Denali 66’’ & 72’’ Plow

Blade & Pushtube Assembly

23001

Industrial Blvd Rogers, MN 55374

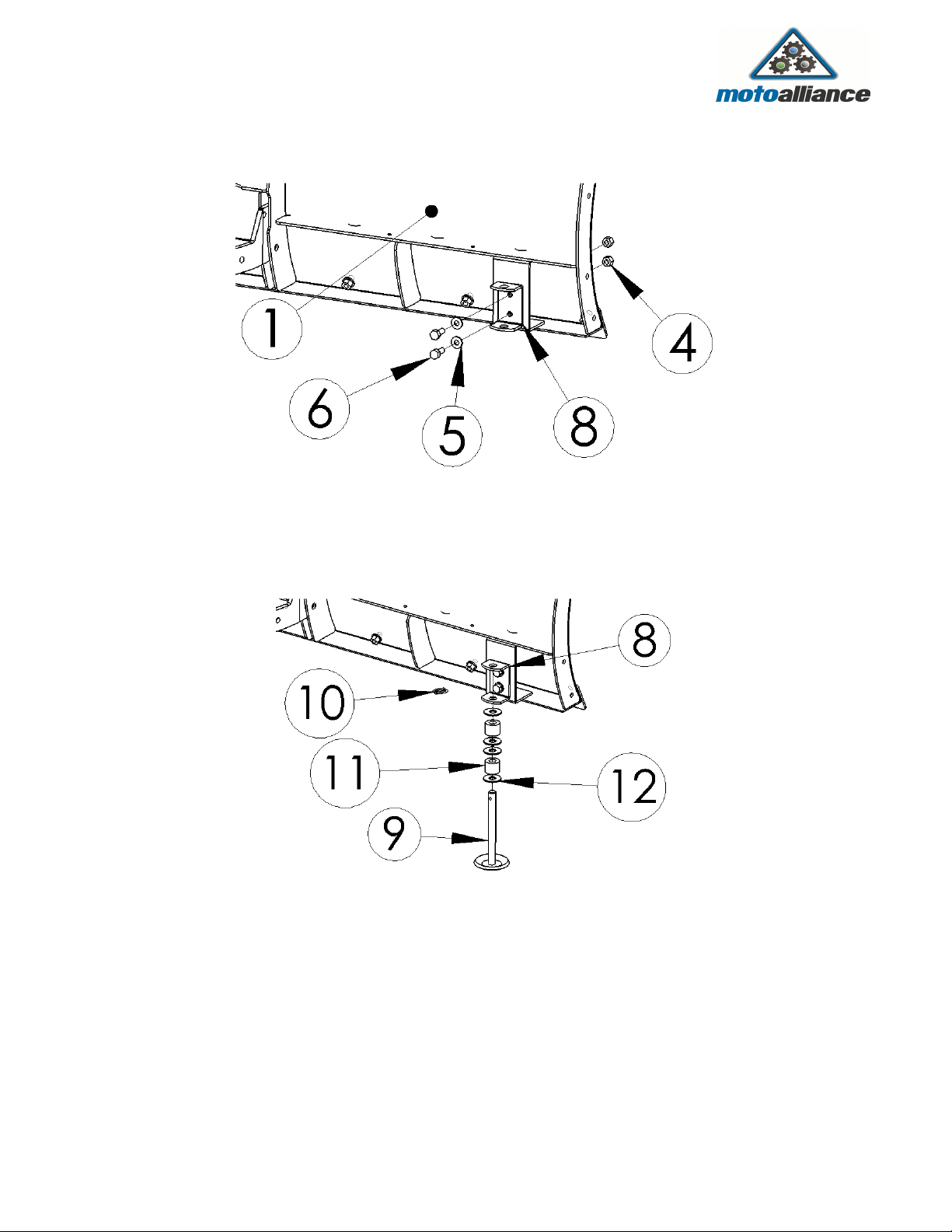

Pushtube Assembly Hardware List

Verify that your Pushtube box includes the following hardware.

ITEM

NO.

Part Description Quantity Reorder

SKU

12 1/4''-20 x 1.5'' Hex Head olt 1 -

13 1/4''-20 Nylock Nut 1 -

14 1/4'' Flat Washer 2 -

15 1/4'' ID Aluminum Spacer 1 -

16 3/8''-16 x 1'' Hex Head olt 11 -

17 3/8'' Flat Washer 17 -

18 3/8''-16 Nylock Nut 2 -

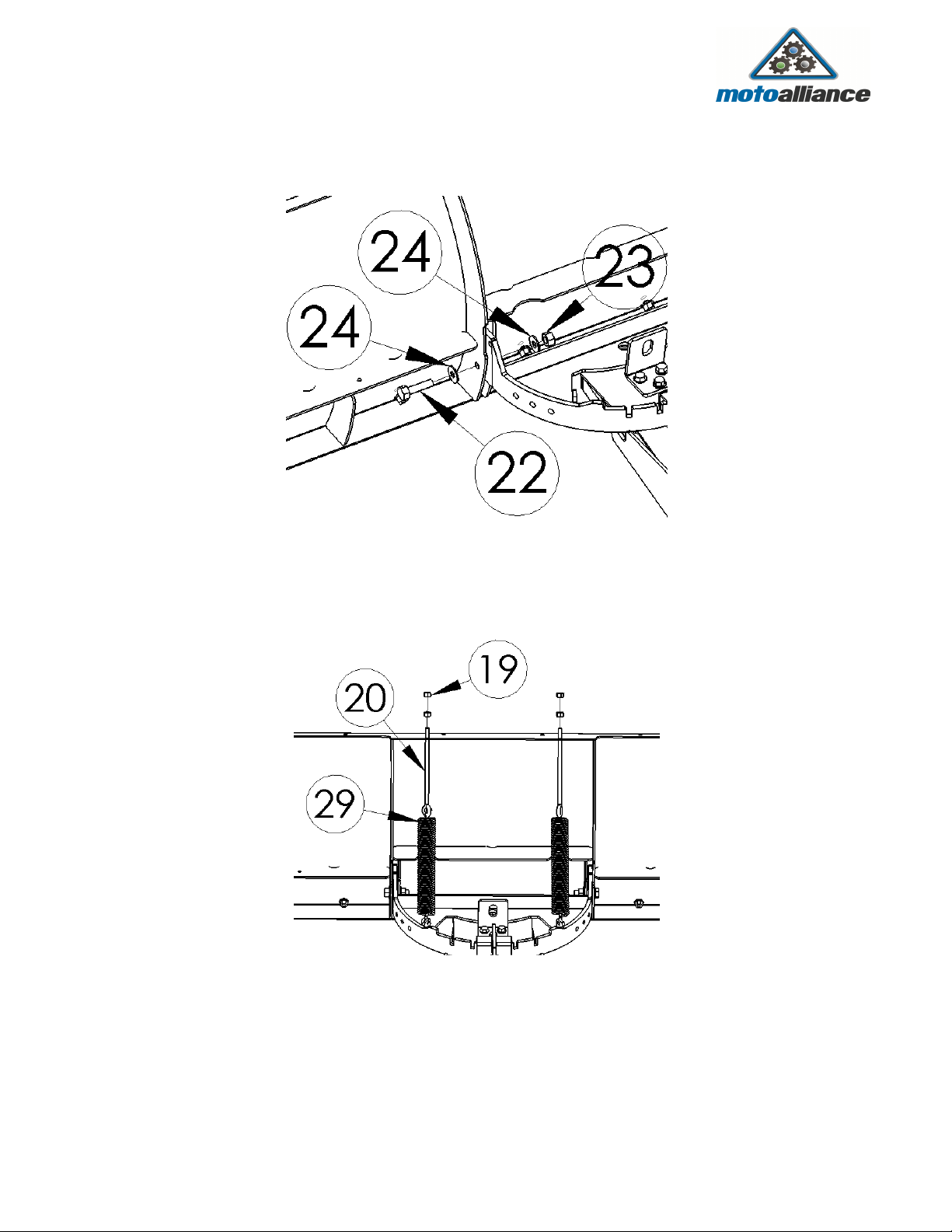

19 3/8''-16 Regular Nut 4 -

20 3/8''-16 x 8'' Eye olt 2

21 3/8''-16 x 1.5'' Hex Head olt 2 -

22 1/2''-13 x 2'' Hex Head olt 2 -

23 1/2''-13 Nylock Nut 2 -

24 1/2'' Flat Washer 4 -

25 5/8''-11 x 2'' Hex Head olt 1 -

26 5/8''-11 Nylock Nut 1 -

27 5/8'' Flat Washer 1 -

28 5/8'' ID Step Spacer 1 -

29 10'' Extension Spring 2

30 Lock Lever Spring 1

31 Stop lock 2

32 Quick Release Pin 2

33 Quick Release Pin Washer 2

34 Pivot Lever Support racket 1

35 Pivot Lever Riser 2

36 Pivot Lock Lever 1

37 Winch Attachment racket 1

38 0.030 spacer for 5/8’’ ID Step 1

Figure 5