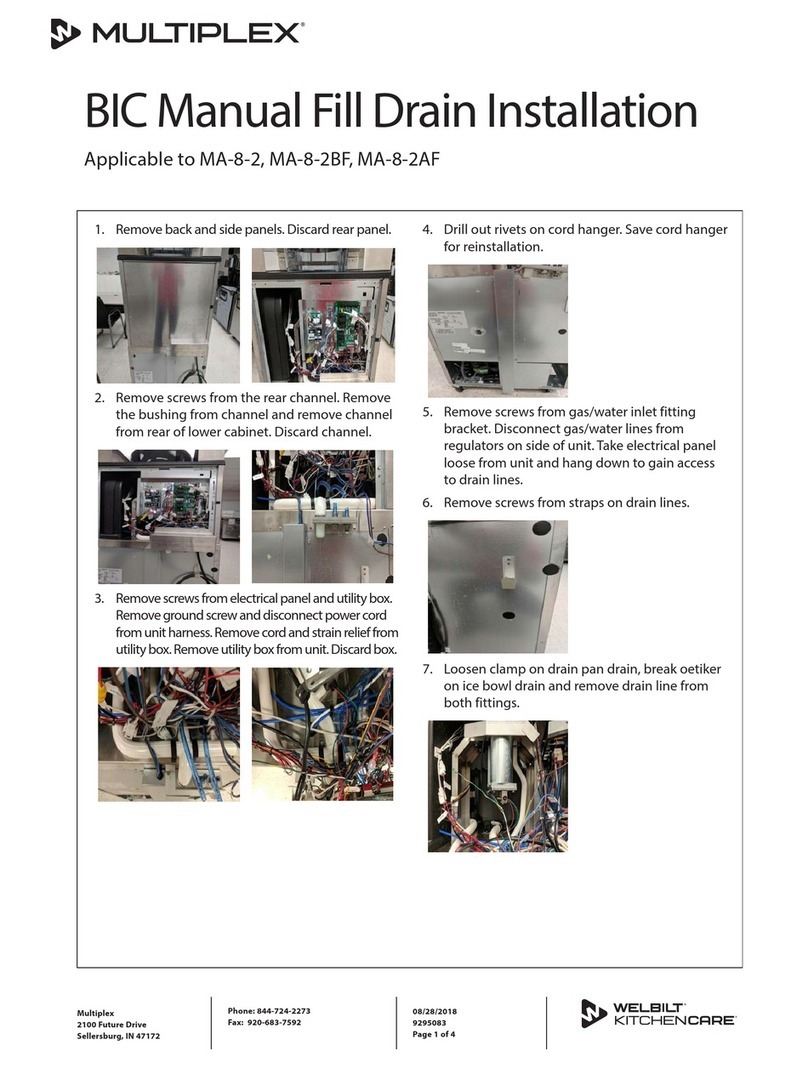

32. Locate the drain tube within upper frame of the unit.

Beginning at the discharge of each drain

outlet squeeze the tubing from front to back

dislodging any buildup within the tubing.

33. Snake each drain with a 3 ft piece of ¼”I.D. x ⁄“

O.D. flexible clear tubing. Verify water is draining

sufficiently out of the blend chambers.

34. Check unit to make sure it is level from front to back

and side to side.

35. Repeat Step 31 until each drain line runs clear.

36. Return and secure the upper right side panel.

37. Return the unit to its serving station and

connect water line, CO line, drain and plug into

the power supply.

38. Power the unit on using the ON/OFF switch

located on the upper left side of the unit next to

the USB port.

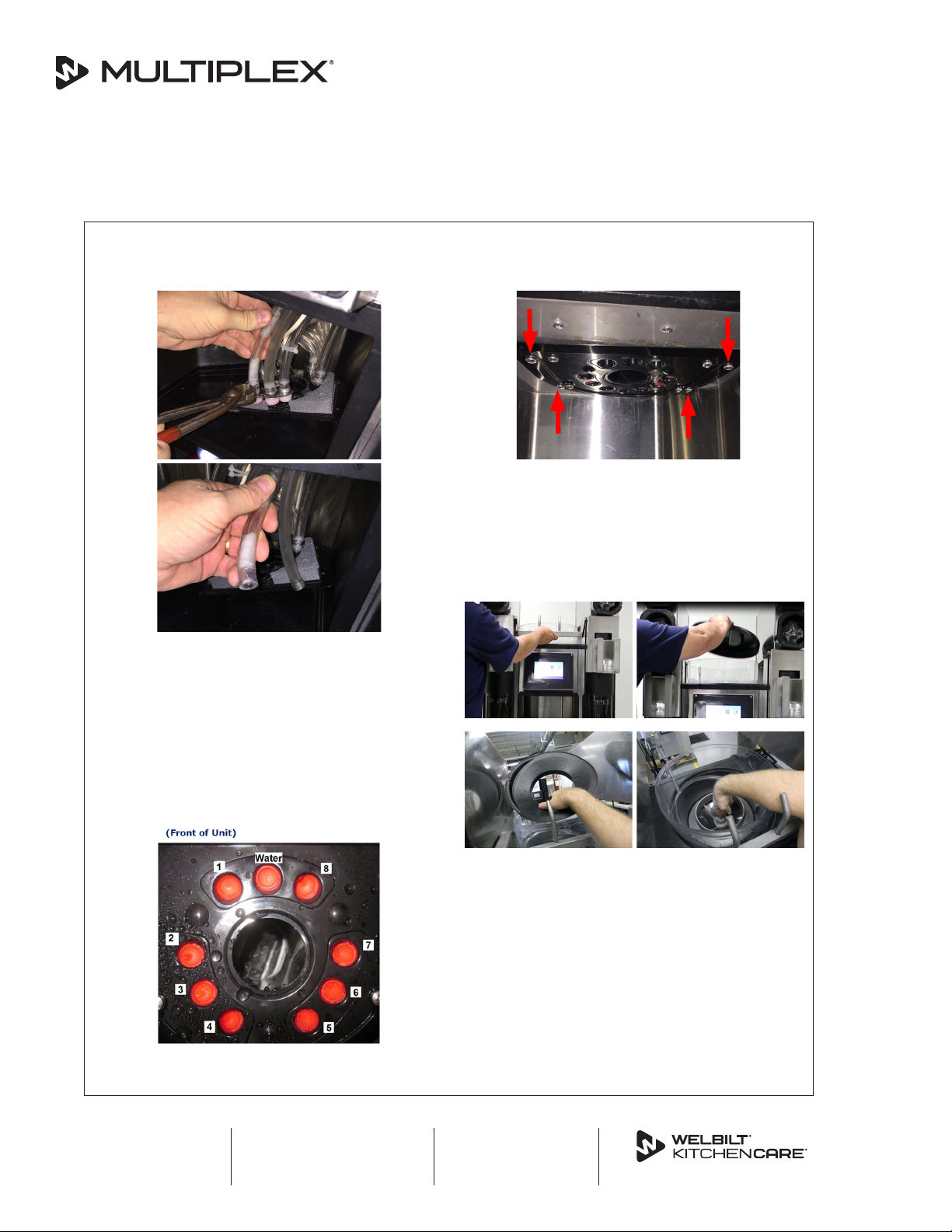

39. From the easyToUCH screen select the hands

icon. Then select the Zone 2 icon and follow the

instructions to complete the weekly cleaning.

NOTE: The manager will need to be informed that

the weekly cleaner timer was reset following the

Zone 2 cleaning. To get the weekly cleaning back

to the stores normal cleaning schedule they will

need to perform the weekly cleaning on the normal

scheduled day.

NOTE: Water and CO pressure settings can be

verified and adjusted during the Zone 2 cleaning.

40. If not completed in the previous step verify the

water and CO pressure regulators are set to 35

psi dynamic.

The regulators are located on the upper left side

of the unit.

NOTE: To achieve a dynamic pressure setting for the

water a water solenoid must be activated. To achieve

a dynamic pressure setting for the CO one of the

product solenoids must be activated.

NOTE: Follow the next steps from the easyToUCH

screen to activate a water solenoid and/or a product

solenoid:

• Select the Manager Menu Icon

• Select "A" for the password

• Select the green check

• Arrow down and Select Service

• Select "A" for the password

• Select the green check

• Select OUTPUTS

• Activate any of the eight (8) flavor

solenoids and adjust the CO regulator to

35 psi dynamic

• Turn OFF selected FLAVOR SOLENOID

• Arrow Down then select either the

WATER, LEFT RINSE, or RIGHT RINSE

and adjust the water regulator to 35 psi

dynamic

• Turn OFF selected water dispense option

• Arrow back three (3) times to return to

the main easyToUCH screen.

NOTE: To increase the pressure lift the knob at the

top of the regulator and turn clockwise. To decrease

the pressure lift the knob at the top and turn

counter clockwise.

Multiplex

2100 Future Drive

Sellersburg, IN 47172

Phone: 844-724-2273

Fax: 920-683-7592 Page 9 of 13

2020 Tune Up, continued