10

Morrison Bros. Co. ‑ Dubuque, IA ‑ 800‑553‑4840

915‑‑‑0142 PP

rev. 03-25-2020

Solenoid Output Verification

915S (if installed):

Ensure all proper connections are made with downstream air activated device.

Verify that:

• The downstream air activated device is fully functional.

915ST (if installed):

1. Set the Timer for 1 minute run time by turning the dial to the 1.

2. Press and release the Start/Stop button in the front panel of the 915ST.

Verify that:

• The Active Indicator now blinks … about one second on, one second off.

• The downstream air activated device is fully functional

3. Wait for the one minute then

Verify that:

• The ACTIVE Indicator stops blinking.

• The downstream air activated device is no longer functional.

Channel Alarm Verification

The following test should be performed on each Input Channel:

1. If the input device utilizes Normally-Open contacts, then connect the two wires together at the tank. If

the input device utilizes Normally-Closed contacts, then disconnect the two wires at the tank.

Verify that:

• The Channel indicator associated with the channel is blinking

• The Horn/Buzzer is sounding

• The Beacon is illuminated

• The Output Devices associated with the channel are in their alarm condition

EXAMPLE: If the channel is associated with Morrison Bros. Co. 915S or 915ST Solenoid unit(s),

the GREEN Active light should be extinguished

2. Acknowledge the alarm by pressing the “Test/Cancel” button on the front of the Solenoid Valve Unit.

3. Remove the alarm condition at the tank.

4. Connect the two Tank Sensor wires to the Tank Sensor

5. Simulate an alarm condition by moving the Tank Sensor oat into the alarming position

Verify that:

• The Channel indicator associated with the channel is blinking

• The Horn/Buzzer is sounding

• The Beacon is illuminated

• The Output Devices associated with the channel are in their alarm condition

EXAMPLE: If the channel is associated with Morrison Bros. Co. 915S or 915ST Solenoid unit(s),

the GREEN Active light should be extinguished.

6. Acknowledge the alarm by pressing the “Test/Cancel” button on the front of the Solenoid Valve Unit.

7. Remove the alarm condition at the tank.

Failure to follow any or all of the warnings and instructions in this document could result in a hazardous

liquid spill, which could result in property damage, environmental contamination, re, explosion, serious

injury or death.

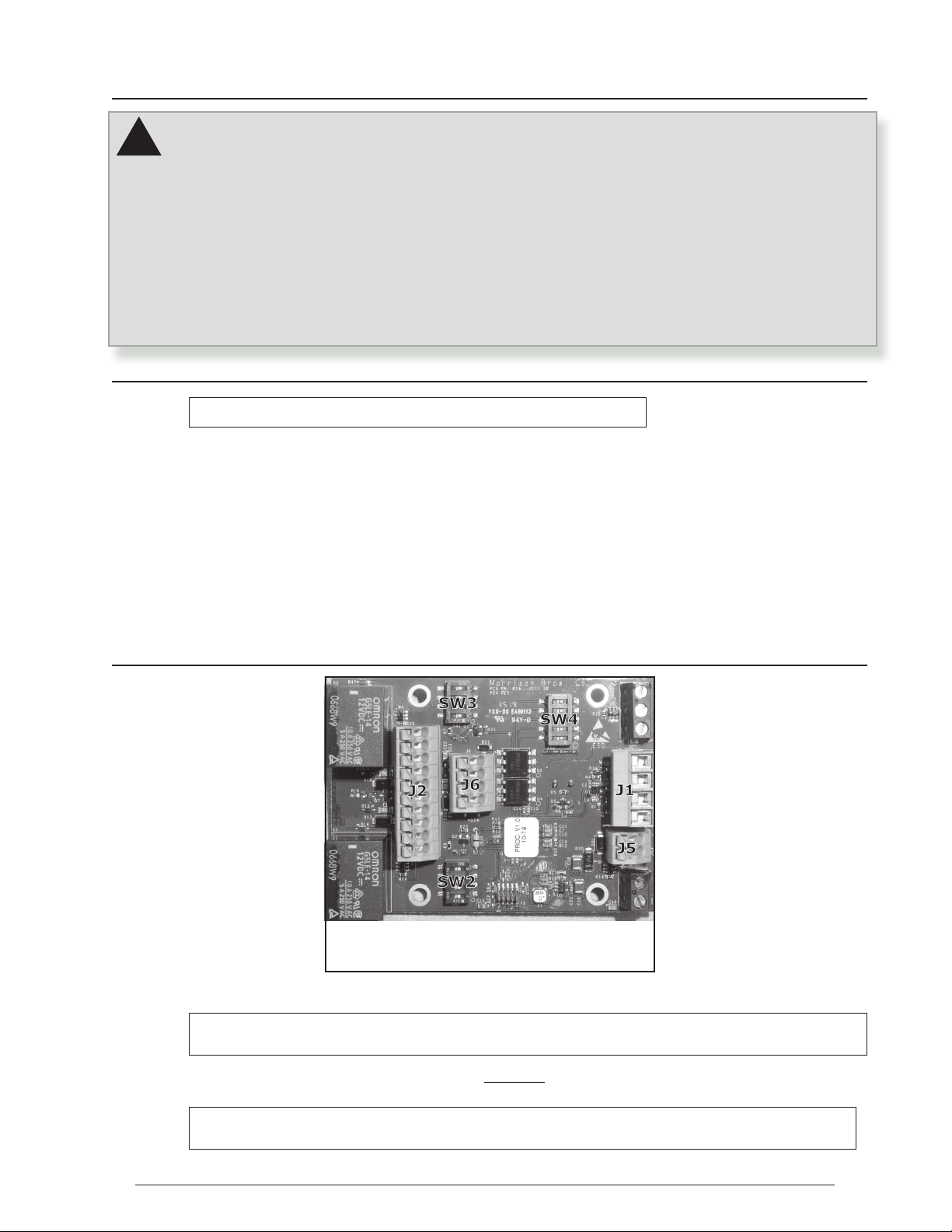

Operation

The 915 Alarm Console may be used in applications where one to two sets of Normally-Open or Normally-

Closed dry contacts are available. Two possible applications are used as an overll alarm or as a low level

alarm. These two uses are addressed below.

Use as an Overll Alarm

Use with the Morrison Bros. Co. 915 Tank Sensor or other similar input device.

1. At the beginning of each work shift press and hold the Test/Cancel button on the front of the 915 Alarm

Console for more than 3 seconds.

!