2 INSTALLATION INSTRUCTIONS

MSD • WWW.MSDPERFORMANCE.COM • (915) 857-5200 • FAX (915) 857-3344

DISASSEMBLY

1. Disconnect the negative battery cable.

2. Locate the radiator petcock and drain the coolant from

the system.

3. Disconnect the MAF, IAC, ICT and TPS sensors (Figure

3). Remove the air intake ducktwork.

4. Once the coolant is drained, remove the upper radiator

hose from the thermostat housing.

5. Loosen the three bolts that secure the crankshaft

pulley/hub assembly. Do not remove them entirely at

this time.

6. Remove the accessory drive belt by moving the spring

loaded idler pulley. Use caution as this pulley is spring

loaded! The belt will slide off the pulley system and the

idler pulley will settle beyond its installed position.

7. Once the belt is removed, proceed with removing the

pulley from the crankshaft hub by pulling the three

retaining bolts. A puller will be required (Figure 4).

8. It may be necessary to remove the cooling fan. This is

done by removing the four bolts and disconnecting the

wiring connection.

9. Disconnect the air pump power wires and remove the

air pump from its mounting brackets.

10. Disconnect the coolant temperature wiring sensor

located on the water pump.

11. Loosen the lower radiator hose clamp and the two

heater hose clamps at the water pump. Coolant will

generally still pour out of the hoses and water pump.

12. To remove the water pump, the power steering pump

may need to be removed. With a short extension, the

water pump bolt should be able to be accessed. There

are six water pump bolts. Once again, more coolant

may spill out.

13. At this point, you should be able to access the distributor

cap! Mark the location of each spark plug wire before

removing them.

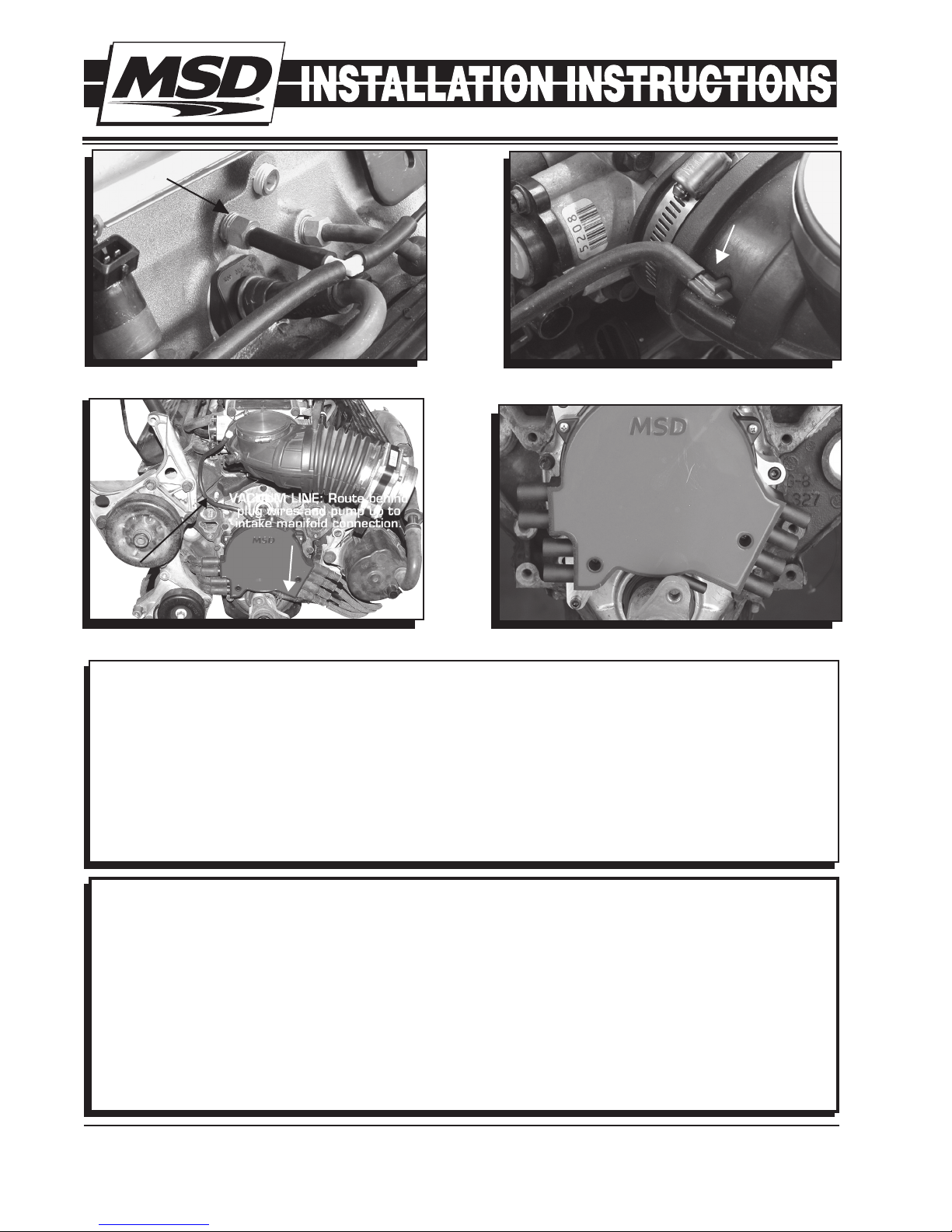

14. Remove the vacuum lines (if equipped) and the

distributor connector at the distributor and on the

passenger side of the intake manifold (Figure 5).

15. Using the supplied special tool and a 1/4" wrench,

Figure 6 Removing the Original Cap.

Figure 5 Disconnect the Distributor Connector.

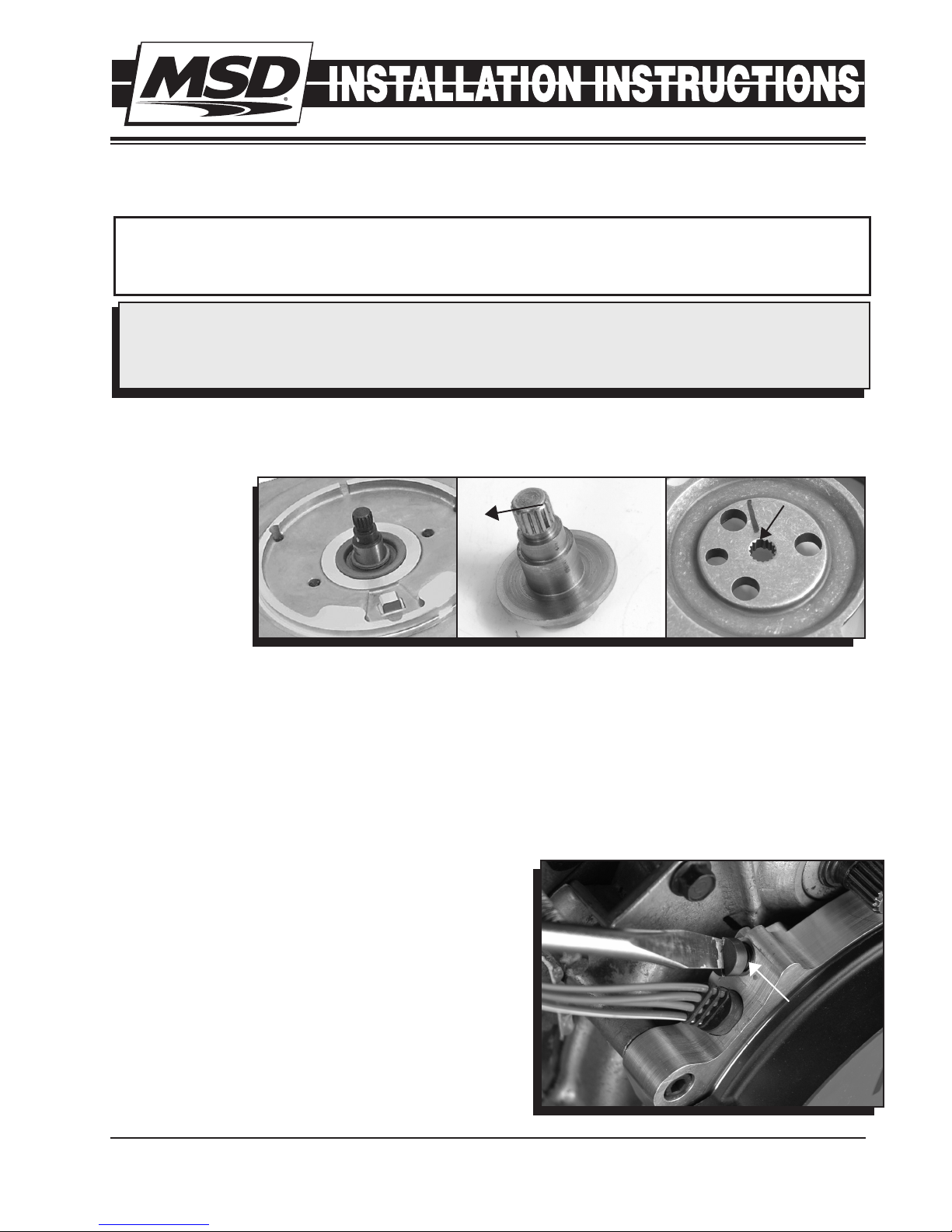

Figure 7 Rotor Location.

MARK ROTOR

LOCATION

Figure 3 Disconnect TPS and IAC.

Figure 4 Removing the Hub.

IAC

TPS