1

Congratulations on your joining as a

MYUNG SAN customer

Myungsan pulverizer have been developed based on the long year’s accumulated

excellent design technologies. Several years field test ensures its durability and high

performance. However, the customer is kindly requested to read this manual and to

understand necessary instructions for the safe and long life usage. Any troubles caused

by improper maintenance, abnormal usage and repairs using non-genuine spare parts

can not be covered by warranty claims.

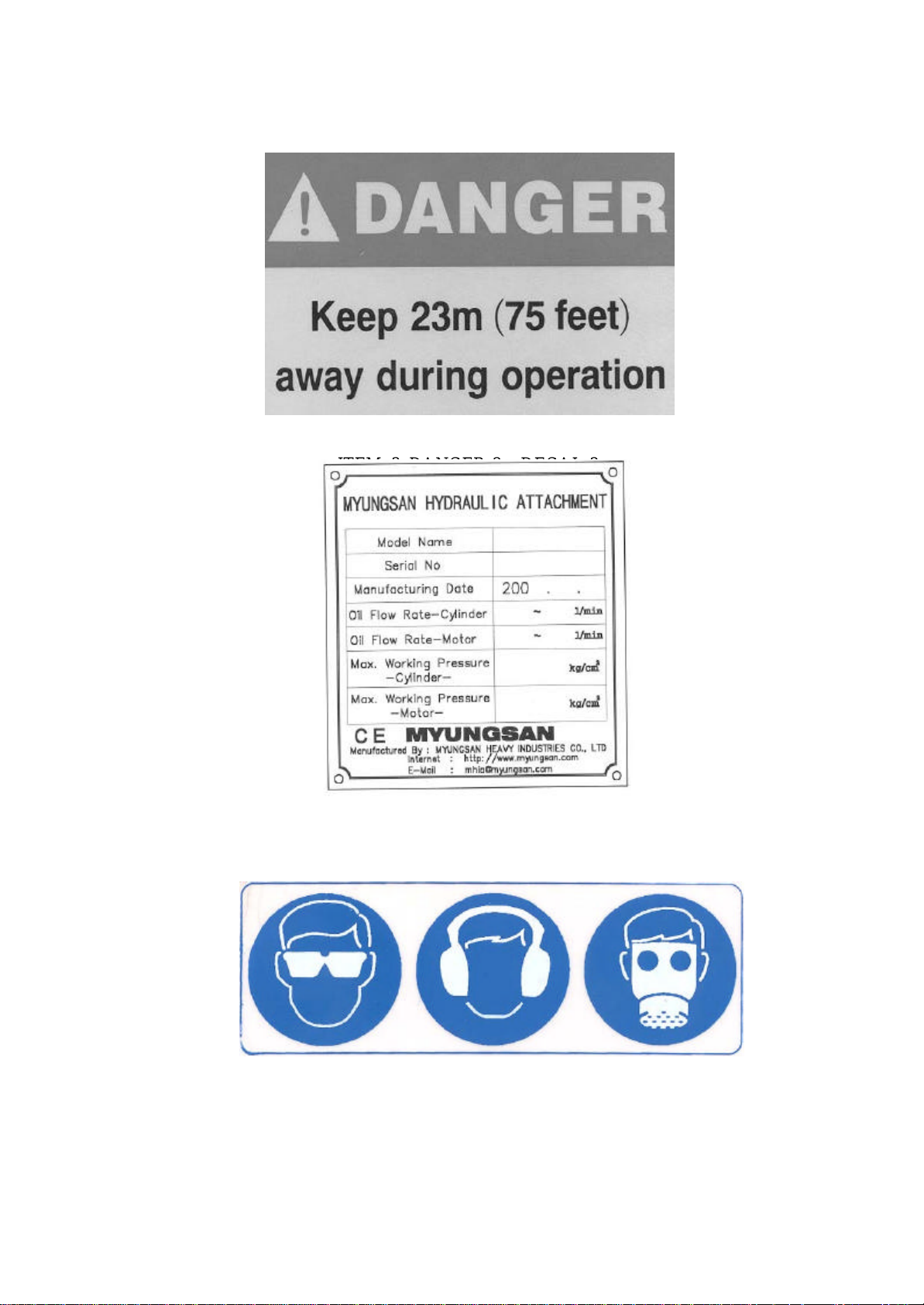

WARRANTY INFORMATION

WARRANTY is provided as part of the Myungsan support program for customers

who operate and maintain their equipment as described in this manual. Should the

equipment be abused or modified to alter its performance beyond original

specifications, the warranty will become void. Setting the carrier hydraulic

pressure above specification or changing the size of the attachment cylinder to

increase performance will also void warranty.

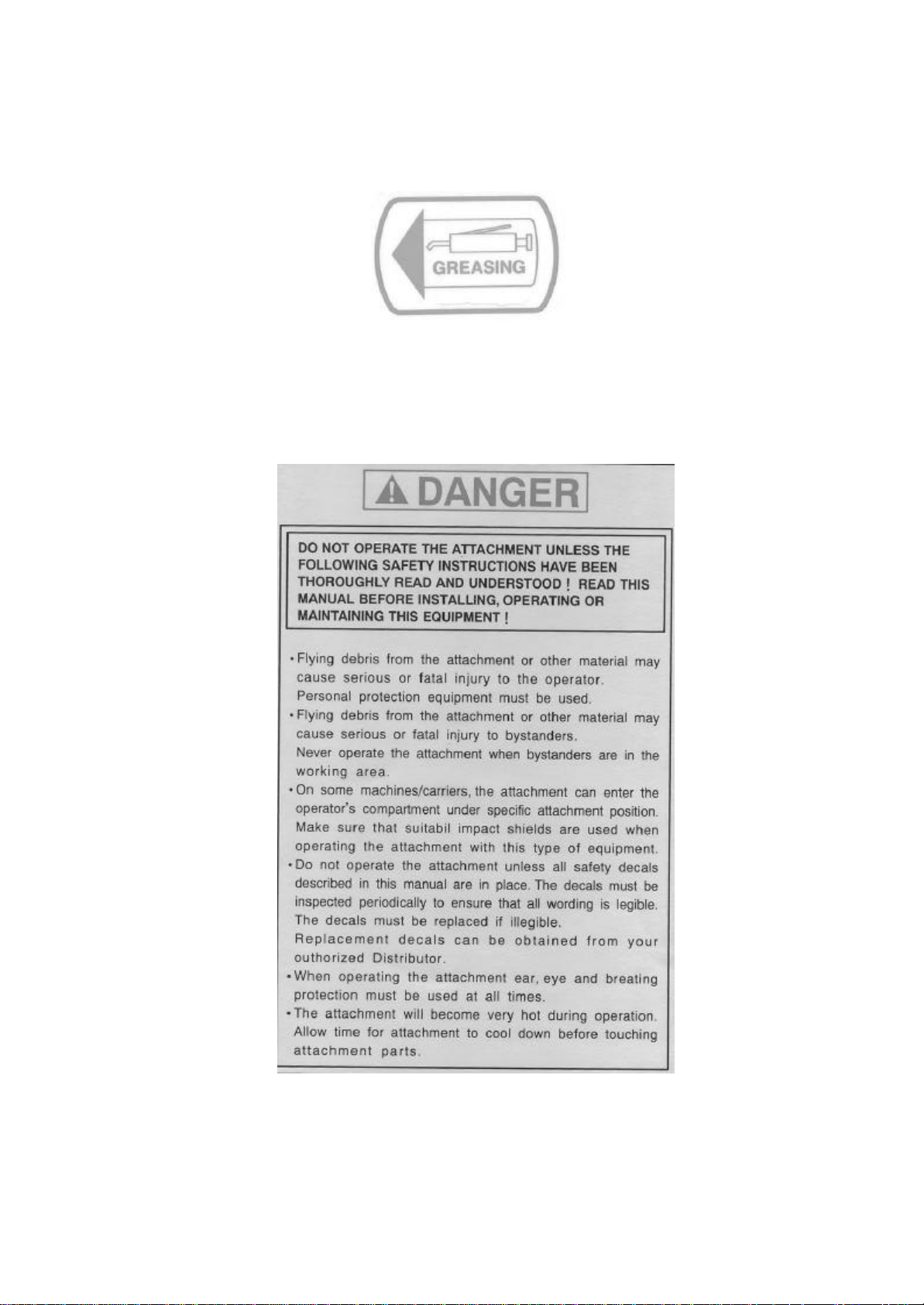

SAFETY FIRST

It is the responsibility of the operator

and service technician to read rules and

instructions for safe and proper

operation and maintenance.

A cautious worker using common sense

is the greatest safety device.