Table of contents Page

Safety Precautions......................................................................................................................................................... 1

1. Introduction............................................................................................................................................................... 3

2. About the manual ...................................................................................................................................................... 4

3. Supplied parts............................................................................................................................................................ 5

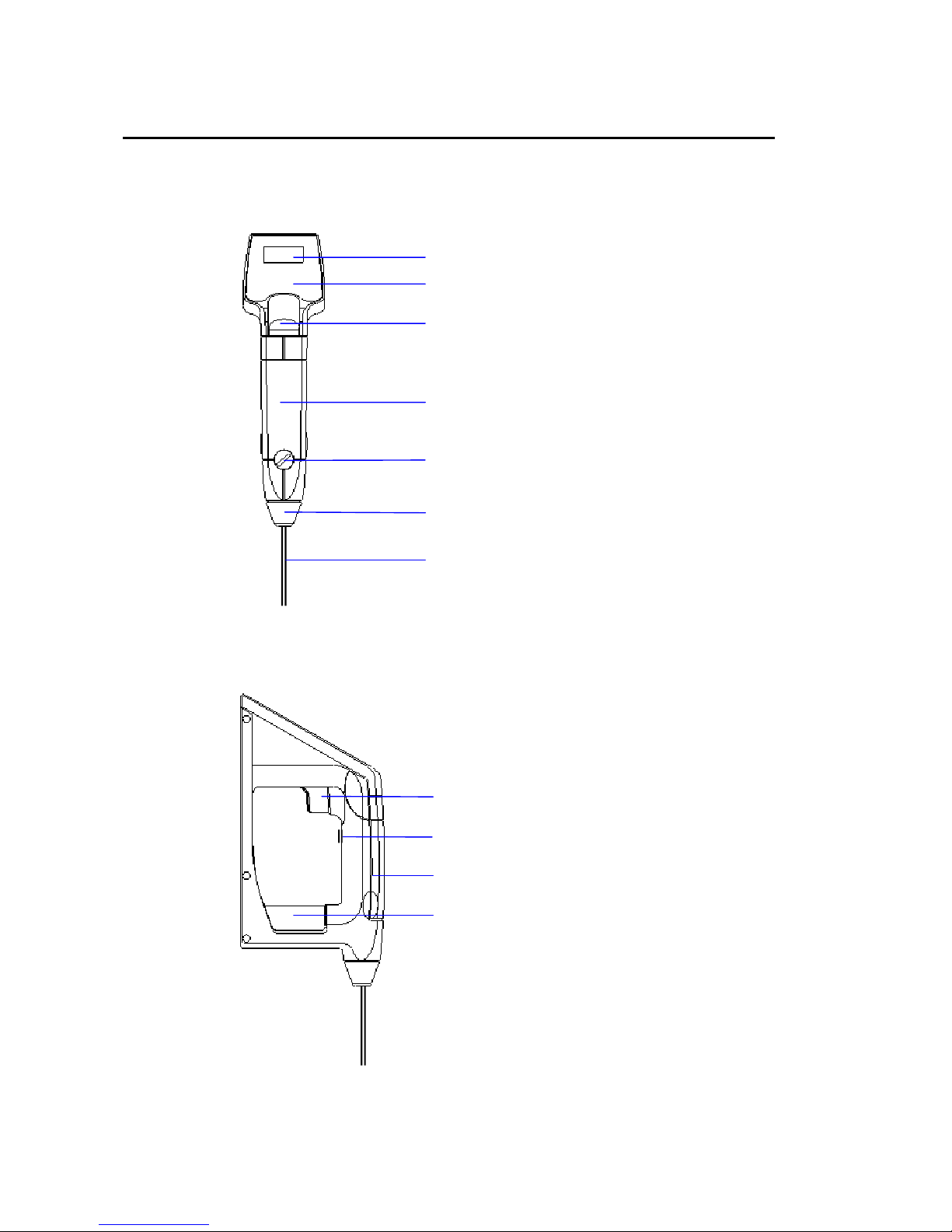

4. Parts configuration .................................................................................................................................................... 6

4.1 Front view........................................................................................................................................................... 6

4.2 Side view............................................................................................................................................................. 6

4.3 Rear view ............................................................................................................................................................ 7

4.4 Display window .................................................................................................................................................. 8

4.5 Operating unit ..................................................................................................................................................... 9

5. Preparation for measurement by DA-130N............................................................................................................. 10

5.1 Loading the battery ........................................................................................................................................... 10

5.2 Setting the sampling nozzle .............................................................................................................................. 11

5.3 Setting the memo pad........................................................................................................................................ 11

5.4 Preliminary test ................................................................................................................................................. 12

6. Setting temperature unit, measuring unit and mode................................................................................................ 13

6.1 Temperature unit ............................................................................................................................................... 13

6.2 Measuring unit .................................................................................................................................................. 13

6.3 Configuration of measurement mode................................................................................................................ 17

7. Actual measurement ................................................................................................................................................ 18

7.1 Cautions on measurement ................................................................................................................................. 18

7.2 Sample measurement ........................................................................................................................................ 19

7.2.1 When the built-in syringe is used............................................................................................................... 19

7.2.1.1 Sampling test materials....................................................................................................................... 19

7.2.1.2 Start measurement .............................................................................................................................. 19

7.2.1.3 Hold measurement data ...................................................................................................................... 19

7.2.1.4 Saving measurement data ................................................................................................................... 19

7.2.2 The use of commercially available plastic syringe .................................................................................... 20

7.2.2.1 Sampling............................................................................................................................................. 20

7.2.2.2 Start measurement .............................................................................................................................. 20

7.2.2.3 Hold measurement data ...................................................................................................................... 20

7.2.2.4 Saving measurement data ................................................................................................................... 20

8. Calibration of measuring cell .................................................................................................................................. 21

8.1 Calibration with pure water............................................................................................................................... 21

8.2 Calibration with standard liquid........................................................................................................................ 22

8.2.1 Calibration with standard liquid of which density is known...................................................................... 22

8.3 Calibration with air ........................................................................................................................................... 22

8.3.1 Calibration with air .................................................................................................................................... 22

8.3.2 How to dry the cell..................................................................................................................................... 23

8.3.3 Procedure of calibration with air................................................................................................................ 24

8.4 Calibration of displayed temperature................................................................................................................ 25

8.5 Recalibration..................................................................................................................................................... 25