6

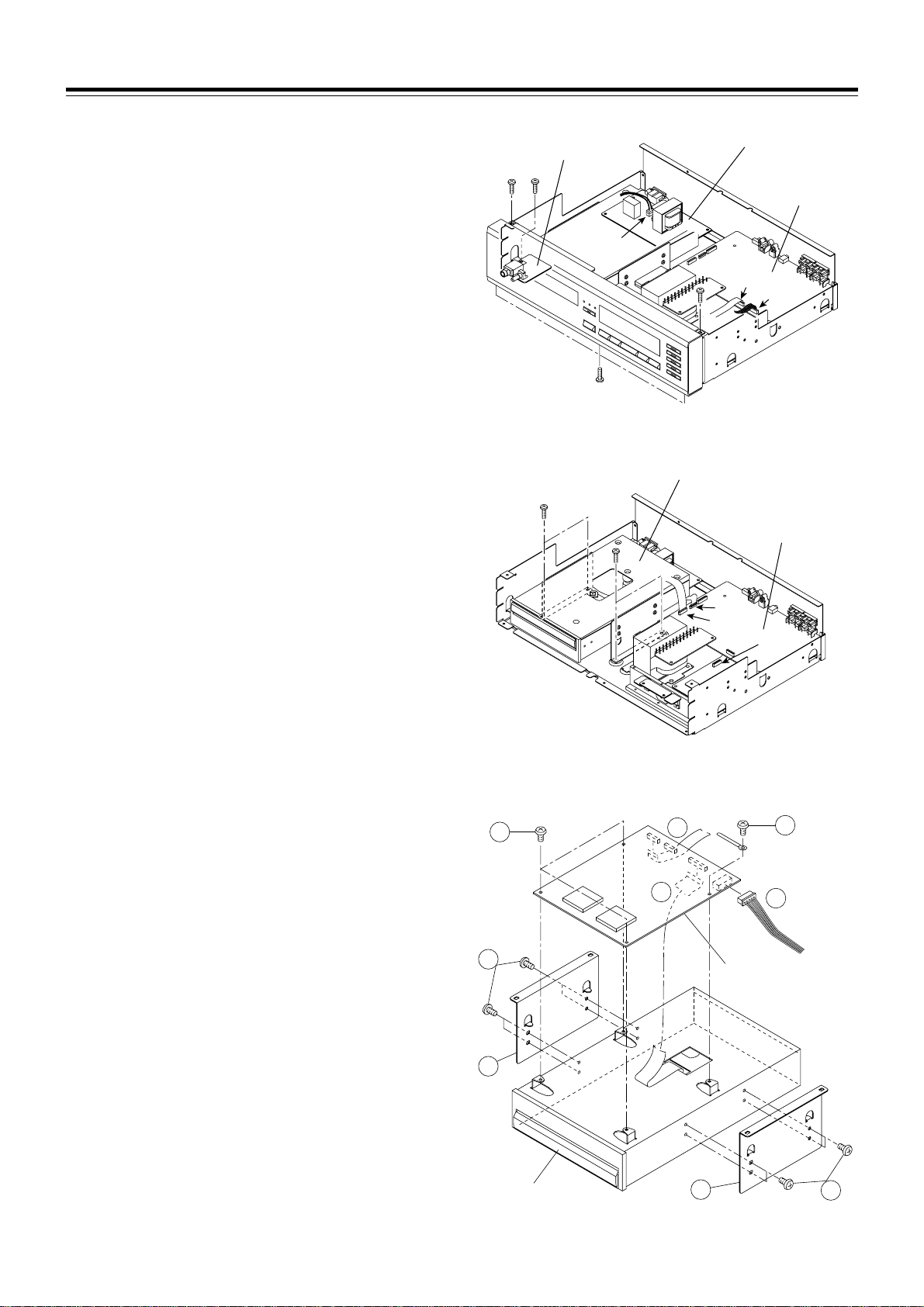

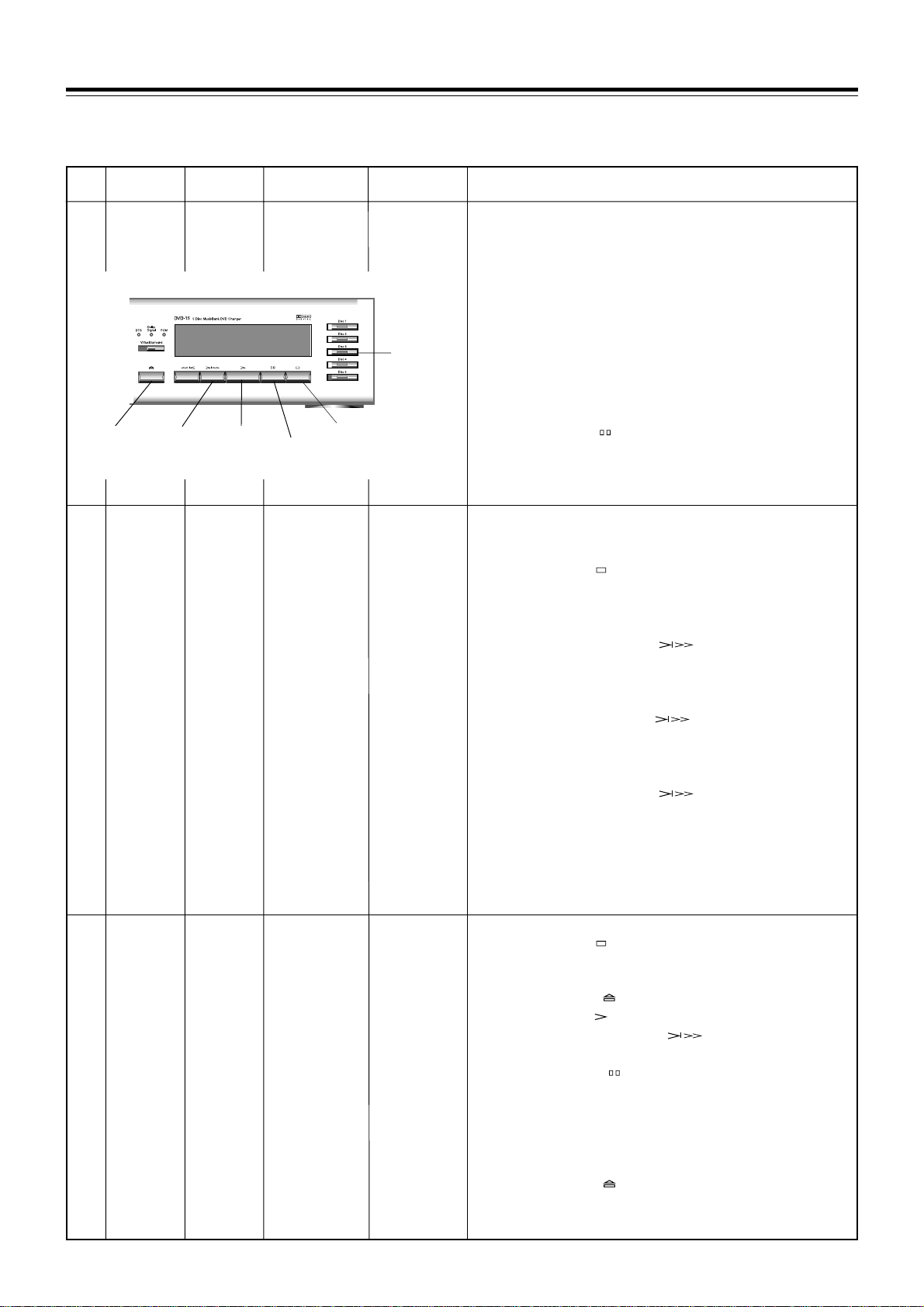

2.6. Bottom Cover EX Ass'y, Top Cover EX Ass'y

and F Panel EX Ass'y (Refer to Fig. 2-7)

1) Remove the 6 screws "1" (M2.6x5 + Pan (#0 Type 3)) and

detach the Bottom Cover EX Ass'y.

2) Remove the 2 screws "2" (M2.6x3 + Pan), and detach the

Top Cover EX Ass'y and F Panel EX Ass'y.

2.7. Mechanism P.C.B. Ass'y (Refer to Fig. 2-7)

1) Remove the Bottom Cover EX Ass'y, Top Cover EX Ass'y

and F Panel EXAss'y. See item 2.6.

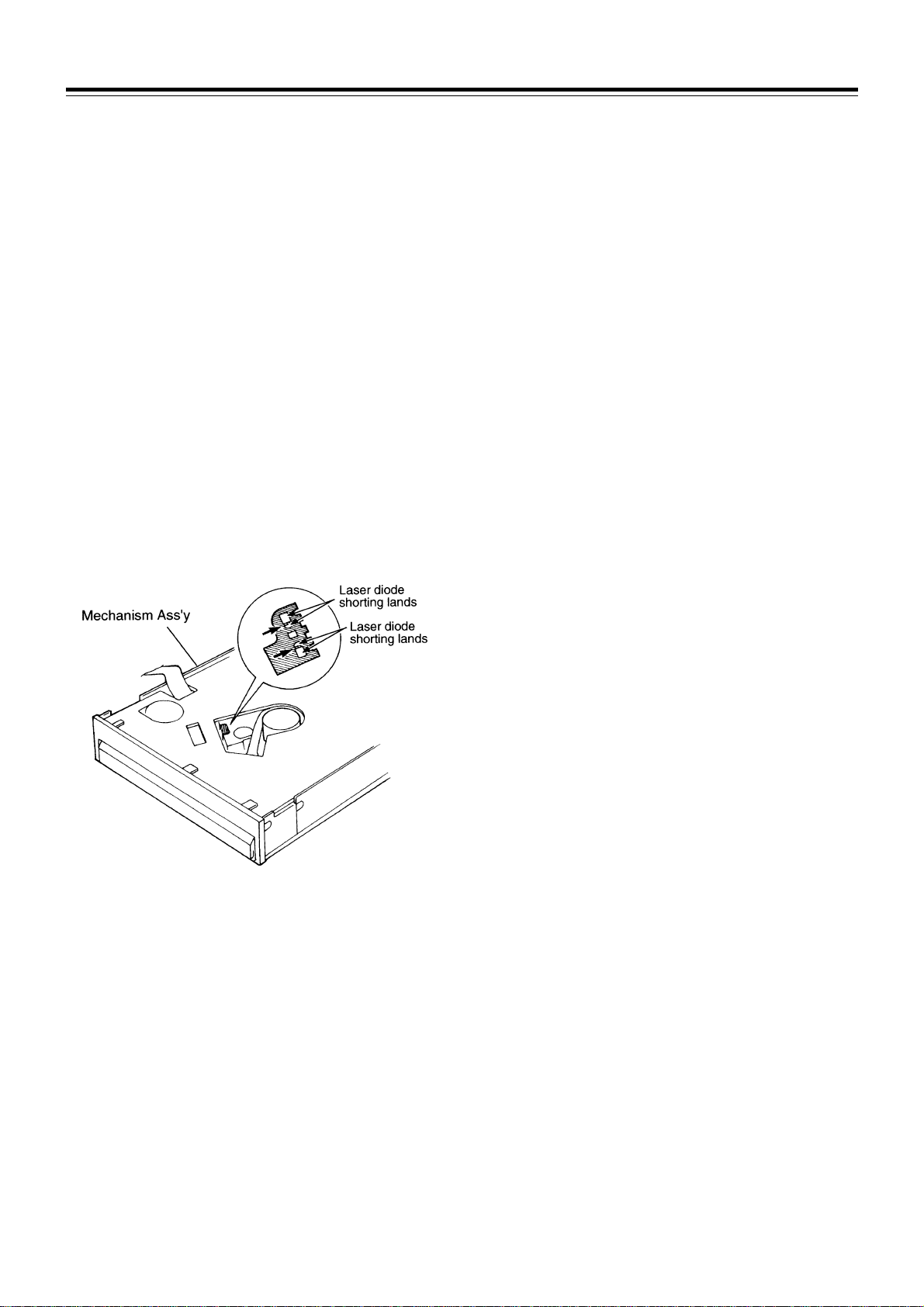

2) Shorting the laser diode shorting land of the DVD Traverse

Ass'y:

Short the laser diode shorting lands (2 places shown by the

arrows) with a soldering iron before removing the Mecha-

nism P.C.B.Ass'y.

Note: Use a soldering iron whose metal part is grounded or

a ceramic soldering iron.

CAUTION: Do not disconnect the Flexible Cable from the

connector P200 on the Mechanism P.C.B. Ass'y unless the

laser shorting lands (2 places) are shorted.

[Shorting the Laser Diode Shorting Lands of the DVD Traverse

Ass'y]

•Note when reassembling:

Unsolder the laser diode shorting lands after reassembling

the Mechanism P.C.B.Ass'y.

3) Remove 1 screw "3" (M2.6x3.5 + Pan (#0 Type 3)) and 1

screw "4" (M2.6x8 + Pan).

4) Disconnect the Mecha Flexible P.C B. Ass'y "5" by pulling

the edges of the connector CP103 "6" on the Mechanism

P.C.B. Ass'y to unlock the connector edges.

5) Pull the edges of the connector CN300 "7" on the Mecha-

nism P.C.B. Ass'y to unlock the connector edges and care-

fully pull out the Traverse Flexible P.C.B. Ass'y.

6) Pull the edges of the connector CN200 "8" on the Mecha-

nism P.C.B. Ass'y to unlock the connector edges and care-

fully pull out the Pickup Flexible P.C.B. "9".

7) Carefully disconnect the 3 connectors CPI04 "10" (EX Mo-

tor Ass'y), CN500 "11" (Sled Motor Ass'y), and CN600 "12"

(Inner Switch)

8) Remove the Mechanism P.C.B. Ass'y from the Mechanism

Ass'y.

2.8. Loading EX Ass'y (Refer to Fig. 2-7)

1) Remove the Mechanism P.C.B Ass'y. See item 2.7.

2) Remove the 6 screws "13" (ST2.6x3 + Pan (#0 Type 3)), 1

screw "14" (M1.7x2.5 + Pan (#0 Type 3) (Black)), and 4

screws "15" (M2x2 + Pan (#0 Type 3) (Black)).

•Note when reassembling:

When reassembling the Mecha Flexible P.C B. Ass'y "5",

move it to the front side.

Be sure that the shutter is positioned in the center of the

shutter sensor on the Mecha Flexible P.C.B.Ass'y, when the

shutter of the Loading EX Ass'y is closed by hand,

3) Remove the EX Loading Chassis block "16" backward while

lifting its to the right side a little.

4) Remove the Loading EX Ass'y while lifting it.

•Note: Do not damage the CatchArmAss'y and the Loading

Link Ass'y of the Loading EX Ass'y.

2.9. DVD Traverse Ass'y(Refer to Fig. 2-7)

1) Remove the Loading EX Ass'y. See item 2.8.

2) Remove the 3 screws "17" (ST2 6x3 + Pan (#0 Type 3)) and

remove the EX Motor Ass'y.

3) Remove the 3 screws "18" (ST2.6x3 + Pan (#0 Type 3)) and

remove the EX Chassis Ass'y.

4) Remove the 4 pcs. of Damper Screw SL"19", 4 pcs of and

SUS Collar B "20", and 4 pcs of SUS Collar T "21", and

detach the DVD TraverseAss'y.

Notes:

1. Pay attention so as not to damage the Door Sensor P.C B.

of the Mecha Flexible P.C.B. "5".

2. Assemble the Door Sensor P.C.B. so as not it is inclined.

3. Be sure that the projection of the Front Door Ass'y can be

correctly inserted into the Door Sensor.

REMOVAL PROCEDURES