6

Assembly and operang instrucons

Assembly for variees of operang condion (Fig.1-4)

Assembly for spraying

a. Assembly in chemical tank Remove the lower cover of chemical tank, change into the pressing lid which is connected with rubber tube (do not forget to put

on the sealing ring,as Fig.2.). Connect the lid to the rubber tube as shown in Fig.1.

Fig. 1: 1.Lid, 2.Sealing washer, 3.jam, 4.Filter net, 5.Tube, 6.Tank, 7.Take over, 8.Tie-in, 9.Take over

Fig.2: Connect spraying pipe to the machine as shown in Fig.3.

Fig. 3: 1.Clip, 2.Bend pipe, 3.Tube, 4.Switch, 5.Plasc pipe, 6.Handle, 7.Handle, 8.Tube, 9.Plasc pipe, 10.Ring, 11.Nozzle

Assembly for dusng

Remove the chemical tank,take down the inlet rubber tube,outlet rubber tube, sucon strainer,spraying lid plate,pressing lid and union,change for lower lid of

chemical tank,then connect the dusng pipe as Fig.4.

Fig.4: 1.Chain, 2.Bend pipe, 3.Clip, 4.Plasc tube, 5.Handle, 6.Handle, 7.Plasc tube, 8.Plasc tube

An-electrostac installaon

Electrostac charging with sparking can occur when working with the dusng and spreading aachment. The risk is greatest in extremely dry weather

condions–when using powdered products,–which create a highly concentrated dust cloud. To reduce the risk of sparking, explosion or re, make sure the

anstac system is completely and properly mounted to the machine. It consists of a conducve wire in the spray tube connected to a metal chain. The

metal chain must make contact with a conducve surface to dissipate electrostac charges. Do not operate your machine on a non-conducve surface (e.G.

Plasc,asphalt).Never operate your machine with a missing or damaged discharge system

For the above reasons, great care is required when using sulphur as it is ammable.

● Assembly as g.4.

Rotaon

Check

a. Checking whether the spark plug and all the connecon are ghtened.

b. Checking whether the cooling air channel is clogged. If so, the engine will be over heated.

c. Checking whether the air lter is dirty. If so, the dirt will reduce the amount of air drawn in. So the engine does not run well and waste fuel.

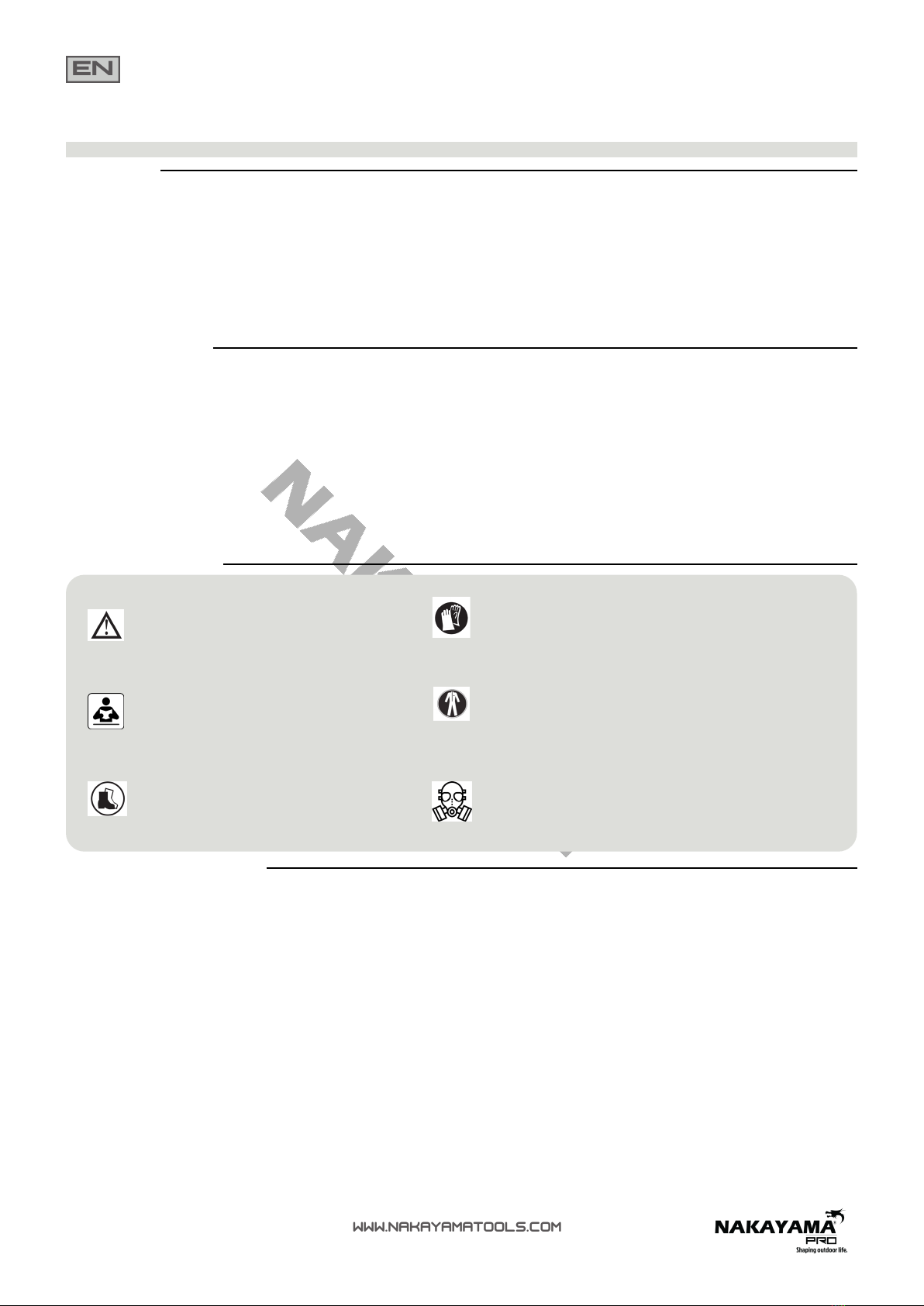

d. Check whether the gap of the sparking plug is 0.6˜0.7mm.

e. Pull the starter 2 or 3 mes, check whether it rotates normally.

Fuelling

a. Use a special type 2-cycle oil (30ml of oil for each 1L of unleaded gasoline 95 octane). The rao between them is determined by the oil instrucon. Incorrect

gasoline, oil and mixture may damage the engine.

b. Never fuel the engine when it is hot or running.

C. When fuel, never take away the strainer.

Adding chemicals

a. During spraying operaon,while adding chemical,the switch must be shut, see Fig.5. During dusng operaon,dusng valve throle and fuel lever should be

on the boom posion,other-wise,the machine will have chemical out.

b. As powder chemical can easily become block,so the chemicals should not be in the chemical tank for a long me.

c. While spraying,the chemical tank lid should be turned on ghtly. Aer adding powder chemical,please clean the screw of the chemical tank mouth,then turn

on the lid ghtly.

Cold starng

Please operate according to the following procedures:

a. Press oil cup unl gasoline into oil cup,see Fig.6.

b. Put the switch on the starng posion,see Fig.8.

c. Put the choker on the full posion,see Fig.7.

d. Pull the starter for a few mes and have it returned slowly. Do not leave the handle to return freely to avoid the damage of the starter.

e. Close the choker and pull starter handle unl the engine ires.

f. Aer starng the engine,open choker fully.

g. Let the engine run at low speed for 2-3 minutes,then start the spraying or dusng operaon.

Starng the warm engine

a. Leave the choker fully open.

b. If the engine draws in too much fuel. Leave the fuel switch fully close,pull the starter 5-6 mes. Then start the engine as above.

Stopping the engine

a. Put the two control handles to their lowest posions and the engine stops.

b. Spray over, turn o the chemical switch rst then stop the machine.

c. Having nished working, turn o the fuel switch. Pay aenon!

Note: While the engine is running, the hose must be mounted to the machine, otherwise cooling air will be reduced and this can damage the engine.