3

volts

on

the

collector

of

Q5.

Current

is

then

fed

through

the

ATTACK

TIME

potentiometer

R12

to

C5

resulting

in

an

exponentially

rising

attack

voltage

on

C5.

The

resistance

of

R12

sets

the

RC

time

constant

and,

therefore,

the

attack

time.

The

voltage

on

C5

is

followed

by

Q22

and

Q21

and

appears

at

one

end

of

R33.

When

the

voltage

on

R33

reaches

approximately

5

volts,

CR3

conducts,

turn¬

ing

on

Q4

and

resetting

the

flip-flop.

This

turns

Q5

off

and

turns

Q7

on.

C5

is

then

discharged

through

the

decay

control,

R16,

to

the

sustain

voltage

on

the

emitter

of

Q8.

The

resistance

of

R16

sets

this

initial

decay

time.

The

SUSTAIN

LEVEL

potentiometer,

R18,

connected

to

pin

12,

sets

the

voltage

on

Q8

which

sets

the

sustain

level.

After

the

initial

decay

time,

C5

is

maintained

at

the

sustain

level

for

as

long

as

a

key

is

depressed.

When

all

keys

are

released,

the

contour

genera¬

tor

goes

into

the

final

decay

mode.

There

are

two

final

decay

modes

available

which

are

selected

by

the

final

DECAY

switch

on

the

Left

Hand

Controller.

In

the

final

DECAY

ON

position,

CR7

is

open

circuited.

When

all

the

keys

are

released,

the

emitter

of

Q8

is

shorted

to

ground

and

C5

is

discharged

through

R15

resulting

in

a

final

decay

constant

rate

to

the

initial

decay.

In

the

final

DECAY

OFF

position,

CR7

is

coupled

through

a

1.5K

resistor

to

the

collector

of

Q12.

When

all

the

keys

are

released,

Q12

discharges

C5

abruptly

resulting

in

no

final

decay.

The

output

from

pin

11

is

passed

through

the

AMOUNT

OF

CONTOUR

control

R17

and

then

to

pin

16

on

board

number

4.

The

AMOUNT

OF

CONTOUR

control

adjusts

the

sweep

of

the

voltage

controlled

low

pass

filter.

The

loudness

contour

generator

is

composed

of

the

following

parts:

•

Set

Reset

Flip-Flop

—

Q25

and

Q15

•

Attack

Time

Electronic

Switch

—

Q16.R13

•

ATTACK

TLME

Control

-

R13

•

Decay

Time

Electronic

Switch

—

Q13

•

DECAY

TIME

Control

-

R16

2-8

•

Voltage

Follower

—

Q3

and

Q2

•

Sustain

Driver

—

Q19

•

SUSTAIN

LEVEL

Control

-

R19

The

loudness

contour

section

also

utilizes

Q20

and

Q12,

the

trigger

drivers

and

the

final

decay

switch.

Operation

of

this

circuit

is

identical

to

the

filter

contour

generator.

Both

contour

generators

are

driven

from

a

de¬

coupled

supply

circuit

which

is

derived

from

the

+15

raw

DC

voltage.

Since

the

timing

capacitors

can

generate

10

milliampere

charging

spikes,

the

de¬

coupling

circuit

keeps

these

spikes

off

the

regulated

+

10V.

The

base

of

Q26

is

referenced

to

the

+10

voltage

so

a

+9.3

voltage

follower

appears

at

the

emitter.

An

external

S-trigger

is

connected

to

the

base

of

Q12

through

R42

for

use

with

such

acces¬

sories

as

the

Moog

SAMPLE

and

HOLD

and

RIB¬

BON

CONTROLLER.

2.11

A-440

REFERENCE

OSCILLATOR

The

A-440

Reference

Oscillator

in

the

Minimoog

is

based

on

a

standard

Wien

Bridge

oscillator

design.

The

Wien

Bridge

consists

of

the

following

parts;

R17,

C13,

R68,

R71,

C19,

R55,

and

R50.

The

input

of

the

bridge

is

connected

to

the

collector

of

Q9

and

the

output

of

the

bridge

is

connected

to

the

base

of

Q22,

where

it

is

amplified

by

Q22

and

phase

inverted

by

Q9.

At

approximately

440Hz

the

Wien

Bridge

has

a

phase

shift

of

zero

degrees,

supplying

positive

feedback,

and

the

circuit

will

oscillate.

The

fre¬

quency

of

the

oscillation

is

set

by

R68.

Capacitors

CR3,

CR4,

C12,

and

resistor

R27

limits

the

signal

amplitude

at

the