57

GB

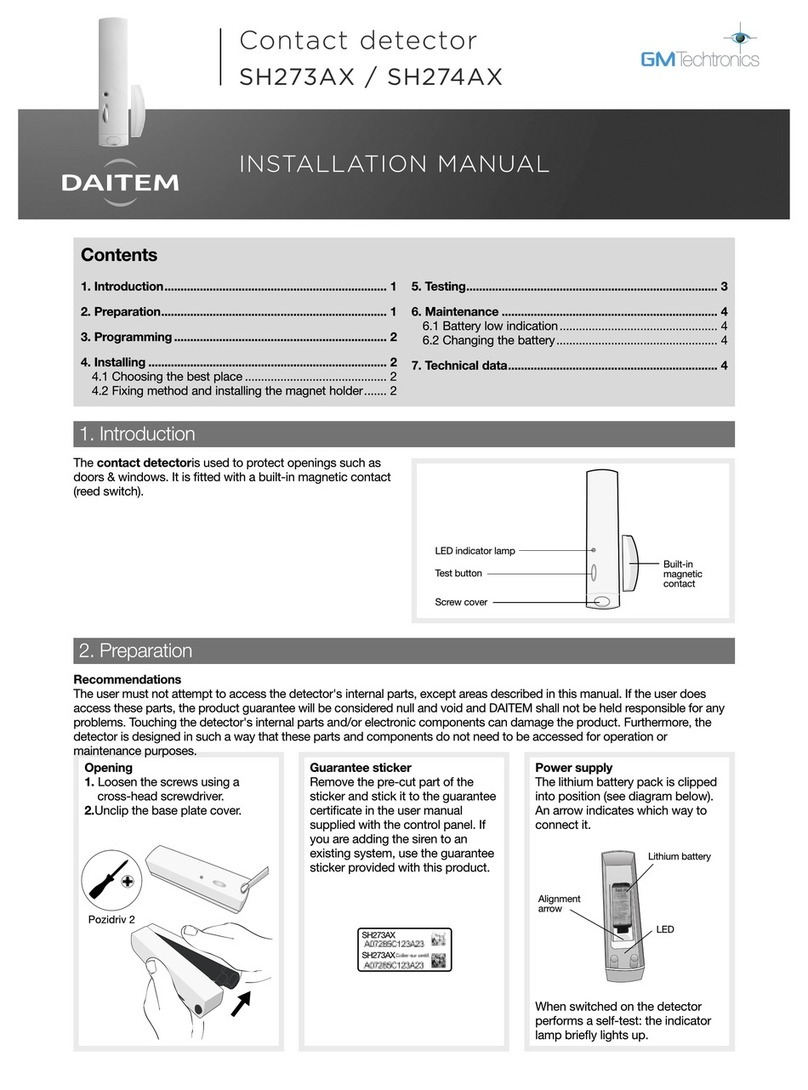

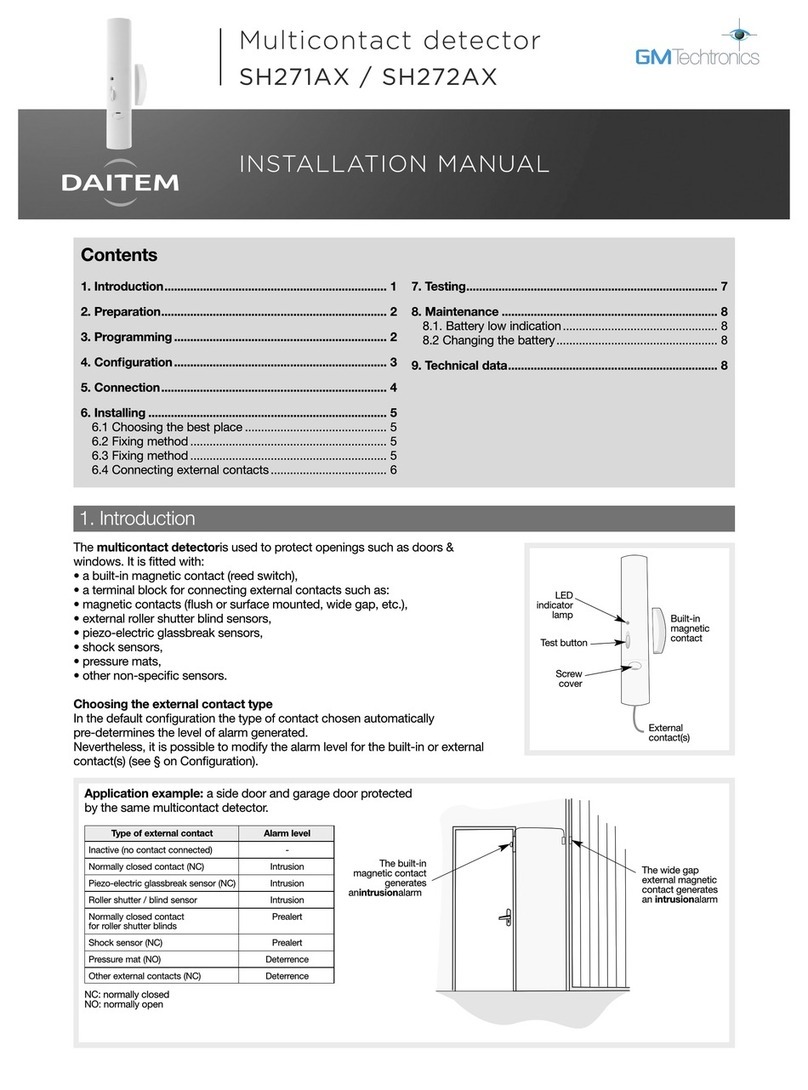

1. Introduction

IMPORTANT

• Some functions are only available

with versions 2.0.0 or later (press

on

the control panel keypad to

check the version).

• The operating differences with

former ranges are described in

the compatibility booklet

available in the Daitem installers

section at www.daitem.co.uk.

Contents

1. Introduction .................... 57

2. Preparation ..................... 58

2.1 Opening...................... 58

2.2 Power supply............. 58

3. Programming.................. 59

4. Installing.......................... 60

4.1 Choosing

the best place ............ 60

4.2 Fixing method

and installing

the magnet holder...... 61

5. Testing ............................. 63

6. Maintenance................... 64

6.1 Battery low

indication.................... 64

6.2 Changing

the battery.................. 65

7. Technical data ................ 66

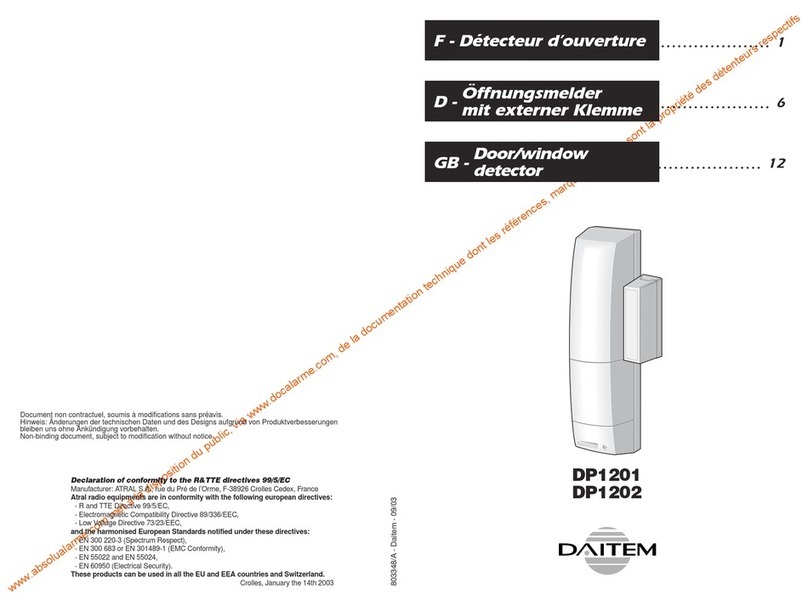

Built-in

magnetic

contact

LED indicator

lamp

Test button

Screw cover

The contact detector is used to

protect openings such as doors &

windows. It is fitted with a built-in

magnetic contact (reed switch).