my!WIND Ltd.

Soola 1a

51013 Tartu, Estonia

Email: info@mywind.ee

Website: www.mywind.ee

2 | P a g e 2 6 / 0 7 / 2 0 1 9

Contents

Contents..................................................................................................................................................2

General remarks .....................................................................................................................................3

1. Introduction......................................................................................................................................4

2. Prior to installation...........................................................................................................................4

2.1 Important safety instructions...................................................................................................4

2.2 Building permits and zoning requirements..............................................................................5

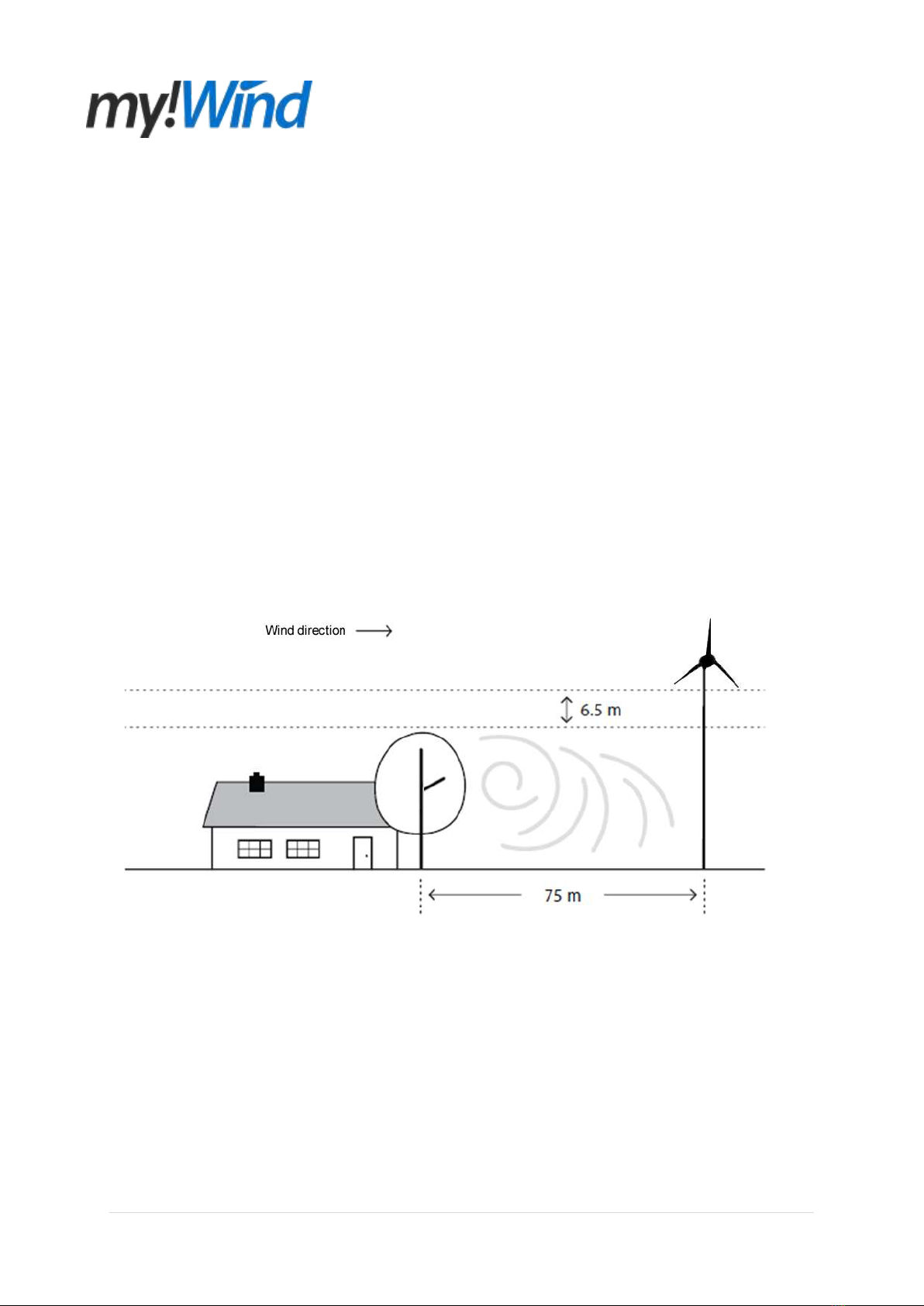

2.3 Siting .......................................................................................................................................5

3. Parts list...........................................................................................................................................7

4. Tools................................................................................................................................................8

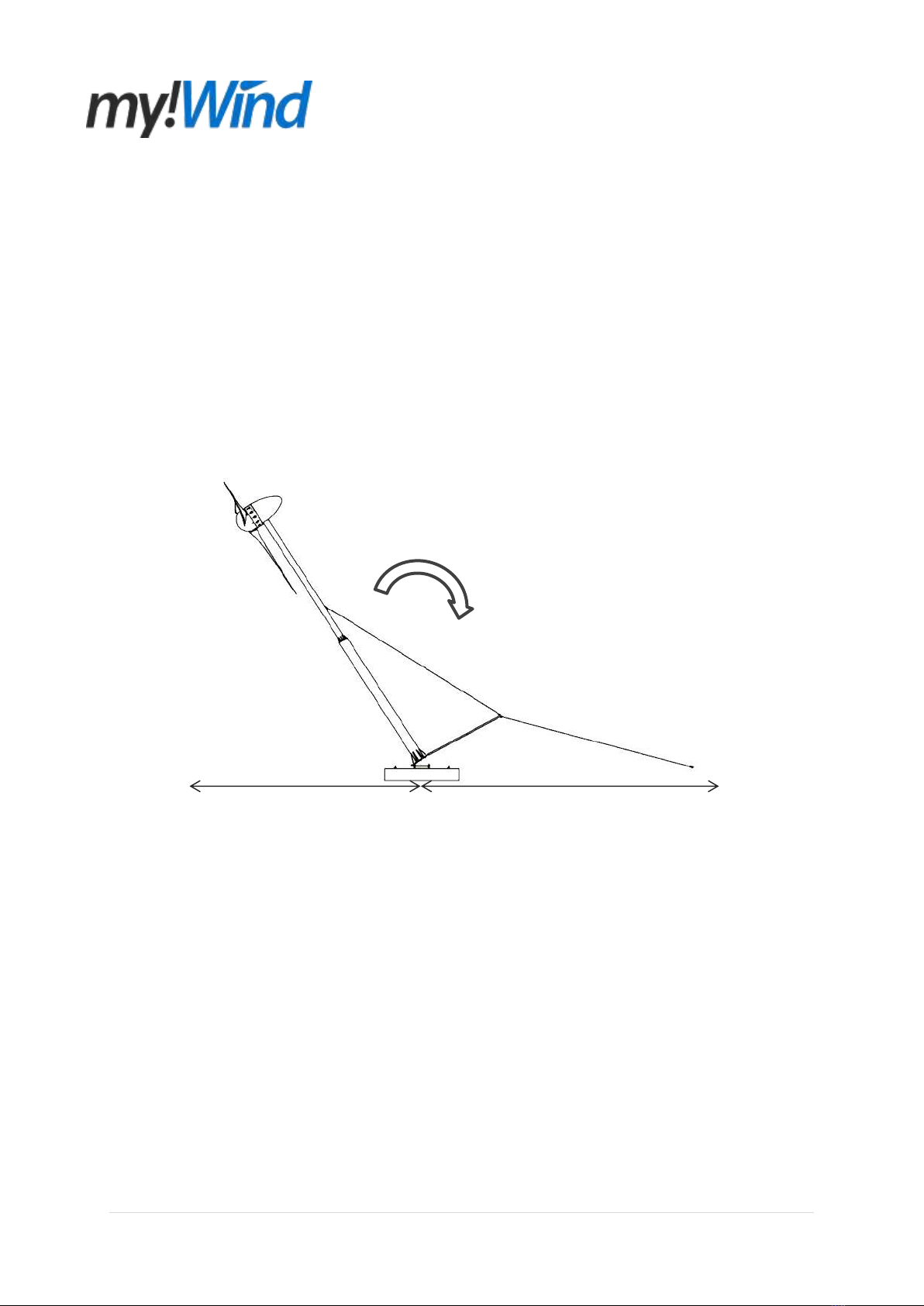

5. Erection the of tower .......................................................................................................................9

Step 1: Placing the tower base plate...................................................................................................9

Step 2: Placing the tower 1st segment...............................................................................................10

Step 3: Placing the tower 2nd segment..............................................................................................11

Step 4: Placing the gin-pole...............................................................................................................12

Step 5: Placing the gin-pole cables...................................................................................................13

Step 6: Connecting the lifting equipment...........................................................................................14

Step 7: Test lifting the tower..............................................................................................................14

Step 8: Levelling the tower................................................................................................................16

Step 9: Lowering the tower................................................................................................................16

6. Assembling the turbine..................................................................................................................17

Step 1: Placing the generator............................................................................................................17

Step 2: Repositioning the tower ........................................................................................................18

Step 3: Placing the cover holders......................................................................................................19

Step 4: Placing the blades.................................................................................................................20

Step 5: Placing the blade cover.........................................................................................................20

Step 6: Placing the nacelle cover......................................................................................................21