!!

!""

##"$

"%"

##"$

"

"

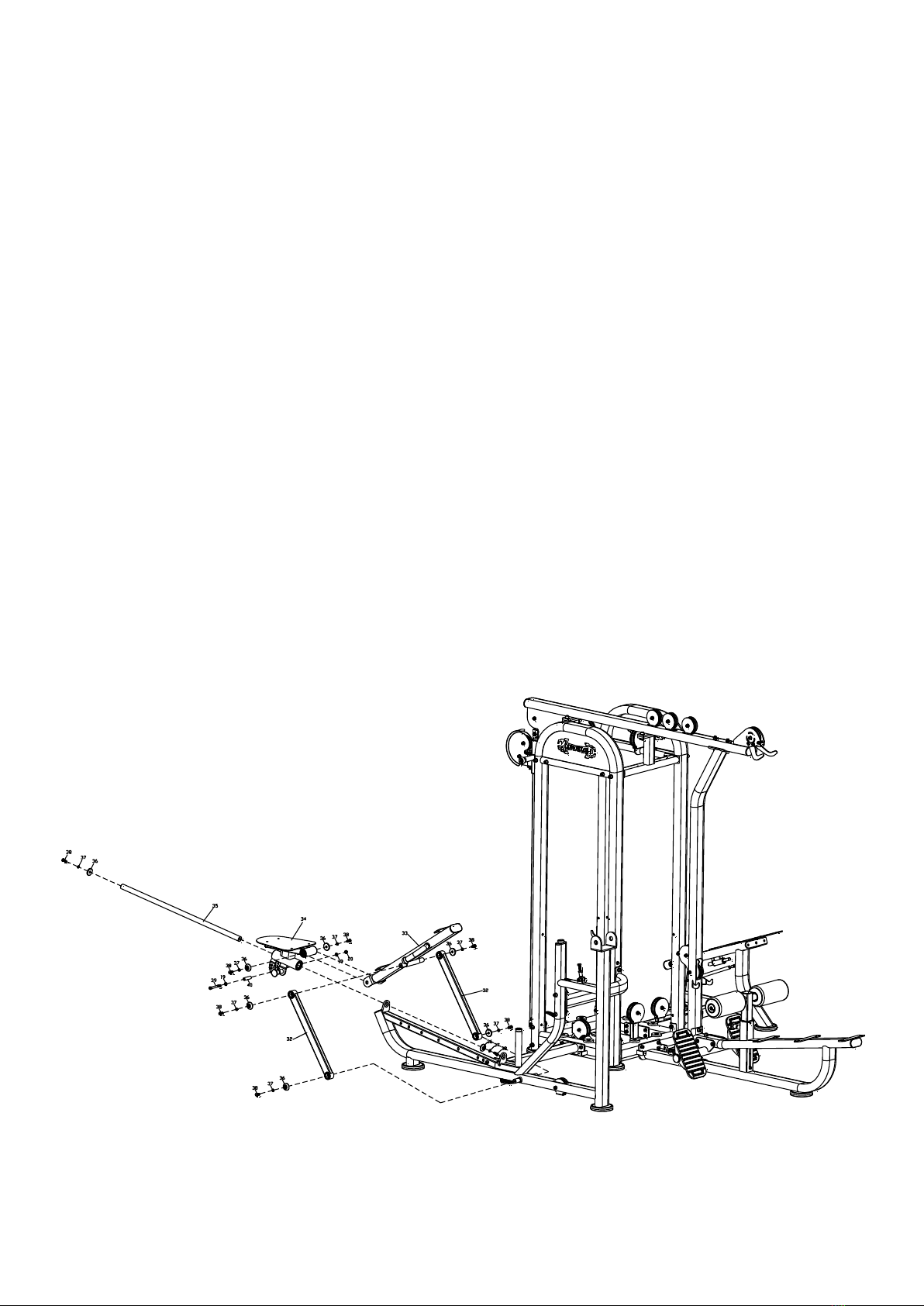

STEP 9:

Attaching Seat Back Support Tube, Seat Handles,

Cam, and Seat Back Adjustment Lever, Scissor

Flat Strap, & Gas Piston to Seat Frame

First attach the seat back support tube to the 4 flat strap metal pieces using 4

short axles. The axles go through the holes at back support tube at the top

holes of the flat straps as well as through the bottom holes on the flat strap

metal pieces secured by bolts, washers, and nuts. Note that one of the 4 flat

straps has a pie shaped metal wedge with Holes and this must go in the forward

most position. Attach the gas piston to the flat strap and to the upright tube

under the seat.