5

EN

1. Description

The wood burning stove is made of a welded

steel construction. The central section fea-

tures the rebox, which is lined with safety

panels. The ash box is located below a sturdy

cast iron trivet. Below this is a space for stor-

ing wood.

Woodburningstovesofthisdesign work using

convection, i.e. the surrounding air is sucked

in by the convection shafts built into the stove,

heated to a high temperature and then blown

back out into the living area.

This wood burning stove has been tested in

accordance with EN 13240.

2. General

Your wood burning stove must be set up with

strict adherence to the relevant regional build-

ing regulations and following consultation with

the local professional chimney sweep.

Once installed, he will also check that the re-

place is connected correctly.

During operation, a replace will draw oxygen

from the room in which it is set up. It is there-

fore absolutely essential to ensure an ade-

quate supply of fresh air to this room.

If the stove is set up in rooms with particularly

tightly-closing windows and doors, malfunc-

tions cannot be excluded.

If you are uncertain whether there is sufcient

air available for the stove in the room in which

you plan to set it up, ask your chimney sweep

for advice.

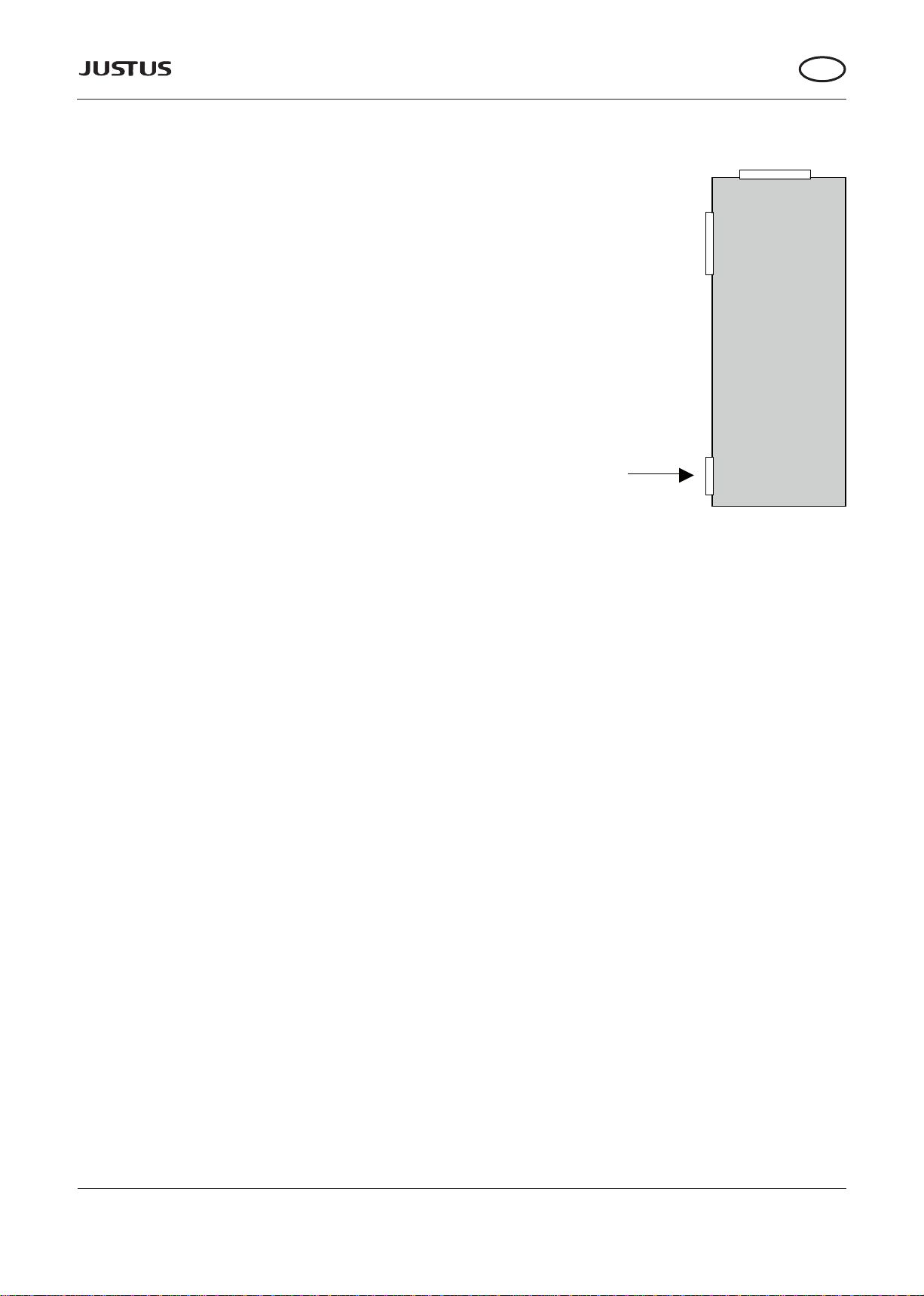

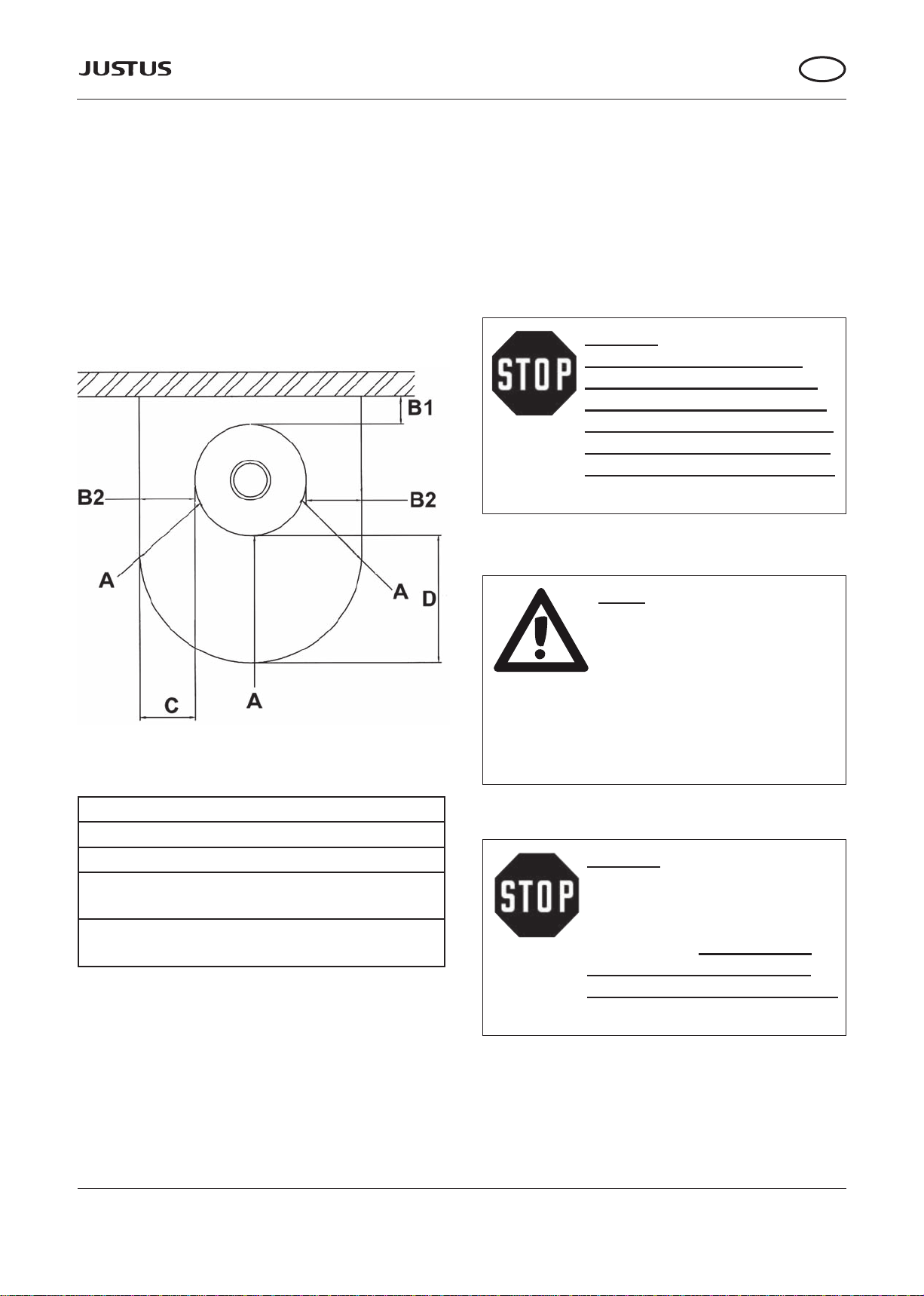

2.1 Externalcombustionairsupply

Ifnecessary,thewoodburningstovecan

beequippedwithaconnectionforanex-

ternal combustion air supply

(See Fig. 1):

For especially well-insulated rooms, an air

supply from outside can be connected. The

connection pipe required for this is available

as an accessory.

Wood burning

stove

Connection for

external combustion

air supply

Rear ue

tube opening

Upper ue tube opening

Fig. 1

When attaching an external combustion

air supply, ensure that the pipes are tightly

sealed!

The combustion air is supplied exclusively via

a supply pipe with a ND of 100 mm, tted dur-

ing installation. The air pipe should be made

from smooth steel or plastic (drainage pipe).

The full length of the pipe should be no longer

than 6 m, have no reductions in the bore di-

ameter and include no more than 3 90° elbow

pieces.

A safety grille attached in front of the exter-

nal air supply opening must not be able to

accidentally restrict or occlude the supply air

cross-section.

It can be connected to a suitable air exhaust

chimney.

In every case, care must be taken to ensure

that the combustion air requirement of around

30 m3/h is met at a feed pressure of 4 Pa.

When not in use, all air slides should be kept

closed to ensure that no cold air is able to cir-

culate via the chimney. The potential build-up

of condensation can be avoided

by insulating the air pipe.

The chimney draught must be able to over-

cometheadditionalresistancesofaring

systemequippedwiththissetup.