Manual Part No: 933929-01

MD Gas Convection Range Page 6 of 32

Manual Rev No: 1

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

This manual contains all the require information to ensure that your new appliance is installe correctly

an that you have all the information necessary to i entify an or er spare parts. It also contains

comprehensive instructions for the user an for cleaning the appliance.

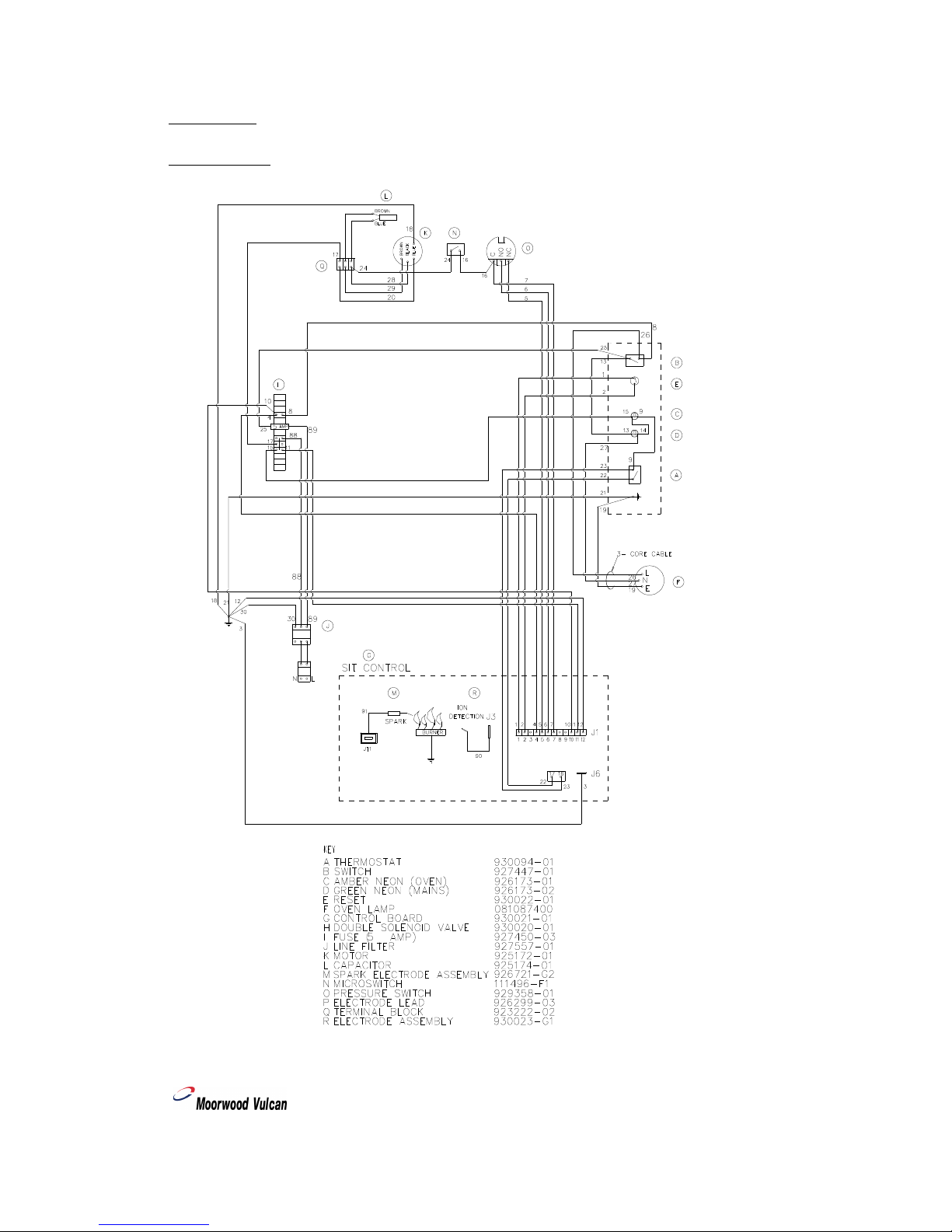

To maintain peak performance, it is recommen e that the appliance be regularly service an that

when or ering spare parts, reference be ma e to the appropriate list quoting the Part No. an the

escription.

THE FITTING OF A NON-STANDARD PART MAY VOID ANY GUARANTEE

.

All work carrie out on this appliance uring installation or servicing must be performe by a competent

person an the connection of the appliance to the gas supply

MUST

be carrie out by qualifie

personnel in accor ance, where applicable, with the relevant regulations.

The siting of the appliance an the connection to the gas/electrical supply must comply with the

GAS

SAFETY (INSTALLATION & USE) REGULATIONS 2000

: the requirements of the

FIRE PRECAUTIONS ACT

1971

; the

HEALTH & SAFETY AT WORK,

etc

ACT 1974

, the

BUILDING STANDARDS (SCOTLAND

)

CONSOLIDATION REGULATIONS 1971

. Detaile recommen ations are containe in British Stan ar s

BS5440: Part 1: 2000, BS5440: Part 2: 2000, BS5588: Part 0: 1996, BS5588: Part 11: 1997 & BS6173:

2001.

The installation must comply with the requirements of Local Authority Regulations an the wiring must

comply with the latest I.E.E. Regulations.

An easily accessible stopcock must be fitte in the gas supply a jacent to the appliance for use in an

emergency. In a ition a fuse isolator must be fitte in the electricity supply.

The etails of the gas supply will be foun on the Data Plate, which is locate on the rear of the flue

upstan /splashback panel.

WARNING

WARNINGWARNING

WARNING: THIS APPLIANCE MUST BE ELECTRICALLY EARTHED

Improvements

The policy of Manitowoc Foo Servi

Manitowoc Foo ServiManitowoc Foo Servi

Manitowoc Foo Service Lt .

ce Lt .ce Lt .

ce Lt . is such that, each pro uct is subject to continual evelopment

an may, therefore, be subsequently improve . The company reserves the right to alter the esign of

any appliance without prior notification an without responsibility to up ate any elivere or in-service

appliance an furthermore, without incurring the responsibility for altering these instructions. In such

circumstances, it may be foun that the appliance etaile herein iffers in certain respects from the one

supplie .

IT IS IMPORTANT, THEREFORE, TO QUOTE THE SERIAL No. AND THE APPLIANCE MODEL No. IN ALL

COMMUNICATIONS WITH THE COMPANY.