3/15 IOM-SDTU

Installation and Operation Manual

Single Du t Terminal Units

Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 1 of 4

Re eiving Inspe tion

After unpacking the assem ly check it for

shipping damage. If any shipping damage is

found, report it immediately to the delivering

carrier. During unpacking and installation do

not handle y the inlet velocity sensor or the

control package.

Determine Position of the

Control En losure

The control enclosure can e installed on

either side of the ductwork y flipping the VAV

unit over 180 degrees. Unit with mercury

contactors, pneumatic controls, and digital

controls (DDC) need to e inspected efore

installing.

Important: Unit with mercury contactors is

position sensitive. As a result, efore installing

unit with mercury contactors, inspect the

position of the mercury contactors in the

control enclosure. Mercury contactors must e

heading up 90 degrees vertically. If they are

heading down, unscrew the mercury contactors,

rotate 180 degrees, and reinstall them.

If unit is equipped with pneumatic controls, it

should e mounted right side up and level

within ±10 degrees of horizontal, and parallel to

the airflow. The first letter in the model num er

indicates control type (P is for pneumatic). If

the unit is mounted upside down, the controller

will have to e repositioned, re-piped, and

recali rated. Analog control units (A-analog

model num er pre-fix) may e installed in any

orientation. Some Digital (DDC) controls

(D-digital model num er pre-fix) are position

sensitive dependent on the airflow sensor

transducer. Check with the controls

manufacturer for verification.

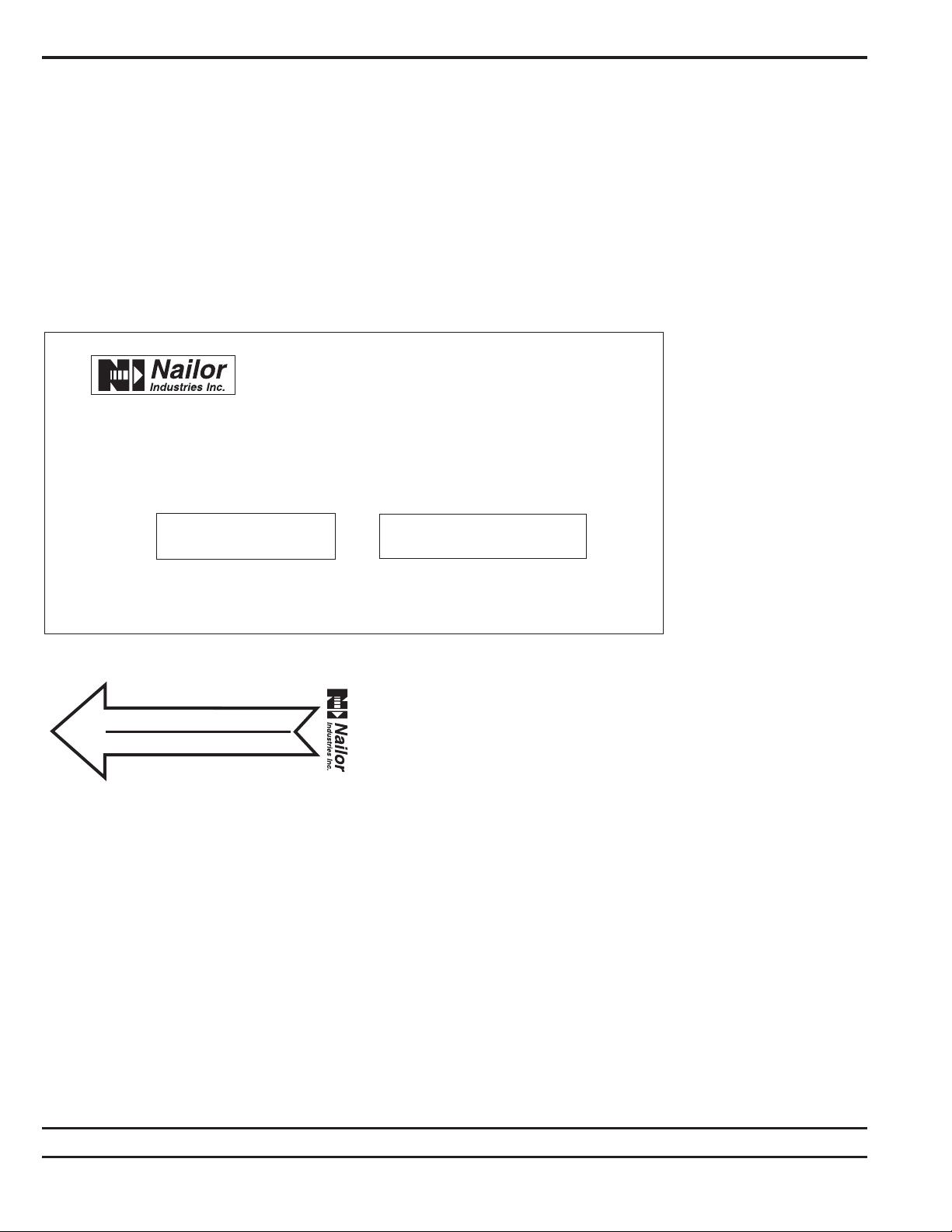

Supporting the Assembly

We recommend that each terminal unit e

independently supported, especially when

accessory modules, such as coils, attenuators,

silencers or multiple outlets are present.

Hanger straps may e used and screwed

directly into the sides or ottom of the unit

casing (see Fig. 1). Alternately, a carriage

made of unistrut may e used, somtimes this is

known as a trapeze setup. Support the VAV

and any accessories separately (Fig. 2). When

requested, unit is supplied with field mounted

hanger rackets for use with hanger rod up to

3/8" (9.5) dia. Hanger rackets should e

screwed into the top of the unit casing (see Fig.

3 & 4). Use the support method prescri ed for

the rectangular duct in the jo specifications.

CONTROL

ENCLOSURE

INLET

OPTIONAL HANGER BRACKET

(FIELD LOCATED

& INSTALLED)

RECTANGULAR

DISSIPATIVE SILENCER

SLIP & DRIVE

CONNECTION

COIL

SECTION

COMPRESSION STRAP ON FLEXDUCT

TO ENSURE AIRTIGHT JOINT

OPTIONAL

ACCESS DOOR

CONTROL

ENCLOSURE

RECTANGULAR

DISSIPATIVE SILENCER

SLIP & DRIVE

CONNECTION

COMPRESSION STRAP ON FLEXDUCT

TO ENSURE AIRTIGHT JOINT

CONTROL

ENCLOSURE

INLET

SLIP & DRIVE

CONNECTION

COMPRESSION STRAP ON

FLEXDUCT TO ENSURE

AIRTIGHT JOINT

OPTIONAL

ACCESS DOOR COIL

SECTION

RECTANGULAR

DISSIPATIVE

SILENCER

SLIP & DRIVE

CONNECTION

ACCESS

DOOR VAV

SECTION

DISCHARGE

DUCT

INLET

DUCT

CONTROL

ENCLOSURE

SLIP & DRIVE

CONNECTION

OPTIONAL HANGER BRACKET

(FIELD LOCATED & INSTALLED)

METAL STRAP HANGERS

SECURED TO BUILDING STRUCTURE

INLET 5/16" OR 3/8" (8 OR 10) DIAMETER HANGER RODS

SECURED TO BUILDING STRUCTURE

MINIMUM 2 DUCT DIAMETERS

OF STRAIGHT DUCT

ON AIR TERMINAL INLET

MINIMUM 2 DUCT DIAMETERS

OF STRAIGHT DUCT

ON AIR TERMINAL INLET

MINIMUM 2 DUCT DIAMETERS

OF STRAIGHT DUCT

ON AIR TERMINAL INLET

DISCHARGE

DUCT

DISCHARGE

DUCT

DISCHARGE

DUCT

Figure 1: Support Using Hanger Straps (Shown: Model D30RW - Single Du t VAV

Terminal Unit with Hot Water Heat).

Figure 2: Support Using Unistrut and Rods (Shown: Model 3001Q - Single Du t

Terminal Unit with Dissipative Silen er).

Figure 3: Support Using Optional Supplied Hanger Bra kets (Shown: Model

D30RWQ - Single Du t VAV Quiet Terminal Unit with Standard Dissipative

Silen er and Hot Water Heat).

Figure 4: Support Using Optional Supplied Hanger Bra kets (Shown: Model

D30HQX - Single Du t VAV Exhaust Terminal Unit with Dissipative Silen er).