MVE FUSION Quick Reference Guide

9 –21205647 B

9. Open the fill valve on the freezer and then the liquid discharge valve on the supply tank.

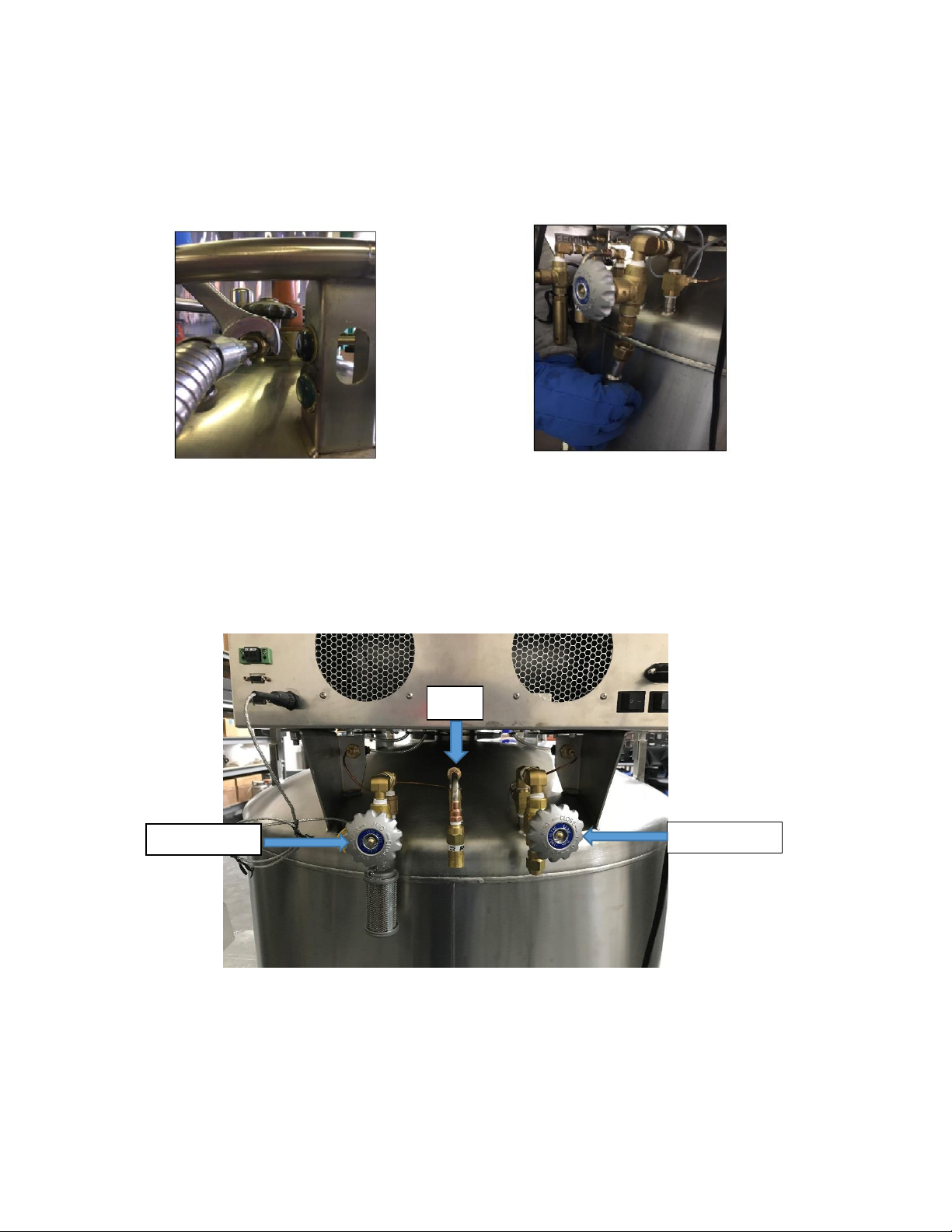

Vent Valve on the left and Fill valve on the right View inside the storage area of the MVE Fusion

10. The LN2 will begin to flow from the supply tank into the freezer. As the cryogen vessel begins to

fill up, LN2 will periodically spray out of the freezer vent valve. When a steady stream of LN2

exits the vent valve, the cryogen vessel is full (the vent valve may spray and sputter for several

minutes prior to discharging a steady stream of liquid). The MVE Fusion first fill will take

approximately 35 to 45 minutes.

11. Once LN2 begins to flow steadily out of the vent, first shut off the vent valve, then second, shut

off the fill valve, then thirdly, shut off the fill valve on the supply tank.

12. Verify LCD displays % of Liquid (Turn on isolation valves on both sides). Wait until the transfer

hose thaws, loosen and remove the hose connection on the freezer inlet fitting.

13. The freezer’s pressure relief valve will begin releasing gaseous nitrogen as the liquid boils off

and build pressure (above 50 PSIG) inside of the storage tank. As the internal chamber and

storage racks come down to temperature the “relief” events will decrease.

14. Equilibration Period 1: Wait 12-18 hours and repeat steps 3, 8-11 to top off the cryogen vessel.

15. Equilibration Period 2: Wait an additional 24 hours and repeat the process (steps 1-6) again. At

this point all internal freezer surfaces should be at operating temperature and the cryogenic

vessel will be full and thermally stable.