XE210C Hydraulic Excavator Operating and Maintenance Manual 5

Content

Preface

Machine Number

Safety

Instruction of safety and warning signs ......................................................................................................... 7

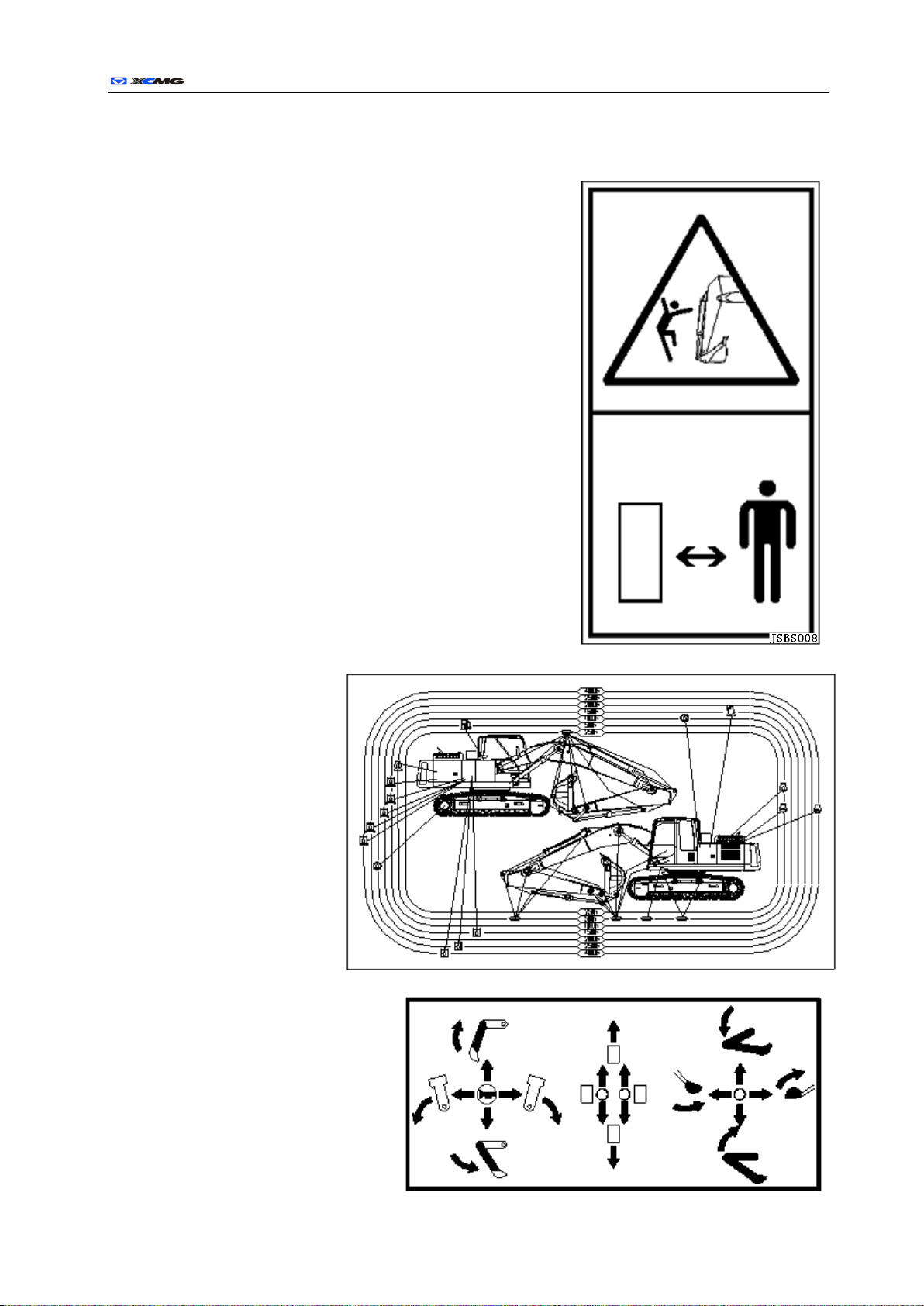

Safety sign and other signs................................................................................................................................. 9

Location of safety signs...................................................................................................................................... 9

Instruction of safety signs ............................................................................................................................ 10

Safety rules....................................................................................................................................................... 17

Safety equipment.............................................................................................................................................. 18

Safe operation of machine ............................................................................................................................. 26

Start the engine................................................................................................................................................. 26

Operation.......................................................................................................................................................... 27

Transportation.................................................................................................................................................. 34

Battery.............................................................................................................................................................. 35

Traction............................................................................................................................................................ 37

Lifting objects by the bucket............................................................................................................................ 38

Optional components........................................................................................................................................ 39

Safety maintenance instructions....................................................................................................................... 42

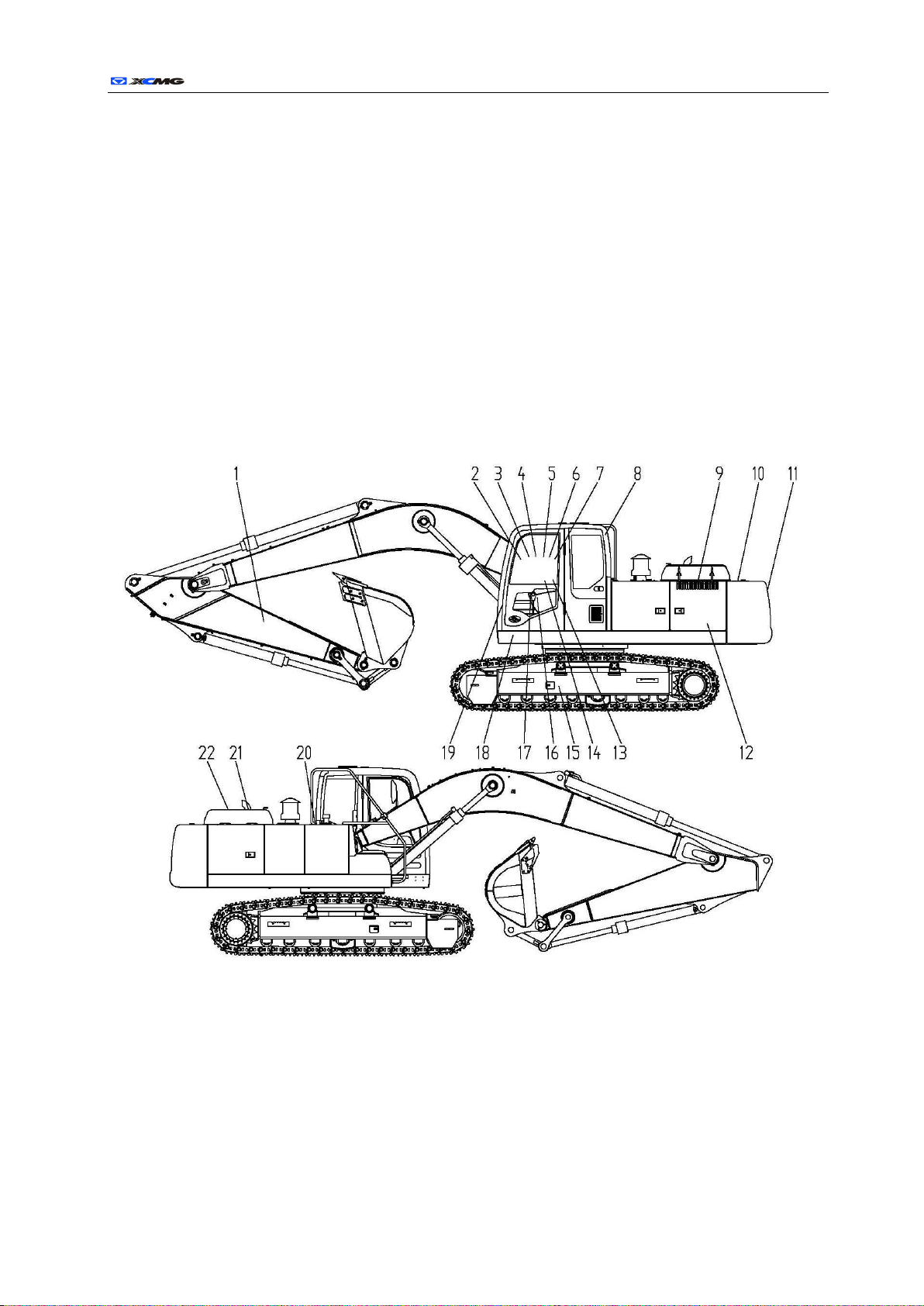

Name of parts

General drawing............................................................................................................................................... 48

Cab................................................................................................................................................................... 49

Monitor............................................................................................................................................................. 52

Displaying interface of main screen................................................................................................................. 54

Control panel of air conditioner ....................................................................................................................... 60

Radio................................................................................................................................................................ 61

Seat............................................................................................................................................................... …62

Switches ....................................................................................................................................................... …63

Operation general principle.......................................................................................................................... …65

Operating procedure......................................................................................................................................... 66

Operating environment..................................................................................................................................... 66

The preparation and operation of starting ........................................................................................................ 70

The preparation and operation of starting ........................................................................................................ 73

Operation of running........................................................................................................................................ 76

Operation of cutoff........................................................................................................................................... 81

Getting on and off the machine........................................................................................................................ 83

Operating procedure......................................................................................................................................... 84

Operation under special conditions.................................................................................................................. 93

Filling procedure of fuel, hydraulic oil, lubricant and anti-freeze fluid ......................................................... 93

Safe operating procedure against fire............................................................................................................... 97

Other operating procedures............................................................................................................................ 100

Lubrication, maintenance and repair

General principle............................................................................................................................................ 105

Lubrication of equipment............................................................................................................................... 106

The Kinds of lubricant.................................................................................................................................... 106

Lubrication points .......................................................................................................................................... 106

Lubrication period.......................................................................................................................................... 110

Safety points for attention and precautionary measures............................................................................. …111

Maintenance and repair.................................................................................................................................. 112

Safety rules..................................................................................................................................................... 112

Maintenance................................................................................................................................................... 116

List of maintenance periods ........................................................................................................................... 130

Trouble shooting ............................................................................................................................................ 131

Periodic replacement of parts......................................................................................................................... 139

Transport, storage and protection

Transport ...................................................................................................................................................... 140

Caution of transport ...................................................................................................................................... 140