MTD 130-432E000 User manual

Other MTD Lawn Mower manuals

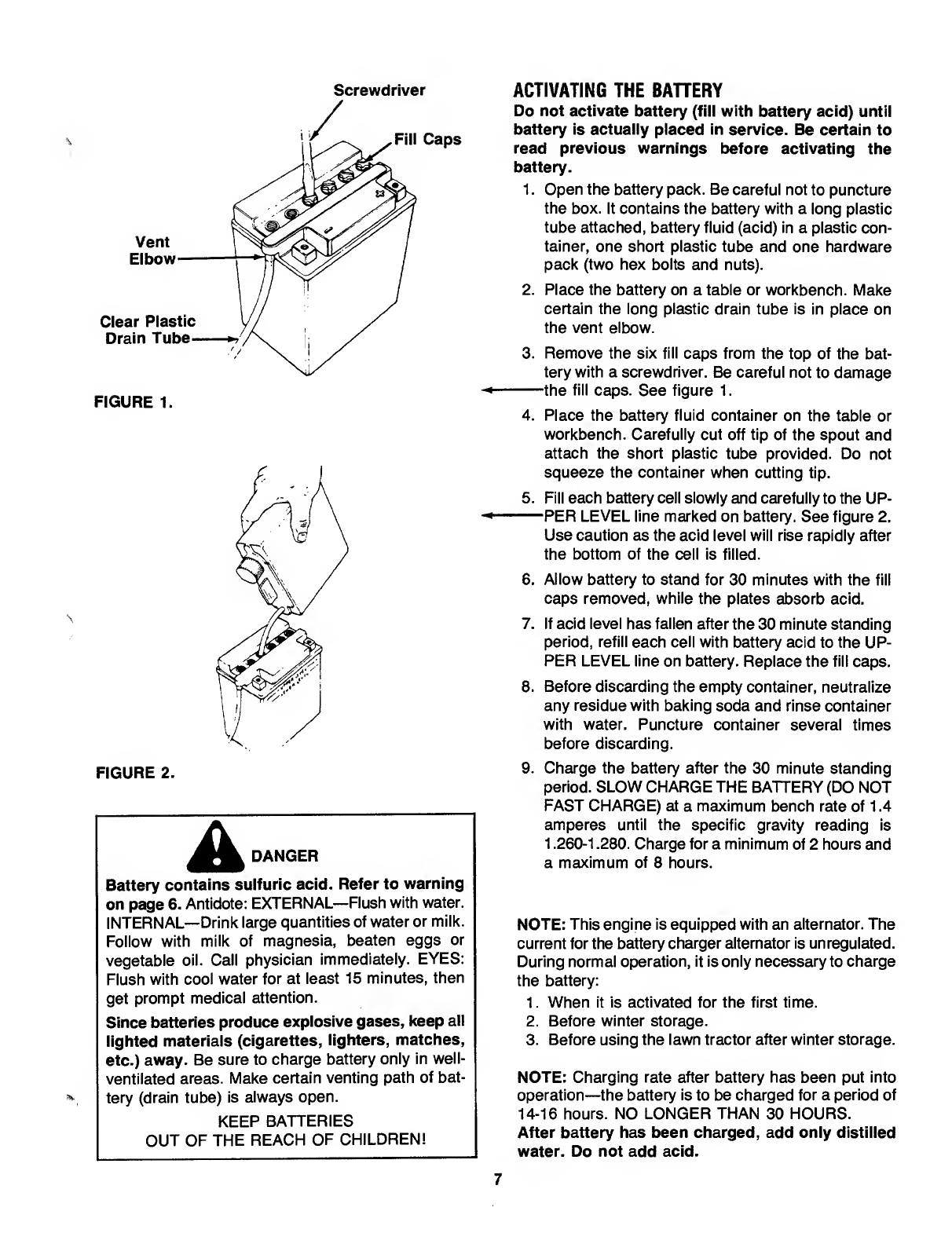

MTD

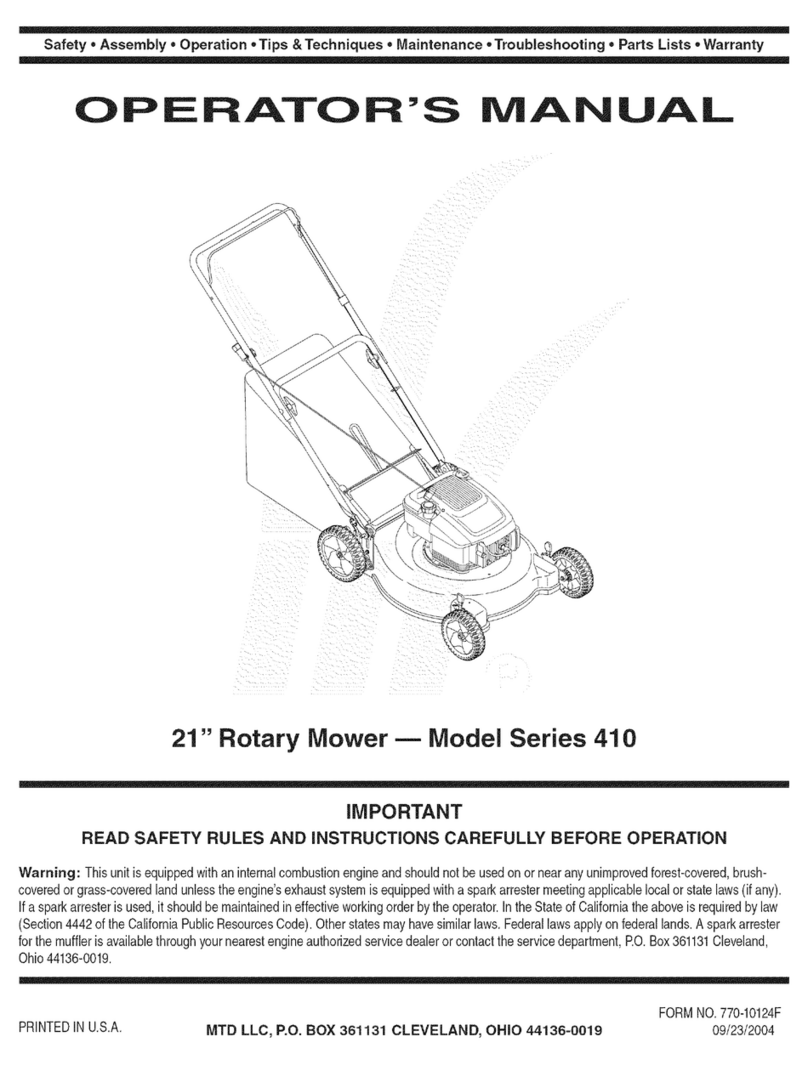

MTD Series 760 User manual

MTD

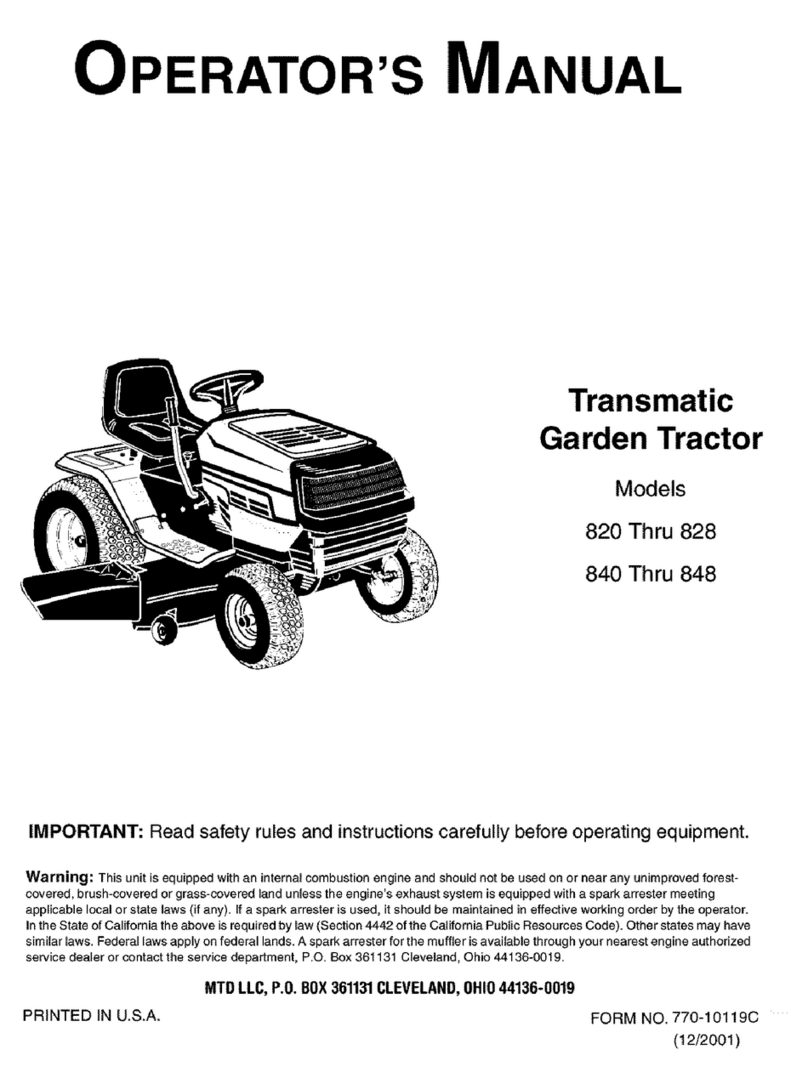

MTD 124-828F000, 124-828I000, 124- Setup guide

MTD

MTD 2005 500 Series User manual

MTD

MTD 11A-414A752 User manual

MTD

MTD 112-530 User manual

MTD

MTD 115-500A Manual

MTD

MTD 111-328-300 User manual

MTD

MTD 840 Series User manual

MTD

MTD 132-698A User manual

MTD

MTD Yard Machines 200 Series User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

Toro

Toro Groundsmaster 3505-D Service manual