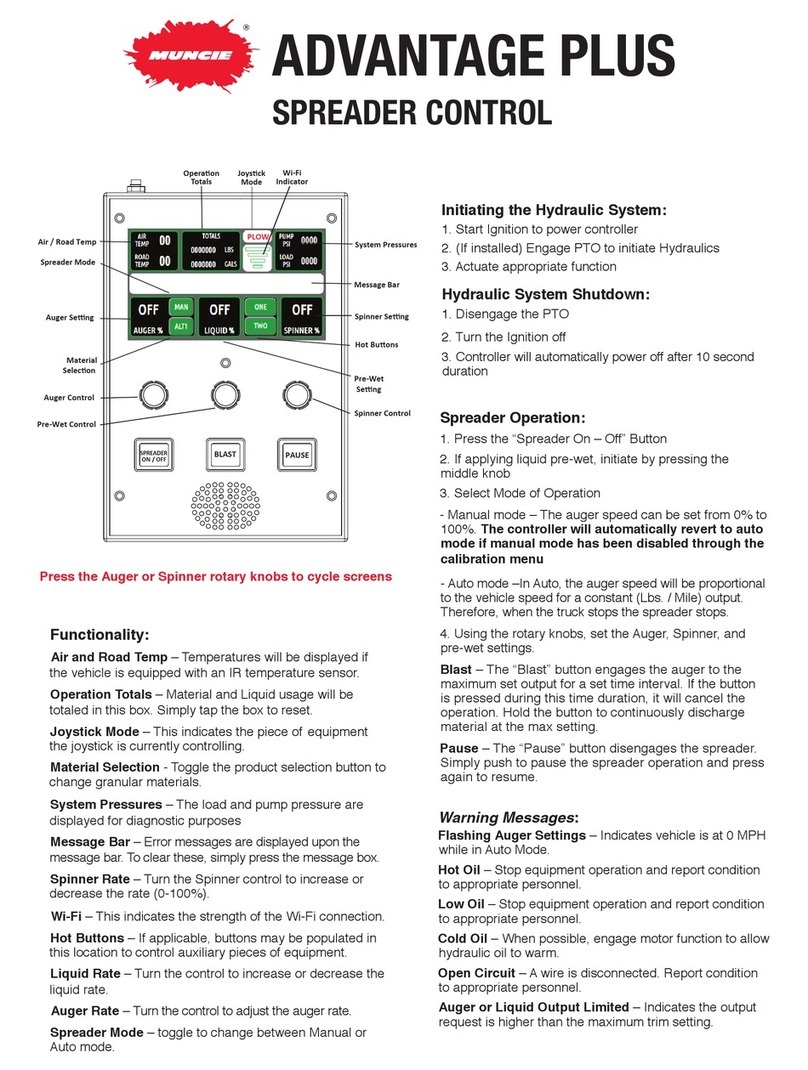

SNOW & ICE DIVISION PAGE 8

MAIN OPERATING SCREENS

Main Operating Screen – Anti Ice:

Air Temp/Road Temp – Displays air and road

temperatures. Temperatures will only display if IR

temperature sensor is installed.

Joystick Mode – Displays the current piece of

equipment the joystick is controlling.

System Pressures/Oil Temperature –

Toggle this selection to alternate between

system pressures and oil temperature.

Message Bar – Displays error messages.

Liquid Rate – Displays the liquid rate. Use the auger

rate knob to control the speed of the liquid output.

Mode – Displays the mode of operation. Toggle

button to change between Auto and Manual.

Boom Controls – Up to 3 booms can be congured with

the system. Booms can either be controlled with on screen

touch buttons or switch controls. Press appropriate boom

controls to actuate. When a boom is actuated, the button

will latch orange to indicate that it is “on”.

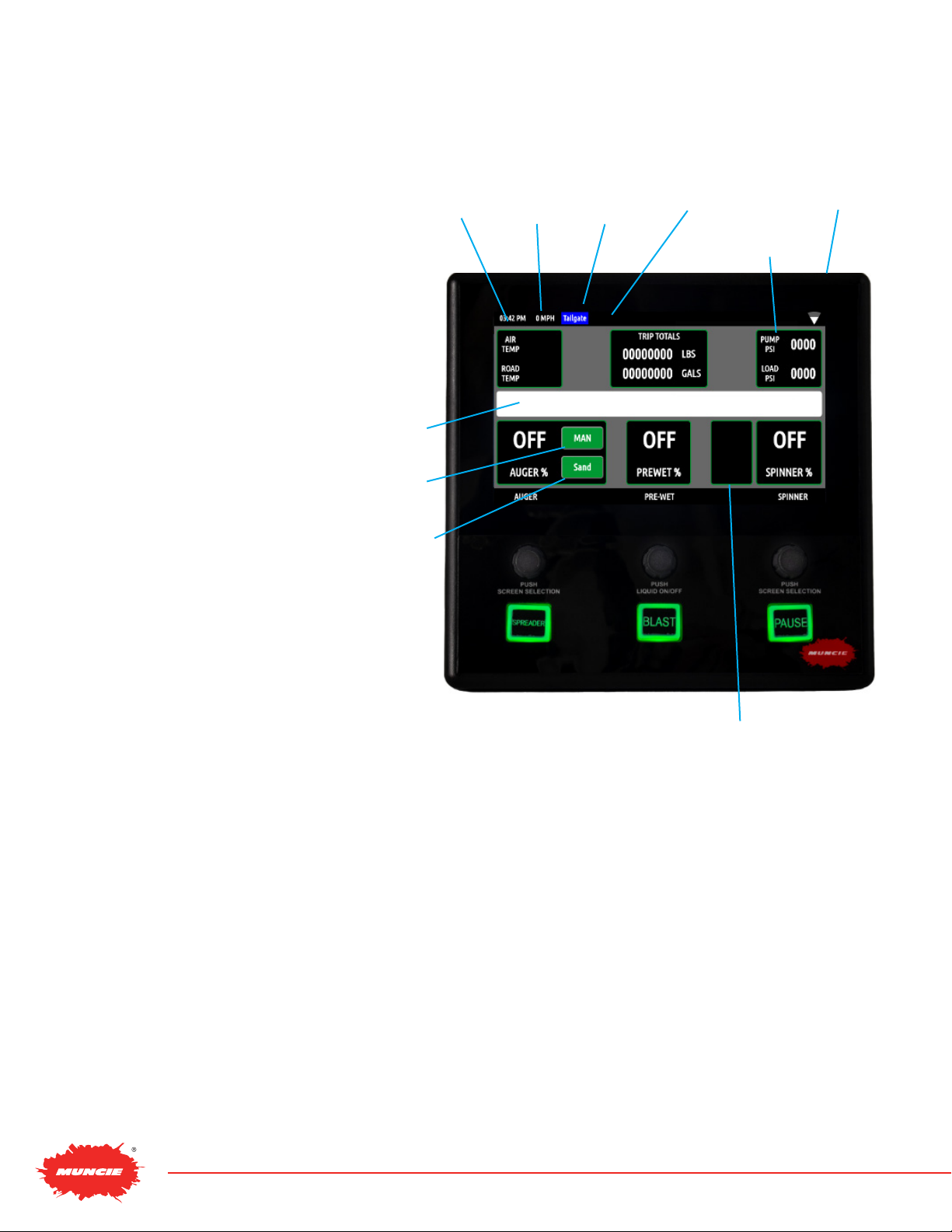

Main Operating Screen – Tow Plow:

Air Temp / Road Temp – Displays air and road

temperatures. Temperatures will only display if IR

temperature sensor is installed.

Joystick Mode – Displays the current piece of

equipment the joystick is controlling.

System Pressures / Oil Temperature – Toggle this

selection to alternate between system pressures

and oil temperature.

Message Bar – Displays error messages.

Auger Rate – Displays the auger rate. In manual

mode, the setting is displayed as a percentage. In

auto mode the rate is displayed as Lbs/Mile.

Auger #2 Rate – Displays the auger rate for the tow

plow. In manual mode, the setting is displayed as a

percentage. In auto mode the rate is displayed as

Lbs/Mile.

Spinner Rate – Displays the spinner rate as a

percent or lane coverage.

Mode – Displays the mode of operation. Toggle

button to change between Auto and Manual.

Joystick

Mode Not

Shown

Liquid

Rate

Spreader

Mode

Wi-Fi

Air Temp/

Road

Temp

Boom

Controls

Message

Bar