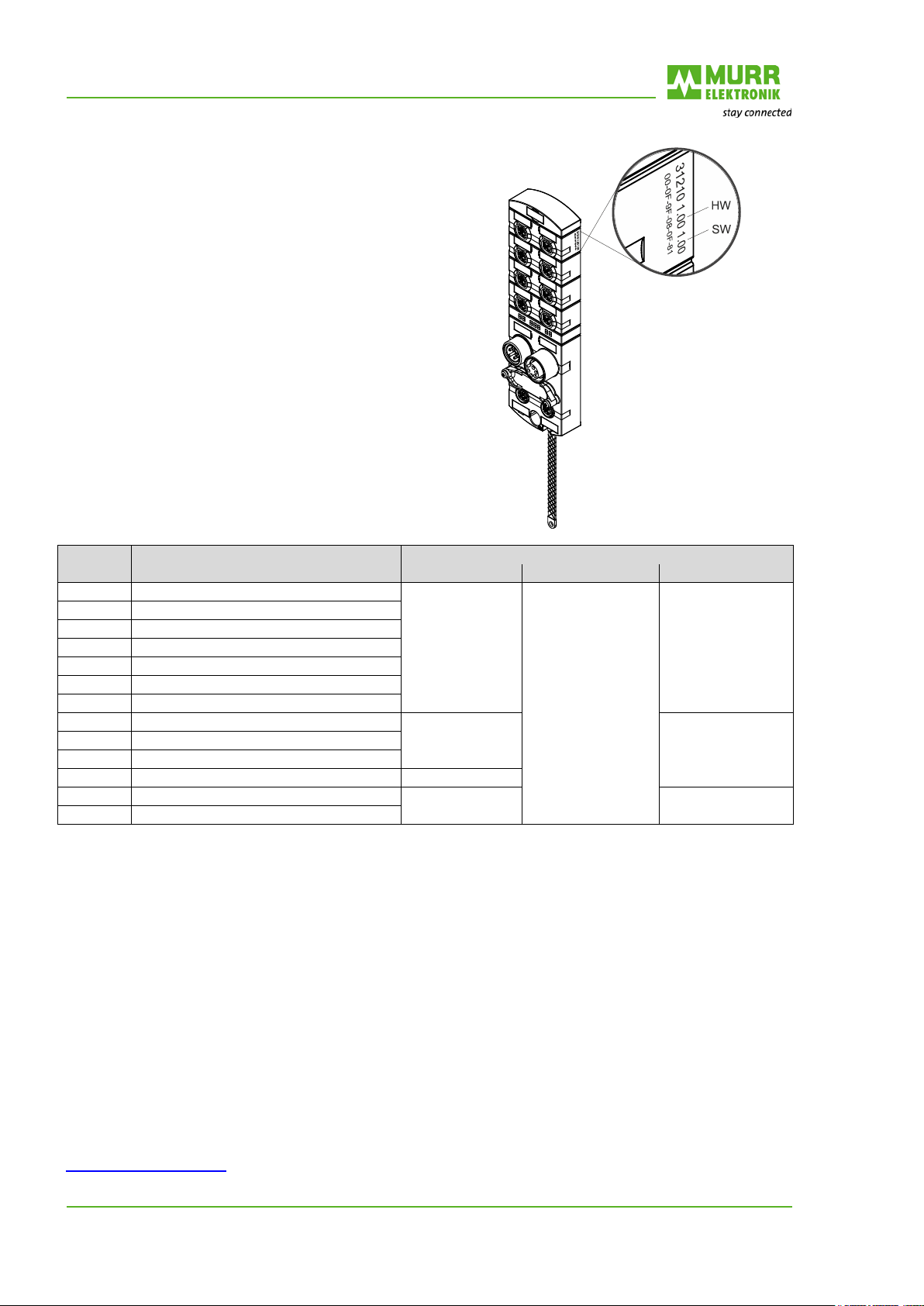

Manual for MVK-MPNIO Modules

4 V 1.9

Content

Service and Support................................................................................................................................... 3

1. Important Information ............................................................................................................................ 6

2. Configuration .......................................................................................................................................... 9

2.1 Power Supply......................................................................................................................................9

2.2 Electromagnetic Compatibility (EMC) ...............................................................................................10

2.3 PROFINET Conformance Classes ...................................................................................................14

2.4 Ethernet Switching Mechanisms.......................................................................................................15

2.5 Media redundancy protocol (MRP) ...................................................................................................16

2.6 Replaceability....................................................................................................................................17

3. Installation.............................................................................................................................................18

3.1 Assembly...........................................................................................................................................18

3.1.1 Mounting space..........................................................................................................................19

3.1.2 Dimensions MVK+ MPNIO PP...................................................................................................20

3.1.3 Dimensions MVK+ MPNIO M23.................................................................................................21

3.1.4 Dimensions MVK+ MPNIO 7/8“..................................................................................................22

3.1.5 Dimensions MVK+ MPNIO POF PP...........................................................................................23

3.1.6 Functional Earth ......................................................................................................................... 24

3.2 Overview of Connections ..................................................................................................................25

3.2.1 Connection of Digital Sensors and Actuators.............................................................................35

3.3 Connections ......................................................................................................................................40

3.3.1 Connecting PROFINET..............................................................................................................40

3.3.2 Connecting the Power Supply.................................................................................................... 40

4. Setup......................................................................................................................................................41

4.1 GSD File............................................................................................................................................ 41

4.2 Configuration with S7 Hardware Manager........................................................................................41

4.2.1 General Information....................................................................................................................41

4.2.2 Project MVK-MPNIO...................................................................................................................42

4.2.3 Parameterization of Fast Start-Up..............................................................................................45

4.2.4 Topology Setting.........................................................................................................................47

4.2.5 Identification of Individual Devices in the Network.....................................................................48

4.2.6 Assigning Device Name and IP Addresses................................................................................49

4.2.7 Plan MRP ...................................................................................................................................50

4.2.8 Optical Data Transfer in Profinet................................................................................................ 52

4.2.9 Plan Shared Device....................................................................................................................54

4.3 Parameterization...............................................................................................................................58

4.4 SNMP................................................................................................................................................58

5. Data Modules.........................................................................................................................................59

6. Diagnostics............................................................................................................................................62