©Copyright Mission Critical Energy Inc, 2019 Version 1-2019

www.superwind.com

6.3.1 Wires...............................................................................................................16

AWG Wire Size Chart Table No. 6.3.1...........................................................17

6.3.2 Strain relief......................................................................................................17

6.3.3 Polarity............................................................................................................18

6.3.4 Batteries..........................................................................................................18

6.3.4.1 Charging the batteries......................................................................18

6.3.4.2 Selecting the batteries .....................................................................18

6.3.4.2.1 Battery Capacity ..............................................................19

6.3.4.3 Protection ........................................................................................19

6.3.5 Charge Regulator SCR 48 V..........................................................................20

6.3.5.1 Technical data..................................................................................20

6.3.5.2 Functional description......................................................................21

6.3.5.3 Installation location ..........................................................................21

6.3.5.4 Connecting the Charge Regulator ...................................................21

6.3.5.5 Wiring diagrams...............................................................................23

6.3.6 Fuses..............................................................................................................23

6.3.7 Stop Switch.....................................................................................................24

6.3.7.1 Mounting ..........................................................................................24

6.3.7.2 Dimensions ......................................................................................24

6.3.7.3 Electrical Connection.......................................................................25

6.3.7.4 Switch Terminals..............................................................................26

6.3.7.5 Component locations .......................................................................27

6.3.8 Diversion Load Power Resistor......................................................................27

6.3.9 Temperature Sensor.......................................................................................27

6.4 Grounding ..................................................................................................................27

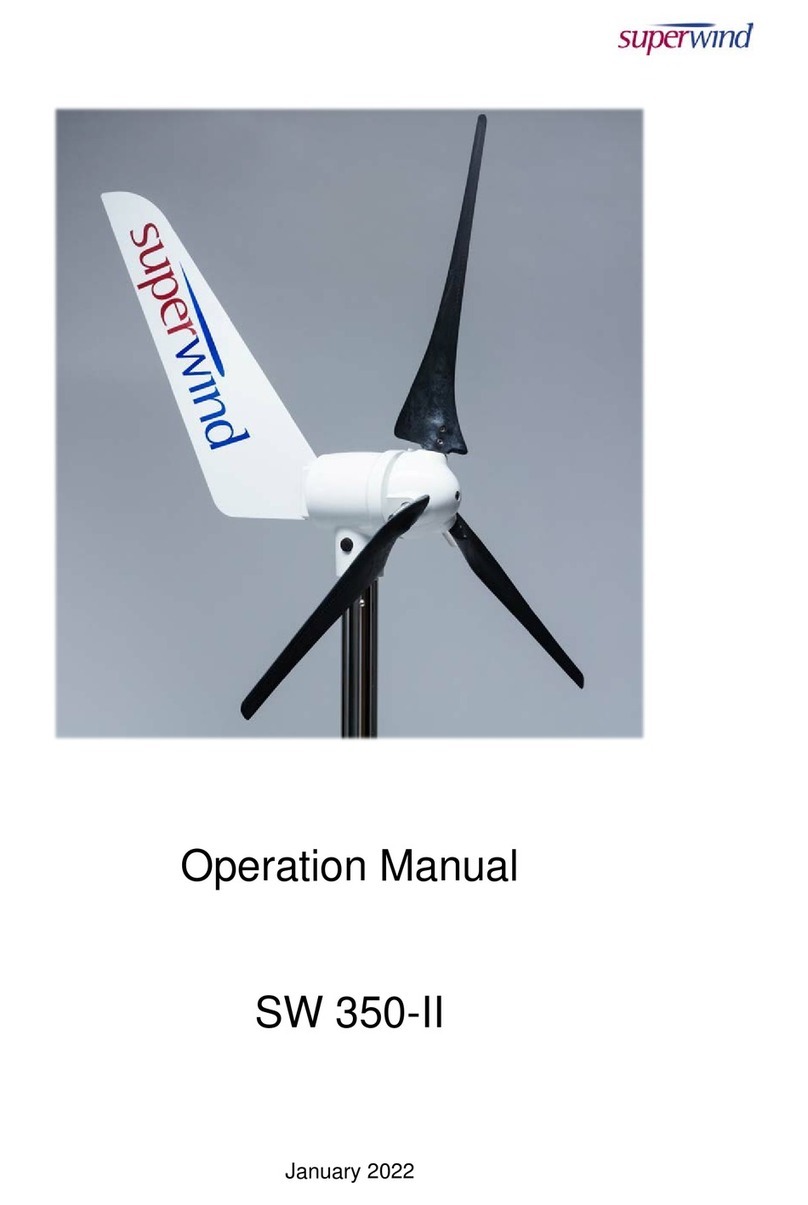

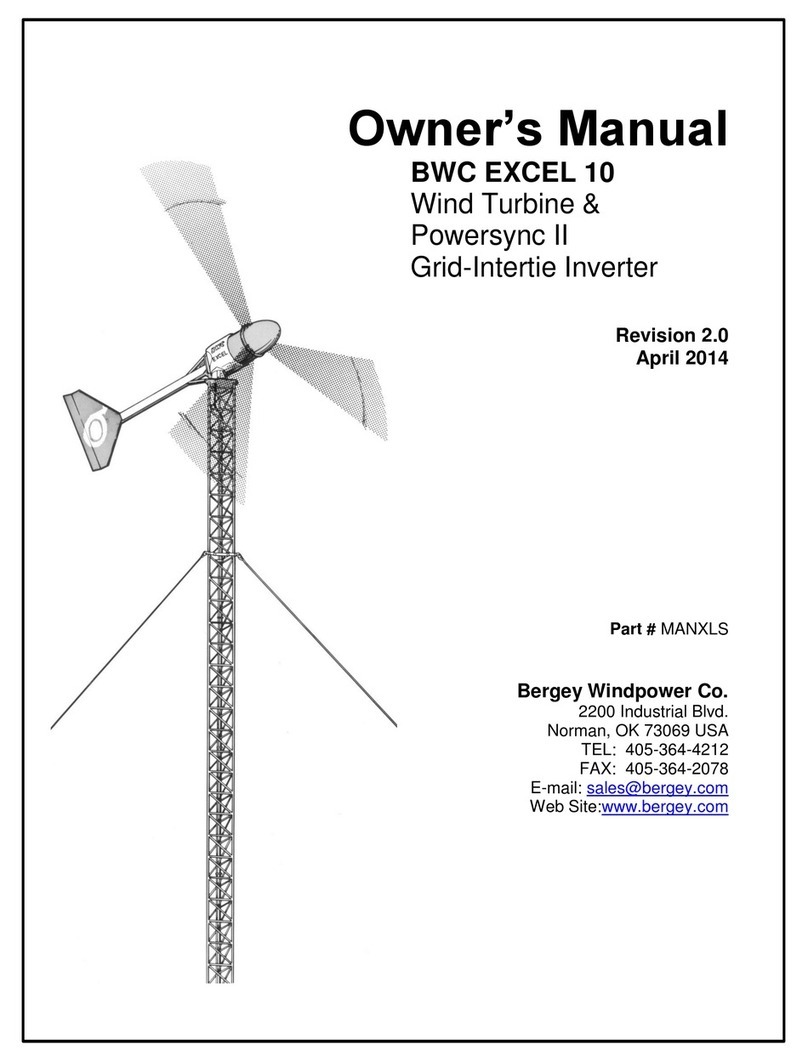

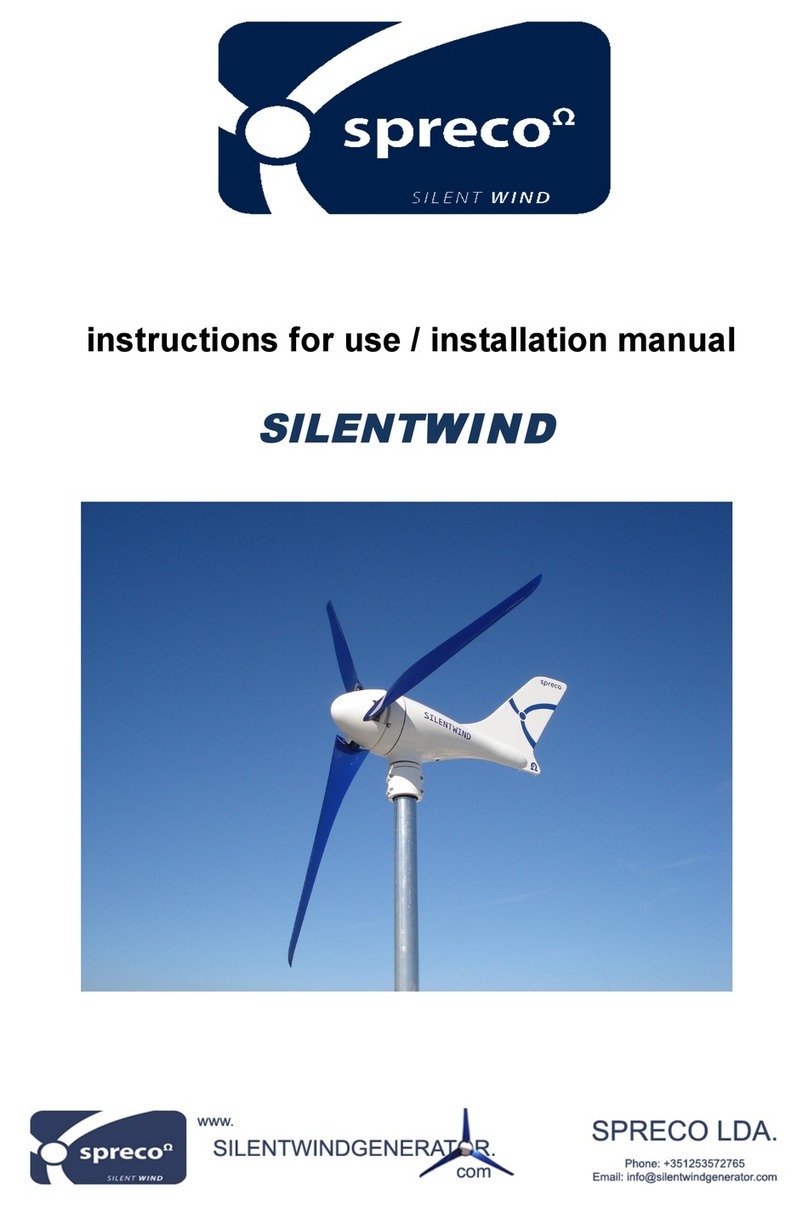

7. SUPERWIND 350/48V GENERATOR ASSEMBLY ................................................28

7.1 Precautions ................................................................................................................28

7.1.1 Short Circuit....................................................................................................28

7.2 Delrin®Bushings ........................................................................................................29

7.2.1 Bushing Basics...............................................................................................29

7.2.2 Bushing Types................................................................................................29

Bushing Quick Guide Chart ..........................................................................31

7.2.2.1 American Delrin®White ...................................................................31

7.2.2.2 American Delrin®Black ...................................................................32

7.3 Mast mounting............................................................................................................32

7.3.1 Mounting on a 60.3 mm or 60.0 mm mast tube .............................................33

7.3.1.1 Preparations at the mast head.........................................................33

7.3.2 Mounting on a 48.3 mast tube........................................................................35

7.3.2.1 Preparations at the mast head.........................................................35

7.3.3 Mounting on other mast tubes........................................................................35

7.3.3.1 Preparations at mast head...............................................................36

7.3.4 Mast Tube Specifications ...............................................................................36

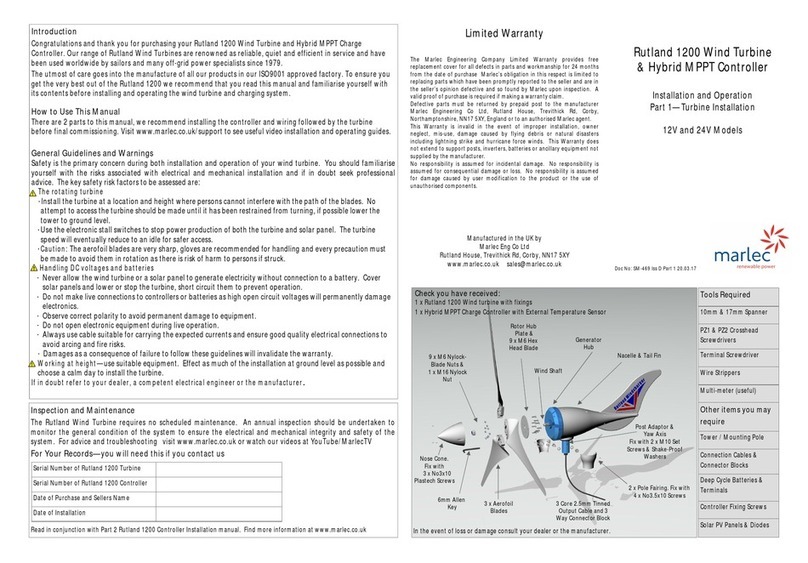

7.4 Rotor Blades ..............................................................................................................36

7.4.1 Mounting on the wind vane.............................................................................37

7.5 Rotor Assembly..........................................................................................................37

7.5.1 Attaching the rotor blades to the hub .............................................................38

7.5.2 Mounting the hub to the generator shaft ........................................................39