MPH Industries SpeedLaser B User manual

USER'S MANUAL

PLEASE SEE BACK COVER FOR CONTACT

INFORMATION REGARDING REPAIRS AND

SALES

P/N 40150-66-MPH

(For Version 6.70 and above)

Disclaimer: The information contained here is accurate and reliable to the best of our knowledge at time of printing and is subject

to change without notice. No responsibility is assumed by MPH Industries for use of this information. MPH Industries, its logo,

Laser Atlanta, its logo and Advantage™, ProFiler™, SmartCharger, SpeedProof™, wiDAR™, SmartAdaptor™ & SpeedLaser®

are trademarks of MPH Industries, Inc. All other trademarks are the property of their respective companies. Patent Numbers

6,108,071; 7,286,955; 7,493,086 © 2012 MPH Industries, Inc. All rights reserved.

TABLE OF CONTENTS

1 INTRODUCTION......................................................................5

Cautions:..........................................................................6

Capabilities ......................................................................7

2 GETTING STARTED.................................................................9

Packing List .....................................................................9

SpeedLaser®Controls & Layout ....................................10

Battery Handle Power....................................................12

Connecting a Handle .....................................................13

To Power ON.................................................................14

To Power OFF................................................................14

3 SPEED MEASUREMENT ........................................................ 15

Speed Detection .............................................................15

Approaching and Receding Targets ..............................15

Approaching and Receding Targets ..............................16

Manufacturer’s Recommended Daily Test.....................17

4 USER SETTINGS ........................................................................... 21

Intensity and Contrast ...................................................21

LCD Backlight................................................................21

LCD Contrast.................................................................21

HUD Brightness.............................................................21

The MENU System ........................................................22

Main Menu ....................................................................25

Test Mode ......................................................................26

Audio.............................................................................27

HUD Mode ....................................................................28

AIMING MENU ............................................................29

Obstructed Mode ...........................................................32

5 APPENDICES................................................................................. 33

Do not copy 3

Appendices: Page #

A: Troubleshooting / Error Messages 33

B:CareandMaintenance 34

C: SpeedLaser® and Accessory Diagrams 36

D: Measuring Surface Datum 37

E:LIDARMenuTree 39

Warranty 38

Do not copy 4

CHAPTER 1 Introduction

Thank you for purchasing the SpeedLaser®. This rugged laser speed

detection device integrates the latest in solid-state laser technologies to

bring you hand-held, eye-safe laser speed and distance measurement.

The SpeedLaser®is a Class 1 eye safe, multi-function device generally

used to calculate range and speed of targets at a distance. Depending on

reflective characteristics of the targets, the environment and other

factors, distance may vary.

The technology utilized by the SpeedLaser®is called LIDAR: LIght

Detection And Ranging. Your SpeedLaser®measures the time it takes a

pulse of laser light to travel from the LIDAR to the target vehicle and

back (pulsed time-of-flight). This round trip time is converted to a

distance (d=ct/2). The distance to the target vehicle is calculated in this

manner over two hundred times per second. Sophisticated computer

algorithms combine these individual range calculations to compute the

extremely accurate speed displayed. The IACP lists this device on their

product list (CPL) after testing to their specifications.

To get the most from your new SpeedLaser®, please take the time to read

through this manual. For your convenience and ease of understanding,

it has been divided into 5 sections:

Chapter 1: Introduction

Chapter 2: Getting Started

Chapter 3: Speed Measurement

Chapter 4: User Setting’s

Appendices: Information on care, troubleshooting, and

specifications

If you have questions or comments, please do not hesitate to contact us.

PLEASE SEE BACK COVER FOR CONTACT

INFORMATION REGARDING REPAIRS AND SALES

Do not copy 5

Cautions:

Every step has been taken to ensure your SpeedLaser®is completely safe to use.

However, certain common-sense precautions should always be taken when using

your SpeedLaser®.

•Do not open the LIDAR unit’s housing under any circumstances.

•Do not point the SpeedLaser® directly at the sun.

•Use only MPH Industries approved power sources and accessories.

(use of unauthorized accessories may void the warranty)

•Do not store SpeedLaser®in areas of high humidity.

•Do not place SpeedLaser®on unstable surfaces.

•Always transport the SpeedLaser®in its carrying case.

SpeedLaser®is a Class 1 Laser Product which does not exceed a PRF of 240Hz,

a Pulse Width of 100 nsec nor a laser power of 238 uWatts, and has a Class 1

Laser Product label in the serial number window (see index D on the Layout

Figures found on pages 11 & 12).

Caution: The use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Any certifications included are void if the product is opened, altered, installed in

other equipment or used for purposes other then intended by the manufacturer.

Using any charger other than those supplied by MPH Industries will also void

the certification.

Although optical viewing instruments may increase eye hazard, it is unlikely

that actual damage can occur. Prescription eyeglasses, contact lenses, and

sunglasses are not considered optical gain devices since they merely correct the

focus of the human eye to normal.

Optical devices that provide magnification may increase the risk of eye-hazard.

These include binoculars, telescopes and magnifying glasses.

Certain municipalities and countries require settings to differing measurements

(mph or km/h). Your unit is factory set to the appropriate unit of measurement.

The pictures/drawings/illustrations in this manual are for illustration only and

are shown in miles per hour and feet as well as kilometers per hour and meters.

Do not copy 6

Capabilities

Performance

•Target Acquisition in 0.3 seconds

(Dependent on environment and reflective characteristics of target)

•Speed Accuracy of one unit of measure

Advanced Input-Output

•Remote Fire trigger switch

•Full Remote control via RS-232 port

•Data Collection via RS-232 port

Ease of Use

•Menu Driven

•Head Up Display (HUD) shows both target and speed or distance

data through the same sighting mechanism

•Optional Rechargeable NiMH or 9 volt Battery Handle

•Optional 12 Volt Cigarette Adapter

•Optional 8X Monocular (S & R only)

•Optional Monopole (S & R only) and Tripod for mounting

•Optional Mapping system upgrade (S & R only)

•Optional USB/SD Memory Drive

Environmental Features

•Water Resistant (R = IP67, optional for B & S which are IP56)

•Ruggedized Housing

•Rechargeable NiMH Battery Handles (S & R only, B batteries

are NiMH internal)

Do not copy 7

Optional accessories, carrying

cases and cords in a variety of

styles are available.

All four models of the SpeedLaser® use the same display and

user interface. The four different keypads are shown below. Any

feature or function shown on one display or key board is available

on all models. The menu tree described through out this manual

is used with all of the key pads:

Do not copy 8

Chapter 2

Getting Started

PACKING LIST

Please check to make sure the following items that were ordered are

included in your shipment, such as:

•SpeedLaser®LIDAR Unit

•Battery Handle (S, T & R only; optional on B)

•Carrying Case

•Battery Charger (if applicable)

•12 volt Charging Cable (if applicable)

•User's Manual

Additionally, you may have received the following optional parts:

•RS-232 Serial Data Cable

•8X Monocular

•Additional Battery Handles

•Additional optional charging cords and accessories

(Please see Appendix C for diagrams of some of these items.)

Do not copy 9

SpeedLaser®Controls & Layout

(Typical – wording may vary in different versions.

Drawings are for illustration only.)

B

A

G

FIRE

BACK

←

POWER

LCD

MENU

HUD

LASER

A

TLANTA LLC S/N: 23456

NORCROSS, GA 30071 Class 1 Laser Produc

t

B C D

H

D

F

E

ENTER

A

C

A: Head Up Display (HUD) E: Liquid Crystal Display (LCD)

B: HUD Sighting Reticle F: Keypad Keys

C: HUD Character Display G: Rear Bumper (R model only)

D: Serial #, Laser Warning H: Optional Memory Drive Slot

Do not copy 10

I J

I: Transmit Optics M: Battery Handle (most models)

J: Receive Optics N: External Data/Charging Port

K: Handle Trigger (Tripod mountable handle

L: Handle Latch has data port on the side)

O: Laser Warnings (Alternate

Location Select Models Only)

Do not copy 11

Battery Handle Power

The SpeedLaser® may come equipped with a rechargeable battery handle

shipped uncharged (B batteries are internal). You may need to charge it

completely (10-12 hours) with the wall charger or 12 Volt cigarette cable

before first use. Each handle provides an average of 8 hours or more of

continuous use per charge (hours vary based on use and conditions).

These handles, and the B model with internal batteries, are also capable

of powering the SpeedLaser from a 12V source such as an automotive

cigarette power adapter using the cable if provided. Plug the small

circular connector onto the Charging Connector on the side of the handle

and the cigarette adapter end into an automotive cigarette-power adapter.

You can charge the handles in this manner while operating the unit. A

Power Handle connected to a B will charge the internal batteries. While

the 9v handle can be used with the B it is not efficient.

To charge your battery:

1. Plug the circular connector into the Charging Connector on the

side of the handle or bottom of B. Do not force the connector as

it is keyed...slowly rotate the connector (holding the black

rubber) and push gently until it clicks and locks into place.

2. Plug the charger into a standard 120 VAC power receptacle OR

plug the cigarette adapter into a power source.

3. Charge the batteries for ten to twelve hours.

4. To remove the connector, pull gently away from the handle on

the outside of the metal connector.

5. Unplug the charger from the wall. The batteries are charged.

CAUTION! DO NOT:

•Charge batteries with chargers not supplied by MPH Industries.

•Short circuit the battery pins

•Charge batteries for over sixteen (16) hours continuously

Do not copy 12

Green Charging Light

Charging Connector

Connecting a Handle

(All Models and B models equipped with handle mount)

To install a handle onto the SpeedLaser®:

1. Press the Handle Latch forward on the handle.

2. Push the front of the handle into the front Handle Catch on the

bottom of the SpeedLaser®.

3. Rotate the rear of the handle upward.

4. Release the handle latch.

NOTE: Make certain the handle latch slides into position and secures the

handle to the SpeedLaser®. If necessary, push the handle latch toward the

back to secure the handle to the SpeedLaser®.

Do not copy 13

Turning the SpeedLaser®ON and OFF

TO POWER ON

1) Press and hold the PWR key located on the back of the

SpeedLaser® for approximately one second.

NOTE: The hardware and software Built In Test (BIT) automatically

runs when the unit is first powered ON. When BIT is completed

successfully the LCD will display “SYSTEM READY.” or

“Self-Test Passed”. Either indicates that the BIT has been completed

successfully.

TO POWER OFF

1) Press and HOLD the PWR key on the back of the

SpeedLaser® (see note) for approximately three seconds.

NOTE: Keep the key pressed until “POWERING DOWN” is displayed

on the LCD then release the keypad. If the button is not depressed for a

long enough time, it toggles the LCD backlight ON and OFF.

Laser Atlanta

SpeedLaser

P/N YYYYY-EEEE vx.xx

SYSTEM READY.

LCD HUD

A B C D

FIRE

PWR MENUBACK

Power Key

Do not copy 14

Chapter 3

Speed Measurement

When the SpeedLaser®is first turned ON, it automatically and quickly runs the

Built In Test (BIT) functions. To capture a speed, simply follow the procedure

below when the BIT is complete.

SPEED DETECTION

NOTE: Always verify operational procedures for Alignment Check.

1. Align the HUD Sighting Reticule (+ symbol in the HUD) on the target

you wish to measure the speed of.

2. Squeeze and hold the Handle Trigger (on B press the fire button on top)

until the speed is displayed.

3. Release the Handle Trigger (or fire button) to stop measurement,

momentarily display the information in the HUD and lock information

on the LCD. The LCD displays the information until one of the

following occurs:

a.) The laser is fired.

b.) The unit is powered down (by the operator or typically after

about 10 minutes of inactivity) or

c.) The menu button is pressed.

The speed will be shown in three places…twice on the rear right of the LCD and

also momentarily in the HUD (when selected) character display. Notice that two

of the speed displays are truncated to the nearest mph or km/h.

The distance to the target will be shown on the left side of the LCD.

- 13

HUD

S

p

eed

NOTE: Pressing the trigger/fire button will take you to the Speed Display Page

regardless of any other mode the SpeedLaser® may be in. (The exception is

when in the TEST mode.)

LCD

Range

Display

Do not copy LCD

Speed

Display

15

APPROACHING AND RECEDING TARGETS

The SpeedLaser®can measure the speeds of both approaching

(oncoming) and receding targets.

When the target is receding, a “-” sign will precede the speed displayed

in the HUD and on the LCD.

Example of an Approaching target

Oncoming

Target

(No “-“ sign)

Example of a Receding target

-13

Recedin

g

Target

Receding

Target

(“-“ sign)

Do not copy 16

Oncomin

g

Target

34

Manufacturer’s Recommended Daily Test

In keeping with NHTSA (National Highway Traffic Safety

Administration) and IADLEST (The International Association of

Directors of Law Enforcement Standards and Training) guidelines

general operational considerations for LIDAR Speed Measurement

devices, the operator must perform the following accuracy checks prior

to beginning enforcement operations:

1) Internal Circuit Check

2) LED Segment Test

3) Range (Chronometer) Accuracy Test

4) Horizontal Sight Alignment Test

5) Vertical Sight Alignment Test

WHAT THE DAILY TEST ACCOMPLISHES:

To ensure that the SpeedLaser®is in good working order, the

SpeedLaser® should be tested using the Manufacture’s daily test

described later in this chapter. This test restores the factory default

settings, checks the LIDAR hardware (including the program and

dynamic memories), tests the displays and timing circuits, and then

allows the operator to verify that the HUD aiming crosshairs are

correctly aligned with the laser beam.

NOTE: The alignment crosshairs in the HUD are set at the factory and

generally do not need realignment over the life of the SpeedLaser®.

1) Internal Circuit Check

When the operator presses Menu, followed by Test, (button A on the

keypad), the SpeedLaser® runs a BIT (Built-In-Test) program. The

BIT program tests the hardware and software by verifying that the

SpeedLaser® firmware is loaded correctly and then checking that the

processor is executing the data gathering, storing (memory), sorting,

filtering, conversion and linear regression algorithms correctly.

2) HUD’s LED Segment Test

This test allows the operator to verify that the seven-segment display,

used to show speed of the target vehicle, is in good working order by

displaying a simple known pattern. The operator can then confirm that

each segment operates correctly and verify the presence of the aiming

reticle.

3) Range (Chronometer) Accuracy Test

Do not copy 17

The SpeedLaser®hardware ONLY measures Time. Range and

Speed are computed values derived from multiple time

measurements by the firmware, which was checked for proper

operation during BIT. The design and accuracy of the firmware was

verified as part of the IACP certification and subsequent testing

processes.

This test uses the SpeedLaser®’s high-speed chronometer (timer) to

measure the time it takes a light pulse to travel a known distance

(i.e.; from the SpeedLaser® to a target at a known distance and back).

Since the speed of light in air is known, the SpeedLaser®can

calculate the range that the light pulse traveled. The operator then

compares the reported range to the known distance to the target. To

verify that the timing hardware is working correctly the computed

range must match the known distance to within ±1 foot (30 cm). At

least two such comparisons using targets at least twenty (20) feet (6

meters) apart must be made.

In normal operation, the SpeedLaser® measures the time it takes for a

light pulse to travel from the SpeedLaser®to a moving vehicle and

back. The SpeedLaser® makes hundreds of such round trip time

measurements each second, each time measurement is converted to a

range and stored. When the SpeedLaser®has sufficient stored

ranges, it performs a linear regression calculation that yields the

speed of the vehicle. Numerous firmware filters are used to confirm

the computed speed before it is displayed.

4) Horizontal Sight Alignment Test

This is a test to confirm that the sighting system and the invisible

light pulse emitted by the SpeedLaser® are aligned horizontally. The

operator uses the sighting system to aim at an object and then

confirms that the light pulses of the SpeedLaser®are hitting that

object by observing that the SpeedLaser®is reporting the range to

that object. The operator then moves the sighting system off of the

object and observes that the reported range changes, just as the

sighting system is no longer on the object and indeed should change.

5) Vertical Sight Alignment Test

Same as Horizontal alignment test but in the vertical axis

Do not copy 18

When the SpeedLaser is initially powered ON, it automatically and very quickly

runs a hardware and software Built In Test (BIT). When successfully

completed, the LCD screen will display “SYSTEM READY” or “Self Test

Passed”. You are now ready to complete the following recommended daily

tests, listed as #1 through #5, prior to conducting any enforcement activity.

Running the Manufacturer’s Recommended Daily Tests

1) Internal Circuit Check

Press MENU followed by “A” on the keypad, which selects Test.

The LIDAR will then automatically:

a) Enter the RESET & TEST Mode

b) Restore factory default settings

c) Run the hardware Built In Test (BIT)

d) Run the software BIT including dynamic memory test

e) Runs an LED count test (1111, 2222, …, 9999)

f) Defaults the HUD display to .8.8.8.8

Wait for “TEST PASS” or “Memory-OK” to be displayed. Either

indicates that steps a to d have been completed successfully.

2) Light Segment Test

Confirm e or f, the HUD is displaying aiming “+” with the data “.8.8.8.8”.

3) Range (Chronometer) Accuracy Test

Confirm that the LIDAR can correctly compute two or more known ranges

using any one of the following methods:

a) From one location, range to two targets at known distances.

b) From two locations, range to one target at a known distance.

c) Range to a random target, back up a known ‘delta’ distance, and

confirm that LIDAR computes a new range with the same delta

distance. Then back up a second, but different delta distance and

confirm that LIDAR computes a new range that matches the new

delta range.

d) Combine method a) with the horizontal and vertical alignment tests

(4 and 5) on next page. This requires that the targets used for the

Horizontal and Vertical alignment are at different known ranges.

Using your preferred method from above:

a) Stand at the selected position.

b) Aim at selected target.

c) Squeeze and hold trigger/fire button until tone sounds (range is

computed).

d) Confirm that reported range is within ±1 foot (30 cm) of expected.

e) Repeat steps a) thru d) using a known distance that is at least

20 feet (6 meters) different than the first known distance.

Do not copy 19

4) Horizontal Sight Alignment Test

a) Locate a vertical object (such as a utility pole) with open sky

behind, preferably at a distance greater then 150 feet/45 meters.

b) Aim to the left or right of the object, pull and hold the trigger/fire

button.

c) While keeping the trigger/fire button pulled, slowly sweep the

crosshair sight across the vertical object.

d) The distance to the pole should be displayed once the target edge

is inside the HUD crosshair.

e) Press D (Done/Next) to display next step.

5) Vertical Sight Alignment Test

a) Turn the unit 90 degrees sideways and repeat steps 4) a – e.

b) Press MENU or DONE to exit Test Mode.

Note: If desirable, the horizontal and vertical alignment tests may be

conducted using an horizontal object, such as a utility wire, with

open sky. However, it will be necessary to turn the Lidar unit 90

degrees to conduct the horizontal test and return it to the upright

position when testing the vertical axis or plane.

Sweep from

the RIGHT

Sweep from

the LEFT

Do not copy 20

This manual suits for next models

3

Table of contents

Popular Security Sensor manuals by other brands

Allen-Bradley

Allen-Bradley Guardmaster GuardLink user manual

Honeywell

Honeywell Ex-Or Digital Gold Series Installation and commissioning instructions

BW Technologies

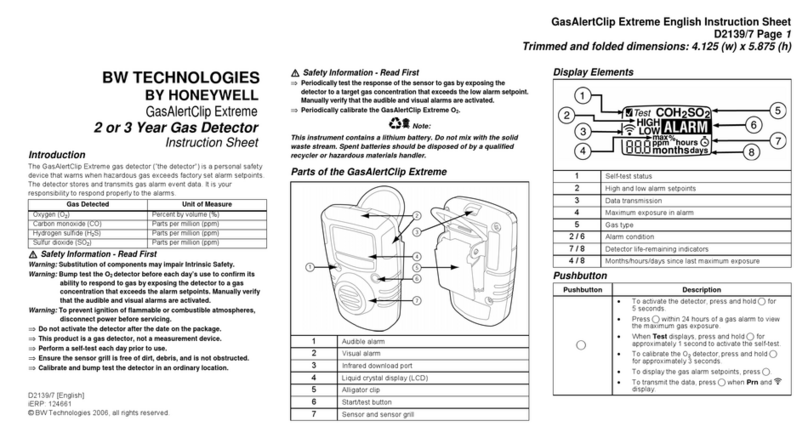

BW Technologies GasAlertClip Extreme SO2 instruction sheet

CRH

CRH CRLTS1320 instruction manual

Hytronik

Hytronik HIR27 manual

Evikon

Evikon PluraSens E2658-VOC user manual