N'Finity 3000 User manual

Page 2 WE 081313

Copyright © 2011. N’FINITY and Wine Enthusiast are registered trademarks of Wine Enthusiast Companies.

All rights reserved.

is manual, the product design, and the design concepts are copyrighted by Wine Enthusiast, with all rights reserved. Your rights

with regard to the hardware and manual are subject to the restrictions and limitations imposed by the copyright laws of the United

States of America. Under copyright laws, this manual may not be copied, reproduced, translated, transmitted, or reduced to any

printed or electronic medium or to any machine-readable form, for any purpose, in whole or in part, without the written consent

of Wine Enthusiast.

Every eort has been made to ensure that the information in this manual is accurate. Wine Enthusiast is not responsible for print-

ing or clerical errors.

Wine Enthusiast reserves the right to make corrections or improvements to the information provided and to the related hardware

at any time, without notice.

N’FINITY and Wine Enthusiast are registered trademarks of Wine Enthusiast Companies. All rights reserved.

Mention of third-party products is for informational purposes only and constitutes neither an endorsement nor a recommenda-

tion. Wine Enthusiast assumes no liability with regard to the performance or use of these products.

08.13.13

We manufacture, test and certify 100% of our wine cooling units in the USA. By

sourcing the best components and closely controlling our manufacturing processes,

we can assure the highest-quality, lowest defect manufacturing rates in the industry.

Page 1

TABLE OF CONTENTS

While great eort as been made to provide accurate guidelines, Wine Enthusiast cannot warrant or warranty its units to properly cool a particular enclosure.

Customers are cautioned that enclosure construction, unit location and many other factors can aect the operation and performance of the unit. erefore the

suitability of the unit for a specic enclosure or application must be determined by the customer and cannot be warranted by Wine Enthusiast.

Quick Reference Guide ...............................

Introduction ........................................

Receiving & Inspecting e Unit .......................

Preparing the Wine Cellar ............................

Installation

Pre-Installation...................................

Preparing the Installation Location..................

Installing the System ..............................

Drain Line.......................................

System Operation

System Operation -Version 2 Controller .............

Version 2 Controller Functions .....................

Version 2 Controller Wiring Schematic ..............

System Operation -Version 1 Controller .............

Version 1 Controller Functions .....................

Version 1 Controller Wiring Schematic ..............

Troubleshooting Guide ...............................

Technical Assistance & Maintenance ...................

Installation Terms and Conditions .....................

2

3

3

4

6

7

8

9

10

11

13

14

15

16

17

19

20

Page 2 WE 081313

N'FINITY QUICK REFERENCE GUIDE

Front / Side View

Rear / Side View

Controller

Front Drain Port

Power Cord

(front location optional)

Power Cord

(rear location standard)

Air Sensor

Rear Drain Port

Page 3

INTRODUCTION

Please refer to pages 15 for complete terms and conditions, warranty guidelines, and policy for your cooling unit.

Receiving and Inspecting the Unit

Note: N'FINITY units are manufactured in the USA and tested prior to shipment.

• Li only at the designated hand hold locations on the shipping container or fully support the unit from underneath.

• Before opening the container, inspect the packaging for any obvious signs of damage or mishandling.

Review the Packing Slip to Verify Contents

• Check the model number to ensure it is correct.

If any items listed on the packing slip do not match your order information, contact Wine Enthusiast Tech Department immediately at

1-800-648-6058.

Check the Accessory Kits for the following contents:

Kit One:

• N'FINITY Owner's Manual

Kit Two:

• 11' Power Cord

• 10 - 1 3/4" #6 Screws

• 6 - 1/2" Self Tapping Screws

• 1 - 10 . 3/8" Drain Line tube

• 1- 3/8" Barb Fitting

• 4 - Insulation Foam Strips

• 1 - Mounting Bracket

Please leave the unit in its original box until you are ready for installation. is will allow you to move the product safely without

damaging it. When you are ready to remove the product from the box, refer to page 6-9 for installation instructions.

Note: Save your box and all packaging materials. ey provide the only safe means of transporting/shipping the unit.

RECEIVING & INSPECTING THE UNIT

ank you for purchasing an N'FINITY cooling unit. We strive to provide the highest quality products and the best possible customer

service. If you have any questions about your N'FINITY unit, please call us at 1-800-648-6058.

is User’s Manual is intended to assist in the proper installation and maintenance of the N'FINITY cooling system. In order to ensure

the longevity of your cooling unit, the equipment should be installed properly and have a proper care and maintenance schedule.

Please read and review this manual carefully and keep it for future reference.

What Is the N'FINITY Cooling System?

e N'FINITY system is a specialized refrigeration unit designed for one purpose only: to maintain the optimal temperature and

humidity levels conducive to the proper storage and aging of ne wines. It is a self-contained cooling unit designed to be used as a

forced-air through-the-wall unit. e system is fully self-contained and can be installed as a through-the-wall application. e stan-

dard through-the-wall units are temperature controlled via air sensor. e N'FINITY unit can be set at any temperature within the

acceptable wine-aging range of 50°F to 67°F. It is designed to cool 30°F cooler than the ambient temperature of the space to which it is

exhausting.

Page 4 WE 081313

e performance and life of your N'FINITY unit are contingent upon the steps you take in preparing the wine cellar.

Note: Improperly preparing your enclosure or incorrectly installing your N'FINITY unit may cause unit failure, leaking of condensa-

tion, and other negative side eects.

IT IS HIGHLY RECOMMENDED THAT YOU OBTAIN THE ASSISTANCE

OF A WINE STORAGE PROFESSIONAL.

Wine storage professionals work with licensed contractors, refrigeration technicians, and racking companies to build well-insulated,

beautiful, and protective wine cellars. Wine Enthusiast has put together some useful tips to assist in the installation process. Our

recommendations are meant to act as a guide in the process of building a proper enclosure. Your intended location may have specic

needs that we do not address. If you have any questions regarding the building of your wine cellar, feel free to contact our storage con-

sultants at 800-377-3330.

Wall & Ceiling Framing

Build wine cellar walls using standard 2x4 or 2x6 construction methods and ceiling joists following the guidelines of local and state

codes in your area. As a general rule, the thicker the walls and the higher the insulation factor in your cellar, the better it will be at

maintaining a consistent temperature.

Insulation

Insulation is REQUIRED with the use of the N'FINITY product. Standard berglass or rigid foam insulation is normally used in cellar

construction or, in some cases, “blown-in” insulation is used. It is very important that all walls and ceilings are insulated to keep the

cellar temperature as consistent as possible during the summer and winter months. e R-value, or quality of insulation, is determined

by the rate at which heat passes through the insulation. e higher the R-value the more resistant the insulation is to conducting heat.

Using higher R-value insulation will lower your operating costs and unit run time. (R-13 minimum, R19 recommended, R30 for ceiling

and exterior walls)

Mounting the Unit

e unit should be mounted within 18“ of the top of the room in order to achieve sucient cooling. As the room cools down, the

warm air will rise to the ceiling. Mounting the N'FINITY high in the room will create a consistently cool environment by capturing the

warm air and replacing it with cool air. Mounting the unit low in the room will result in a temperature variation in the room due to the

unit’s inability to draw warm air from the ceiling of the cellar to the unit itself.

PREPARING THE WINE CELLAR

Cellar Wall

85ºF 55ºF

N’FINITY

45°angled fans

(side view)

FRONT - WINE CELLARBACK - EXHAUST ROOM

N'FINITY' A C

Page 5

Ventilation

e necessity of dissipating heat away from the unit is critical to the unit’s performance and cannot be overstated. As the unit operates

and cools, a greater amount of heat is generated on the exhaust side of the unit. Adequate ventilation is required in order to dissipate

heat away from the unit. If ventilation is inadequate, the exhaust will heat up and adversely aect the unit’s ability to cool.

Vapor Barrier

Vapor Barrier is REQUIRED to prevent the intrusion of water vapor so that the cellar can be kept at the correct temperature and

humidity. 6 mm plastic sheeting (recommended) should be applied to the warm side of the cellar walls. e vapor barrier must also

be applied to the outside walls and ceiling. If it is impossible to reach the outside, then the plastic must be applied from within the cel-

lar. e most common method is to wrap the entire interior, leaving the plastic loose in the stud cavity so the insulation can be placed

between each stud. All of the walls and ceiling must be wrapped in plastic for a complete vapor barrier.

In areas of high humidity, such as Southern and Gulf States, the vapor barrier will prevent inltration of warm moist air. e moist

air can cause mold to form, and standing water in drain pans promote microbial and fungal growth that cause unpleasant odors and

indoor air quality problems. If mold is found, remove it immediately and sanitize that portion of the unit.

Unobstructed Airow

Unobstructed airow to and from the unit is a critical factor in the unit’s overall performance. Make sure there is a minimum 3 . hori-

zontal clearance from the rear of the unit as well as a minimum 3 . clearance in front of the cooling unit. is will assure that the unit

can move the air around in an ecient manner. Avoid any attempt to camouage the unit by installing racking in front of the unit. is

will restrict the airow and lower the performance of the unit.

Ambient Temperature Factor

e cooling system has the ability to cool a maximum of 30°F below the ambient temperature of the room it is exhausting to. ere-

fore, you want to exhaust the unit in a room which will not exceed 85°F and preferably a consistent 75°F. Otherwise the unit will not

have the capacity to keep the wine at a desirable 55°F.

Door and Door Seal

At minimum an exterior grade (1 3/4”) door must be installed as a cellar door. It is very important that weather stripping is attached to

all 4 sides of the doorjamb. A bottom “sweep” or threshold is also required. e door must have a very good seal to keep the cool air in

and the warm air out. One of the most common problems with cooling units running continually is the door not sealing properly.

Sizing the Unit to the Room

e specication chart will provide information on the units room size cooling capacity. ere are circumstances in which a cellar design

may require a larger unit due to some existing design restrictions. In such a case, we recommend that the customer consider purchasing

a unit with a larger capacity to compensate for the design limitations. Issues such as glass doors, concrete, or brick walls and oors may

seem adequate but do not oer the insulation capacity required to maintain the optimum environment.

4200 1000 81 5 14.25”x 15.75”x 17”

3000 650 76 5 14.25”x 15.75”x 17”

Model Room Size Weight AMP’s Product Dimensions

(cubic feet) (lbs) (running) (W x H x D)

Temperature Delta - 30°F (when exhaust environment does not exceed above 85°F and below 50°F)

Warranty - 2 yr parts & labor / 5 yr compressor only

Page 6 WE 081313

Electrical Needs

e N'FINITY System requires a dedicated 110-volt 20-amp circuit. e unit draws a large amount of amps at initial start up. By

designating a dedicated circuit breaker, you will guarantee the unit has enough power to run eectively. Contact an electrician for

assistance with the installation of this dedicated electrical circuit:

1. Match the electrical outlet to the plug provided on the N'FINITY unit.

2. Provide a dedicated circuit and wiring for the unit.

Electrical Outlet

Plug your N'FINITY unit into a surge protector or power conditioner. As with any sensitive electrical equipment, the N'FINITY

electrical equipment may be damaged by power surges and spikes. Power surges and spikes are not covered in the N'FINITY warranty.

WE RECOMMEND THAT YOU DO NOT USE A GROUND FAULT INTERRUPTER (GFI) WITH THIS PRODUCT.

Testing the Unit Prior to Installation

Carefully remove your N'FINITY unit from the box. Do not destroy your packaging material, as it provides the only safe

means of transporting the unit. Place the N'FINITY system on a tabletop to prepare it for installation and testing. Plug

system into a live electrical outlet and turn unit on. e system may take up to 10 to 15 minutes before operating correctly,

meaning all four fans are running. Cold air coming out on cellar side, hot air coming out on exhaust side. Once the

operation has been tested, turn the unit o, and unplug the unit from the electrical outlet.*

* Note: If the system does not seem to be fully functional aer 15 minutes, please refer to the Troubleshooting Guide on page 15.

Location of Supply and Return Grilles

Locate the supply and return grilles inside the cellar to create an airow pattern that maximizes air circulation in the room. Avoid short

circulation of the air.

DO NOT:

• Install through-the-wall return air grilles at oor level, as they will collect dust from the oor.

• Mount the unit lower than 18” from the top of the room.

• Locate the supply or return air grille where it is blocked by bottles, boxes or cases

Units weigh 75-85 pounds and are cumbersome for one person to carry. We recommend that you get someone else to help you during

the installation process. NEVER LAY UNIT ON ITS SIDE.

PRE-INSTALLATION

Page 7

PREPARING THE INSTALLATION LOCATION

Minimum Tools Needed

Locate the desired installation location (no lower than 18” inches from the ceiling). Using

a stud nder, locate the studs on either side of the center point, and mark them with

vertical lines.

Using a level and a pencil, mark a horizontal line on the wall between the two studs, no

less than 1 1/2” and no more than 18” from the ceiling.

Using a ruler or measuring tape, measure 16” down, and mark another horizontal line

parallel to the rst one.

Using a saw, cut along the uppermost horizontal line until your saw reaches the stud.

Turn the saw around, inserting it into the cut you have just made, and cut toward the

opposite stud so that you have a clean horizontal cut between the two studs. Be careful

not to cut into the studs themselves.

Now make the second horizontal cut from stud to stud on the line 16” below the rst cut.

Once the horizontal lines have been cut, make vertical cuts using the inside edge of the

studs as a guide. Once you have made both vertical cuts, you should have a rectangular

hole in the sheetrock. Now you have to make the same hole on the other side of the wall.

Since you already have one hole, this is an easy process. Using a nail, mark all four corners

of the rst hole by making nail holes through the sheetrock. en on the other side of the

wall, connect the holes with a pencil mark and cut.

Once the horizontal lines have been cut, make vertical cuts using the inside edge of the

studs as a guide. Once you have made both vertical cuts, you should have a rectangular

hole in the sheetrock. Now you have to make the same hole on the other side of the wall.

Since you already have one hole, this is an easy process. Using a nail, mark all four corners

of the rst hole by making nail holes through the sheetrock. en on the other side of the

wall, connect the holes with a pencil mark and cut.

Sheetrock alone cannot support the weight of a cooling system. erefore, it is necessary

to frame the hole that you have just cut with upper and lower supports. ese supports

also provide solid material for the mounting bracket screws.

Using two 2x4s at 14.5” in length and eight 6d nails, secure the upper and lower supports

to the right and le studs, just inside the sheetrock. Make sure that the internal height

remains at 16” so that the system will t snugly through the framed cut-out.

Hammer SawScrewdriver

Level

Page 8 WE 081313

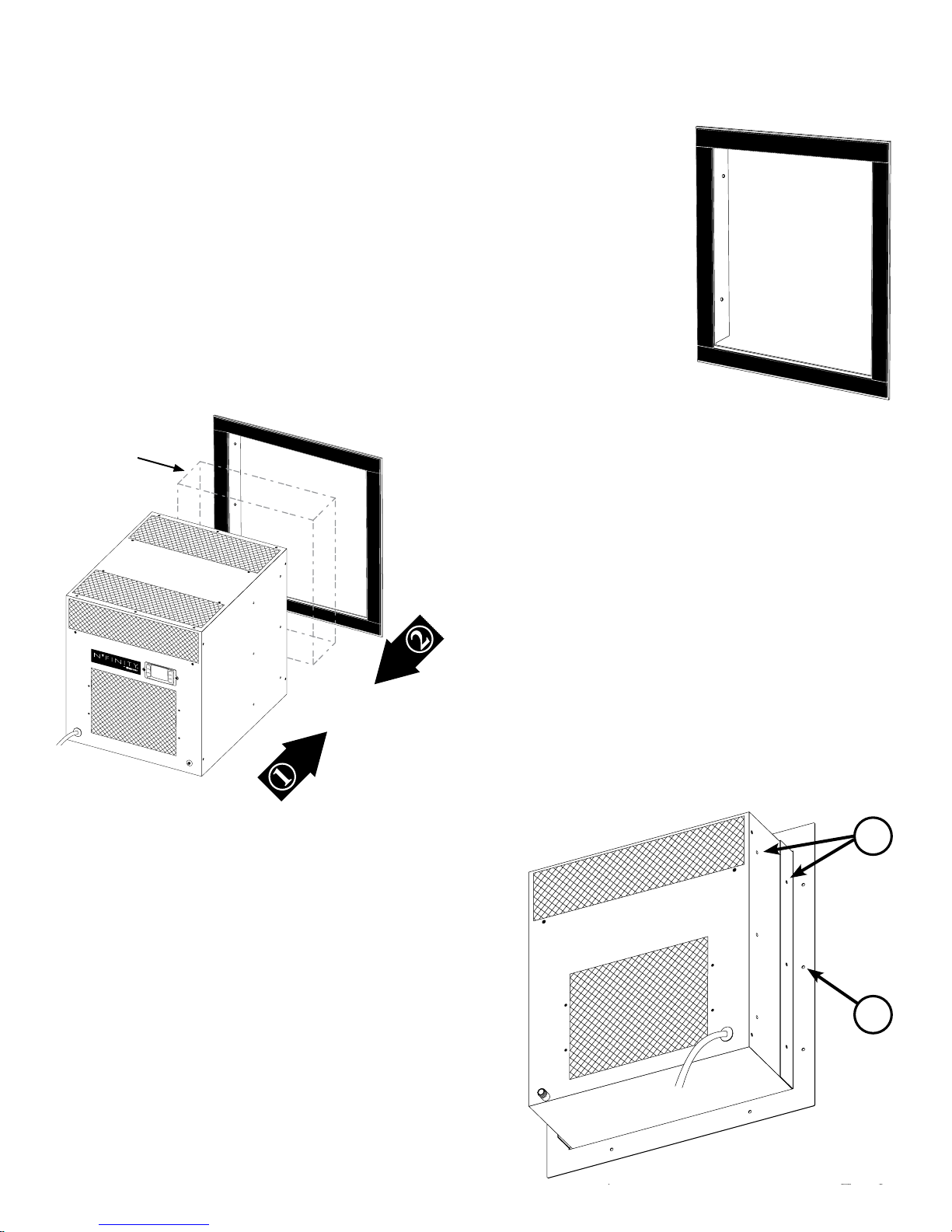

INSTALLING THE SYSTEM

rough-the-Wall

1. Slide the unit into the installation location from INSIDE the cellar,

make sure the controller side of the unit is inside of the cellar.

2. Slide the prepared single piece mounting bracket on the unit from

OUTSIDE the cellar.

3. On each side of the side of the unit you will notice 6 indents, these

mark 2 dierent installation depths. Select one of the 2 mounting

depths and attach the single piece mounting bracket to the unit with

the (6) supplied 1/2” self tapping screws. It is imperative to not use

self tapping screws longer than 1/2” in length.

4. Finally, secure the mounting bracket to the wall through the pre-drilled

holes with the (10) supplied #6 1 3/4" hex head screws. e screws should

penetrate the studs as well as the upper and lower supports to provide

adequate support for the unit.

5. Seal all cracks and gaps around the unit on the cellar side with an air-

tight sealant and caulking to prevent air leakage. e hole that the unit is

installed through is basically a break in the vapor barrier, an air tight seal

is imperative.

Note: If you use decorative moulding, it should be attached to the walls

and never to the cooling unit itself. e moulding itself should be remov-

able incase the unit needs servicing

Cellar Wall

3

4

Single Piece Mounting Bracket

e unit utilizes a single piece mounting bracket, this sturdy bracket frames the installation location

and secures the unit to the wall.

Applying Insulation Tape

Locate the (4) precut pieces of black foam tape included with the system, two larger pieces and two

smaller pieces. To apply, simply peel back the white-paper adhesive covering and place on the mount-

ing bracket. e large pieces are applied to the top and bottom while the smaller pieces are for the

sides. is foam creates a tight seal between the bracket and the wall.

Page 9

DRAIN LINE

Condensation Drain Line Tube

e condensation drain line tube is used to remove excess condensation from the unit to a proper discharge location. It is important

that the drain line tube is properly connected and used to prevent leakage and other problems associated with excess condensation.

Failure to use the condensation drain line tube will void the warranty on the unit.

Drain Line Choices

Your unit is equipped with both a front and rear Drain Line Port. is allows you to choose if you would like to have excess condensate

drain back into the cellar for additional humidity. Simply remove the cap from the Drain Port you would like to utilize and thread the

supplied drain line and tting on. It is important that the drain line tube is properly connected and used to prevent leakage and other

problems associated with excess condensation. Please take note of the below illustrations that cover how the drain line needs to be

positioned.

Front Drain Port

Rear Drain Port

*DO NOT ALLOW

DRAINLINE TO BE

SUBMERGED IN WATER

*DRAIN LINE SHOULD

HANG ABOVE THE WATER

LINE.

Page 10 WE 081313

SYSTEM OPERATION - VERSION 2 CONTROLLER

EFFECTIVE JUNE 2012

Initial Start-Up:

When power is applied to the unit, the control will briey display all symbols, and the Compressor symbol will be displayed (if

unit is calling for cooling). ere may be a brief delay prior to the evaporator and condenser fans turning on.

Set Point:

e set point is set from the factory at 55°. It can be adjusted by the customer between 50° and 70° in one degree increments.

Cooling Operation:

Cooling is activated once the air sensor probe senses a temperature that is four degrees greater than the set point. e controller

then energizes the compressor relay which activates the compressor, evaporator fans and condenser fans. e unit provides cool-

ing until the air sensor probe senses the set point. At this point the compressor relay is de-energized which stops the compressor,

evaporator fans, and condenser fans.

Defrost:

Aer two hours of compressor operation the controller will activate defrost. e compressor relay will de-energize, stopping the

compressor, evaporator fans, and condenser fans. e compressor relay will remain de-energized for ve minutes, and then the

unit will return to normal operation. e set point and the dripping snowake will be displayed during defrost and until the unit

reaches set point aer a defrost cycle.

Display:

e Set point is displayed by default. e air sensing probe temperature can be accessed by pushing the set button and scrolling

through PB1 and set point parameters.

Safety Features:

Once the compressor relay is de-energized the controller must wait 5 minutes before re-energizing the relay. is prevents the

compressor from repeatedly turning o and on. If the unit is calling for cooling during this time, the compressor symbol will

blink indicating that cooling is needed but the control is waiting for the anti-short cycle delay.

In the event of a faulty air sensing probe, the compressor will cycle o for 10 minutes and on for 40 minutes. E1 will be displayed

on the screen.

Alarms:

e high temperature alarm (AH1) will be displayed if the room temperature reaches 10 degrees above the set point. e alarm

will reset once the temperature drops by 2 degrees. is alarm will only be active 10 hours aer the unit is turned on and will be

disabled for an hour aer an anti-frost cycle.

e low temperature alarm (AL1) will be displayed if the room temperature reaches 10 degrees below the set point. e alarm

will reset once the temperature increases by 2 degrees. is alarm will only be active 10 hours aer the unit is turned on. And

will be disabled for an hour aer a defrost cycle.

E1 will be displayed in the event of a thermostat probe failure.

NOTE: Conrm if you have a Version 2 Controller using the

above illustration as a guide. If Your controller does not match this

illustration than you have a Version 1 Controller featured on page 14.

Page 11

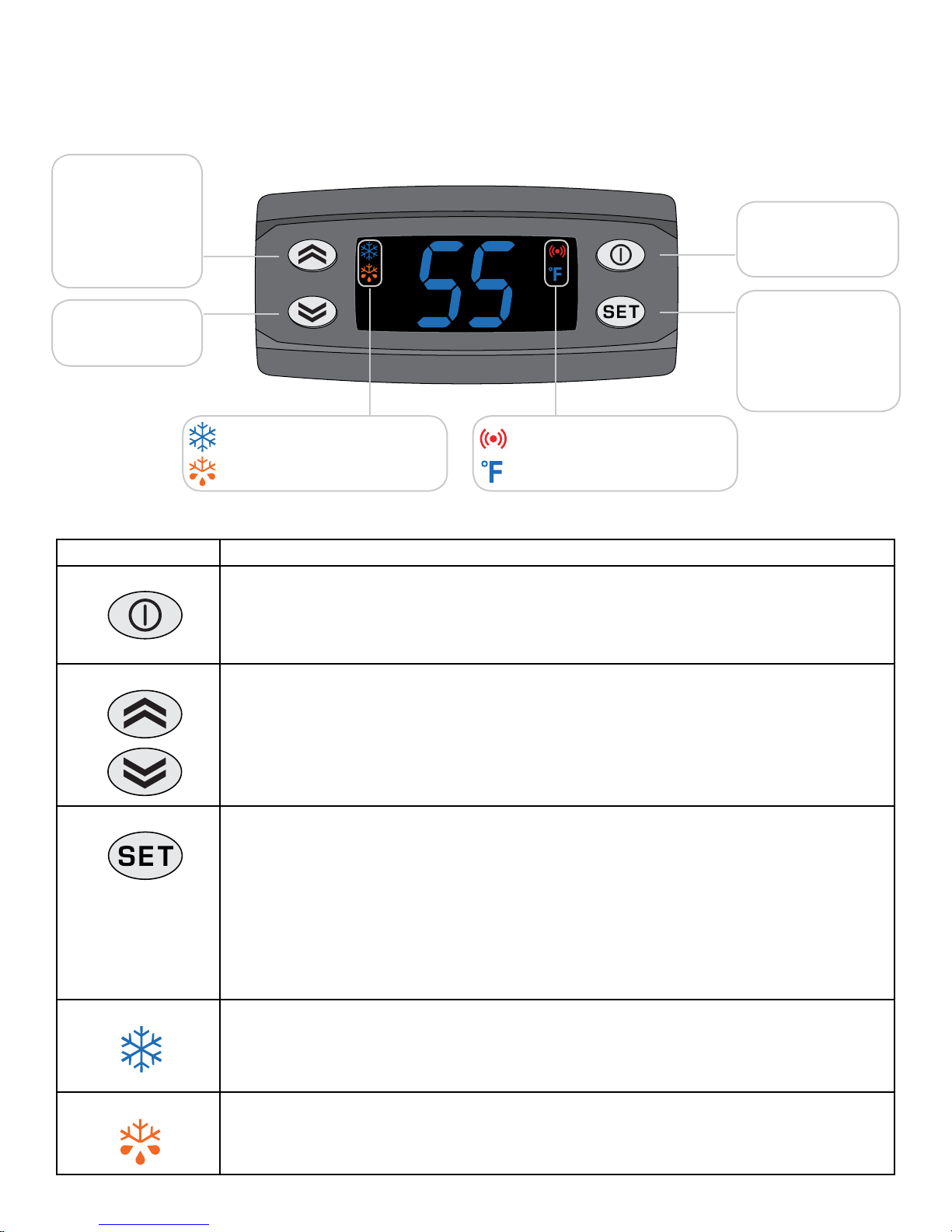

VERSION 2 CONTROLLER FUNCTIONS

Button/Symbol Normal Functions

ON/OFF • Press and hold the on/o button for approximately 3 seconds to turn the unit on or o.

Note: is does not disconnect power from the unit. In order for the power to be shut o from

the unit, the power cord must be unplugged from the wall receptacle.

• is button also serves as an escape button.

Up and Down • Use these buttons to scroll up or down a menu.

• Press and hold the up button for approximately ve seconds to manually start the defrost sequence.

SET • Press the set button once to view the set point, temperature of the air sensing probe.

• Once the set button is pressed “SEt” will be displayed. Press the up or down arrows to scroll through

Pb1 and the set point parameter.

• Press the set button again to view any of these values.

• To change the set point, press the set button when “SEt” is displayed on the screen. e current set

point will be displayed. Use the up or down arrows to change the set point to the desired temperature.

Press the set button again once the desired temperature is reached.

• Hold the set button for approximately 5 seconds to enter the CPSM (Customer Preference Selection

Mode) menu. (CPSM detail on next page)

Snowake Constant - Unit is in cooling mode and the compressor and fans are running.

Blinking - e unit is calling for cooling, but must wait 5 minutes before restarting the compressor. is 5

minute delay serves as an anti-short cycle for the compressors protection.

Dripping Snowake Unit is in defrost mode. e compressor and fans will be turned o during this cycle.

Compressor On

Unit is in Defrost Mode

Alarm is Present

Temperature Measurement

Menu Navigation

& Value Increase

*Press and hold

to manually enter

defrost mode.

Power On/O

(hold for approx. 3 seconds)

& Escape

Menu Navigation

& Value Decrease

Probe Value &

Alarm Folder

*Press and hold to

enter the parameter

menu.

Page 12 WE 081313

Alarm e Alarm symbol is shown when the unit encounters an issue that needs attention, the dis-

played alarm codes are explained below. e alarm code will remain displayed until corrected.

Alarm Codes

CPSM (Customer Preference Selection Mode)

Message Cause Solution

“E1” Faulty Air Sensing Probe Contact Customer Service

“AH1”

e air probe is sensing a

temperature that is 10° above

the set point

1. Allow time for the wine to reach the desired temperature.

2. Make sure all windows and doors are closed and have a proper seal.

3. Follow the procedures in the pre-installation instructions to test the unit for proper

cooling.

“AL1”

e air robe is sensing a tem-

perature that is 10° below the

set point

1. Make sure unit is not in cooling mode. (the snowake symbol will not be lit)

2. Add heat to the room until the wine reaches the desired temperature.

Press and hold the set button for approximately 5 seconds to enter the CPSM menu.

Use the down arrow to access the following parameters.

PA2 No adjustable settings in this parameter.

tab No adjustable settings in this parameter.

Rel No adjustable settings in this parameter.

LOC Change this parameter from “n” to “y” to lock the keyboard from changes to the set point.

CA1 Change the value to increase or decrease the temperature reading of the air sensor.(is process

re-calibrates the probe to the controller)Increasing the value by 1 means an increase in the tem-

perature reading by 1 degree. Decreasing the value by one means a decrease in the temperature

reading by 1 degree. is parameter can be adjusted +- 12 degrees. If needed: Adjust this setting

to match your temperature sensor inside the cellar.

Page 13

VERSION 2 CONTROLLER WIRING SCHEMATIC

Cond.

Fan

Compressor

Cond.

Fan

Evap

Fan

Evap

Fan

Page 14 WE 081313

SYSTEM OPERATION - VERSION 1 CONTROLLER

FOR SYSTEMS PURCHASED PRIOR TO JUNE 2012

Initial Start-Up

When power is applied to the unit, the control will briey display all symbols.

Normal System Cycle

Aer the unit or cellar has reached the set point, unit will turn o until temperature rises above set temperature (all units

are shipped with the set point of 55°F and a dierential of 4°F).

Anti Short Cycle

e Anti Short Cycle ensures that the unit will remain o for a period of 5 minutes aer the unit has reached the set point

to allow the pressure in the refrigeration system to equalize prior to starting the compressor.

Defrost Cycle

e Defrost Cycle is a precautionary measure, as icing or frosting of the coil does not occur during normal operation. e

system will go through a defrost cycle every 2 hours. During the defrost cycle, unit shuts down.

Air Sensor

Each N'FINITY cooling unit comes equipped with an air sensing probe. e air sensing probe senses the temperature of

the cellar air and cycles the unit on and o based on the desired cellar temperature.

Note: e desired cellar temperature is the temperature set by you.

NOTE: Conrm if you have a Version 1 Controller using the

above illustration as a guide. If Your controller does not match this

illustration than you have a Version 2 Controller featured on page 10.

Page 15

VERSION 1 CONTROL FUNCTIONS

SET button

Display Set Point - press 1 sec

Modify Set Point - hold 3-5 sec

In programming mode it selects a

parameter or conrms an operation.

Up and Down Buttons

Use to adjust values or browse

parameter codes.

Defrost button

Manually start Defrost - hold 3-5 sec

Set Point e set point is set from the factory at 55°. It can be adjusted (hold SET button for 3-5 seconds) by the cus-

tomer between 50° and 67° in one degree increments.

e air probe is oset by three degrees so that the controller will think it is three degrees warmer than the

actual temperature. is allows the customer to set the thermostat at the temperature that they desire their

wine to be.

Defrost Aer two hours of operation the controller will activate defrost. e compressor relay will de-energize, stop-

ping the compressor, evaporator fans, and condenser fans. e compressor relay will remain de-energized

for ve minutes, then the unit will return to normal operation. “Df” will be displayed during defrost.

e Defrost cycle can be manually initiated by holding the Defrost button for 3-5 seconds.

Cooling Operation Cooling is activated once the air sensor probe senses a temperature that is four degrees greater than the set

point. e controller then energizes the compressor relay which activates the compressor, evaporator fans

and condenser fans. e unit provides cooling until the air sensor probe senses the set point. At this point

the compressor relay is de-energized which stops the compressor, evaporator fans, and condenser fans.

Display e air sensor probe temperature is displayed in °F to a resolution of 1°. e display will update immediately

on temperature decrease and 1° every 15 minutes on temperature increase. During the defrost cycle the

display will show “Df”.

Safety Features Once the compressor relay is de-energized the controller must wait ve minutes before re-energizing the

relay. is prevents the compressor from repeatedly turning o and on.

In the event of a faulty air sensor probe, the compressor will cycle on for 40 minutes and o for 10 minutes.

Alarms e high temperature alarm (HA) will be displayed if the room temperature reaches 80 degrees.

e low temperature alarm (LA) will be displayed if the room temperature reaches 45 degrees.

e alarm will show 15 minutes aer the detection of a temperature alarm condition.

P1 will be displayed in the event of a thermostat probe failure.

e alarms will not display for 99 minutes aer the unit has turned on.

e alarms can be switched o by pushing any key on the controller.

SET button

Display Set Point - press 1 sec

Modify Set Point - hold 3-5 sec

In programming mode it selects a

parameter or conrms an operation.

Up and Down Buttons

Use to adjust values or browse

parameter codes.

Defrost button

Manually start Defrost - hold 3-5 sec

SET button

Display Set Point - press 1 sec

Modify Set Point - hold 3-5 sec

In programming mode it selects a

parameter or conrms an operation.

Up and Down Buttons

Use to adjust values or browse

parameter codes.

Defrost button

Manually start Defrost - hold 3-5 sec

SET button

Display Set Point - press 1 sec

Modify Set Point - hold 3-5 sec

In programming mode it selects a

parameter or conrms an operation.

Up and Down Buttons

Use to adjust values or browse

parameter codes.

Defrost button

Manually start Defrost - hold 3-5 sec

Page 16 WE 081313

VERSION 1 CONTROLLER WIRING SCHEMATIC

Page 17

TROUBLESHOOTING GUIDE

Unit has ice forming on the evaporator

Possible Cause

Evaporator lter and/or coil are dirty.

ere is something blocking the supply and or return air

One or both evaporator fans are not turning on.

e temperature of the room, the unit is exhausting to,

has dropped below 50°

e unit has not gone through its anti-frost sequence, yet.

If unit continues to ice.

Unit does not run/power up

Possible Cause

Unit is not plugged in

No power to outlet

Line voltage is incorrect rating for unit

Room at set point

ermostat not calling for cooling

Faulty thermostat or wiring

Cellar Temperature is to Warm

Possible Cause

e temperature or the room unit is exhausting to has

exceeded 85°

e unit is undersized for the room.

ere is something blocking the supply and/or return air,

on evaporator or condenser side of the unit

Unit is mounted too low in the cellar

One or more of the fans is not turning on.

Compressor is not turning on.

Compressor keeps cycling on overload

Poor seal around door.

Controller set too high

Evaporator coil is frosted or iced up

Solution

Clean lter and coil with a vacuum.

If coil is very dirty, use a small hand spray with a small amount of liquid

dish washer detergent. Spray coil, let set for 5 min, then ush with fresh

water.

Remove blockage

Call a service tech to troubleshoot

Raise the temperature of the exhaust room

Check for ice in the depth of the coil. Melt with blow drier until coil is

warm to the touch. Soak up water with a towel.

O

bserve ice formation pattern. If only part way up the coil face, unit could

be low on refrigerant. If so, call Technical Support at

800-648-6058

Solution

Make sure the unit is plugged into an outlet

Contact an Electrician

Check line voltage to make sure there is 115v/15amp

Lower set point

Lower set point

Call Technical Support at 800-648-6058

Solution

Lower the temperature of the exhaust room.

Order correct size unit

Remove air ow obstruction

Re-Locate unit so the distance from the ceiling and top of the

unit is no more than 18”

Call Technical Support at 800-648-6058

Call Technical Support at 800-648-6058

Make sure all fans are working and there are no airow obstruction.

Make sure there are no air gaps around the door. If door seal is dam-

aged, replace it.

Lower the set point.

O

bserve ice formation pattern. If only part way up the coil face, unit could

be low on refrigerant. If so, call Technical Support at

800-648-6058

Page 18 WE 081313

TROUBLESHOOTING GUIDE

Solution

Unit should be level in wall to prevent leaking

Check drain line to make sure water can ow freely.

Disconnect Drain and clear out.

Fix drain line so there is a downward slope from the

unit to the drain.

Melt ice with blow drier. Soak up with a towel.

Solution

Make sure fans are unobstructed; clean evaporator if necessary

Compressor may have overheated. Shut unit o for 1 hour to

allow compressor to cool. Turn back on and check for cooler air

ow out. If compressor runs, check for and clean condenser coil

as possible cause of compressor overheating. If problem repeats,

call Technical Support 800-648-6058

Call Technical Support at 800-648-6058

Solution

Call Technical Support at 800-648-6058

Compressor may have overheated. Shut unit o for 1 hour to

allow compressor to cool. Turn back on and check for cooler air

ow out. If compressor runs, check for and clean condenser coil

as possible cause of compressor overheating. If problem repeats,

call Technical Support.

Solution

Call Technical Support at 800-648-6058

Call Technical Support at 800-648-6058

Solution

Call Technical Support at 800-648-6058

Solution

Install proper vapor barrier

Unit leaks water

Possible Cause

Unit is not level

Drain line clogged or kinked

Drain is clogged preventing water from escaping

Drain line does not have a downward slope

Coil is iced causing excess condensation.

Unit runs but does not cool

Possible Cause

Lack of air ow/heat exhaust (outer room)

Fans run but compressor does not.

Unit undersized

Evaporator fan runs but compressor does not

Possible Cause

Compressor and/or starting components faulty

Fans run but compressor does not.

Compressor runs; evaporator fan does not

Possible Cause

Faulty fan motor

Faulty fan relay

Compressor short cycles

Possible Cause

Compressor and /or starting components faulty

Humidity in cellar too high

Possible Cause

Cellar vapor barrier not sucient

Other manuals for 3000

1

This manual suits for next models

1

Table of contents

Other N'Finity Wine Cooler manuals