MPI InfoPrint 6700 Series User manual

Second Edition (September 2009)

This edition applies to the Online Data Validator (DB15) for the InfoPrint 6700 Series Thermal

Printer and replaces the following publication:

InfoPrint 6700 Series Thermal Printer: Online Data

Validator (DB15) User’s Manual,

G550-1173-00.

You can send comments by e-mail to printpub@infoprint.com or by mail to:

InfoPrint Solutions Company

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

This product is or contains commercial computer software and commercial computer software

documentation developed exclusively at private expense. As specified in Federal Acquisition

Regulation 12.212 in the case of civilian agencies and Defense Federal Acquisition Regulation

Supplement 227.7202 in the case of military agencies, use, duplication and disclosure by agencies

of the U.S. Government shall solely be in accordance with the accompanying International

Program License Agreement in case of software products and in accordance with the licensing

terms specified in the product’s documentation in the case of hardware products.

© Copyright InfoPrint Solutions Company 2009. All rights reserved.

Before using this information and the product it supports, read the information in “Notices” on

page 77.

Note:

Visit our home page at: http://www.infoprint.com

Internet

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

1 Installation Instructions ......................................... 7

Overview................................................................................................ 7

Safety Notices........................................................................................ 9

Installation and Removal ..................................................................... 10

Prepare The Printer....................................................................... 10

Install The Ferrite .......................................................................... 10

Install The Validator ...................................................................... 17

Attach The Power/Data Cable....................................................... 20

Restore The Printer To Operation ....................................................... 22

Enable The Validator ........................................................................... 22

Adjust The Scanning Beam ................................................................. 23

Continuous, Tear-Off, and Tear-Off Strip...................................... 23

Peel-Off Media Handling Mode ..................................................... 24

Cut Media Handling Mode............................................................. 25

Scanning Beam Vertical Alignment............................................... 27

Scanning Beam Skew Adjustment (R40 and R60 models only) ... 27

Shifting The Scanning Beam ............................................................... 28

Calibration............................................................................................ 29

Bar Code Validation Demo Page .................................................. 31

2 Operation ............................................................ 33

Basic Validator Setup .......................................................................... 33

VALIDATOR Menu........................................................................ 34

Configuring The Validator .................................................................... 37

Enabling And Disabling The Validator........................................... 37

Validator Reporting ....................................................................... 38

Validator Statistics......................................................................... 41

Defining Validator Options ............................................................ 41

Advanced Validator Options.......................................................... 45

General Process For Barcode Analysis ........................................ 59

Operation ............................................................................................. 60

Print Speed Limits ......................................................................... 60

On-Demand Printing ..................................................................... 62

Table of Contents

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

Bar Code Failures................................................................................ 63

Bad Bar Code Error Detection ...................................................... 63

Missing Bar Code Error Detection................................................. 63

Validator Action/Error Action ......................................................... 64

Error Messages............................................................................. 69

Troubleshooting................................................................................... 73

Maintenance ........................................................................................ 75

Notices ................................................................ 77

Product Recycling and Disposal.......................................................... 79

Communication Statements................................................................. 80

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

7

1Installation Instructions

Overview

The online data validator (ODV) is an external bar code scanning device

attached above the paper exit of the printer. When activated, it scans the

printed output looking for bar codes. When it finds a bar code, it determines

what type of bar code it is and monitors the bar code quality as it passes

through the scan area.

After the entire bar code has passed under the scanning beam, the validator

grades the bar code and sends a report to the printer. How the printer

responds is determined by the validator settings, explained in “Configuring

The Validator” on page 37.

Operational Parameters

The design parameters of the validator are as follows:

•The validator can track the performance of up to four horizontal bar codes

at one time.

•The validator requires a minimum distance of 1/2 inch or 20 times the

minimum element width (x-dimension), whichever is greater, between bar

codes.

•The validator recognizes the following linear, picket fence bar codes:

Codabar, Code 39, Code 93, Code 128, Interleaved 2 of 5, and UPC/

EAN.

•The validator can also evaluate PDF 417 bar codes. For PDF 417

Limited, the validator works best with security level 5 or higher, using the

current default printer settings for Defects Percentage, Percent Decode,

and Decodeability. For lower security levels, lower the Defects

Percentage to 5% to enable checking for bar code damage.

•Stacked, 2D, and vertical (ladder) bar codes are not supported.

•Bar codes must have a minimum x-dimension of 10 mil (0.010 inch) to be

recognized by the full width of the scanning beam. The validator can

recognize bar x-dimension as narrow as 6.6 mil (0.0066 inch) for 300 dpi

printers, and 10 mil (0.010 inch) for 203 dpi printers. The validator cannot

recognize x-dimensions smaller than 6.6 mil (0.0066 inch) or larger than

40 mil (0.040 inch).

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

8

Chapter 1 Overview

Refer to Table 1 for the minimum x-dimension requirements for each printer

size of a 300 dpi printer.

Tools And Materials You Will Need

•

InfoPrint 6700 Series Thermal Printer User’s Manual

•Static wrist strap*

•2.5 mm hex key*

•#2 Phillips Screwdriver*

Parts List

•3 mm hex key

•Validator

•Validator bracket and mounting screws

•Cable ties, black

•Bar code calibration card

•Ferrite*

•Cable assembly*

•Wire saddle*

•Grommet*

•ODV Interface PCBA (used for 6700 Energy Star models only)

* Only for a field installation

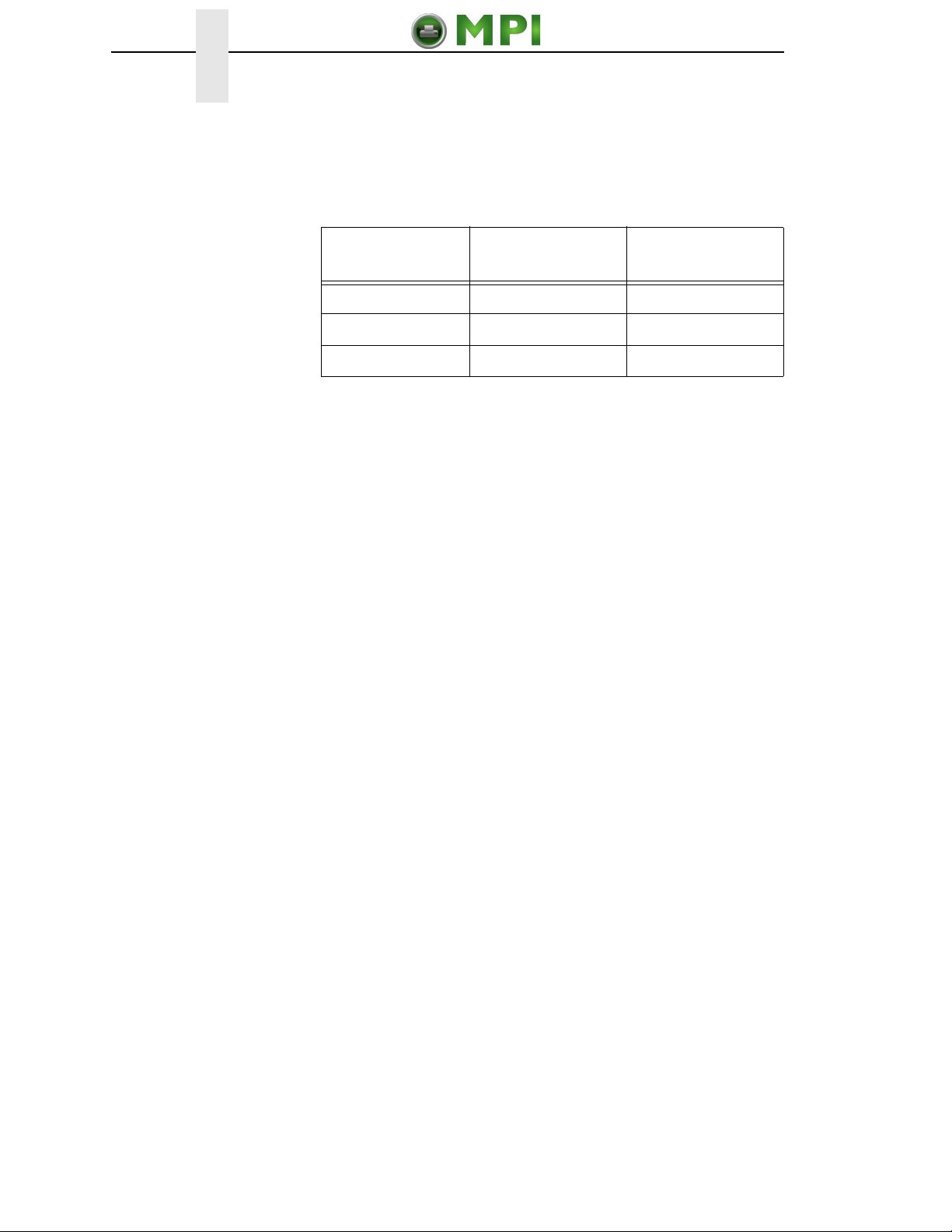

Table 1: Minimum X-Dimension and Beam Width for

a 300 dpi Printer

Printer Size Beam Width Minimum

X-Dimension

4 inch 4.5 inches 6.6 mil

6 inch 6.5 inches 10 mil

8 inch 8.5 inches 13 mil

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

9

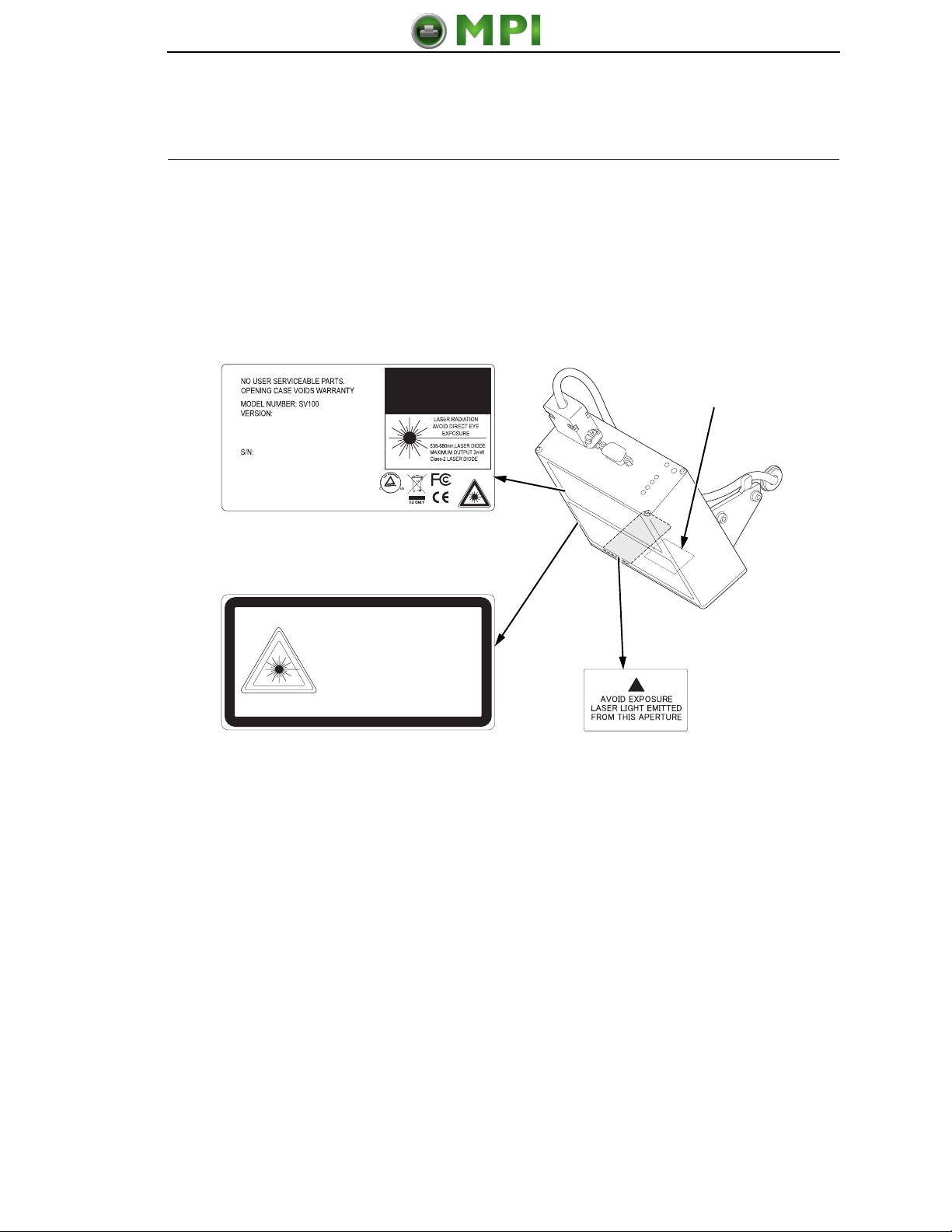

Safety Notices

The validator is a Class 2 laser product. The following notices apply at all

times when the printer is powered on and the validator is active:

WARNING

Class 2 laser light. Do not stare into the laser beam or a reflected image

of the laser beam.

WARNING

Using controls, making adjustments, or performing procedures other

than those specified herein may result in hazardous radiation exposure.

Figure 1. Safety Warnings

183453a

CAUTION

MADE IN U.S.A. by Printronix

CANADA ICES/NMB-003 CLASS/CLASSE B

Scan Distance:

CAUTION

LASER RADIATION. DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

ATTENTION

RAYONNEMENT LASER. NE PAS REGARDER DANS LE FAISCEAU.

APPARELL À LASER DE CLASSE 2

ACHTUNG

LASERSTRAHLUNG NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

636-680NM, LASER DIODE

MAXIMUM OUTPUT 4.2MW

IEC60825-1:1993+A1+A2

Note: This is the

laser exit window.

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

10

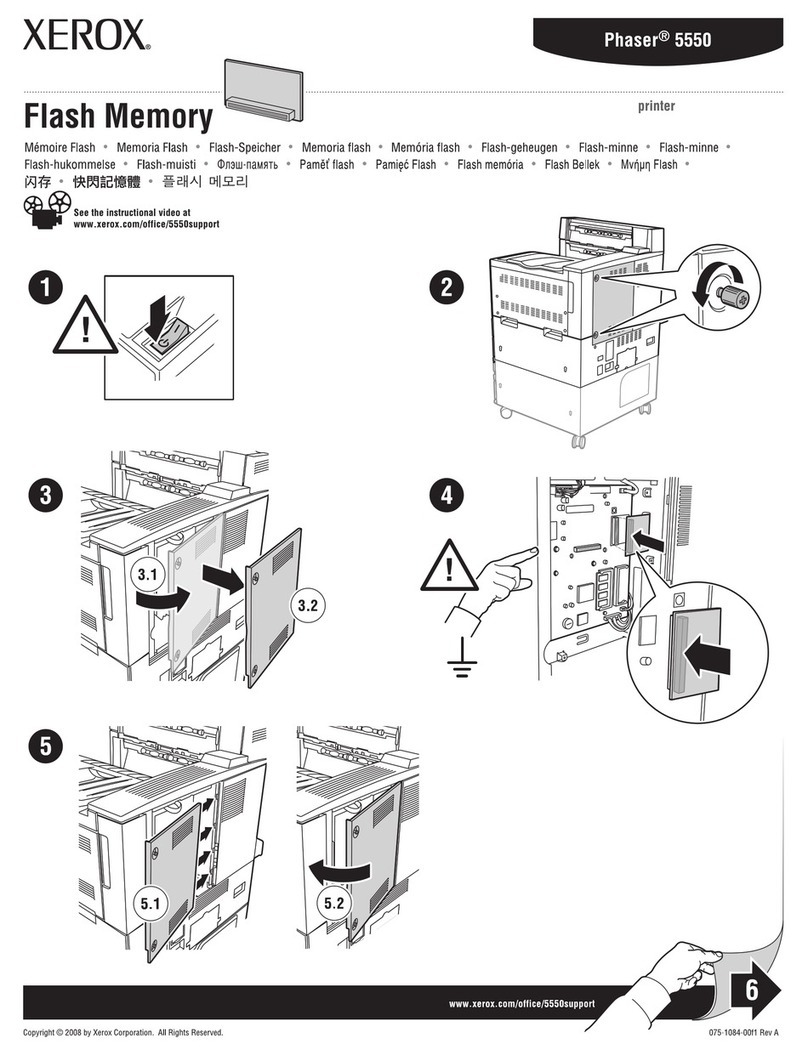

Chapter 1 Installation and Removal

Installation and Removal

This section describes how to install the validator. To remove the validator,

reverse the steps of this procedure.

Prepare The Printer

1. Set the printer power switch to O (Off).

WARNING

Always unplug the printer power cord from the printer or power outlet

before doing any installation procedure. Failure to remove power could

result in injury to you and damage the equipment. You will be instructed

when to apply power.

2. Unplug the printer power cord from the printer or the AC power source.

Factory Installation

If your printer has a factory installed validator, the ferrite, cable, wire saddle,

and grommet have already been installed. Go to “Install The Validator” on

page 17.

Field Installation

If you are doing a field installation, you must install the ferrite, cable, wire

saddle, and grommet. Go to “Install The Ferrite” on page 10.

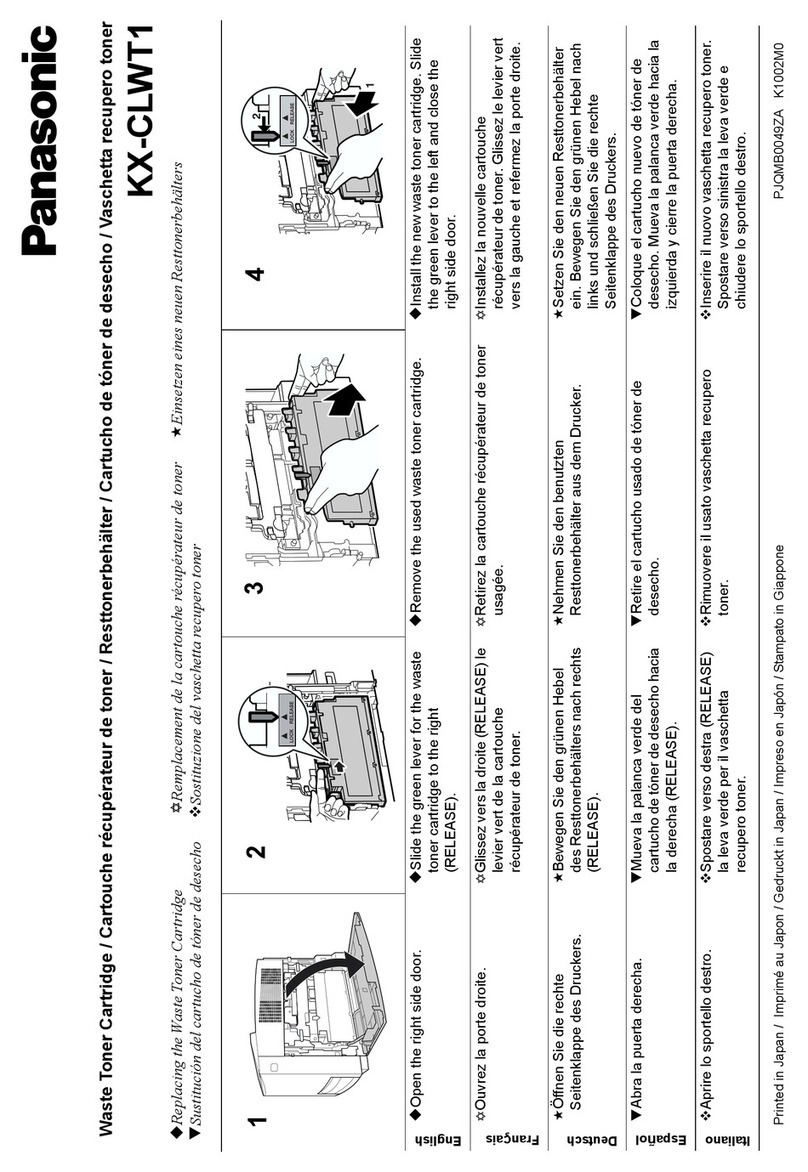

Install The Ferrite

1. Loosen the two captive screws securing the top of the frame side cover.

(Figure 2.)

2. Tilt the frame side cover back from the top and lift it until the tabs along

the lower edge disengage from the slots in the printer frame.

Figure 2. Removing the Frame Side Cover

183454a

ETHERNET

PARALLEL

USB

GPI0

RS232

STATUS

DEBUG

Captive

Screw (2)

Frame Side Cover

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

Install The Ferrite

11

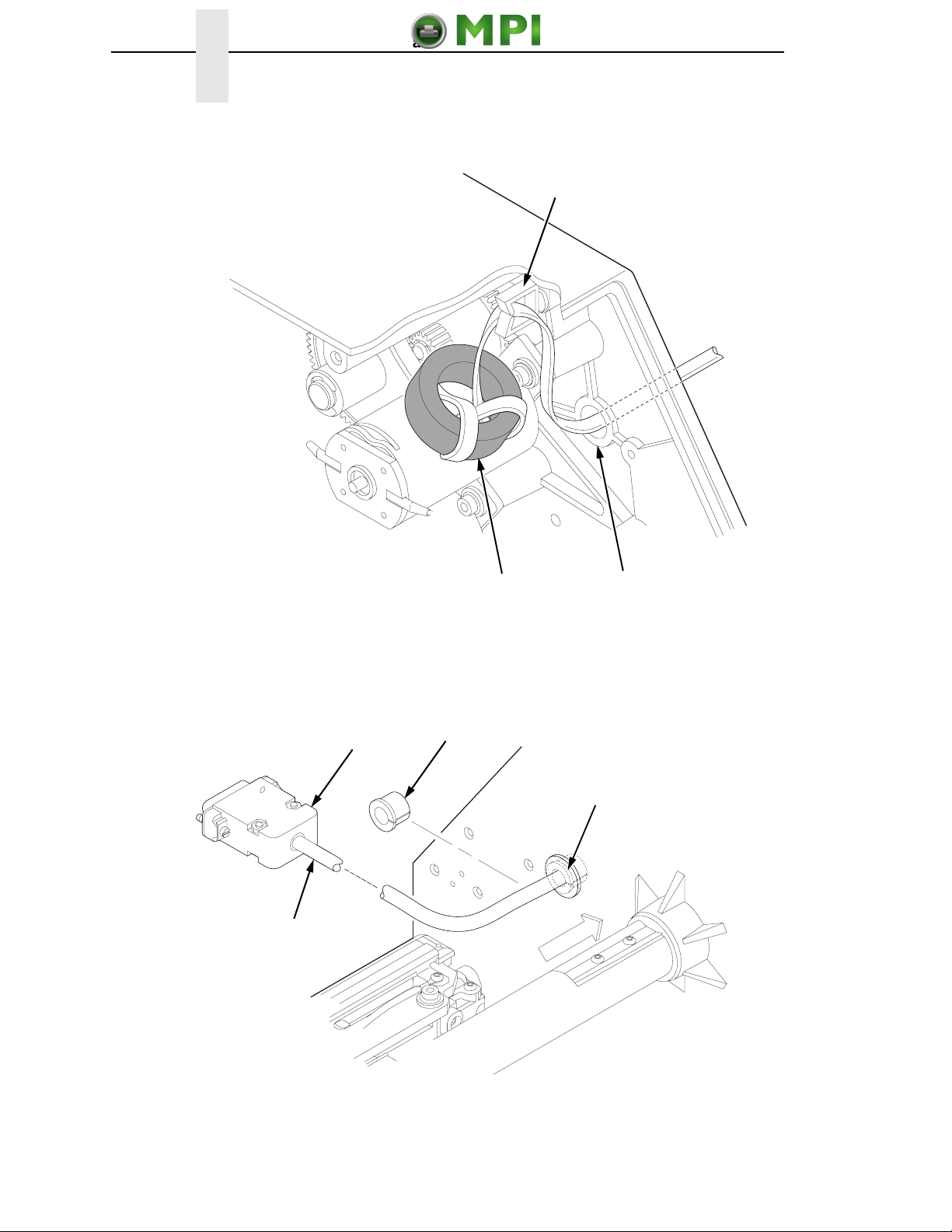

Figure 3. Locating the Ferrite Position on the Power/Data Cable

3. Stretch the Power/Data cable out straight on a flat surface.

4. Measure back 20.0 ± 0.5 inches from the DB15 connector and mark the

cable with a pencil line. (Figure 3.)

Figure 4. Routing the Power/Data Cable

183455a

±

20.0 0.5

inches

DB15 Connector

183456a

P10 Connector

Plastic Plug

Frame Opening

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

12

Chapter 1 Installation and Removal

CAUTION

To prevent electrostatic damage to electronic components, always wear

a properly grounded static wrist strap when you handle circuit boards.

5. Put on a static wrist strap and ground it to an unpainted part of the printer

frame. Touch the frame with the hand wearing the wrist strap.

6. Raise the media cover and remove the plastic plug from the frame

opening.

7. Gently press the small wires of the P10 connector end of the power/data

cable against the connector and route the connector through the frame

opening. (Figure 4.)

Figure 5. Wrapping the Power/Data Cable Around the Ferrite

8. Using the P10 connector end of the power/data cable, insert the cable

through the ferrite. (Figure 5.)

9. Wrap the power/data cable around the ferrite twice.

10. Adjust the position of the ferrite so that the length from the ferrite to the

DB15 connector is 20 ± 0.5 inches.

183457a

P10 Connector

(to controller board)

Ferrite

Pencil Line

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

Install The Ferrite

13

Figure 6. Inserting the Wire Saddle Into the Frame Boss

11. Insert the wire saddle into the frame boss. (Figure 6.)

183458a

Frame Boss

Wire Saddle

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

14

Chapter 1 Installation and Removal

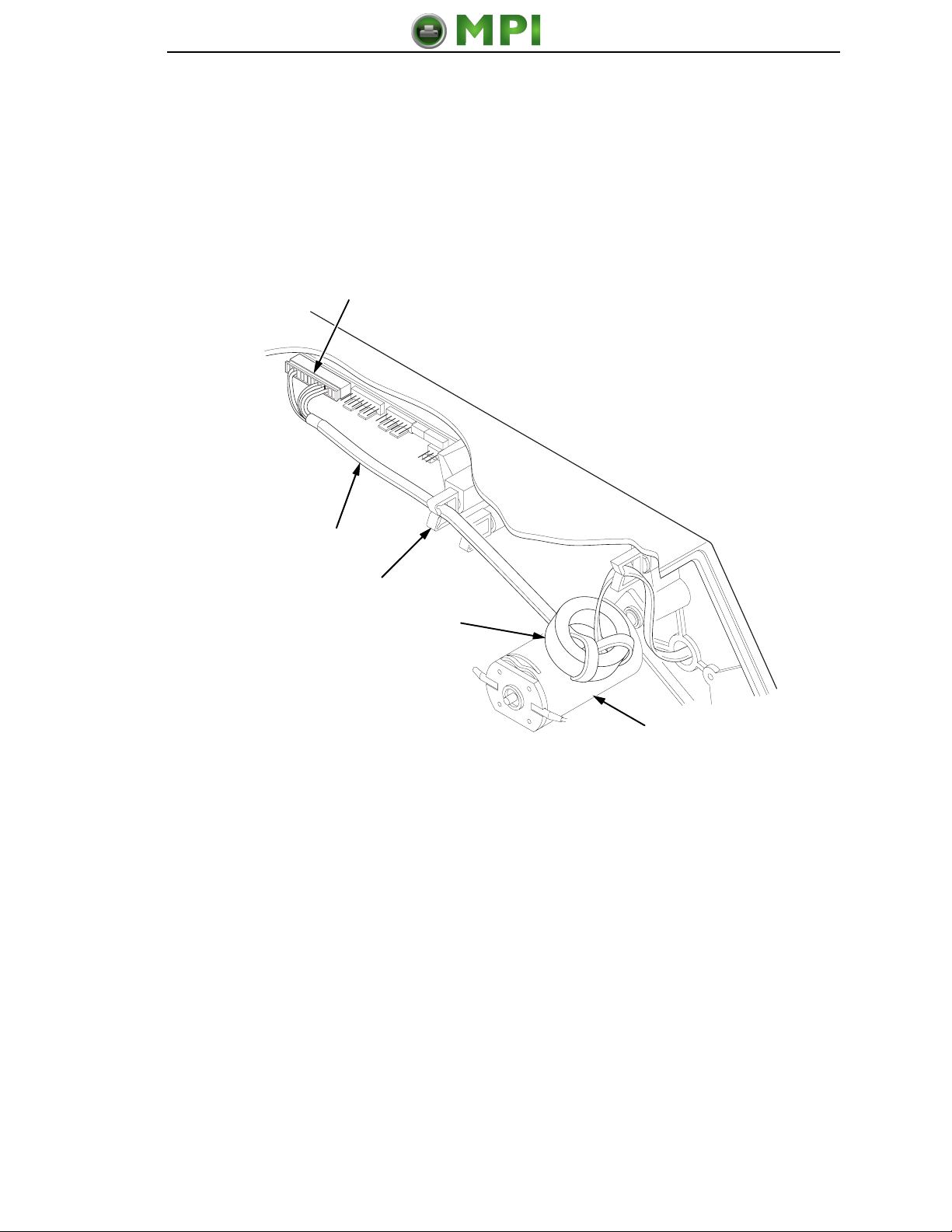

Figure 7. Routing the Power/Data Cable From the Hole in the Frame Wall

12. Route the power/data cable through the wire saddle.

Figure 8. Adding the Grommet to the Power/Data Cable

183459a

Ferrite

Wire Saddle

Frame

Opening

183460a

Split

Grommet

Power/Data Cable

(approximately

17 inches exposed)

InsertedSplit

Grommet

(media side)

DB15

Connector

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

Install The Ferrite

15

13. On the media side of the printer, slide the split grommet onto the power/

data cable and insert it into the frame opening. (Figure 8.)

14. Inspect the power/data cable to ensure approximately 17 inches of cable

is exposed from the grommet to connect it to the validator.

NOTE: You will plug the power/data cable into the validator later.

Figure 9. Position the Ferrite

15. On the electronics side of the printer, position the ferrite on top of the

upper DC motor. (Figure 9.)

16. Route the power/data cable through the wire saddle as shown in Figure 9.

17. Plug the P10 connector end of the power/data cable into the J10

receptacle on the controller board.

NOTE: For 6700 Energy Star models see Figure 10 on page 16.

183461a

J10

Power/Data Cable

Ferrite

Upper

DC Motor

Wire Saddle

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

16

Chapter 1 Installation and Removal

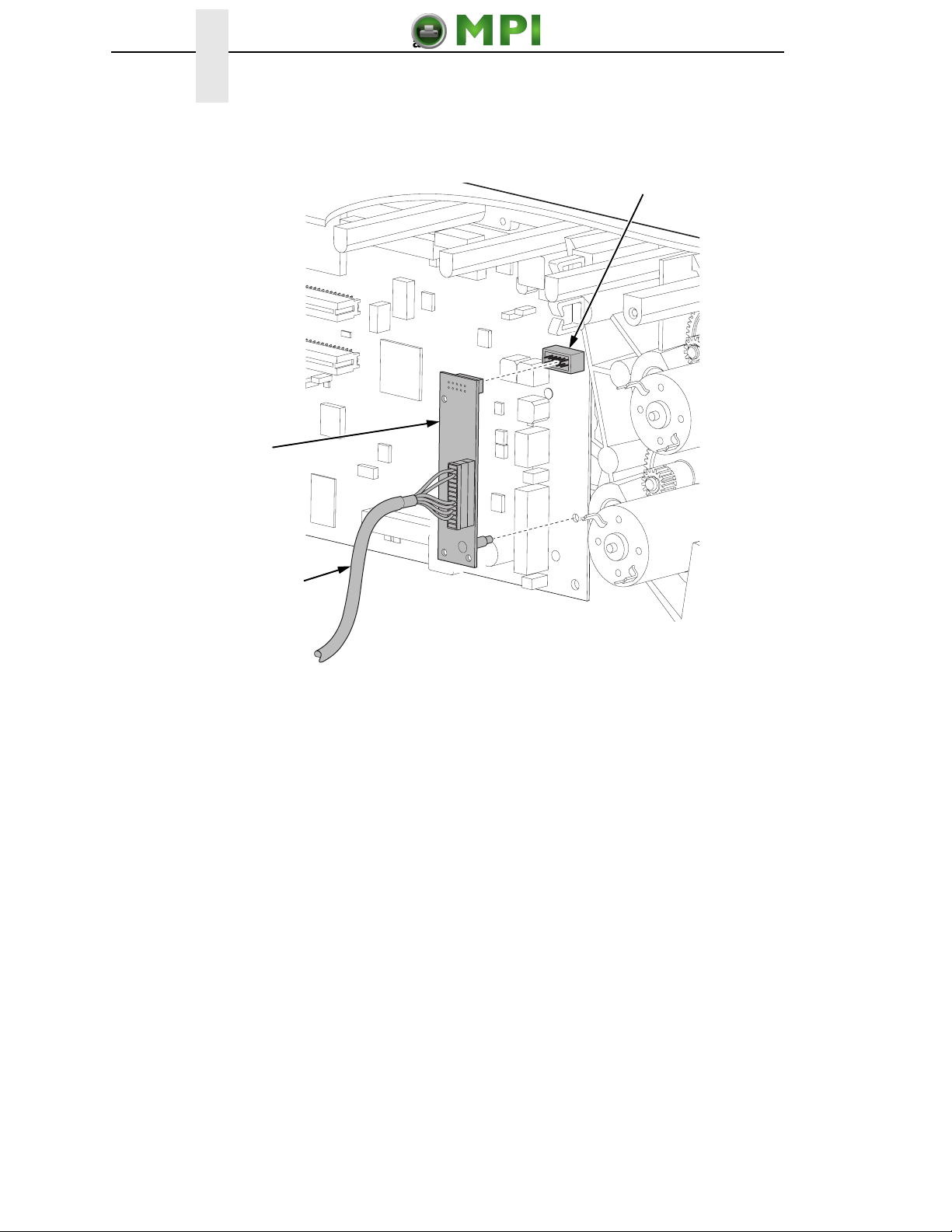

Figure 10. 6700 Energy Star Models – Plugging the Power/Data Cable into the ODV Interface

PCBA and then into the Controller Board

183658a

J10

Power/Data Cable

ODV Interface

PCBA

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

Install The Validator

17

Install The Validator

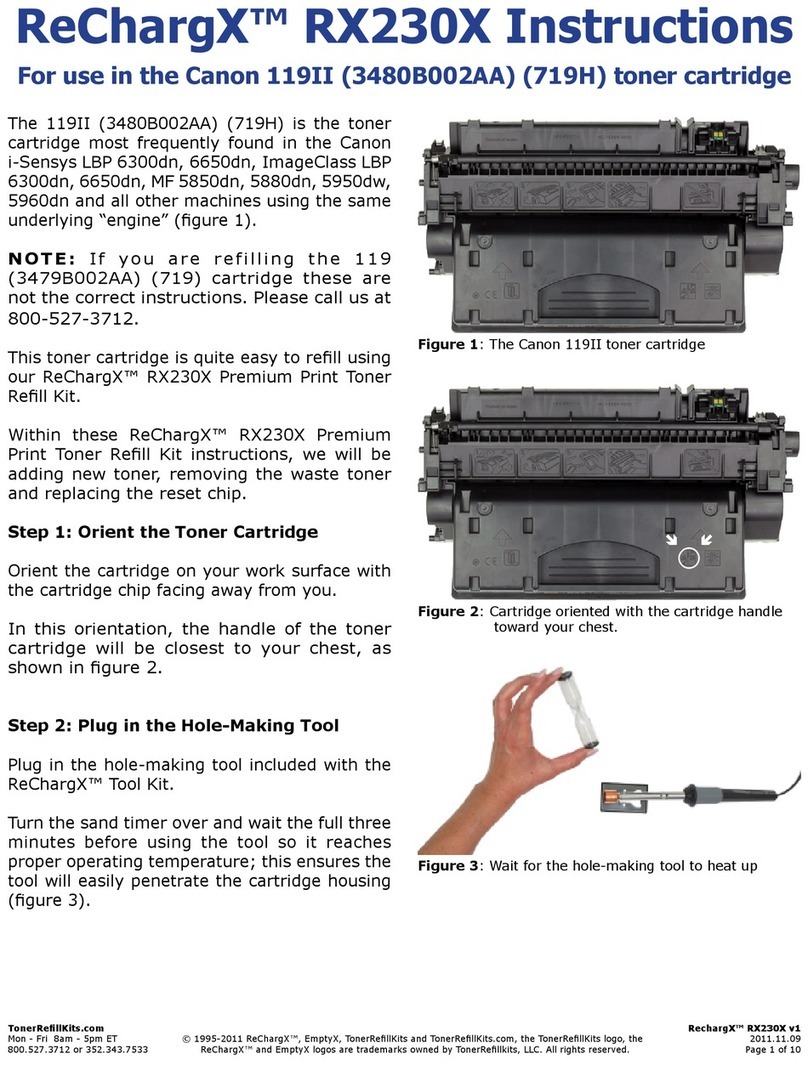

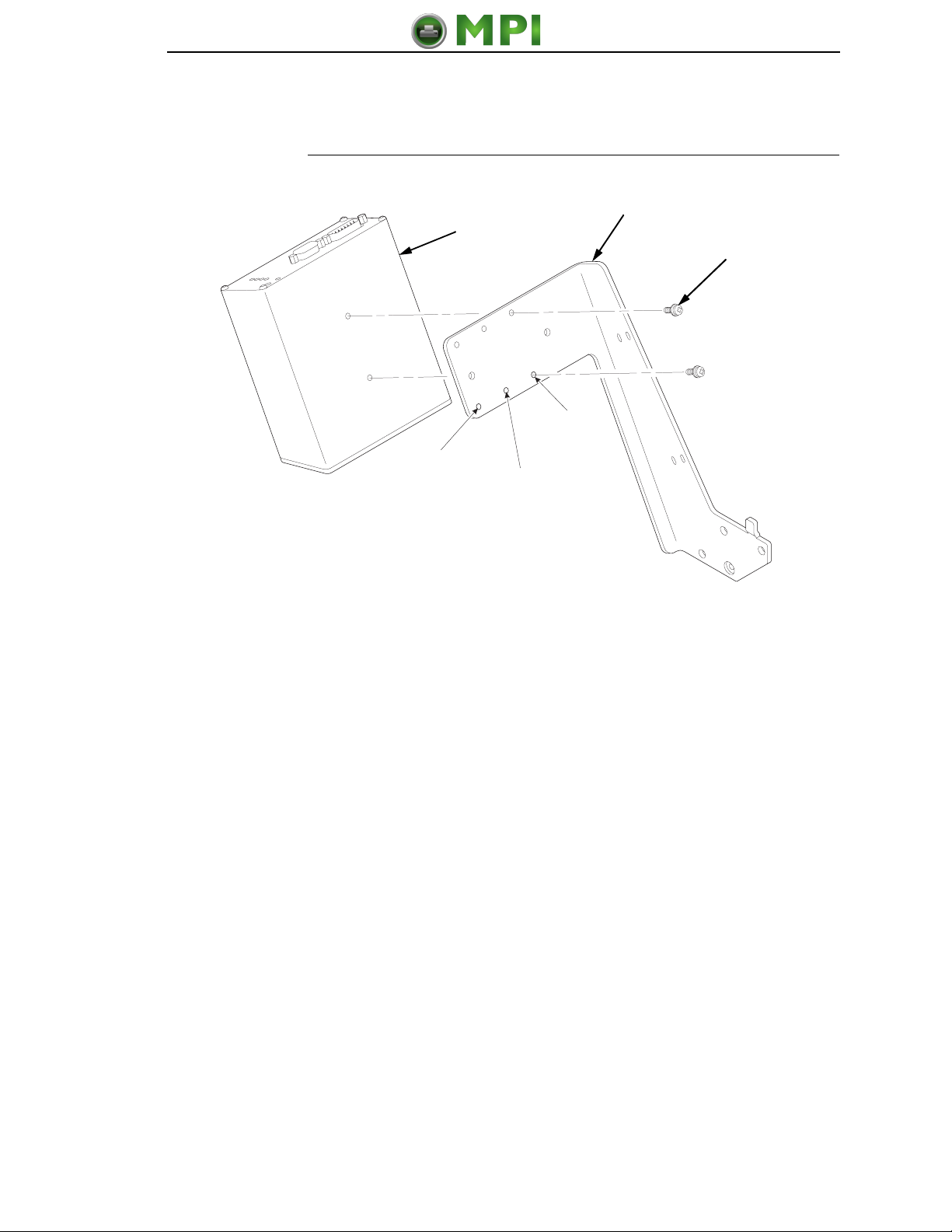

Figure 11. Attaching the Validator to the Bracket

1. Using two 6-32 Phillips head screws, attach the validator to the bracket as

shown in Figure 11.

2. Use the appropriate holes on the bracket, depending on the media width.

183339a

8”

Printer 6”

Printer

4”

Printer

Bracket

6-32Phillips

Screw (2)

Validator

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

18

Chapter 1 Installation and Removal

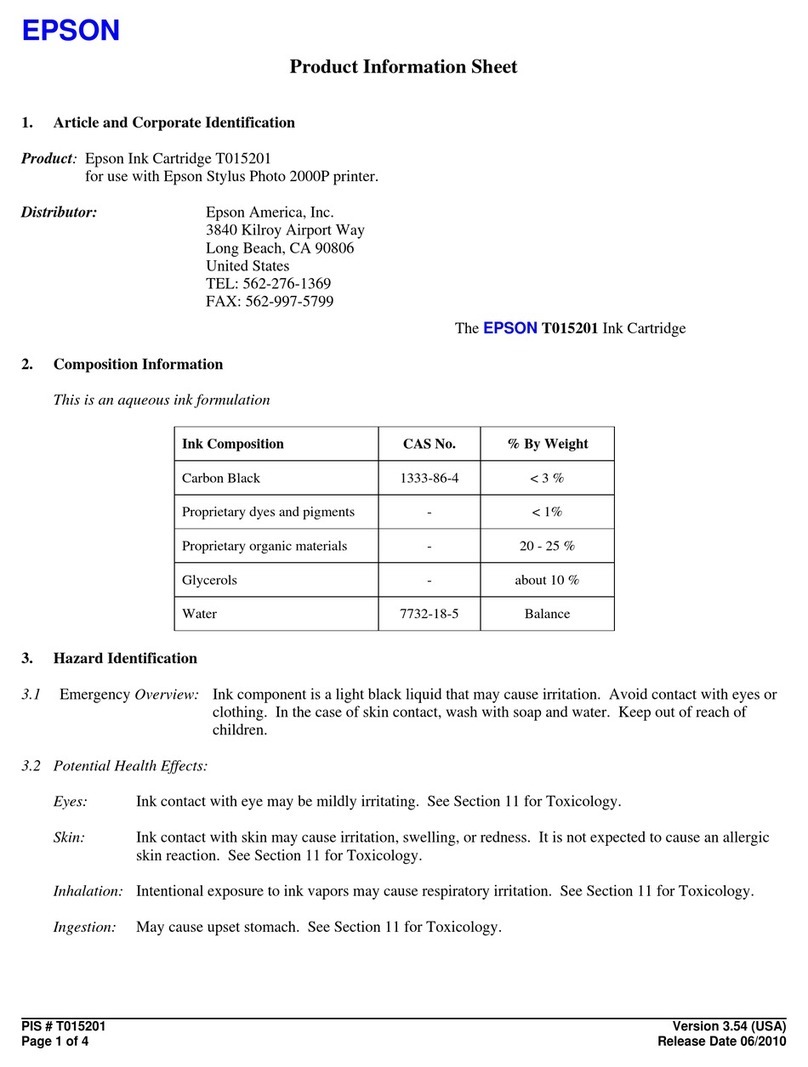

Figure 12. Positioning the Validator on the Bracket

1. Apply even pressure to the side of the validator as you tighten the screws

on the bracket as shown in Figure 12.

2. Make sure the validator is firmly seated against both screws to insure

proper beam alignment.

183340a

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

Install The Validator

19

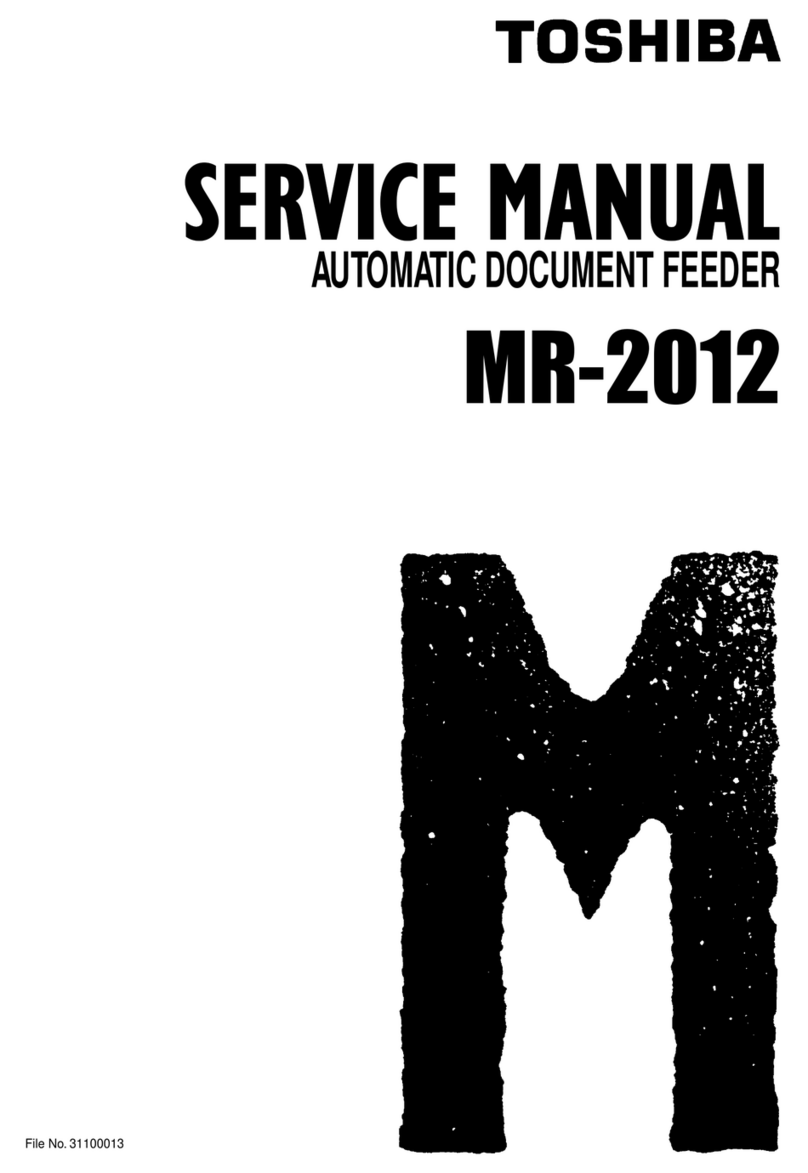

Figure 13. Attaching the Validator/Bracket Unit to the Printer

3. Face the front of the printer while installing the validator/ bracket unit.

4.

Using four M4x10mm screws, attach the validator/bracket unit to the

printer frame as shown in Figure 13.

5. Tighten the four screws finger tight. You will adjust the

validator/bracket unit in a later step using the 3mm hex key (provided).

183341a

Validator/Bracket Unit

M4x10mm

Screw (4)

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

20

Chapter 1 Installation and Removal

Attach The Power/Data Cable

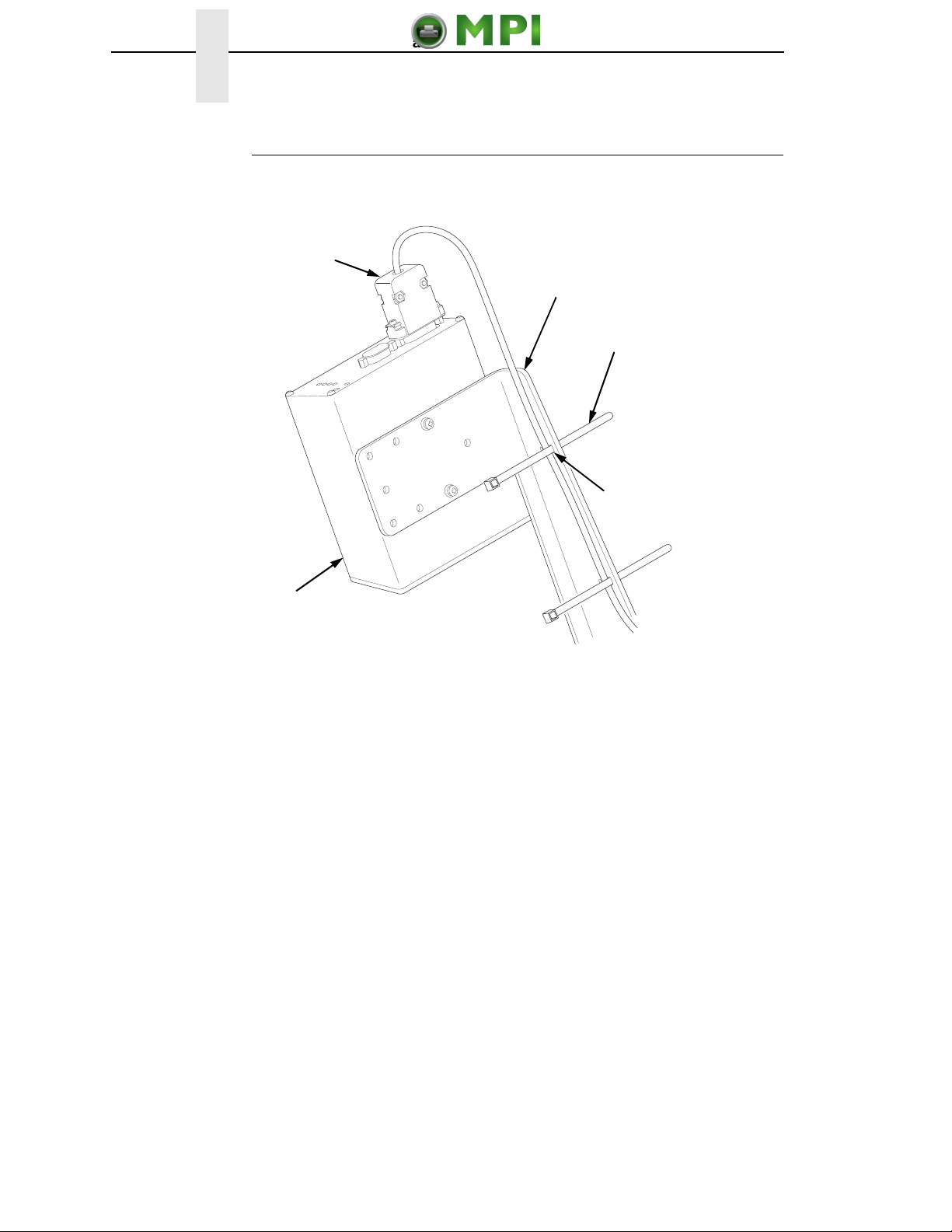

Figure 14. Attaching the Power/Data Cable

1. Plug the DB15 connector end of the power/data cable into the validator.

2. Route the power/data cable along the inside of the bracket, as shown in

Figure 14.

3. Route a tie wrap from the inside of the bracket through the first upper slot

as shown in Figure 14, keeping the power/data cable underneath the tie

wrap.

183342a

Tie Wrap (2)

Power/Data Cable

DB15 Connector

Validator

Bracket

First Upper

Slot

Mantenimiento Periféricos Informáticos C/Canteras, 15 28860 Paracuellos de Jarama (Madrid) Tel: 00 34 917481604 Web: https://mpi.com.es/

This manual suits for next models

1

Table of contents

Other MPI Printer Accessories manuals