CHAPTER 1: SAFETY INSTRUCTIONS The Scooter™

1. WHEN THE MACHINE IS DELIVERED

Check the carton and machine carefully for signs of rough handling. Remove the machine from

the carton. IF THE MACHINE IS DAMAGED, NOTIFY THE CARRIER IMMEDIATELY AND

REQUEST AN INSPECTION. Be sure to keep the carton, packing list, packing inserts and carrier’s

receipt until the inspector has verified your claim. Manufacturer’s liability ceases when carrier

picks up the machine or shipment.

2. BEFORE OPERATING THE MACHINE

Read the Manual carefully and completely before attempting to operate the unit. This Manual has

important information for the use and safe operation of the machine. Keep this manual handy at all

times.

3. GENERAL PRECAUTIONS

1. Make sure the machine is plugged into an electrical outlet with the same voltage as shown on

the switch plate of the machine. DO NOT attempt to plug a 115-volt machine into a 220-volt

outlet.

2. Disconnect power cord from the outlet before attempting maintenance or repair work.

DO NOT leave machine connected to an electrical outlet when unattended.

3. DO NOT abuse power cord. Never pull the machine by the cord or yank the plug from the

receptacle. The machine is operated on a wet carpet and a potential shock hazard can result

from a damaged cord. Replace a damaged cord immediately.

4. DO NOT operate machine in standing water. Such use can cause electrical shock.

5. DO NOT use volatile substances such as gasoline or kerosene in the machine or on or near

the surface to be cleaned. The use of such materials could cause an explosion and fire.

6. If an extension cord is necessary, use a three conductor grounded cord 12 gauge wire or

heavier to prevent motor burnout and over heating of wire.

7. To avoid electric shock, DO NOT expose to rain - store indoors.

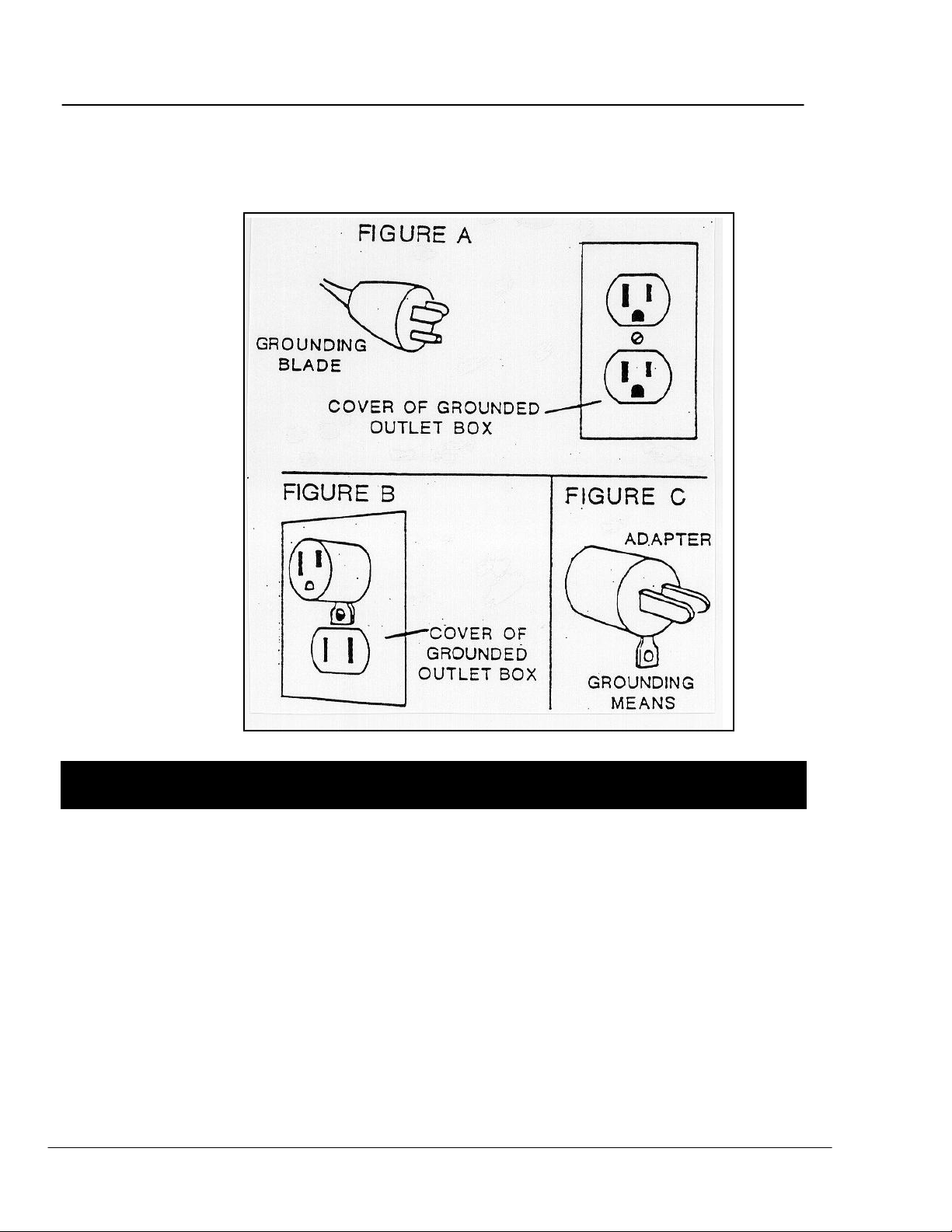

4. GROUNDING INSTRUCTIONS

To protect the operator from electrical shock, the machine is factory equipped with an approved

three-conductor cord and grounding plug. (figure A - see page 2)

This plug is to be used only with proper grounding type receptacles.

The machine has a plug like the one shown in figure A. An adapter (figure B & C - see page 2) is

available for connecting three prong type plugs to two prong receptacles. The green rigid lug

extending from the adapter must be connected to a permanent grounding such as a properly

grounded outlet box. DO NOT break off or pull out the grounding blade.