9

7 - USING THE STOVE

7.1 - Combustion

For an optimal combustion, it is essential that the-

re is a sufficient intake of combustion air inside the

combustion chamber. Therefore, it is appropriate

to verify that the external air intake is present and

is not obstructed, and that the combustion air inlet

tube on the rear of the stove is free from obstruc-

tions.

For a more efficient combustion, there are several

combustion air inlets inside the combustion cham-

ber: one primary air inlet and one secondary air

inlet.

The primary air is essential during the lighting up

phase and is fed into the lower part of the combu-

stion chamber; The secondary air is instead fed

into the upper part of the combustion chamber

and serves to improve combustion itself and help

keep the door glass clean.

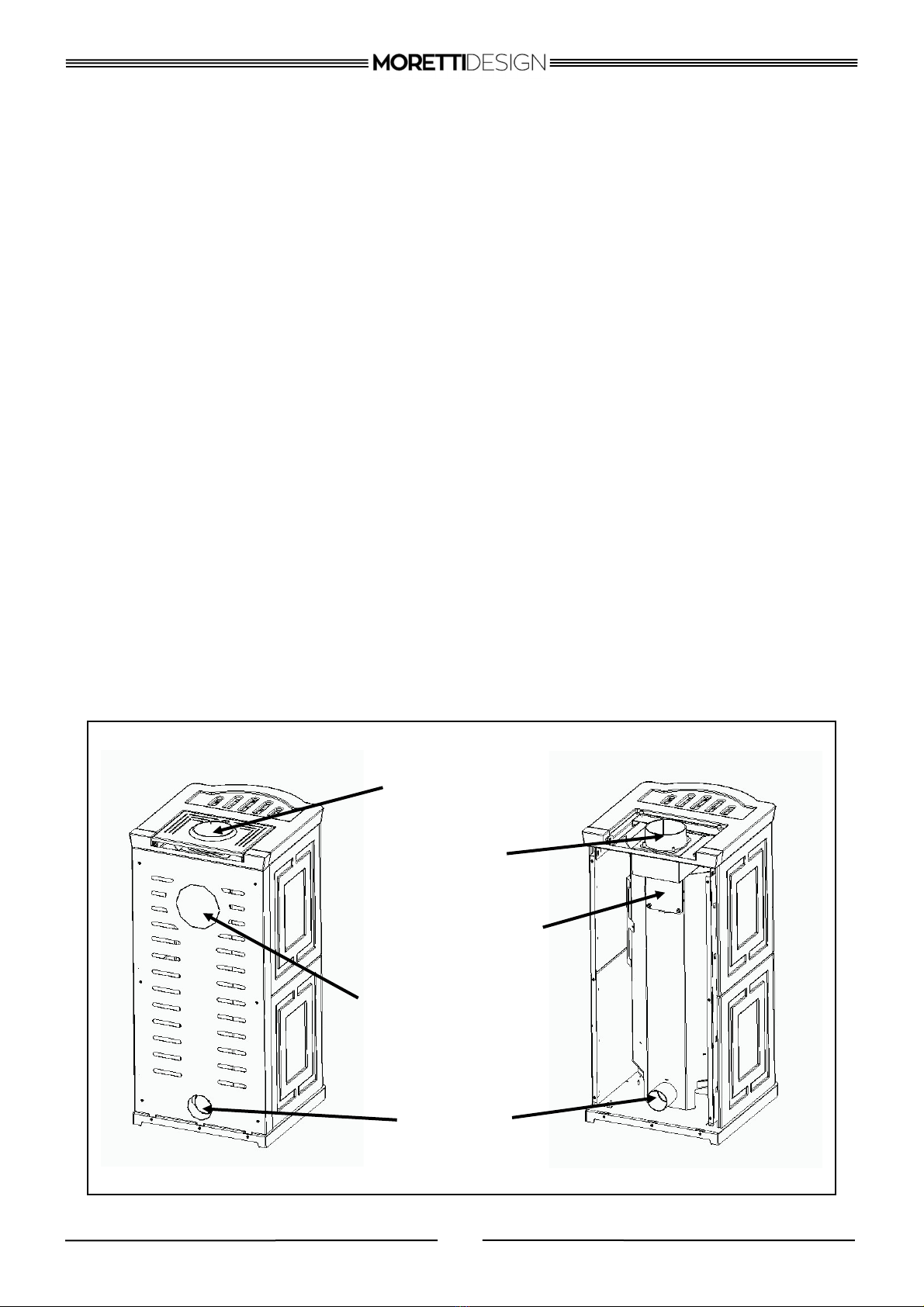

Both primary and secondary air are adjustable.

For an efficient combustion it is essential to regu-

late the right amount of air in the combustion

chamber, so as to also reduce emissions of

harmful gases into the environment. To best ad-

just primary and secondary air, act on the levers

shown in the figure below.

To open the air to the maximum, position the le-

vers towards the outside of the stove.

To completely close the air, position the levers

towards the center of the stove.

5 - PERMITTED FUELS

The stoves are designed for using wood. For a

high efficiency, the use of wood with humidity lo-

wer than 20% is recommended. For drying wet

wood, storage in a well-ventilated room for a pe-

riod of 2 years is recommended.

If wooden logs are used, they must be kept in a

dry environment so as not to compromise them

with excessive humidity. The use of excessively

damp wood or logs leads to a loss of efficiency of

at least 20%, to a higher fuel consumption and to

tar production which further reduces the efficiency

of the stove.

6 - INSTRUCTIONS FOR A SAFE USE

OF THE STOVE

It is absolutely forbidden to use flammable liquids

for lighting up and using the stove. It is also forbid-

den to burn any type of plastic, wood containing

chemical materials and other chemically treated

wood waste. Use only the permitted fuels listed in

paragraph 5.

Some surfaces of the stove, especially the front

glass areas, are subject to severe overheating and

can cause serious burns on touch. It is therefore

recommended to handle the stove with the utmost

attention when it is lit up or during the minutes

immediately after the flame is put out.

It is prohibited to place flammable materials on the

stove when in use or when it is still hot, it can igni-

te and cause a fire. It is forbidden to place any

type of container containing cold water on top of

the stove.

It is recommended to be extremely cautious when

removing hot ash. Hot ash must not come into

contact with flammable substances, for example

when they are emptied into a dustbin.

In the event the chimney catches fire, immediately

extinguish the flame in the stove by closing the

combustion air inlet through the special levers

(see paragraph 6.1), remove the hot ashes with a

small shovel and deposit them in a non-flammable

container. Contact the fire brigade immediately.

MORETTI DESIGN will not be held responsible for

any damage to people, animals or things resulting

from unauthorized modifications to the appliance

or from failure to comply with the indications provi-

ded here.

Secondary

air lever

Primary air

lever