3 | P a g e

Safety Notes

The Futurenergy Tower Kit has been design to be a low cost tower solution for use with the Airforce

1 wind turbine. Raising and lowering towers can be dangerous if done incorrectly or in high winds or

other adverse weather conditions. Futurenergy does not accept responsibility in any way for

personal injury, damage to equipment or damage to property from using this kit. The following

instructions represent what Futurenergy believe to be the safest way to erect a tower using the

parts supplied. However, it is the installer’s responsibility to assess the hazards involved with its use.

Futurenergy recommend using an experienced installer for initial installation who may be able to

provide training for future raising and lowering of the tower to the end user.

The following is a list of key safety points.

1. Install the tower / turbine well away from (a distance greater than the tower height)

overhead power cables, buildings, livestock, roads, vehicle parking areas, paths, children’s

play areas and any other area that a failed installation attempt or falling tower may cause

injury or damage.

2. Do not use the tower kit with any other turbine (turbine loading is calculated only for the

Airforce 1).

3. Use personal safety clothing when working with items at height (hard hat, safety shoes).

4. Have help, at least three people should be involved when raising / lowering the tower

manually.

Parts Supplied With Kit

P0083, Ground Anchor 5 off

P0094, M16 Ground Anchor Screw 5 off

P0093, M16 Washer 5 off

P0224, Guy Rope Floor Bracket 3 off

P0330, Turnbuckle Unit, Cone Clamp & rope grips 8 off

P0086, Steel Rope (5m & 7.5m Long) 8 off

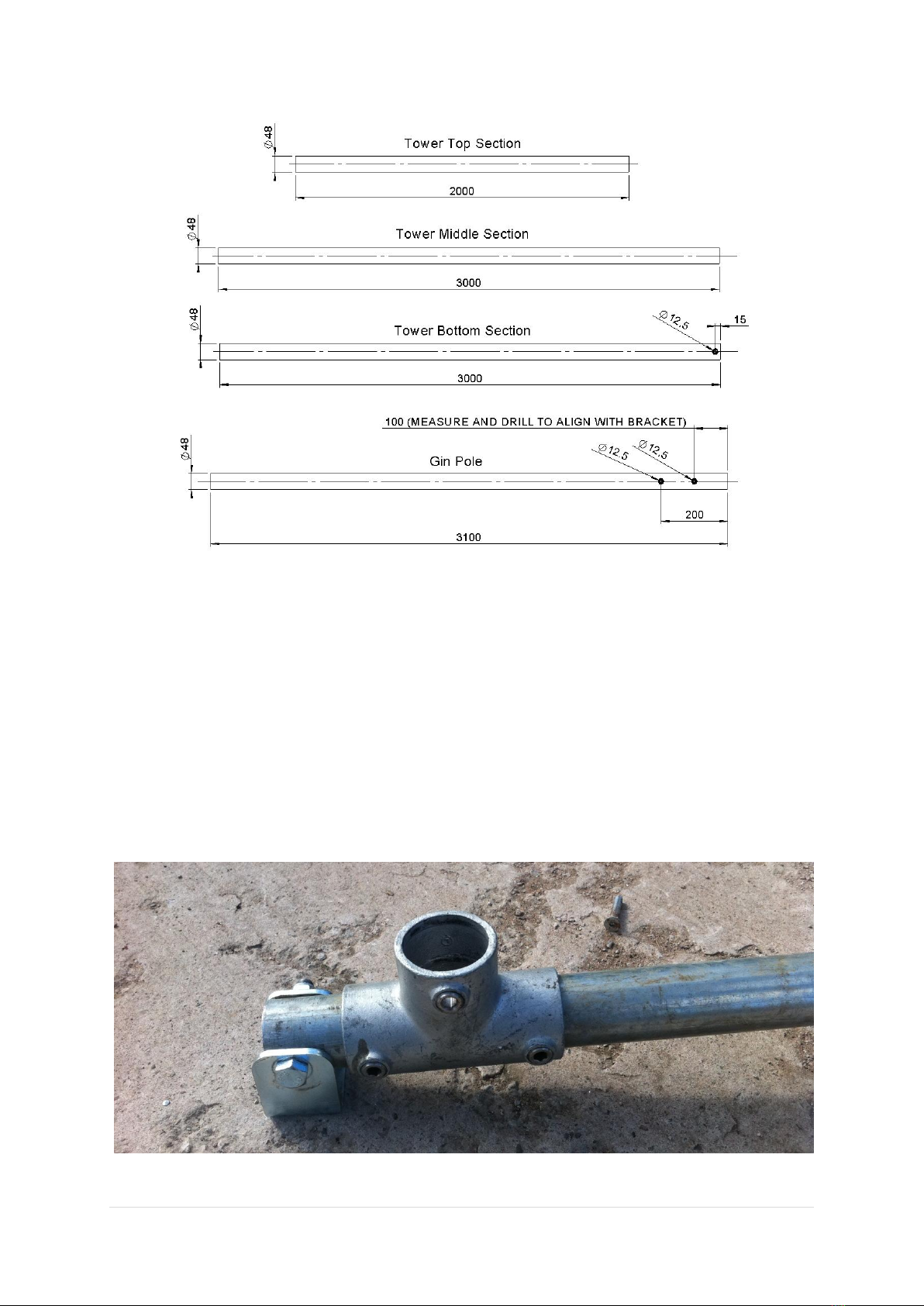

A0023, Tube Coupling 2 off

P0092, M12 x 35 Long Screw 8 off

P0091, M12 Nylock Nut 11 off

P0227, Base Hinge Bracket 1 off

P0598/9, Gin Pole Ground Bracket 1 off