8

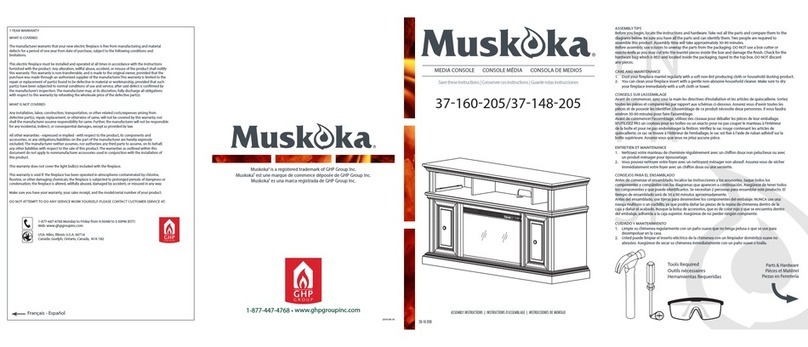

WARRANTY

Greenway Home Products is pleased to offer in-home warranty repairs. Please refer to your Firebox Use and Care Guide for warranty

information on your Firebox. Retain receipt as proof of purchase should repair, parts or service be required.

DO NOT RETURN THIS PRODUCT TO THE STORE: Please contact Customer Service at: 1-866-253-0447 Monday to Thursday

from 8:30AM to 5:00PM (EST), Friday from 8:30AM to 4:00PM (EST)

Web: www.greenwayhp.com

Canada: 400 Southgate Dr., Guelph, Ontario, Canada, N1G 4P5

USA: 1270 Flagship Dr., Perrysburg, Ohio, USA, 43551

Limited Warranty Definitions:

Greenway Home Products: (Greenway)Manufacturer.

Mantel: Mantel manufactured by Greenway Home Products.

Purchaser: Purchaser of the Mantel

Distributor: Facility authorized to sell Greenway Home Products.

Warranty Card: Greenway Home Products Limited Warranty Registration Card identifying the Purchaser and product model.

Greenway Limited Warranty:

Greenway warrants to the Purchaser that the Mantel is free from defects in material and workmanship, under normal use and service, for 1

year (1 year limited parts) from the date of purchase.

All warranty repairs must be preauthorized by Greenway Home Products. Greenway will, at its’ option, replace or repair free of charge any

defective part, which the Purchaser shall notify their Distributor or Greenway Home Products within the warranty period. The obligation of

Greenway Home Products under this warranty, is expressly limited to such replacement or repairs.

The provisions of this limited warranty shall not apply to the following:

1. Accidents.

2. Unauthorized repairs or alterations.

3. Normal maintenance.

4. Changes made to other units manufactured after this mantel was manufactured.

5. Incidental damages caused by failure of the mantel such as inconvenience or loss of use.

6. Improper installation.

The provisions of this limited warranty shall not apply to deterioration due to wear and exposure beyond the following limitations:

1. For 180 days from the date of purchase for exterior finished surfaces.

Due to the properties of natural wood, Greenway Home Products makes no warranty against mineraling of wood components.

Greenway Limited Warranty is void unless the following conditions are adhered to:

1. Warranty registration must be completed and returned to a Greenway Home Products.

2. All warranty repairs must be preauthorized by a Greenway repair facility.

3. Greenway reserves the right to inspect defective parts that have been replaced under warranty. Dealer is expected to hold

defective parts for 60 days.

4. Only parts and accessories and other material, available through Greenway Home Products are to be used in the performance

of warranty service.

5. Purchasers are responsible for presenting/notifying their Distributor as soon a problem exists. The warranty repairs should be

completed in a reasonable amount of time from the date of authorization. Not to exceed 30 days past notification.

This limited warranty is expressly in lieu of any other expressed or implied warranty, including any implied warranty or merchantability or

fitness for a particular purpose and of any obligations or liabilities on Greenway Home Products which neither assumes nor

authorizes any other person to assume for it any other liability in connection with the Mantel manufactured by it.

The warranty is null and void if used in commercial or industrial applications.