www.nassarelectronics.com 2

EN-3P LIQUID LEVEL CONTROL RELAY

Features

ŸControls Level of Conductive Liquids in

Pump Up (Fill) or Pump Down (Drain)

Applications.

ŸAdjustable Sensitivity from 5K to 100K

ohms.

ŸDual Voltage 120 or 220 VAC Supply.

ŸLED Status Indication.

ŸProtects Pumps from Dry Running.

The EN-3P is a dual-probe conductive liquid level

control designed to monitor the levels of conductive

liquid and control the actuation of pumps or valves to

regulate levels. It is also suitable for protecting

submersible pumps against dry running or protecting

tanks from an"overflow". This device can also be used

to control dosing of liquids in mixing processes and to

protect heating elements in the event of non

immersion.

The sensitivity can be adjusted within the range of

5KΩ to 100KΩ by rotating the knob on the unit. This

sets the level at which the relay determines whether

liquid is present at the probe or not.

The EN-3P is dual voltage, it can be used with either

120 or 220 VAC.

Description

Voltage supply

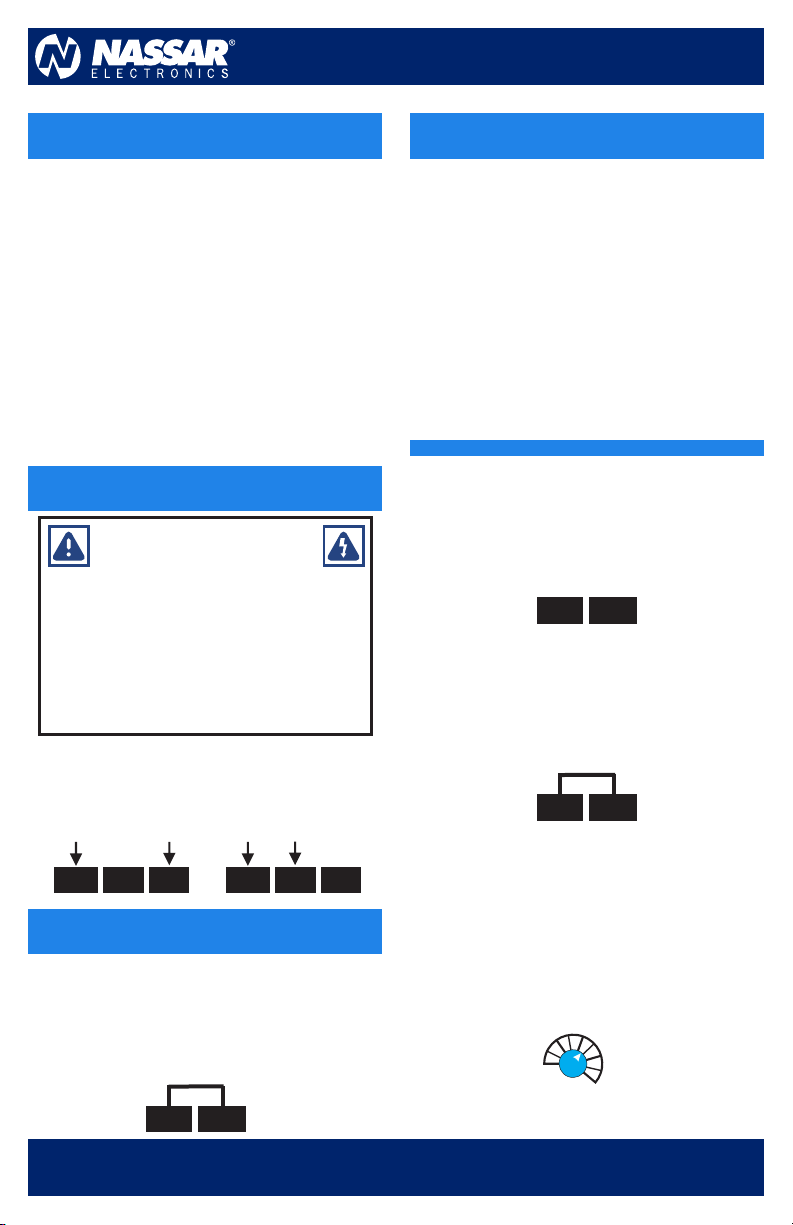

To use a 220 VAC voltage supply use the terminals T1

and T3. To use a 120 VAC voltage connect the supply to

terminals T1 and T2. After the supply voltage is

connected the green LINE LED will turn ON.

Operation

220 VAC 120 VAC

T1 T1T3 T3T2 T2

PUMP DOWN (DRAIN) APPLICATION

The relay energizes when the liquid level comes in

contact with the high probe (PH) and remains

energized until the liquid level falls below the lower

probe (PL). To use this application place a wire

between terminals F/D and PC.

F/D PC

PUMP UP (FILL) APPLICATION

The relay energizes when the liquid level falls below

the low probe (PL) and remains energized until the

liquid level comes in contact with the high probe (PH).

To use this application leave terminals F/D and PC

disconnected.

PUMP DRY RUNNING PROTECTION

To protect the pump from dry running use the same

connections as the Pump Down (Drain) application

and connect the contact between NO and C in series

with the pump starter control.

F/D PC

F/D PC

SENSITIVITY ADJUSTMENT

To adjust the sensitivity within the range of 5KΩ to

100KΩ rotate the knob on the unit. This sets the level

at which the relay determines whether liquid is

present at the probe or not. For water it’s

recommended to set the sensitivity adjustment at 50K

Ω . To set the sensitivity follow the next procedure:

SENSITIVITY

75K

100K

5K

50K

25K

DANGER!

Potentially hazardous voltages are present. Electrical

shock can cause death or serious injury.

Installation should be done by qualified personnel

following all National, State & Local Codes.

BE SURE TO REMOVE ALL POWER SUPPLYING THIS

EQUIPMENT BEFORE CONNECTING OR

DISCONNECTING THE WIRING.

READ THE INSTRUCTIONS BEFORE INSTALLING OR

OPERATING THIS DEVICE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.