Powered

Walk

B

ehind

Mower - CE Form

No.

769-08619

Rev

12-11-2012

©

Copyright 11/2012

1

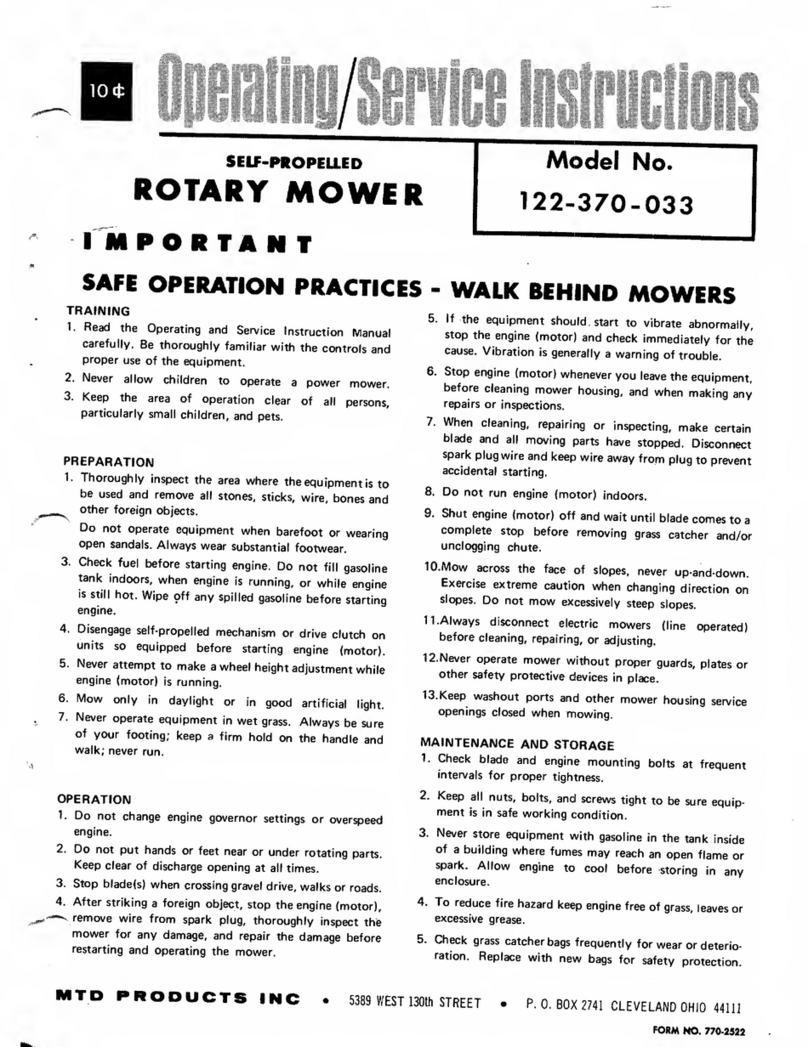

TR

AINING

•

Read the

instructions

carefully. Be familiar with the

controls

and the proper use of the

equipment.

•

Never

allow children or

people

unfamiliar with

these instructions

to use the

mower.

Local

regulations

may

restrictthe

age of the

operator.

•

Never

mow while

people, especially

children, or pets are

nearb

y

.

•

Keep in mind that the

operator

or user is

responsible

for

accidents

or hazards occurring to other

people

or their

proper

t

y

.

PREPAR

ATION

•

While

mowing,

always wear

substantial footwear

and long

trousers.

Do not

operate

the

equipment

when

barefoot or

wearing open

sandals.

•

Thoroughly

inspect the area where the

equipment

is to be used and

remove

all

stones,

sticks, wires, bones and

other

foreign

objects.

•

WARNING

-

Petrol

is highly

f

lammable.

Take the following

precautions:

-

Store

fuel in

containers

specially

designed

for this

p

urpose.

- Refuel

outdoors

only and do not

smoke

while

refuelling.

- Add fuel before starting the

engine. Never remove

the cap of the fuel tank or add petrol while the engine is running

or when the engine is

hot.

- If petrol is spilled, do not

attempt

to start the engine but

move

the

machine

away from the area of spillage and

a

v

oid

creating

any

source

of ignition until petrol vapours have

dissipated.

- For

reasons

of safety the petrol tank and tank cap lock must be

replaced

if

damaged.

•

Replace faulty

silencers.

•

Before

using, always visually inspect to see that the blades, blade bolts and

cutter assembly

are not worn or

damaged.

Replace worn or

damaged

blades in sets to

preserve

b

alance.

•

On

multibladed machines,

take care as

rotating

one blade can cause other blades to

rotate.

OPER

ATION

•

Do not

operate

the engine in a conf ined space where

dangerous

carbon

monoxide

fumes can

collect.

•

Mow only in daylight or in good artificial

light.

•

Avoid

operating

the

equipment

in wet grass, where

feasible.

•

Always be sure of your footing on

slopes.

•

Walk, never

run.

•

For

wheeled

rotary

machines,

mow across the face of

slopes,

never up and

do

wn.

•

Exerciseextreme

caution when changing

direction

on

slopes.

•

Do not mow

excessively steep slopes.

•

Use

extreme

caution when reversing or pulling the

mower towards

y

o

u.

•

Stop the

blade(s)

if the

mower

has to be tilted for

transportation

when crossing

sur

faces other than grass and

when

transporting

the

mower

to and from the area to be

mo

w

ed.

•

Never operate

the

mower

with

defective

guards or shields, or

without

safety

devices,

for

example

def

lectors

and/or

grass

catchers

in

place.

•

Do not change the engine

governor settings

or

overspeed

the

engine.

•

Disengage

all blade and drive

clutches

before starting the

engine.

•

Start the engine or switch on the

mower

carefully according to

instructions

and with feet well away from the

blade(s).

•

Do not tilt when starting the engine or switching on the

motor,

unless the

mower

has to be tilted for starting. In this

case,

do not tilt it

more

than

absolutely necessary

and lift only the part which is away from the

operator.

•

Do not start the engine when standing in front of the discharge

chute.

•

Do not put hands or feet near or under

rotating

parts. Keep clear of the discharge

opening

at all

times.

•

Never

pick up or carry a

mower

while the engine is

running.

•

Stop the engine and

disconnect

the spark plug

lead:

-

Before

clearing

blockages

or unclogging the

chute.

-

Before

checking, cleaning or working on the

mo

w

er

.

- After striking a foreign

object.

Inspect the

mower

for

damage

and make repairs before

restarting

and

operating

the

mo

w

er

.

- If the

mower

starts to vibrate abnormally check

immediately.

•

Stop the

engine:

-

Whenever

you leave the

mo

w

er

.

-

Before refuelling.

•

Reduce the

throttle setting

during engine run-out and if the engine is provided with a shut-of f valve, turn

of

f the

fuel

at the

conclusion

of

mo

wing.

MAINTENANCE

AND

ST

OR

A

GE

•

Keep all nuts, bolts, and screws tight to be sure the

equipment

is in safe working

condition.

•

Neverstore

the

equipment

with petrol in the tank inside a building where fumes may reach an open

f

lame or

spark.

•

Allow the engine to cool before storing in any

enclosure.

•

To

reduce

the

f

ire hazard, keep the

engine, silencer, battery compartment

and petrol

storage

area free of grass,

lea

v

es,

or

excessive grease.

•

Check the grass

catcher frequently

for wear or

deterioration.

•

Replace worn or

damaged

parts for

safet

y

.

•

If the fuel tank has to be drained, do this

o

utdoors.

W

ARNING