§

~

y /;J$iWJO)

~'ii~···········

2

1Y!ffl_LO)

~'j_£~.......................

2

1.

ft

**................................... 2

2.

;J$i1W

0)

~11m·············

...

·

..

·

..

··

..

· 3

2-1

~

~

;;-

O)w

X.1t

~

t ·······.......·

..

·· 3

2-2 .:c-

-7-

t

O);J"f~··.

....

..

..

.

..

..... 3

2-3

~lliiiO)Jfl{t~t········

..

·····

..

····· 3

2-4 rwll: ·

J:.f~JJ:O)~~.............

4

3

.1Y!ffl

_t

0)

~'ii

~.......................

4

3-1

IE

1W····

..

···

..

·········

..

·····

.........

4

3-2

tP

i

O)*ftrm~~··

...................... 4

3-3

~Jv

~

7J

J'\'-O)Jf~1·J't

............... 5

~~y/0)1Y!v)7J

.......................

5

4-1

~tO)J&1t~t1J···......................

5

4-2

r

*0)~

~

1J......................... 6

4-3

J:.*'O)illi

L1J......................... 6

4-4

~~"'13ft~

O)~~n

c

~

L~"'....

7

4-5

*'

~

.::;............................. 7

4-6

J:.*~~:t.J

O)il~..

.................... 7

4-7

r

*~~:t.J

0)~~......

................

8

4-8

*'If~

~

){;f,............................ 8

4-9

w

X.J±:t.J

O)~Ji('j..

...

....

..

..

..

..

.

....

8

4-1o

~tc

n70)001*...................... 8

4-11

J2S

~

lljtj

~

............................ 9

4-12 w

X.JE

c

..till~

)EO)f1!!li1JjWj

~

.... 9

4-13

~

X.JE

c

J:.m

~

JEO)~li..t

r

ill!w1Ji11:

9

~~4-14

~tt~t~!tJJaO)wH~f)]:·tiO)~~·...

10

4-15

~*

~

7

7~

;f,

")

~

O){)i:m;:..........

10

4-16

1m

!l!i

;e

.7..

0)

:fJJ

WH~

·mt

..

•............· 1o

4-17

*W

tJ

-71

~;;-~f

...................

11

4-18

*'W

tJ

O)¥!fi1J1Ji~·

..

....·......·....

11

4-19

;e

7-.0)x~

............................

11

4-20

1mW1*~-r............................

12

4-21 ;(

7-.J±O)j,mj~

.........................

12

4-22

~"'13ft~

glj~"'~J!t-~ilil<

....

12

5.,%W

~

~:.B~t;:,JJ.~t

)Jj{

129

•

:k'.t

~...............................

13

6.ffi

JJJt

:g:~

&=6

..

..

..

..

.

..

.

..

..

....

..

.

....

.

..

...

..

14

6-1

~

~

;;-tfB~

.............................

14

6-2

)'~-

·:;

1)

.7..

~

..........................

18

CONTENTS

page

CAUTIONS

BEFORE

OPERATING

THE

MACHINE

.......

2

CAUTIONS

WHEN

OPERATING

THE

MACHINE

..........

2

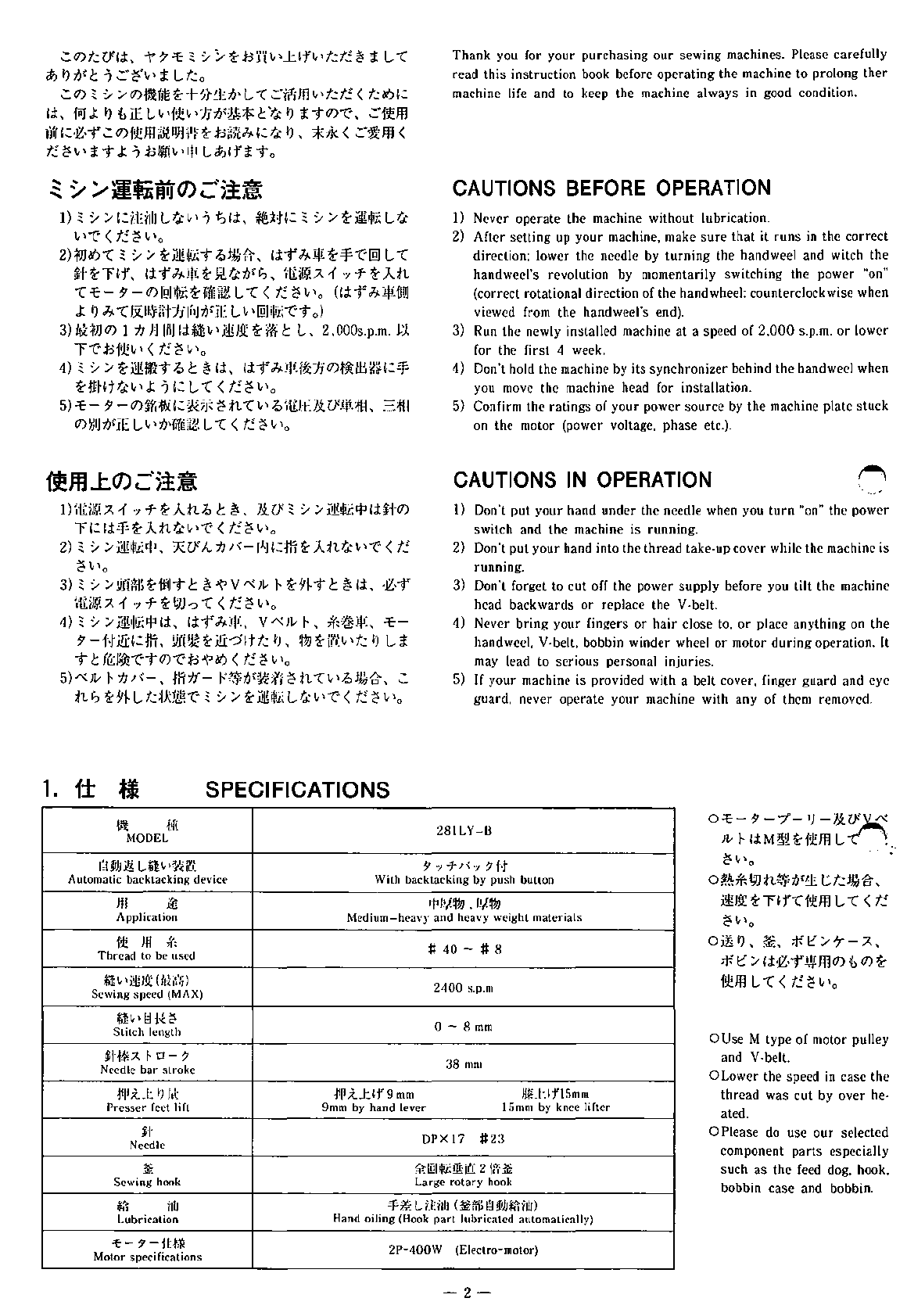

1.

SPECIFICATION

.............................................................

2

2.

PREPARATION

BEFORE

OPERATING

THE

MACHINE

................................................................

3

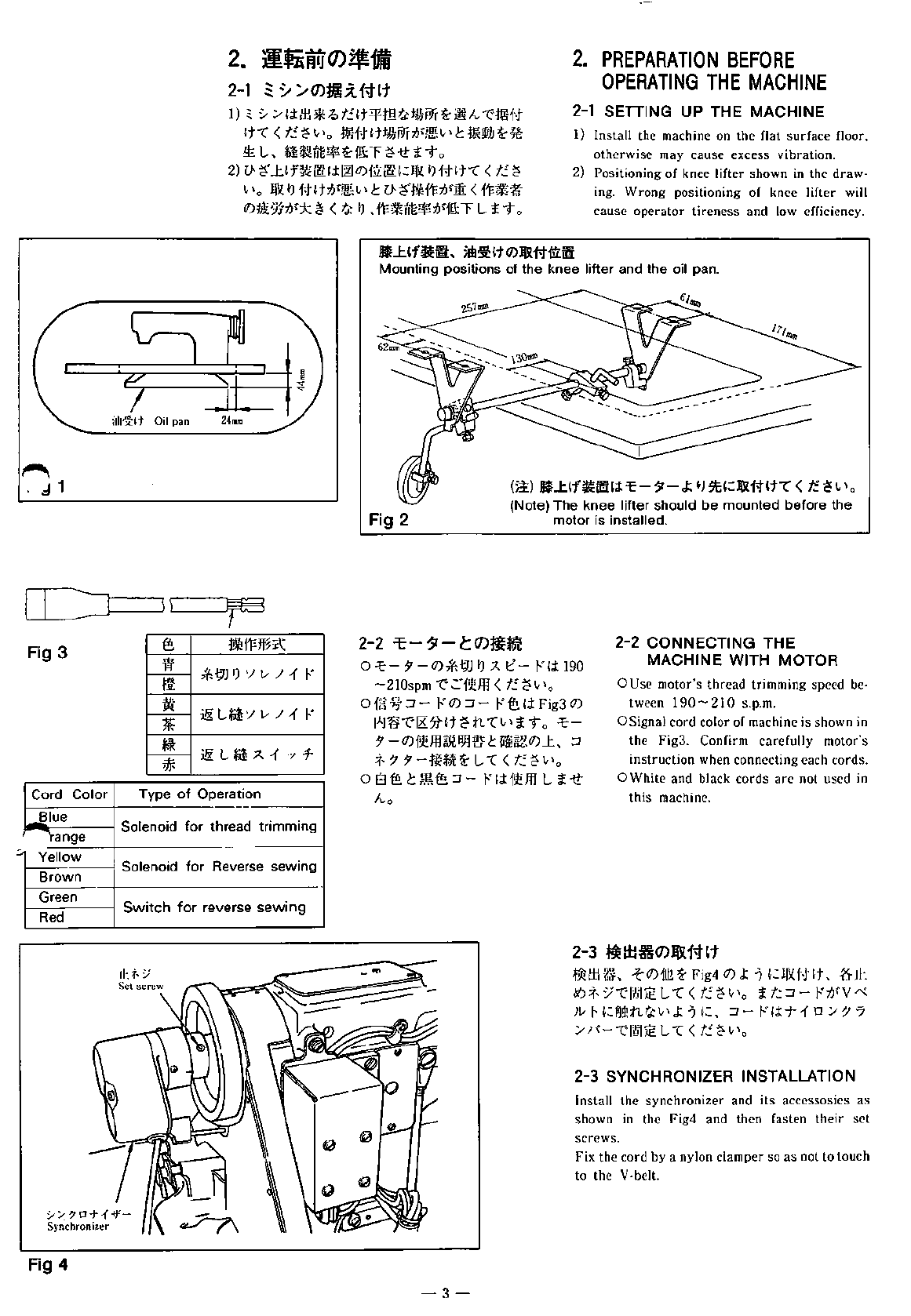

2-1

SETTING

UP

THE

MACHINE

................................................ 3

2-2

CONNECTING

THE

MACHINE

WITH

MOTOR

.......................... 3

2-3

SYNCHRONIZER

INSTALLATION

.......................................... 3

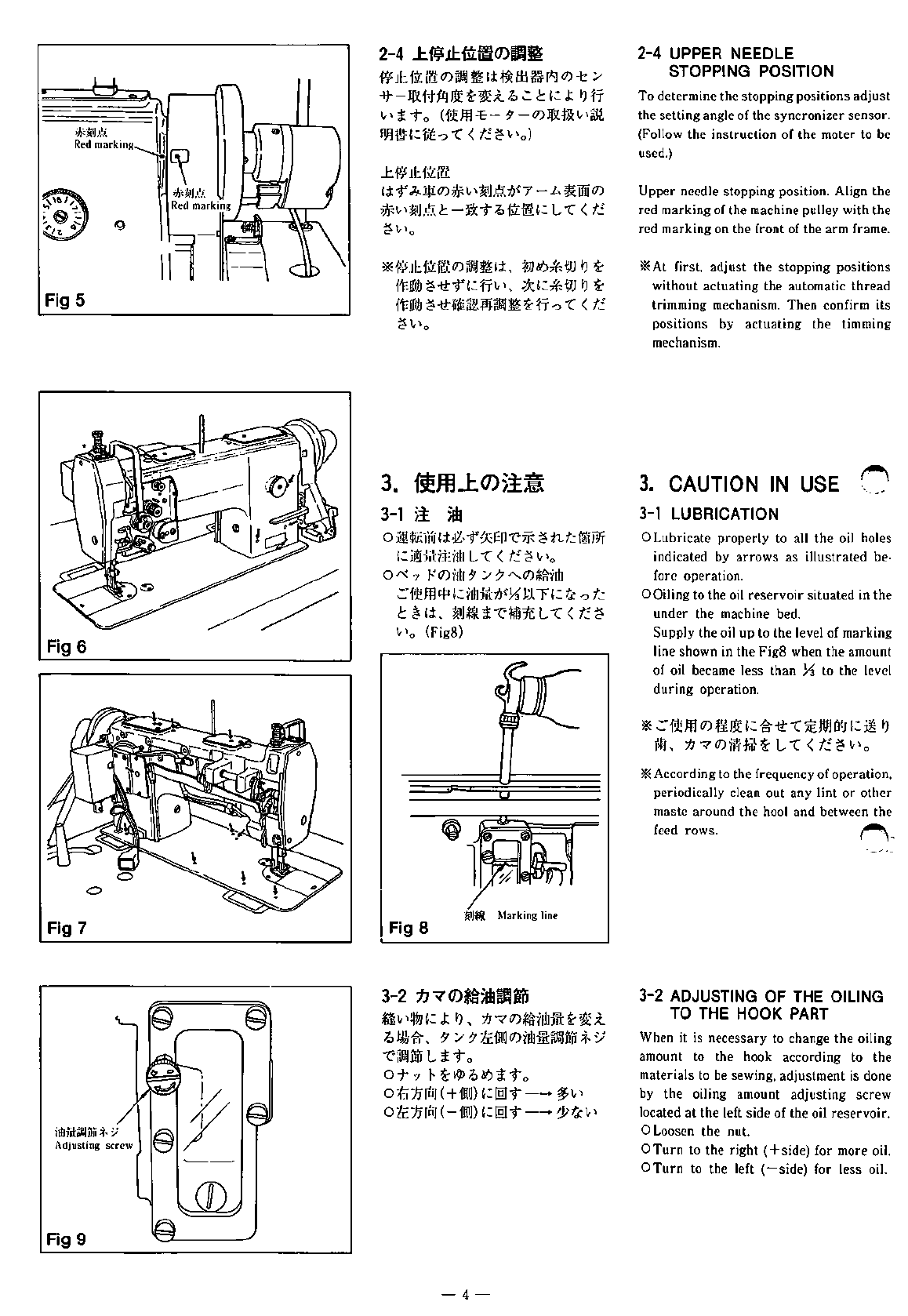

2-4

UPPER

AND

LOWER

NEEDLE

STOPPING

POSITIONS

............... 4

3.

CAUTION

IN

USE

..........................................................

4

3-1

LUBRICATION

................................................................... 4

3-2

ADJUSTING

OF

THE

OILING

TO

THE

HOOK

PART

.................. 4

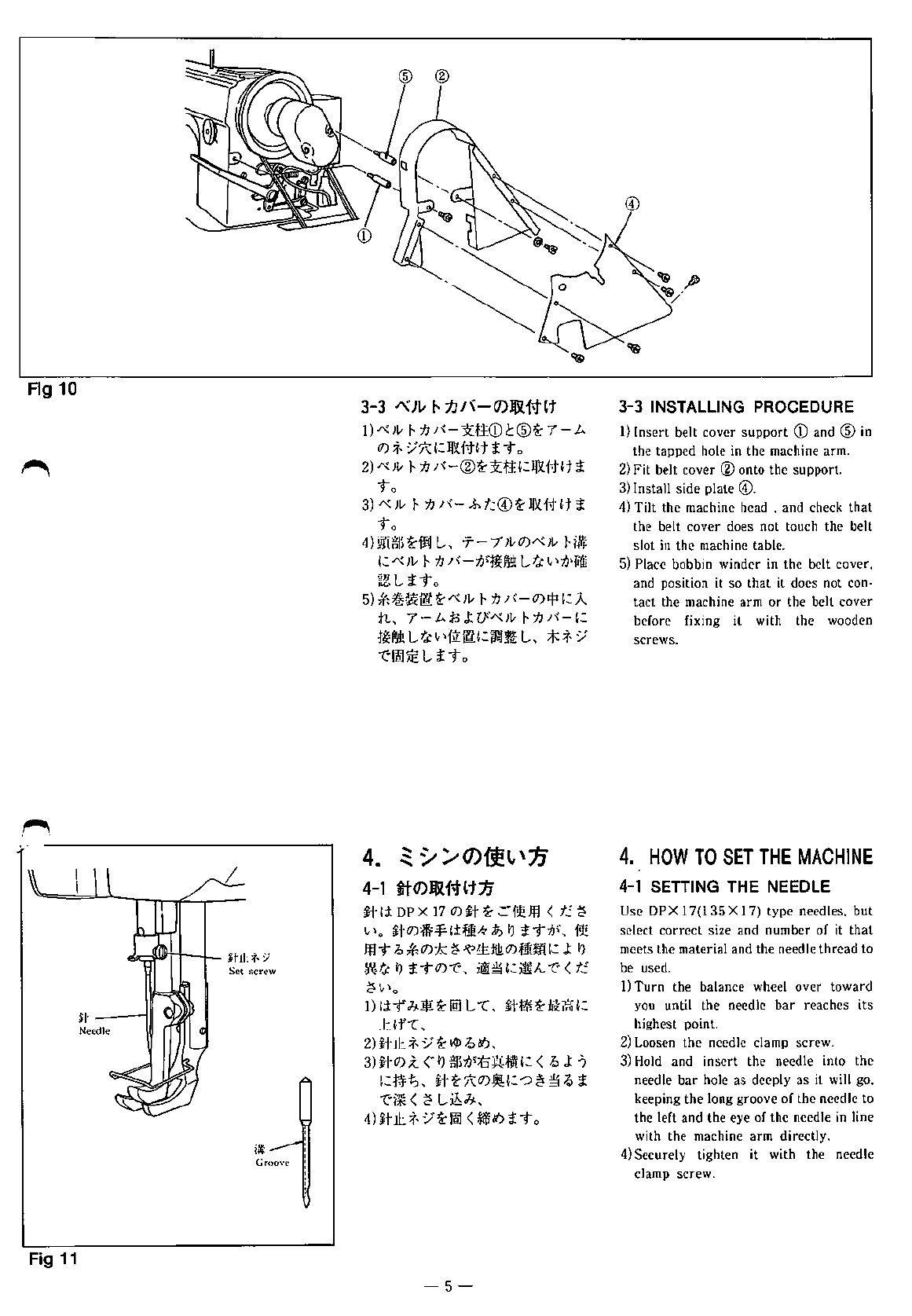

3-3

INSTALLING

THE

BELT

COVER

..

·....·....·......·....·

..

·....·.......... 5

4.

HOW

TO

SET

THE

MACHINE

..................................

5

4-1

SETTING

THE

NEEDLE

....................................................... 5

4-2

WINDING

THE

BOBBIN

THREAD

.......................................... 6

4-3

THREADING

THE

UPPER

THREAD

....................................... 6

4-4

ADJUSTING

THE

STITCH

LENGTH

AND

REVERSE

FEED

......... 7

4-5

THREAD

TENSION

............................................................. 7

4-6

THE

NEEDLE

THREAD

TENSION

.......................................... 7

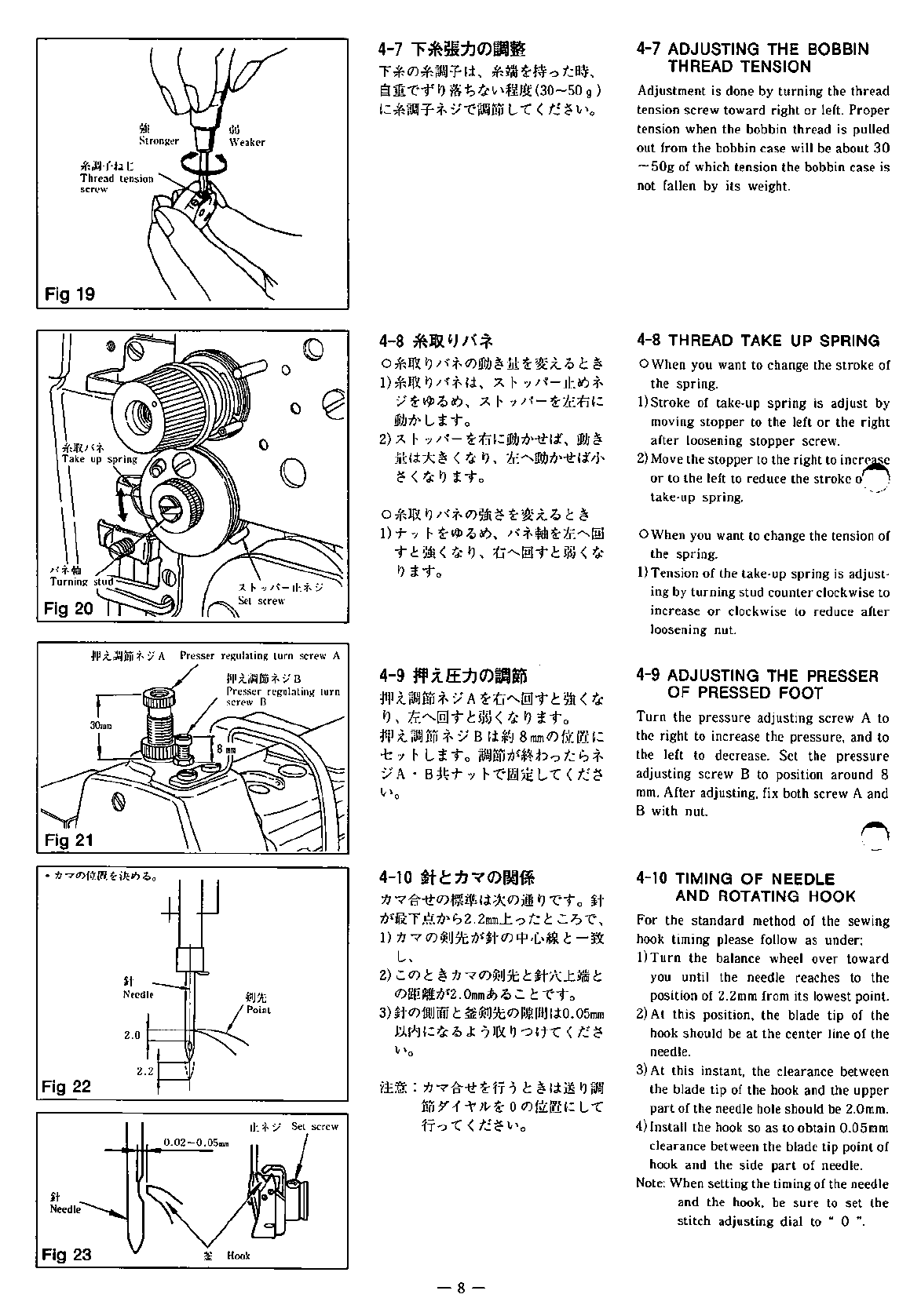

4-7

ADJUSTING

THE

BOBBIN

THREAD

TENSION

......................... 8

4-8

THREAD

TAKE

UP

SPRING

................................................. 8

4-9

ADJUSTING

THE

PRESSER

OF

PRESSED

FOOT

....................... 8

4-10

TIMING

OF

NEEDLE

AND

ROTATING

HOOK

.......................... 8

4-11

ADJUSTING

THE

HEIGHT

OF

FEED

DOG

............................... 9

4-12

ADJUSTING

THE

HEIGHT

OF

PRESSER

FOOT

AND

FEEDING

FOOT

·................·....·....·................·

..

·

..

·

..

·.... 9

4-13

ALTERNATE

STROKE

AMOUNT

OF

PRESSER

FOOT

AND

FEEDING

FOOT

..................................· 9

4-14

ADJUSTING

THE

LONGITUDIAL

POSITION

OF

THE

NEEDLE

BAR

FRAME

.............................................

10

4-15

POSITION

OF

THE

REVERSE

FEED

SOLENOID

.......................

10

4-16

HOME

POSITION

OF

THE

ROTARY

KNIFE

.............................

10

4-17

ADJUSTING

THE

THREAD

TRIMMING

CAM

...........................

11

4-18

HOW

TO

MANUALLY

OPERATE

THE

THREAD

TRIMMER

........

II

4-19

HOW

TO

REPLACE

THE

KNIVES

..........................................

11

4-20

AUXILIARY

THREAD

TENSION

CONTROLLER

........................

12

4-21

PRESSURE

OF

THE

FIXED

KNIFE

.........................................

12

4-22

STITCH

LENGTH

AND

SPEED

..............................................

12

5.

PHENOMENA,

REASON

AND

ITS

CORRECTIVE

MEASURE

AT

THE

THREAD

TRIMMING

..........................................

13

6.

COMPONENT

PARTS

...................................................

14

6-1

MACHINE

PARTS

...............................................................

14

6-2

LIST

OF

PARTS

·................................................................

18

-1-

From the library of: Superior Sewing Machine & Supply LLC