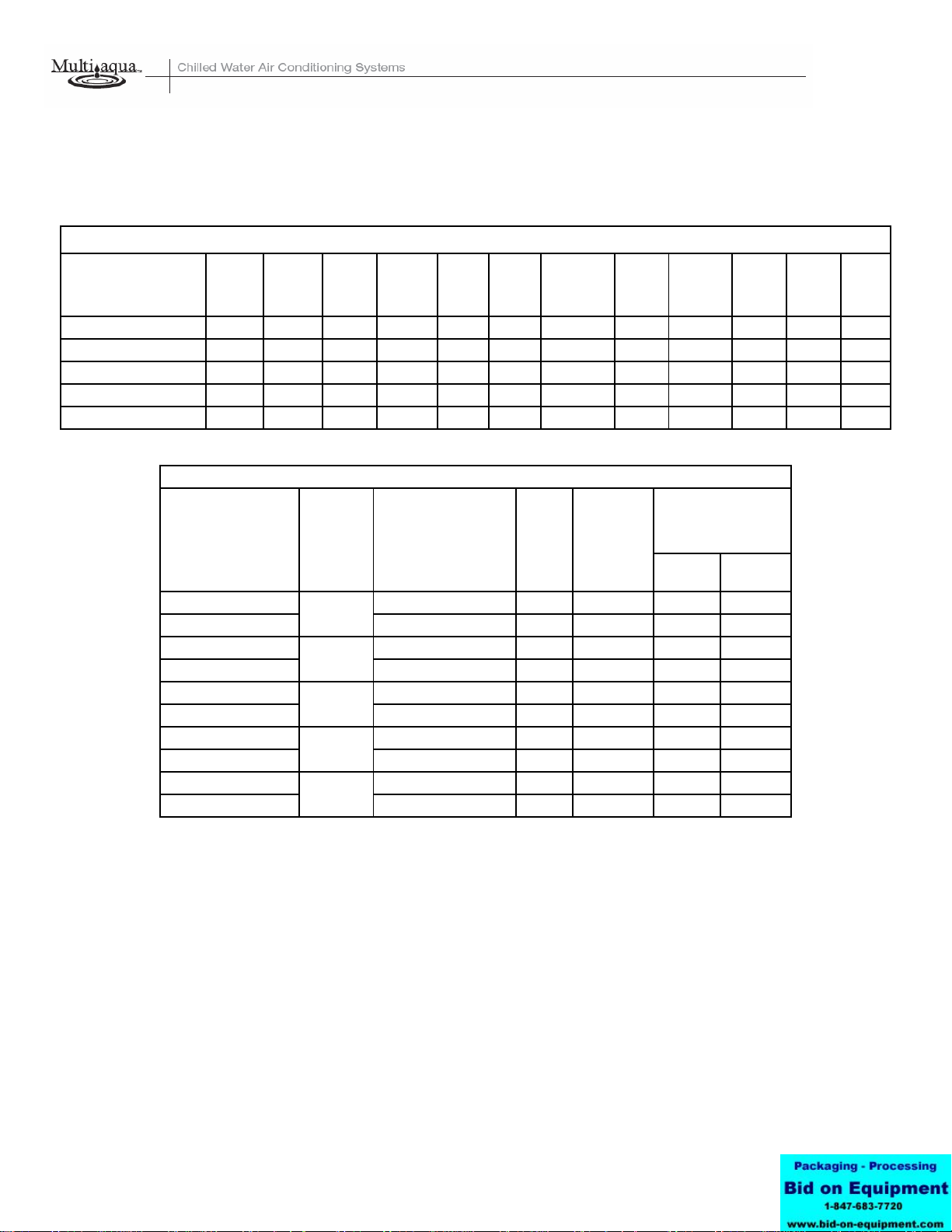

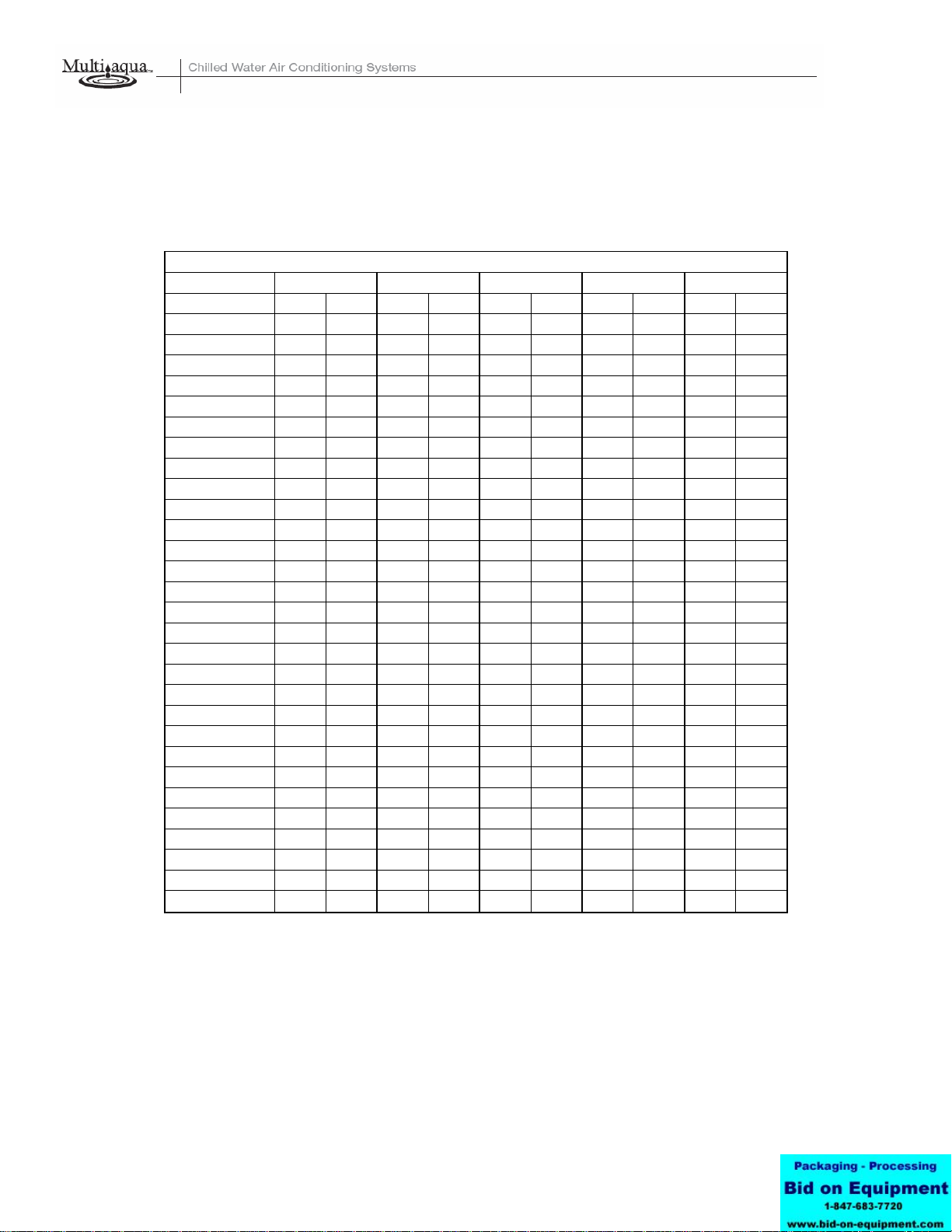

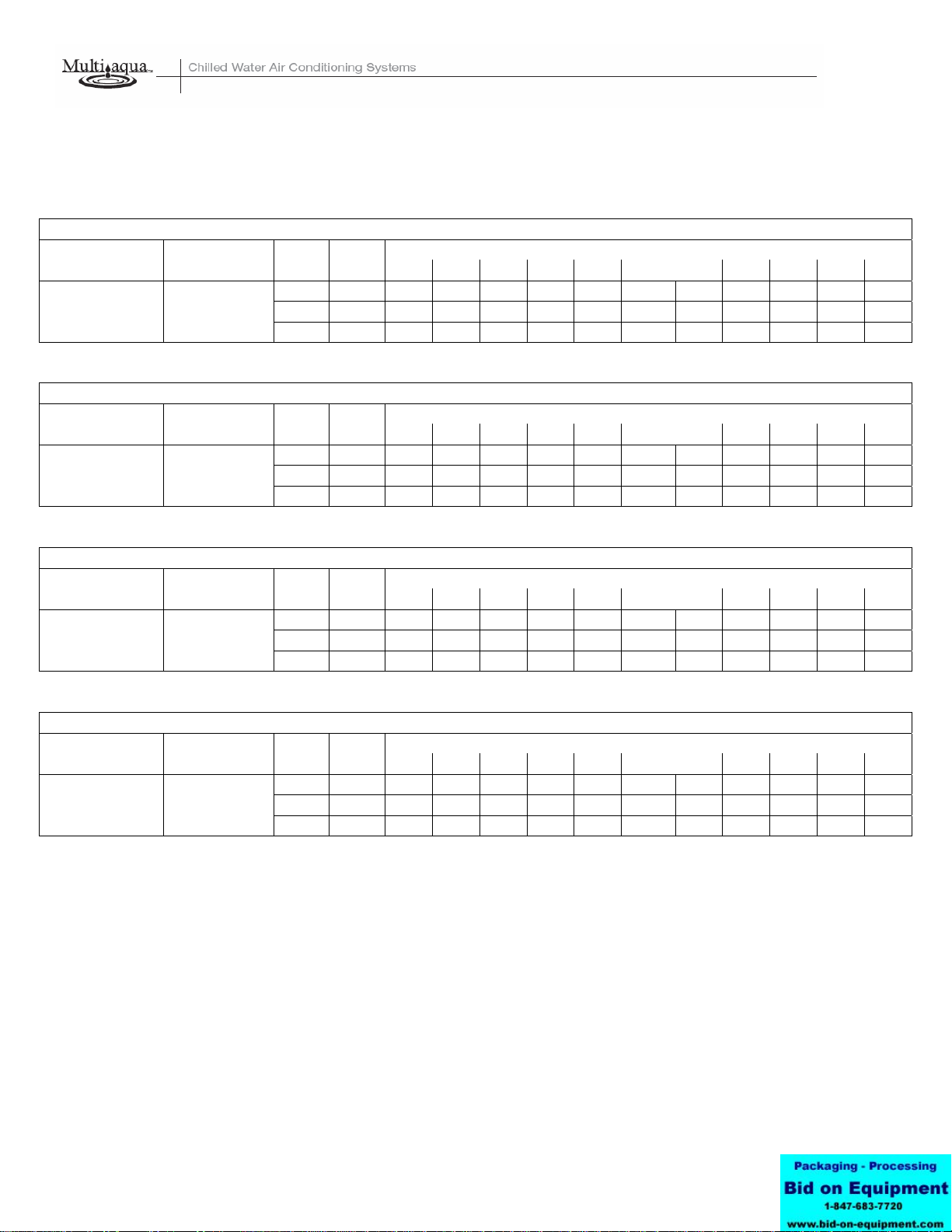

HVAC Guide Specifications

Direct Expansion and Hot Water Fan Coil

4-Pipe

Nominal Size:

12,000 – 36,000 BTUH

Multiaqua Model Number:

MHNCCX04

MHNCCX06

MHNCCX08

MHNCCX10

MHNCCX12

Part 1-General

1.01System Description

Multiaqua DX and Chilled Water Fan Coils are manufactured with heavy gauge galvanized steel to resist

corrosion.

1.02Quality Assurance

A. Certified in accordance with U.L. Standard 95, latest version (U.S.A.)

B. Manufactured in a facility registered to ISO 9002, Manufacturing Quality Standard.

C. Fully load tested at the factory.

D. Damage resistant packaging.

1.03Delivery, Storage and Handling

A. Packaged and readied for shipment from the factory.

B. Controls shall be capable of withstanding 150°F storage temperatures in the control compartment.

C. Stored and handled per manufacturer’s recommendations.

Part 2-Product

2.01 Equipment

A. General:

1. Unit shall be a factory assembled and tested DX and hot water fan coil.

2. Shall be assembled with heavy gauge galvanized steel.

3. Contained with the unit shall be all factory wiring, piping, associated controls and special

accessories required prior to start up.

B. Unit Cabinet:

1. Composed of heavy gauge galvanized steel casing with a baked polyester powder.

2. Shall be internally insulated to insure quiet operation.

C. Fan Motors:

1. Shall be available in 115-1-50/60 and 208/230-1-50/60 vac.

1. Fan motors shall be three speed, direct drive, and PSC type.

2. Totally enclosed.

3. Internal overload protected.

D. Blower Wheels:

1. Blower wheels are forward curved and dynamically balanced.

E. Water Coil:

1. Manufactured with water coils containing 3/8” copper tubing mechanically bonded to aluminum

fins.

2. Contain both a manual water drain and manual air bleed port per coil.

3. Coils shall be factory tested to 350 psig.

4. Coils shall be capable of being field converted from right to left hand connection.

F. Direct Expansion Coil:

1. Manufactured with water coils containing 3/8” copper tubing mechanically bonded to aluminum

fins.

2. Will contain a thermal expansion valve.

3. Coils shall be tested to 350 psig.

4. Coils shall be capable of being field converted from right to left hand connection.

320