Infiltrator CM-1060 User manual

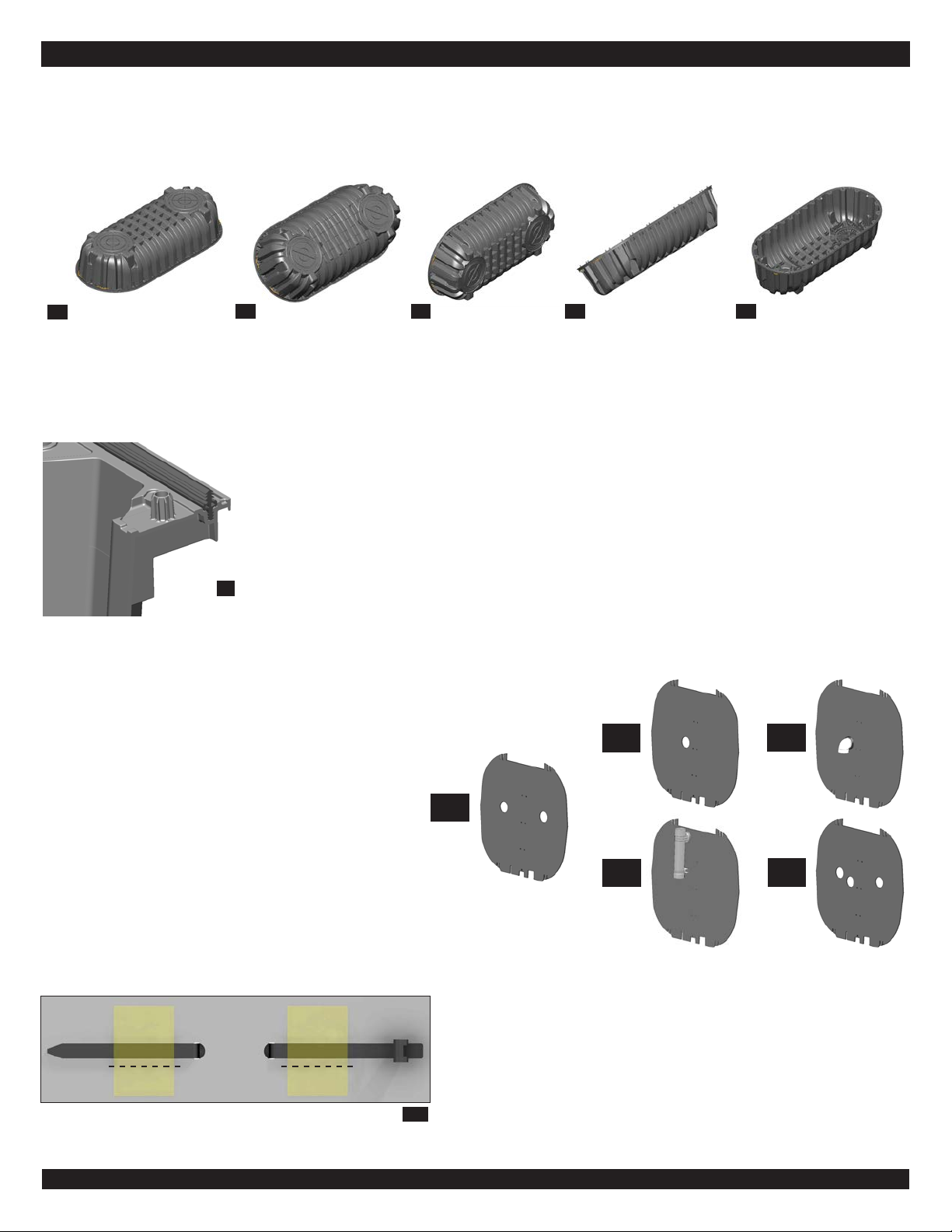

SupportPosts(2) SeamClips(64) Bae

Lids (2)

Before you Begin

The following is a complete list

of tank components:

•Tanktophalf

•Tankbottomhalf(withpre-installed

mid-seamgasket)

•Bae(two-compartmentcongurationonly)

•Seamclips(64)

•Supportposts(2)

•Lids(2)

•Lidshippingscrews(4)andwashers(4)

•Lidspacers(1)

•Lidscrewkits(2)

•Plumbingkit

The following tools facilitate

tank assembl

y:

•Forklift(5,000lb[2,268kg]capacity,

32”[0.81m]loadcenter,min.66”[1.68m]

arm,min.12’[3.66m]pickheight)

•InltratorLiftingStrapAssembly*

•22oz.[0.6L]spraybottle*

•16oz.[0.5L]liquidsoap*

•Utilityknife

•Coarse-bristledpaintbrush

•Metalhammer(16-20oz.[0.5kg])

•Rubbermallet

•Holesaw(5”[125mm]diameter)

•Nutdriver(3/8”,5/16”sockets)

•Cleanrags

•Headlamporashlight

•Screwgun

•Safetyglasses

*Supplied in Inltrator CM-1060 Starter Kit

Infiltrator CM-1060 Tank

Assembly Instructions

Itisrecommendedthataminimumoftwopeopleparticipatetosafelyassemblethetank.

Assemblers must wear safety glasses during the entire assembly. The top half of the

tankweighsapproximately169pounds(77kg)andthebottomhalfofthetankweighs

approximately162pounds(74kg)foratotalapproximateweightof331pounds(151kg).

Eachtankhalfmustbeliftedapproximately30 inches (750 mm) above groundduring

the assembly process. There must be enough side and overhead clearance to freely

maneuverthetankcomponentsandtooperateliftingmachinerywhenused.

TheCM-1060tankmustbeassembledbyanInltratorWaterTechnologiesAuthorized

Assembler. Tanks assembled by unauthorized assemblers will not be warrantied by

InltratorWaterTechnologies.AsignedcopyoftheCM-1060TankAssemblyChecklist&

AssemblyAuthorizationisrequiredforallAuthorizedAssemblers.

IMPLOSIONS MAY CAUSE SERIOUS INJURY

Follow Infiltrator Water Technologies, vacuum test instructions

NEVER EXCEED 2.5 inches mercury vacuum pressure

WARNING: These assembly instructions do not include a protocol for vacuum testing the CM-1060 tank. If required,

vacuumtestsontheCM-1060shallonlybeperformedinstrictaccordancewithInltrator’sCM-1060tankvacuumtesting

guidance documents. Failure to follow an Inltrator vacuum-testing protocol and/or exceeding 2.5 inches (63 mm) of

mercuryvacuumpressurecouldresultinpersonalharm.NeverapplyapositiveairpressuretotheCM-1060tank.Inltrator

willnotbeliableforanyproblemsthatarisefromsuchunauthorizeduse.

WARNING

Tanktopand

bottomhalves

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436

MARCH2022

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436

(2-compartmentcongurationonly)

AlignmentDowels(22)

Inltrator CM-1060 Tank Assembly Instructions Page 2

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436

Seam Clips (64)

LidScrewKit

P1PlumbingKit

Components CM-1060 Tank Pallet Handling

CM-1060palletsholdeither5or10tanks.

Overall Dimensions (for10-tankpallet)

• Stackedtanks:134”Lx62”Wx79”H(3.4mLx1.6mLx2.0mH)

• Stackedtanksonpallet:136”Lx67”Wx86”H(3.5mLx1.7mLx2.2mH)

Weight:3,600lbs(1,633kg)

Aforkliftthathasthefollowingminimumspecicationsisneededtosafelyhandleando

loadtheCM-1060pallet:5,000lb(2,268kg)capacity,32”(0.81m)loadcenter,minimum66”

(1.68m)armandminimum12’(3.66m)pickheight.

The tank halves must be safely removed from the pallet using the Inltrator Lifting Strap

Assembly.The CM-1060 tank pallets should never be tipped over!TheInltrator

Lifting Strap Assembly is sized to pick up a maximum of 4 tank halves at a time using

a forklift. The safety lock spring hooks are to be connected to the rope handles on the

endwallsofeach tank. Setthetankhalvesona clean surface topreventdamage or the

introductionofdirtanddebrisintothemid-seamareawherethegasket,gasketgroove,and

molded-indowelsarelocated.Setthetankhalvesonacleansurface,pallet,acrossseveral

4”x4”s, or a tarp to prevent damage or introducing dirt and debris to the mid-seam area

wherethegasketislocated.Neversetthetankhalfwiththegasketonanysurfacewiththe

gasketfacingdownward.

Tank Assembly

1.

RemoveallplasticwrapandstrappingfromtheCM-1060tankandcomponentsshipping

pallet.Ifserialnumbersneedtoberecorded,Inltratorrecommendsrecordingthemwhile

thetankhalvesarestackedonthepallet.Theserialnumberislocatedatthemid-seam

ontheoutletend.

2.

Using the Inltrator Lifting Strap Assembly, attach the four lifting strap hooks to

the CM-1060 rope handles, located two on either end of the tank bottom half.

Slowly lift the inverted tank bottom straight up and o of the tank top nested below.

WARNING: TThe Inltrator Lifting Strap Assembly supplied with the starter kit

is sized to pick up a maximum of four Inltrator tank halves at one time. Never lift

more than four tank halves at one time with the Inltrator Lifting Strap Assembly.

The Inltrator Lifting Strap Assembly is intended for use ONLY with Inltrator tanks

in accordance with these instructions; any other use of the Inltrator Lifting Strap

Assembly is prohibited. Inltrator Water Technologies will not be liable for any

problems that arise from unauthorized use of the Inltrator Lifting Strap Assembly.

Note: Never set the tank half with the mid-seam area facing downward without the use of

4”x4”s on a clean surface, pallet, or clean tarp to prevent damage or the introduction of

dirt and debris into the mid-seam area where the gasket, gasket groove, and molded-in

dowels are located.

3. Lift and set the tank bottom half down on 4”x4”s above a clean surface or pallet, to

preventdamage or the introductionofdirtanddebristothemid-seamareawherethe

gasketgroove,andmolded-indowelsarelocated.

2

3

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436

Inltrator CM-1060 Tank Assembly Instructions Page 3

4. RemovetheInltratorLiftingStrapAssemblyfromthetankhalf.Positionyourselfandyourassemblypartnerononesideofthetank.

Usingtwoofthefourliftinghandles,oneoneitherendofthetankhalf,liftandtilttheinvertedbottomtankhalf.Together,gentlyrollthe

tankbottomhalfontoitsatbasesothattheangegrooveandmid-seamgasketarefacingupwards.Placetherotatedtankbottomon

aclean,dry,levelsurfacesothatitisstable.

6. Identify the appropriate perforated bae port opening(s)

corresponding to the desired bae conguration below.

Carefullyremovetheperforatedopeningsbyknocking the

portcenterwithahammerormallet.Baeconguration25

shallbeusedinallstatesandprovinces,withthefollowing

limitedexceptions:

•15–Kentucky

•15E(requireselbowattachmentinbaeport)–

Alaska,Arizona,NewMexico

•15T(requiresteeattachmentinbaeport)–

Delaware,Pennsylvania

•35–Minnesota,Indiana

Note: If you are assembling a 15E bae, use the Inltrator

IM-1060 15E Bae Assembly Instructions document. If you

are assembling a 15T bae, use the Inltrator IM-1060 15T

Bae Assembly Instructions document. For all other bae

congurations, continue to Step 7.

7.Preparethebaetiewrapendsbyslittingthetapethatsecuresthem

tothebaeforshipping.Theslitshouldbemadejustaboveorbelow

thetiewrapendsandparalleltothelengthofthetiewrapends.This

willfacilitatefasteningofthebaetotheverticalsupportpostinStep

18.

4B

4A

5

6

(15)

6

(15T)

6

(25)

6

(15E)

6

(35)

slit tape

7

5.

Visuallyinspect the gasket toensurethat it isundamaged,seatedproperlyinthegrooveand freeof

materialsthatmaycompromisethewatertightnessoftheconnection.Thegasketinspectionshallinclude

anexaminationwhileviewingthetankfromboththetopandsideperspectives.Whenviewingfromthe

top,visually examinethegasketfordamage,anundulatingappearance(wherethegasketisnotfully

insertedintothegrooveanditsheightvaries),dirtanddebris,andanyothersignsofdefectordamage.

Whenviewingfromtheside,positionyoureyesatgasketheighttoevaluatetheheightofthetopofthe

gasketaroundthe entiremid-seamperimeter. Looking horizontallyacrossthe tank at mid-seam level

(fromtopofgaskettotopofgasketacrossthetankaxes),inspectthegasketalongthelongandshort

axesofthetank.Verifythatthegasketdoesnotundulate,wherethetopelevationofthegasketvaries.

Correctdecienciesifidentied.Ifthegasketisnotproperlyseatedinthegroove,manuallypressitinto

place.Useacoarse-bristledpaintbrushandcleanragstothoroughlyremoveanydirtordebrispresent

onthegasket.

4E4C 4D

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436

Inltrator CM-1060 Tank Assembly Instructions Page 4

8. Fold the tank baffle along the

perforationsasshown.Thefolds

are made toward the side of the

bafflewiththetiewrapends.

9. Insertthefoldedbaeintothebaeslotontheoutletsideofthetankbottomhalf.Theslotsonthebaebottomedgewillindexto

verticalribswithinthebaeslotonthetankbottomhalf.Thiswillresultinthetopfoldedportionofthebaepointingtowardstheoutlet

endofthetank.Donotunfoldthebaeatthistime.

10. Beforejoiningthetankhalves,lla22oz.(0.6L)spraybottlewith8oz.(0.25L)ofliquidsoapmixedwith14oz.(0.4L)oftapwater(1/3

+2/3mixture).Applyanevencoatofsoapywatertoallsurfacesoftheexposedgasketalongitsentirelength.Spraythegasketdirectly

fromabovesobothsidesofthegasketarelubricatedequally.Applysoapywatertoallowplacementofthetanktophalfwhensurfaces

arestillwet.ThiswillfacilitateengagementofthegasketinthegrooveonthetanktophalfduringtankassemblyinStep12.

8A

9A 9B 10

8B 8C

8D

11. UsingtheInltratorLiftingStrapAssembly,attachthefourliftingstrapstotheCM-1060rope

handles,locatedtwooneitherendofthetanktophalf.Slowlyliftthetanktopstraightupand

oofitslocation.

12.The CM-1060 features molded-in alignment dowels. The

molded-inalignmmentdowelsandreceivingholesalternate

between corrugations in the CM-1060 bottom and top

halves.Carefullylowerthetanktophalfontothetankbottom

half,aligningthetopandbottomtankhalfalignmentdowels

with the corresponding receiving holes. Once the top half

hasbeenloweredontothebottomhalf,positionyoureyes

atgasketheight andevaluatetheseam. Inspecttheseam

aroundtheentireperimeterofthetank.Visuallyinspectthe

seamandverifythatthegasketissecurelyseatedwithinthe

gasketgrooveofthetanktopandbottomhalves.Verifythat

theInltratorLiftingStrapAssemblyisnotcaughtwithinthe

seambeforeproceedingtoStep13.

13.

Identify clip-attachment locations along the mid-seam where the straight

sidewalltransitionstothecurvedendwall,asshowninimageNo.13A.Two

clips are attached at each of four locations at the inlet and outlet ends of

thetank as shown. At eachclip attachment location, push the top tank half

downwardtoengagethegasketinthetoptankhalf.Foralleightclips,place

theopensideofa seam clip against the joined seam rail of the tankhalves

at a 45-degree angle relative to the seam rail. These seam clips must be

attachedalongtheseamrailfromtheoutsideintowardsthetankcenterline.

Usingahammerandholdingthetopandbottomsidesoftheseamclip,tap

theseamclipalongthetankseamrail;theclipwillpulltowardtheseamrail.

Engagethecliptoafullstopoverthelockingtabs;theseamclipwillclickinto

placewhenproperlyengaged.Theseamclipisdesignedtolockinplacewith

twoorthreeswiftblowsofahammer.Ifsubstantialresistanceisencountered

13A

11

12A

12B

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436

Inltrator CM-1060 Tank Assembly Instructions Page 5

15. Slowlyrollthejoinedtankontoitssidealongitslongaxis.The

tankwillresttiltedasshown.Donotover-rotatethetankordrag

thetankalongthemid-seamfromthisposition,asdoingsomay

damagethetank.

Note: If you are assembling a one-compartment tank conguration

without a bae, then proceed to Step 17. Otherwise, continue to

Step 18.

16. Reachinthroughtheaccessopeningandunfoldthetankbaeandinserttheunfoldedtopcornerbaesectionsintothebaesloton

thetanktophalf.

15A

16A 16B 16C 16D

15B

17B

17. Insertthesupportpostthroughthetankaccessporton

theinletside of thetank.Placeone end ofthepostinthe

bottomcorrugationwiththepostseat,beyondthepostseat.

Do not yet engage the post end in the bottom post seat.

Swingtheoppositepostendintothesamecorrugationwith

thetoppostseat.Donotyetengagethepostendinthetop

postseat.Onceeachpostendisinsidethesamecorrugation

withthepostseats,thepostbottomcanbeinsertedintothe

bottomseat,andthenthetopcanbeinsertedintothetop

seat.Arubbermalletmaybeusedtofacilitateproperpost

seating. Repeat this process with a post through the tank

accessportontheoutletsideofthetank.Useaheadlamp

orashlightasneeded.

17A

CAUTION! Do not use a metal hammer to strike the support posts as this may cause permanent damage.

Note: If you are assembling a one-compartment tank conguration without a bae, then proceed to Step 19. Otherwise, continue to Step 18.

14. Usinganutdriverwith3/8”socket,unscrewand

remove the two lids from the tank top half (two

#14 hex-head shipping screws with washers per

lid)andspacers.Setthelidsasideandreservethe

four shipping screws, washers and spacers for

lateruseinStep22.Iftheinletandoutletholesare

pre-drilled then spacers are not needed and will

notbepresent.Optional: The lids can be removed

prior to Step 11 if preferred.

14A

engagingtheseamclips,removethetopofthetankandinspectthegasketfordamage,anundulatingappearance(wherethegasket

isnotfullyinsertedintothegrooveanditsheightvaries),dirtanddebris,andanyothersignsofdefectordamage,asdescribedinStep

5.Onceengaged,theseamclipcannotberemovedwithoutdamagingtheseamcliporthetanklockingtabs.Attachtheadjacentclip.

Attachtheremainingsixendclipsinthesamemannertonishthisstep.ThiswillmaintainseamconnectivityduringassemblySteps15

to19thatrequiretiltingthetank.Optional: All seam clips can be installed at this point of the assembly if preferred.

13B 13C 13D

14B

Table of contents

Popular Tank Equipment manuals by other brands

Astro Pneumatic Tool

Astro Pneumatic Tool PT2-4 quick start guide

Franklin Fueling Systems

Franklin Fueling Systems EVO 600 Operation guide

TransTank

TransTank TopCrop Operator's handbook

WELBA

WELBA TW-32 quick start

Amtrol

Amtrol FILL-TROL FT-109 Installation & operation instructions

Regulus

Regulus RBC 200 Installation and operation manual